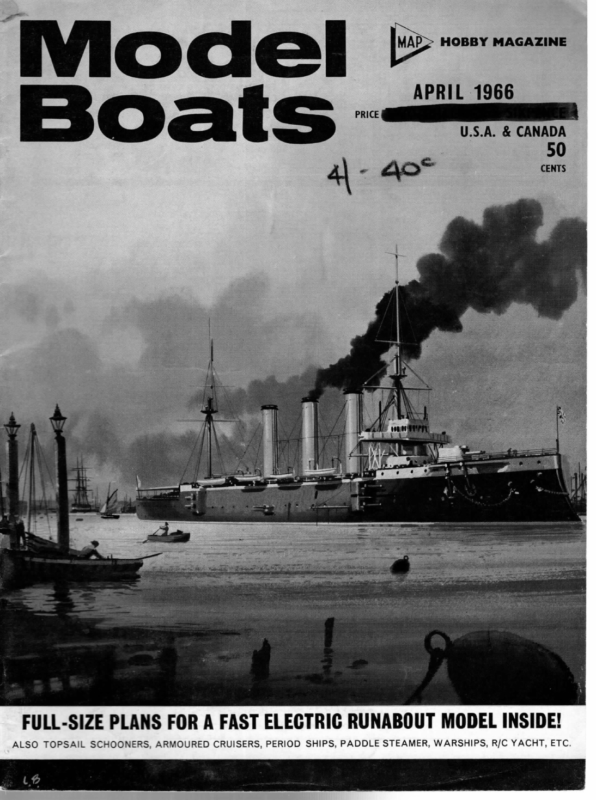

TM ce et @| Juiz HOBBY MAGAZINE APRIL 1966 PRICE U.S.A. ai 50 CENTS ee se QT 4\ – ZO & CANADA FULL-SIZE PLANS FOR A FAST ELECTRIC RUNABOUT MODEL INSIDE! ALSO TOPSAIL SCHOONERS, ARMOURED CRUISERS, PERIOD SHIPS, PADDLE STEAMER, WARSHIPS, R/C YACHT, ETC.

MUU MODEL BOATS ~ ==DECK — a ai 4 a \ es SWITCH cea \ / Spies ah Gal Gata He : , one members of the L.R.C.M.S. puts it, a power of i] 50 36 watts—also that the time lapse from sheets full out to mba lll hl] 38 NO LIMIT OF OUTHAUL. many factors enter into the final decision such as diameter and speed of winch drum, position of sheet attach ment on booms, etc. _ It used to be advised that, on account of the difference Sas ee [ 100 full in should be about 5 seconds. No hard and fast rules can be laid down as to how this can be accomplished as so II = (Diagram 3) required for the satisfactory operation of the sails—or as MOTOR SFINDLE| Sw / ‘WoORM——4 -Co Sail Control Unit The power and speed of operation of sail control units is repeatedly being discussed by R.C. yachtsmen and I think it is generally agreed that a pull of about 10 Ibs. is e (6 ) SHEET GUIDE | is in length of the two booms, it was necessary to have two 4 —o amen order to maintain nis ee | winding ate on see Ling ea the booms parallel in operation, but i the points of attachment of the sheets to the booms are kept the same distance from the points at which the booms -AC = swivel, the winding can be done on only one diameter. The winch gearing on Arabesque gives a direct pull of about 7 lbs. with a time lapse from full in to full out of L | F gz 5 secs. I find that this power is not quite adequate in strong winds and I propose to modify this eventually by fitting a more powerful motor. There is a dearth of really suitable small motors for this job and I will probably settle for a E €) R A N : O [ D> Hectoperm run off accumulators giving 8 volts. in [A D Y The motor now in use is an Ex-W.D. 5U/4798 (reviewed Model Maker, February 1960) designed to run on 24 v. It is very smooth running, having a 9 pole arm- ature with ¢ in. steel spindle running in ball races at each end. It is of comparatively low current consumption and I run it on 34 v supplied by eight 44 v flat batteries, the higher voltage being tolerated easily and the batteries PART THREE lasting for about 8 hours sailing. The motor drives a gear train of Meccano gears mounted in a frame fabricated of sheet brass. (Diagram 3) The E. W. GEAREY CONCLUDES HIS yeas gear sae om mn te diagram coed Hoke -1 NOTES ON THE CONVERSION OF AN ‘A’ CLASS YACHT TO ‘A? i) dS y dy ON CONTROL YQ y GEAR provided y ~ Qy dy s” dy dy dy SWIVELLING PULLEY BLOCK IN SCREW EYE IN DECK TRL CRIA OF SHEET CORD TOPREVENT ANY POSSIBILITY OF TRAPPING. all gears to their shafts as the grub screws will work loose under the abnormal strain between these plates with wooden doweilling or meta] tubing—in my case I adapted a cotton reel of about 14 in. diam. The experience of many yachtsmen in the past has been that, unless some sort of tensioning device is used on the sheets in the form of additional elastic cords attached to the sheets to ensure that they are kept under tension at all times, winch drums tend to cause tangling. I gave this matter considerable thought as these tensioning devices looked untidy, necessitated further, often complicated, deck fittings in the way of guide pulleys etc., and wasted power from the winch motor as, when maximum power is required, these tensioning devices are under maximum tension. In short I didn’t like them and wondered if the problem of tangle could be overcome by YQ SPACE BETWEEN LOWER PLATE OF DRUM MUST in the train—this is a ‘must?’ under which they are called on to work. The final drive shaft protrudes through the deck and the winch drum above deck level consists of 2 Meccano 23 in. diam. face plates as shown. The actual diameter of the winding drum can be determined by building up SHEETS FEED ON TO DRUM y rather noisy is very robust an or the sails will drive the motor. Another word of warning—pin SHEET GUIDE ON RAISED SURROUND TO MAKE SURE Ry, although a worm has been included R/C WITH SOME PRACTICAL NOTES gearing and has given no trouble cae installed. It will be noted that reac ae oeek other means. TO CHANGE DIRECTION Sreccwecheun: ‘ After much thought I devised a means of ensuring that the sheets would be fed on to the drum through guides without possibility of tangle and have found this 4 method to be entirely reliable and foolproof throughout the season under all sailing conditions. This device (Diagram 4) consists of a shallow circular well inside which rotates the lower plate of the winch 170

APRIL drum, the tolerance between this well and the edge of the lower face plate being less that the diameter of the sheet cord being used so that it is quite impossible for the sheet to be caught in this space. Mounted on top of this well side are two sheet guides—two small screw eyes will serve very well—these being positioned so as to be directly in line with the edge of the drum and the deck pulley so as to cut friction to a minimum. The only ‘don’t’ is—don’t let out too much sheet if there is insufficient wind pressure on the sails to draw any loosened sheet off the drum. If this is done there is the risk of excessive slack between the drum and the first sheet guide and there is a risk of the sheet being rewound the wrong way on the drum. No advantage is gained by sheeting out under conditions of low wind strength, it being only under these conditions that there is any risk. I have found no difficulty in curbing my impatience for the sails to take up any slack sheet, and any slack between the boom attachments and the sheet guides adjacent to the drum which may be present at any time during tacking etc cannot possibly cause tangles as it is controlled by the sheet guide before being rewound. Diagram 4a shows the very simple and straightforward run of the sheets on Arabesque necessitating only one guide pulley attached to the deck and two swivelling pulley blocks. No deck fittings other than these are anywhere near the area which might be occupied by loose sheets so that it is impossible for them to be caught in any obstruction. As I have already said, this device has been entirely trouble-free throughout the season. Limitation of winch winding was only considered necessary in the close hauled positioned as the outhaul position can be readily determined visually by the position of the sails. A limit switch has therefore only been fitted to check the winch in the close-hauled position and is operated by a cam on a geared-down extension of the gear train. The reason for this is obvious as the winch drum makes several revolutions between the close-hauled and out-hauled positions. The gear box and the winch drum sections are accurately positioned relative to one another in order to maintain the close tolerance between the lower winch plate and the sides of the well section and this is done by bolts passing through the deck fitting into matching nuts which are very accurately positioned and soldered to the gear box. Rudder Control Unit Diagram 5. Discussion will continue among R.C. yachtsmen for a Fa OF SHEETS – FROM WINCH TO BOOMS JIB BOOM HATCH DECK CENTRE LINE 4a GUIDE WINCH PULLEY BLOCK than light winds. Under these conditions the speed of the control motor can be reduced by means of adjustment of a variable resistance in series with the motor and mounted so as to be easily accessible through the main hatch. Rudder movement has been limited to 35 degrees either side of centre by fitting two limit switches which are operated by a cam cut to a suitable contour and fitted on an extension of the main shaft. I do not claim any originality for either the sail or rudder control unit, with the possible exception of the non tangle device round the winch drum, but I can claim that they are sturdy and reliable and fool-proof. This has been demonstrated by their completely troublefree performance over 7 months very concentrated sailing, and this reliability is I feel in no small way due to sturdiness and simplicity. My advice to anyone setting out to design any similar intergear is to work out plans on paper in advance of any construction and then go over these plans repeatedly until all possible snags or complications have been removed. Simplicity is the keynote of reliability. I hope that this series of articles may have been of some slight assistance to any readers who are contemplating converting an old boat or building a new one— especially to the new ‘R’ class which has been specially designed for R.C. As I have already said I do not claim any original ideas but little has been published on either the theory or practice of R.C. yachting for at least 5 or 6 years and radical changes have taken place during that time in methods of control. On behalf of all those engaged in R.C. yachting I extend a very hearty welcome to all newcomers—join a Club, come and meet us at regattas—you are ensured of a very warm welcome. Do not be put off as a ‘beginner’-—we are all learning all the time and we might learn from you as much as you from us. [DIAGRAM OF RUDDER SERVO AND GEARING] h stay there. Many sailing conditions require a slight rudder deviation from centre to hold a desired course and = with a self-centering rudder it is impossible to hold this correction and it is necessary to carry out a lot of ‘button pushing’ to establish a mean position of a rudder constantly on the move. In other words those in favour of self-centering would be better off if they went proportional. have always employed progressive control in power boats it is understandable that I have continued with this method in Arabesque. It is certainly far simpler and more foolproof than proportional and in my opinion far superior to self-centering. The rudder control unit shown in Diagram 5 is a slightly smaller version of the sail control unit using an identical motor and gears mounted in a smaller brass sheet frame. This unit gives a very rapid rudder movement of about 4 seconds from full port to full starboard which has been found to be very effective in all conditions other MAIN BOOM MAST long time as to the relative merits of progressive, proportional or self-centering steering. Personally I prefer progressive or proportional as I like to be able to set the rudder rapidly to any one position and know that it will I think it is really a matter of what one is used to. As I 1966 LIMIT SWITCH l MOTOR SPINDLE Ps , 38 ifA A ae 20 ae mo ) F \ y y woe NS WORM 5 é / 959 CAM TO OPERATE LIMIT SWITCHES “CUT QUT 35° EITHER o \ SIDE OF CENTRE