APRIL 1969 TWO SHILLINGS AND SIXPENCE © Pa | Ss U.S.A. & CANADA — HOBBY MAGAZINE

APRIL 1969 NIPPY JUNIOR A small-size model yacht with pleasing performance. By Rex Young FULL-SIZE PLANS OVERLEAF HE idea for this small yacht was evolved on a sunny day at my local lake when half a dozen schoolboys were watching the model yacht sailing activities, and several youngsters were heard to ask their fathers: ‘Can’t you make me a small boat, Dad?’ Of course, ready-to-sail small yachts are available at the toy-shops, but these in many cases are far from inexpensive and involve quite a dip into father’s pocket. What was wanted, I decided, was a design that would be cheap and easy to construct, and yet provide easy handling and good sailing qualities. ‘Nippy Junior’ was the outcome of these thoughts, and led to my building first the prototype, which sailed very well in the hands of a novice schoolboy to whom I gave it, and then two more, both of which now also have keen youthful owners and are performing well on the lake. The yacht is small—only 114 in. overall, light — only 7 oz. all-up weight, and easily carried in a small bag on any schoolboy’s bicycle. The construction is all-balsa fitted first. These are cut from stiff paper templates taken off from the hull, and the edges abutting the keel can thus be accurately fitted, the outer edges being cut with + in. overlap and trimmed flush after glueing. They should be except for ply keel and fin, hence its very light weight and resultant good sailing qualities, and the total cost of building is around fifteen shillings complete ‘Nippy Junior’ also has an encouraging pedigree, as it is based on a scaled-down version of my successful sailing-cruiser model of Js/ander-23, which was fully described in Model Boats in February 1968. In Junior’s case, however, the full run of the top deck is unobstructed by any cabin superstructure, and the little boat has trim lines and a shallow draught. Construction is quite pinned to assist adhesion, and pins removed when set. Fitting and glueing the side panels then follows, cut with a small overlap on both sides, again pinned after glueing and trimmed when set. With the shell of the hull now complete, the whole interior is then given two coats of varnish or paint and set aside to dry out. Meanwhile, the deck may be cut from 1/16 in. sheet balsa, to overlap by 1/8 in. all round, and the deck planks scribed on it with a fine-pointed pencil. Then file out the 4+ in. mast hole and 1/8 in. hole for the rudder trunk, and also glue small blocks of scrap balsa underneath the deck at the points where the small brass screw-eyes will later be inserted when the deck fittings come to be added. The deck is then glued to the hull, held in place while drying by rubber bands placed right round the hull and positioned over the six bulkheads and the transom. When glue is dry, trim deck sides flush with the hull. If cut separately, fin and skeg are then glued with epoxy to the base of the keel, and the rudder made and fitted. straightforward, and the procedure is as follows: The keel of 1/8 in. ply is cut as shown by dotted line on the drawing. This may be cut separately from the fin and skeg and the latter items glued on to it later, or for maximum strength the whole can be cut out all in one piece if desired. The six bulkheads and transom are then cut from 1/8 in. sheet balsa, then notched 1/8 in. x 3/8in. at the base and 1/8 in. square on the four corner-points as shown on bulkhead 1 on the drawing. If a cambered top-deck is desired, the bulkheads should be cut with a top-curve as indicated by dotted line. For a flat deck they can be cut straight across as shown. The small under-deck mast-step box as shown on the drawing should then be made up from 1/8 in. sheet balsa and bulkhead 3, then cut into two pieces by re- Two strips of 1/16 in. lead sheet are then epoxied to the fin as shown, and the yacht is ready for painting: three coats of clear varnish for the deck and three coats of Valspar for the hull. As regards choice of glue for the balsa components, quick-drying balsa cement such as Britfix will be found quite satisfactory. The deck fittings are small brass screw-eyes placed as indicated. The small Braine steering quadrant is cut from a scrap of 1/16 in. Perspex and glued with epoxy to the top of the rudder-post. In use it is tensioned by a small rubber band looped on the transom. moving a half-inch width vertically from its centre and the two halves then glued to the box. All the bulkheads are then glued to the keel. Four strips of 1/8 in. square balsa for chines and inwales should then be steamed to the approximate curve of the deck-sides and then glued into place, chines first, The mast and sail booms are cut from +in. and 1/8 in. dowel, and the sails can be run up from any light fabric available, though terylene is the best choice. If made to the foregoing specification the small yacht will be found to sit accurately on he waterline and to move very freely on the water. Moreover, she is also a very stiff little boat and is pleasingly stable in gusts. followed by the inwales. Pin after glueing and remove pins when dry. This structure is then ready for the hull panels. These are of 1/16 in. sheet balsa, and the two bottom panels are 157

(/I6 SHEET BALSA oe TT rN PEPE 5 UN | — SR t KEEL NIPPY DESIGNED 1/8 2 Se STE : ee PLY — a JUNI — BY REX YOUNG = g Za (/8° PLY 16 SHEET LEAD a ke ee i i 1 1/8 SHEET BALSA 158

WIRE PINTLE SAIL HALF ers _ SIZE fe) yy IF CAMBERED DECK REQUIRED FULL BULKHEADS 1/8 SHEET BALSA

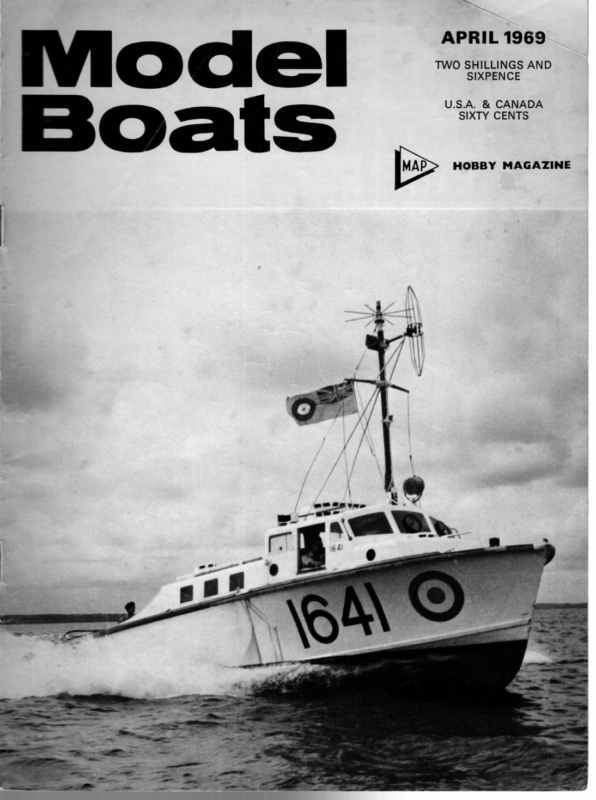

‘0 MODEL Seen at the Nurnberg Fair.. 160

APRIL 1969 AUTICAL interest among West German modellers increases annually and the 1969 Spielwarenmesse at Nurnberg revealed more new items to whet their appetite. Just a few are shown here. They indicate the scope and varied sources for the flourishing model trade in a prosperous nation. Opposite, top left are ready to sail Metre, *M’, 10r and ‘X’ yachts to very high standard by Adolf Hug of Ohringen who also makes a winch for radio control. All hulls in glass fibre. Waterline collection to 1/1250th scale by ‘Delphin’ covers 60 naval vessels, by Roland Saltler of Aufham, diecast and ready to paint. Second row are Graupner’s new gems, the ‘Commodore’ motor cruiser and ‘Elke’ fishing cutter, each for R/C, electric power and superbly kitted with plastic hulls, full accessories including anchor windlass on ‘Elke’ which is 1/36th scale. Third row left are Imai’s 1/700th plastics from Japan of Haruna, Kongo, Ise and 1/550th scale Myoko, Mogami, Atago and Chokai, each motorised and rare examples of IJN subjects. So too are Eggenweiler’s Nurnberg, Scharnhorst, and Bismarck rare, as they are for R/C, electric drive to 1/200th scale with plastic hulls in kit, also available separately. Prinz Eugen and Graf Spee are in the same series. Bottom left, from Mantua of Italy, the ‘Racer’ kit with epoxy hull, in this case driven by Super Tigre G.15 with belt to lower level shaft. At right, from Norway, another ‘Racer’ for .19 to .60 by Justnaes, having a steering skeg in one enormous casting at rear of glass fibre hull. This page, at right, remarkable Cox (U.S.A.) ready to run with pull start .049 in. plastic moulded hull. Clockwise below, at top left is French ‘Nova’ ready made yacht by G. Barkett. Collection of ‘S’ class ready mades is by Eggenweiler. Billing Boats latest is the B/uenose top right, another detailed kit. Below it is ‘M’ class R/C yacht by Rowan (cost £50). Centre at bottom is control box and twin screw ‘Samara’ by Schuco with 4 metre umbilical cable to convey control! In corner is Standard’s ‘M’ class R/C yacht with Heinrich Grassle’s R/C gear supplied ready to sail and, in centre, ‘La Sirene’ by Heller of France, a superb plastic in an impressive range. 161 More next month