Vintage Construction Methods

Basics

Constructing a replica of a vintage boat is very much a scratch-building proposition. There are no kits available, and detailed construction plans are quite rare. What we do have are “lines plans,” which give the basic shape of the hull, a sail plan, and occasionally a diagram of the deck fittings. From there on, you’re pretty much on your own. We have reprinted a set of construction articles from the 1940s, available as our book Building Planked Models.

We also have a report from Earl Boebert on his experience building a perfect Rip Tide.

While a very wide range of materials were used at one time or another, including varnished paper, glue-impregnated cloth, and (in the latter days of the vintage era) fiberglass, the vast bulk of vintage hulls were made of wood. Indeed, it is the lure of the wooden boat that attracts many people to the vintage movement. Wood hulls are either carved or built-up (plank-on-frame) in a manner similar to full sized boats.

Carved Hulls

While a very small hull (1 ft or less) may be carved from a single block, larger carved hulls are usually laminated from 1- to 2-in thick “lifts”. This technique saves material and simplifies construction, and is sometimes referred to as “bread and butter” construction.

The most common approach is the “horizontal lift” method shown below. In this approach, the laminations follow the horizontal sections or “waterlines” of the lines plan. The diagram is from Thomas Moore’s 1927 book, and shows the way the edges of the lift are carved away to form the smooth shape of the hull.

A variation of the horizontal lift method was popularized by Claude Horst, a shop teacher who wrote two popular books on model boat building. Horst made his hulls in halves, with each half constructed from horizontal lifts. He then glued the two halves to a center keel of thin marine plywood. He argued that this method simplified the carving of the the interior of the hull and led to a stronger hull for a given weight. His method was seldom seen in competition boats.

A less common approach is the vertical lift method, where the laminations follow the vertical sections or buttocks of the lines plan. The photograph, which shows John Black’s Cheerio I prior to carving, is from his 1934 book Yachting with Models. The vertical lift method was favored by the Marblehead area builders on grounds that it made it easier to construct a symmetric hull.

Carved hulls are usually made from clear pine (“patternmakers pine”) or cedar.

Built-Up Construction

Built-up construction follows the practices of full-scale construction. There are three basic methods: Sawed frame, bent frame, and cold-molded.

In the sawed-frame method, the frames are cut from material such as birch aircraft plywood and the planks laid over them. Planks are generally cedar. The result is a hull with an internal structure comprised of the frames and keel; sometimes a center backbone of plywood is used to support the deck and rigging.

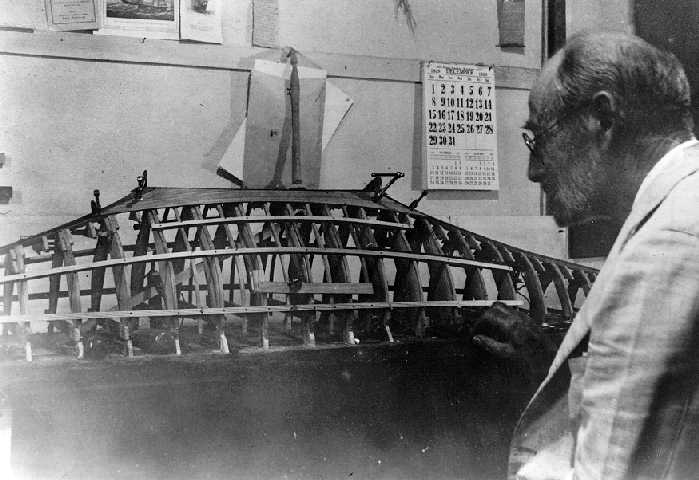

In the bent frame method, thin strips of wood are steamed to shape and laid over temporary “shadows” that look like frames but that are pre-cut to permit removal when planking is finished. The result is a hull whose internal structure must be added in the form of transverse or diagonal braces. The diagram below, again from Moore’s book, shows a typical plank over bent frame hull. The bent frames are usually oak, with the planking again being cedar.

Here we see the master yacht designer N.G. Herreshoff building a sailing model with planks over steamed frames. The garboard strakes have just been laid in and are clamped for gluing. Note the intermediate frames not supported by molds, the floors between frames to reinforce the keel, and the battens screwed temporarily to the molds. The battens will be used with wedges to put lateral pressure on the planks for gluing.

In the 1940’s one of the most popular methods was planks over permanent frames. In this method the frames were used first as molds to lay the planks over, and then cut away to their final form. We have reprinted a series of classic articles by Charles Farley on this method of construction. The drawing below shows the frames on the building board prior to planking and cutting away.

The fourth method of wooden hull building is called “cold-molded” construction. In this technique, a carved form is made (usually by the bread and butter technique) much as if the hull were to be laid up in fiberglass. Thin strips of cedar are laid on the form, usually in three layers. The first two layers are laid up diagonally and crosswise to each other; the third layer is laid fore-and-aft like conventional planking. This technique was popular amongst the West Coast M class builders of the 1940’s, and produced some remarkably light boats.

Sails

Vintage sails were made of cotton; the particular form that was used is no longer available. Modern sails are made of synthetics, such as Dacron. For those of you who need to make an authentic set of vintage sails, we have reprinted a series of articles from the 1940’s.

Fittings

Our traditional source of fittings, the A.J. Fisher Co., sadly went out of business in July of 2000. We list suppliers of fittings, plans, and hulls on our ever-growing Suppliers page.