bese 7 © sate 4 DECEMBER 1976 30p EXTRA PAGES AGAIN! Build a 36in. sailing model from cereal packets! MADD HORuV READE FULL-SIZE PLANS INSIDE fx x xan wOrMedWo’ TIV HOI cae Nitloggs SPREE. FOR ALL competition Prizes worth £45000 sie H.M.S. Mohawk torpedo boat destroyer Radio-control hydroplane @ @ Italian cruisers Making glass-fibre hulls @ ©@ Lifeboat Paddle steamer Princess Elizabeth

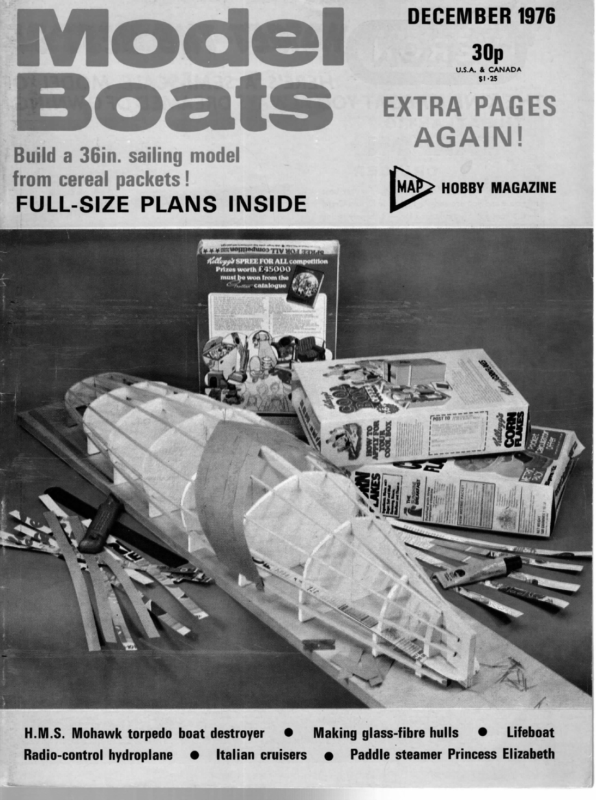

MODEL BOATS KRISPIE A 36in. Restricted Class racing model yacht which can be built from card planks on a balsa frame YOUR HEN we decided to resuscitate a technique we last used 30 years ago — building working boats from cereal boxes — we thought that perhaps a cross-channel packet, or maybe a container ship, would be appropriate. Or as a sailing model, one of those small coastal cargo vessels (stretching a point) a sugar smack ? The reason for reviving old memories is the reaction of many would-be modellers to the cost, and in some cases the difficulty of obtaining, some of the conventional materials most of us take for granted. You can’t get much cheaper than discarded cereal packets, and surely they are available in most places? Many more people will have a dabble at building a model if it’s not going to cost them very much to start it; it’s a bit off-putting to some to have to go out and spend a fiver on materials before they can get going. A yacht was chosen because sailing is one of the main growth areas in modelling, and if a racing yacht can be made successfully, quite clearly the method can be applied to many other types of model. There has been a dearth of published 36in. Restricted designs (three in the last five years, but before that nothing since the *50s) and with the resurgence of interest in this, the smallest racing class, new designs are welcome. This one can be built FREE PLAN conventionally if preferred, and it is also big enough for R/C if required. Perhaps the obvious shape for building in thin card is a hard chine hull, but this is equally ‘obvious’ for thin ply, and look what can be done with that. In fact, curved surfaces produce a stiffer and stronger structure when laminated, although since card is rather an inert medium, to achieve the same strength with card as with ply would require more laminations and probably an unacceptable increase in weight. If the idea of card doesn’t turn you on, the hull could be diagonally planked with +;in. (-8mm) ply, which would produce a stiff and very light hull but would require careful work, or it could be double diagonalled with veneer. If preferred, it could be conventionally planked with balsa and then either diagonalled with a veneer surface or glass fibre tissued. Or, again using cheap material, it could be planked using the single thickish veneer used as protection on crates of plywood and usually burned or thrown away by timber yards when the ply is unpacked. In any of these methods, it would be necessary to check the shadows and reduce them by drawing a line round the edge allowing for the additional material thickness. Since complete beginners may be involved, perhaps we should explain that the shadows are the moulds or bulkheads numbered 3-8; all but the end ones of these are removed after the hull is planked. As drawn, they allow rather less than yin. planking thickness (two layers of card) and if your planking will be thicker than this they must be reduced in size to allow for the extra thickness. The main thing to watch is that the maximum beam of the hull does not exceed the 9ins. allowed in the 36R rule. Let us turn for a moment to adhesives. Very few glues or cements are completely waterproof, and those that are are either a shade expensive or a nuisance to use. However, since card or wood is not waterproof either, the hull has to be protected on all surfaces by thorough painting or varnishing, and this should therefore afford protection to the adhesive. The biggest danger comes when a boat is allowed to stand after a sailing session with an unnoticed pool of water inside the hull. Contact adhesives which we have tested are not by any means waterproof; two small wood blocks stuck together and floated in water will separate quite easily after 24 hours, but, strangely, if pushed back together and allowed to dry out, will again be reasonably firmly stuck. This suggests that contact adhesives can reasonably be used to stick the second layer on, if required. Alternatives would be universal adhesives such as those offered by Uhu, Gloy, Humbrol, Bostik, etc. and theseare all suitable Top left, keel and shadows cut ready for assembly. Centre, keel and transom (No. 8) temporarily stood on building board. Note pencil lines on board and ultimate cutting lines on keel ends. Bottom, first stage of assembly, keel dropped into shadows I-8. 706

DECEMBER 1976 (as indeed is balsa cement) for sticking the first layer to the stringers etc. White PVA glues are possible, but lose their bond on soaking in water as contact cements. Thorough painting or varnishing inside and out is again stressed. Construction The first stage with any yacht, or any other boat built on frames, is to procure a sound and true building board. That used for the prototype was an 8in. wide offcut of 3in. blockboard, with the core timber running along the length, which had been kept in a warm dry atmosphere for some months and which had remained flat and untwisted. Building a true hull on a warped board is, if not impossible, not very easy. A straight centre line was drawn on this and the shadow stations drawn squarely across. Note that the shadows go on in a particular way and the accurate face of the shadow is positioned on the station line; this is because the hull tapers and so the shadow is only a proper fit at one place. It would of course be possible to chamfer the shadows but this is not really necessary. In the interests of absolute cheapness, we decided to test the feasibility of using shadows cut from expanded polystyrene. Three 3p tiles, tin. thick, supplied enough material, and any fears about the styrene squashing when, for example, the inwales were positioned, were soon dispelled. However, it is very difficult to trace on to the material, and we therefore cut out the tracings of the half-shadows and drew round them witha fine ball-point pen. Cutting paper templates for long, thin items should be avoided, but no discernible distortion arises with relatively small low aspect ratio patterns. The shadows should be cut with a very sharp blade, and if any sanding is required fine wet or dry paper should be used, dry; coarser glasspaper will tear ‘bubbles’ out of the polystyrene. Check that each shadow is accurate and symmetrical, and only cut out the notches required when you are sure of the size you need them to be, if you are using any variation of material. To explain this last point, we used in. balsa for the keel, but it would be quite acceptable to use jin. (5 or 6mm) ply, or tin. obechi, or even, for absolute economy, hardboard. For stringers we used hard 4 x in. balsa, but it would be OK to slice say -;in. strips off a straightgrained planed deal or cedar lath, which is (a) cheap, (b) available in places where balsa may be less easy to obtain. (Remember we have readers in Nigeria, Nepal and New Guinea, and many other places remote from model shops!). Similarly, fin. x fin. spruce is specified for the inwales (two lengths each side) and a lath which can be sawn down is an excellent alternative here too. Note that the transom, which remains part of the finished boat, is 4in. ply with a balsa inside face (or balsa with a ply or veneer outside face!) and that No. 3 also remains in place and can be balsa etc. Forward of $ will be block balsa or cork. Glue the shadows lightly in place on the building board; if you use polystyrene this means white PVA glue. Alternative materials for the shadows are of course balsa, ply, hardboard, or even thick card, laminated or reinforced with say ice lolly sticks or pipe spills to be stiff enough to avoid buckling. Trace and cut the keel and drop in place in the slots in the shadows. It should be an easy fit and should not be forced into undersize slots. It is glued only to 3 and 8, and to the building board at the points of contact at either end. When dry, cut or file the Jast notches in 4, i.e. next to the keel. Slip the stringers in their notches and check that they make fair curves and are flush with each shadow; if not, modify the notches by cutting and/or packing. These too are only cemented at $ and 8. (please turn to page 735) 707 Above, No. + in place and knuckle strips pre-laminated from card; shown in place in second picture. Below, stringers in place and second lamination of inwales glued to first. Clothes pegs ensure close contact. Note rubber band between pegs in upper picture, ensuring inwales are snug in notches while glue dries.

MODEL BOATS L. White found out the hard way, and at our invitation sets out his findings in A Clot’s Guide to GRP Hulls i AS a result of the BBC TV programme on model yachts, I decided to try and build a yacht for myself. you with the lay-up, but about all you will need are a 2 inch washer roller, 2ml and 10ml syringes for measuring After building a Gosling 36RI felt it was time for something larger and faster and so moved up to a radio Marblehead. At about the time that I was trying to select a suitable design from the MAP plans book, Model Boats carried a fair amount of correspondence on radio Marblehead design which basically meant that a vane steering Marblehead design was unsuited to radio work. Thankfully the ‘247 design appeared about this time and so I sent off for the plans. After much perusing of the plan and ‘Model Racing Yacht Construction’ I decided to go ahead and build a planked hull with glass tissue sheathing. Sometime later I was told that rubbing the coats down was a devil of a job and the best system was to mould the hull in GRP. I am a lot wiser now and realise that this was simply a ploy to get me to make a mould and thus I could easily mould a second hull for my informant (misinformant ?). Up to this time my only dealings with GRP had been to patch holes in a rusty car, which had been a very sticky process. Off I went to thumb through as many books on the subject as I could find, which seemed to show that the hardener, a couple of 14in. brushes and a number of waxed paper cups (vending machine cups will not do), while you still require a tin of polishing compound later and a quantity of brush cleaner. My first mistake when laying up the mould was to use a paste type hardener. It is very difficult to obtain a good homogenous mix so throw it away and use only liquid hardener. I have only used pre-accelerated resin and presumably the majority of builders will too. These notes are written on that basis. The recommended mixes for resins and hardeners are as follows: 1lb pre accelerated Gel Coat Resin to 10cc hardener 1lb pre accelerated Lay-up Resin — 4cc hardener (cool weather); 23cc hardener (warm weather) While the amount of hardener in lay-up resin can be varied to allow for weather conditions do not attempt to use less than 10cc per lb of hardener to gel coat resin or the next coat of resin will attack it, leaving marks on it like worm tracks (Oh yes, I found that out the hard way). It is usual to include colouring pigment in the resin, at the rate of 5% to 7% and mixing well before adding process was easy enough. It is, if all you want to do is make a fishpond or something similar where exterior finish and weight are not important. In the process of building my ‘247’ I have discovered plenty of pitfalls which have cost me both time and money. Perhaps the following notes will help you to profit from my mistakes. If we are to produce a moulded GRP hull, the first item to produce is a plug, i.e. something that looks like the final hull, from which we produce a mould. The chapter on planked hulls in Model Racing Yacht Construction by R. Griffin is your best guide for this. We must try and produce a really smooth and exact hull shape, for any blemishes will be faithfully reproduced in the mould; they almost appear magnified. In my case, after applying and rubbing down 10 coats of paint I decided enough was enough and used Brasso to polish to an acceptable gloss. Now, the remarkable thing about resin is its adhesion, especially on objects where it is not required to adhere, such as the plug. We therefore need release agents on the plug, a wax type, followed by a PVA type. For wax I use old style Simoniz car polish from the yellow tin, two coats of this followed by PVA which you obtain from glass fibre stockists. The PVA is best applied with a swab of cotton wool. We are now at a stage where we can start laying up the mould around the plug. If you look at a glass fibre stockist’s catalogue you will see a great range of materials to use. The main materials we will use are chopped strand mat and glassfibre fabric. We require the mould to be stiff and are unworried by weight, while the final hull should be light and strong. For these reasons we use mat for the mould and fabric for the hull, with an initial layer of surfacing tissue in each case. The catalogue will also show a number of tools to help hardener. At last, we are ready to start, with the plug mounted on its building jig, the work bench covered with old newspaper and a quantity of gel coat ready in the waxed paper cup. If you use a dark pigment in the gel coat you will be better able to see and polish out blemishes in the mould. Now mix in the liquid hardener (at the rate of 10cc per Ib) and brush on to the plug in an even, thick coat, but not on the transom of course. If the plug has been painted a contrasting colour this will help to show patches that have been missed. Once this has been done, and before the resin has set, clean the brush and your hands. Resist the temptation to leave the job out in the sun to cure quicker, for the job must be kept out of any draughts while curing; this applies also to later stages. Also, do not work during damp weather. I usually leave the gel coat for a day or two to cure before laying up the surfacing tissue. Marblehead hulls in general and the ‘247’ hull especially have plenty of double curvature and so it is advisable to apply the tissue rather like tiles, i.e. smallish overlapping sections. There are sections where strips 2 feet long by 3 inches wide can be used but usually the 3 inch wide strips are best cut shorter. The gel coat is slightly tacky and will hold the tissue until you are ready to apply lay-up resin. Throughout the lay up procedure you will find a sharp Stanley knife invaluable for cutting glass. Simply run it along a straight edge and you get a fine cut, much better than scissors. With a pot of lay-up resin, mixed with pigment and hardener, we can now brush on to the plug with its layer of tissue, ensuring that the tissue is thoroughly impreg- nated with resin and staying on the plug. The greater the curvature at a point the smaller the pieces of tissue should be, or the natural stiffness of the tissue will cause it to spring away from the plug. 714

DECEMBER Once this tissue layer has had time to set, say a day or SO, we Can get on with the main part of the lay-up, namely two layers of chopped strand mat of 450gm/m? (140z/sq.ft). Again I leave a day between layers. This is where the washer roller can best be used, to work the resin through the mat and ensure that no ‘dry’ patches are left. While the resin is still curing, say four or five hours after application, the Stanley knife is run around the edge of the plug, trimming the glass mat. At this stage trimming is simple, leave it until the resin has fully cured and you’ve a job on your hands. The mould will take a week to cure fully and if removed prematurely will tend to deform. When the week is up, you will require strips of thin plywood, say +,in., which should be introduced gently between the plug and the mould. As resin contracts slightly during curing the mould will be a very tight fit. The ply strips should be slid about to free the mould and plug. Disregard the crackling sounds, they are normal. Eventually you will feel that the two are free. Should the hull be of a similar type to the ‘247’ with plenty of tumble-home and a deep stem they will still be locked together. This is where you will need both faith and strength! Ease the plug rearwards as far as possible (that is why you did not mould the transom) and try to lift the plug out. It may take several attempts, but you can feel it coming further at each attempt. Once the two have parted, with a fair amount of noise, you can see the blemishes from the plug that you never really thought would show. Well, they do! Any blemishes are best polished out with wet and dry paper and soapy water, working down to 600 grade and only rubbing straight up and down the mould, from stem to stern. Follow this with the rubbing compound and in time you should see a good shine coming up. Once a satisfactory finish is obtained leave the mould for three or four days for the remains of the rubbing compound to fully evaporate. Failure to observe this precaution will mean that the gel coat on the moulding will be attacked. The time can be employed, however, by laminating a piece of timber on to the mould exterior to allow it to be held in a vice and provide a stable working surface. We can now apply two well-polished coats of Simoniz wax and one of PVA release agent to the inside of the mould. The routine for moulding the hull is the same as before, except that instead of mat, which gives a laminate containing 60 to 70 per cent resin, we use two or three layers of 110gm/m? glassfibre fabric which gives a lower resin content and a lighter hull. These layers of course follow the gel coat and tissue. I prefer to use open weave fabric for the first layer, simply because it seems to ‘lay down’ so well, with little tendency to produce voids in the laminate. The final two layers are close weave fabric. As before the material is laid-up like tiles. The ‘247’ design has a deep, very narrow stem and I found the best way to get the glass into the stem was to push in strips of tissue about in. wide and Sin. long for the initial layer, while for later layers lengths of 12-5mm glass tape were pushed in and impregnated in situ. It may not be pretty, but it works. You may be unable to complete a full layer before the resin becomes unusable in the pot, do not worry, simply do what you can and ensure that the glass that has come into contact with the resin is fully impregnated, using the brush rather than the roller to work the resin through. The Stanley knife should be used before the resin is fully cured, to trim the laminate at the mould edges. After a week has elapsed from the last layer, the moulding can be parted from the mould, with far less of a struggle than previously. The moulding is relatively flexible and can soon be lifted out. Once it has been ascertained that the 715 1976 hull is satisfactory a start can be made on fitting the inwales. Because of the flexible nature of the hull it is best to put the moulding back into the mould and use the mould’s stiffness as a support and to ensure that the hull does not distort. I prefer to laminate inwales from }4in. by }in. spruce strip, using epoxy for the initial layer onto the hull, ensuring that the area of glass has previously been roughened to improve adhesion. After approx 14 laminations had been affixed to the hull it was removed from the mould for the last time. In this state, with no bow block or transom, the hull weighed just on 2lbs. Obviously omission of the third layer of fabric would reduce this, and further reduction could be made by carefully considering where the lightly stressed areas occur and using only one layer of fabric. Avoid excess resin, but make sure that all the glass is thoroughly wetted out. The lighter a hull becomes the more risk it runs of damage, both during handling and sailing. I would think that more advantage would be gained by trying to fit one of the nickel cadmium batteries in the bulb. I briefly considered making a GRP fin, skeg and rudder but decided to use ply instead, as this is a much easier solution and a few coats of polyurethane gloss paint will give a finish comparable with resin. Quite by accident I discovered that the paint that Woolworths simply list as eae matches the Jasmine pigment I have used for the My initial attempts at producing a mould were with a two piece mould split along the centre line, as I initially thought that a one piece mould would be impossible, but providing the transom is not moulded in it has proved quite feasible, despite the rather extreme lines. One does not then have the problem of a join along the length of the hull. Asaresult of my earlier mistakes I needed more materials and as postage would have doubled the price of the materials I decided to try a local firm of grp moulders. Not only were they prepared to sell me odds and ends but they were happy to give me tips and show me where I was going wrong when I “just happened to have’ my latest disaster with me. Had it not been for them I might still be floundering. I hope that these notes are not too detailed, but I have found that articles of a general nature such as “… glass was laminated to a thickness of x ounces” leave too many unanswered questions.

MODEL BOATS The first RIOR National @& Championships = — Poole, September 11-12 by Trevor Rees n° Photo by R. L. Hanner shows Poole Commodore Ray Wills, mayor Councillor Hewitt, sec Colin Sayer, radio sec Trevor Rees, and MYA vice-chairman Norman Hatfield. Yachts are Dee Jay, Noname and Kestral. Be only advantage of sailing in salt water is that invariably it is associated with the open sea and therefore topping-up the water level is fairly easily accomplished. Hence the Year of the Drought produced no nightmarish problems for the Radio Committee of Poole Model Yacht Club who were hosts for this first national championship. Initial steps to organise the event were taken as far back as last March when Charlie Brazier accepted our invitation to be OOD for this very special regatta and, later in the year, preparations were put in hand to enlist publicity support from television, radio and press. The support of the Parks Superintendent was also obtained in providing a larger fenced-off water front. His Worship the Mayor of Poole, Councillor R. G. W. Hewitt, was invited to open the regatta and we were all extremely pleased to learn that our invitation had been accepted. During this period we had visions of being inundated by 30 or 40 entrants but by mid August we had formal confirmation of 22 entrants from nine clubs. And so the opening day arrived, having been preceded by a deluge of rain the day before. Alas, despite the vast expanse of open water there was scarcely a ripple in sight and the indicator in the portable wind strength meter remained resolutely at the bottom. With racing scheduled to commence at 10.30am, a hint of wind arose by 10am and the marks of the course were laid. The Mayor arrived precisely on time and having given a very appropriate speech, declared the regatta open and the first race started. Some ten minutes later the first and only lap of that race 1 2 S 4 5 6 7 8 9 9 Yacht Knut X100 Hercules Mimi Fleetwood Poole Poole Poole Basildon Leeds & Bradford Basildon Basildon Gosport Tango N. Curtis Woodley Arrakis Kestral 18 19 20 21 22 Club Poole D. White D. Graham C. Thompson N. Hatfield O. Lee D. Jones 13 14 15 16 17 D. Priestley L. Thompson R. Dehon Deboni Superpuss Barbapooh Axed Squiblet 10 Dee Jay 11 11 Skipper J. Cleave Misty Cloud Pacemaker Noname Hairy Nellie Albertross Twiga Dove Ava Repos R. Hanner B. Askell* D. Ellis T. Abel G. H-Redlich N. Grinter K. Corke F. Walker R. Seager C. Poulton J. Soper *Entered by J. Lawrence, sailed by B. Askell Poole was finished but with a protest at the finishing line. By the second race the wind strengthened enough to justify two laps, but with a clockwise circuit, and as this was the opposite of the first race, some of the forthcoming contrariness of the wind became evident, backing and veering between south and northwest. During the first schedule of 22 races, John Cleave with his Klug designed Knut was able to finish three minutes ahead of all others in Race No. 10 and Race No. 17 and in all, Nil points for time out were awarded 15 times. Unfortunately Mr Roper of Woolley MYC (Reading) was unable to compete at all during the first day, so there were several five boat races. Only six races were completed by lunchtime and by 3.30 a heavy shower damped down the last remaining whisper of wind and finally racing was abandoned at 4pm with only 17 races completed out of the first schedule. A prompt start at 10am on Sunday with a force 1-2 northerly wind soon enabled the remaining five races to be completed and the second schedule was started. With the wind strengthening to force 2-3, the racing was completed by 4.15pm, leaving only a sail-off between Derrick White and Don Graham for 5th place, which was won by Derrick. The RIOR Trophy was not put on show until Sunday afternoon and was then seen to be a beautiful work of art in bronze giving a contemporary impression of a yacht under sail, mounted on an ebony and hardwood base. This had been made by Vic Bellerson of the Birmingham and Bournville Clubs and really is a magnificent trophy which anyone would be proud to win and display. The MYA vice-chairman, Norman Hatfield, formally Score 128 114 104 98 98 94 92 88 82 82 74 74 Gosport 72 Poole Guildford Gosport Woodspring Gosport Poole Hove & Brighton Poole Woodley 726 Designer — Stollery Dehon-Walker Dehon Dehon-Walker Lewis Billings D. Knowles O. Lee Stollery Dehon-Walker Abel Lewis 68 62 60 46 Abel Abel Dehon-Walker Lewis 42 38 30 2 Walker Abel Dehon-Walker 44 Abel Design Klug Mr Rusty —: Mimi = Cracker Ranger (modified — Prototype Warlord oo Pacemaker Cracker Pacemaker Pacemaker — Cracker Pacemaker Twiga Pacemaker = Pacemaker

DECEMBER Interspersed with these, John Cleave performed some of his well known Knut type knot tricks — no wonder he has donated the trophy which was presented to the winner by the deputy mayor of Poole, Councillor D. Gooding JP. Out of a maximum of 144 points, John Cleave with his Knut had scored 128 points and so became the first very worthy National Champion for R10R yachts. The runner up with 114 points was Derek Priestley (Commodore of Fleetwood MYC) with his X100. The individual race scores for the first six competitors shows how close these two skippers were and with more wind on the Saturday problems with his rigging! As usual, the sailing was all the more enjoyable by the untiring efforts on the part of the ladies to feed so many hungry mouths and especial thanks are due to Marguerite, Patsy, Pam and Amey for their long hours of preparation, serving and cleaning up. Thanks are also due to Peter Wiles who had the monotonous but essential job of running the transmitter compound and so was unable to watch much of the racing. And so the event was com- the results may have been quite different. During the first schedule, 19 penalties were awarded to 10 skippers and in the second, 13 penalties were awarded to 9 skippers and this should emphasise the need for windward boats to keep well clear in light airs. On Saturday evening some 35 skippers, officials and ladies enjoyed an evening meal at a local hotel after which we were treated to the melodious voice and romantic aspirations of Charlie Brazier followed by Norman (Higher and Higher) Hatfield with a hilarious recitation. 1. 2 3 4+ 5 6 Yacht Knut X100 Hercules Mimi Deboni Superpuss > Indicates Penalty Skipper J. Cleave D. Priestley L. Thompson R. Dehon D. White D. Graham 12 2 10 6 10 8 T Indicates NIL score on time out pleted with a high standard of racing and sportsmanship, enjoyed by all, and in the aftermath, enjoyed several good write-ups in the local press. For the Poole Model Yacht Club, we were pleased to see that our own members did so well individually and no doubt all skippers will be looking forward to the RIOR National at Gosport in 1977 with yet another chance to win this new trophy. Details of the first six competitors’ scores were: Schedule 1 Scores 4 3 2 12 12 10 10 12 6 12 12 T 6 “1 8 12 4 8 10 12 8 = of his own design, Scheherezade, back in 1962. Always a keen competitor, he has come 3rd and 6th in National A Championships, was Guildford club champion in 1974, won (with team-mate Alex Austin) the Pugwash Trophy in 1975, and won the Gosport Bilmor Open Cup this year. He also scored most points in the 1970 Model Maker 10 12 8 12 12 10 8 12 12 6* 10 8 6 9 6 12 12 12 6 10 10 12 12 10 2 6 8 11 12 8 10 12 2 8 12 12 2 6 10 Total 128 114 104 98 94 94 Two more familiar names on » « the modelling scene Trophy but still came 3rd; that year it was sailed in divisions with a 6-boat final, and Roger was the unlucky one in the toss for the three-boat sail-off. Close to the 30 age mark, Roger was a music master for some years and is now a Deputy Headmaster. He is a very talented musician, playing a variety of instruments and keen on composing; his school orchestra has broadcast and he has been paid for writing music for the BBC. Activities have included/include playing in a folk group and an orchestra (largely, he says, hours spent lovingly polishing a ’cello), and playing hunt the spanner with 20-month-o]d son James, who is convinced he is God’s gift to motorcycle mechanics. Roger was presented with a daughter in October by his very attractive wife Christine, so we can take this opportunity of congratulating them on behalf of all their yachting friends. KEITH PARKIN, bachelor in motor), moved to Galloping Ghost control, built a Sea Queen with the first Gannet engine in the area (£27 —!) and E.D. Black Prince 6-channel radio. Latest model is an H.P.61 Arrowshaft with Futaba M, but he feels he had more fun with his old equipment, tuning for a current drop and walking half a mile for a range check! and in occupation he is Company Secretary to a Bradford firm of wool merchants; he joined the company from school at 16 and was appointed a director on his 21st birthday. He was born in Bingley but Not particularly competition-minded, Keith has occasionally collected the odd prize and won the petrol class in last year’s Keighley annual regatta. His interests include working on cars and he has become keen on live steam locomotives, owning a 5in. Bagnall 0-4-0 saddle tank and a Sin. 4-4-4 Metropolitan tank which he enjoys driving at club events. High spots of the organisational work he has put in, with Mike, were undoubtedly the World Championships at Keighley in 1974 and the FSR and Multi events at the European Championships at his mid-30s, is the other half of the very successful Mike Varley/KP team which has run so many enjoyable multi-races in Yorkshire. He is in fact secretary of Keighley DMES, a: Schedue 2 Scores 6 12 6 8 6 12 4* 12 10 10 10 8 8 Introducing. ROGER COLE is a member of Guildford, Gosport, and Portsmouth model yacht clubs and, as a motor-cycle racing fan in the process of restoring an ancient Norton, also belongs to the Norton Owners Club. He is unusual in having started modelling not only in the A Class, but with a boat 1976 moved around the East and West Ridings since his father was in the police force; he returned to Bingley in 1954 and became interested in all aspects of modelling. First model a Veron police launch, E.D. Tx, E.C.C. Rx, Mills .75 was Welwyn in 1975. HAPPY CHRISTMAS AND PEACEFUL AND PROSPEROUS 1977 TO ALL OUR READERS FROM EVERYONE AT M.A.P. 727

MODEL BOATS Round the Regattas Some of the boats present at the sail-in for scale models held on 19th September, by Sedgemoor M.B.C. Manchester ‘Open 30’ Multi, 12th September 1976 This event, arranged by the Manchester Radio-Controlled Models Club, looked like being very popular early in the season. By the end of July nearly all the available ‘spots’ were booked up, and only a few odd splits were left. When the ‘glorious 12th’ arrived, over 120 entries were on the books. Due to non-arrivals and mixed-up entries classwise, eventually 123 boats took part in the day’s racing. The day started off (unusually for Manchester) with grey skies, a cool breeze, and a damp atmosphere not conducive to a pleasurable day of outdoor activities. However, Peter Kirk and his band of hardworking helpers had got the course laid out, and the first heat started only 15 minutes after schedule. A time which, by the way, was halved before the end of the day, due to the efficient system in operation for dealing with lap-score card issue and return, under the able direction of Northern Area Chairman, Jan Podlaski, and the slick ‘radio-check’ technique of the pit officials. Turn-round at the finish and start of each heat was really something; the quickest, I believe, was under three minutes. The racing was keen but friendly, although a little whisper from the ‘noise-man’ said that a few offenders did some ‘throttle-jiggling’ along the home straight. (Nuff said.) Even though the same names keep cropping up regularly here and there, it’s nice to see that some of the people who have been on the scene a long time without Class Club Laps Telford Telford Halifax : 34-2 21:0 B B B Ist 2nd 3rd H. Callow R. Burrell J. Barraclough Telford N. Birmingham Bradford 49-4 46-4 43-3 W. Ogara Coventry K. Wigglesworth Leeds 48-4 Manchester Halifax Manchester 32-2 27:4 Zieh G D D D Ist 2nd 3rd Ist 2nd 3rd I. Chadwick J. Podlaski D. Lightley A. Clegg Liverpool 57-4 D3 Wellworthy Cup, Sunday 19th September The New Forest R/C MYC were the hosts for the third annual contest for the Wellworthy Cup for ‘RM’ class yachts, held at Snails Lake, Ringwood, Hants. Some 40 boats were expected to enter, but unfortunately, the final entry was 31, which enabled our computer expert to produce a perfect schedule Again the first race commenced exactly at 10am. It is nowa tradition for the New Forest club to start on time. Many other clubs might bear this in mind; it is simply poor organisation to start late. The weather proved to be dry, some sun, and a light wind up to force 3, a day for high aspect sails. The first race was won by J. Curtis of the Woodley club, sailing his modified Aguaplane design eith. Frantica, He was able to win a further four races, and only Throughout the day there was never a dull moment, with up to ten boats (twelve in some heats) taking part in 12 heats and, despite the damp start before lunch, there dropped two points the whole day, when he was beaten into second place in one race by D. Andrews of Leicester, He made a score of 70 points out of a possible 72 and was were not too many problems, either mechanical or radio- At the end of the day, after our worthy President, Frank Bradbury, had presented the trophies, the visitors expressed their thanks for an enjoyable day’s sport, although there were a few workshop repair jobs required to be done before the next regatta. For my part, I must apologise for not moving round the compound more, but I was just getting over a bout of gastric flu. J.H.F. RESULTS A. D. Jones J. Wilkie D. Lightley Cc success are creeping up with the leaders. One of these is effort. Name Ist 2nd 3rd Cc Dr Dennis Lightley, who managed to get placed 2nd and 3rd in his respective classes. Well done, Dennis. Also, Jan Podlaski, who has had a run of bad luck this year, with ‘engine-gremlins’ being over-active. He has got an excuse though, with a big social event taking place at the Podlaski establishment this September. A wedding, where Jan and nee gained a son-in-law. Congratulations to Elaine and wise. The rain managed to hold off for most of the time, with just the odd shower during the afternoon, when there was some real hairy dicing, as the Telford and Yorkshire contingents battled it out for supremacy, not forgetting Manchester’s Alec Clegg, who was suffering from radio problems, and at times was circuiting like a ‘waltzing Matilda’! I would like to take this opportunity to thank, on behalf of the Manchester RCMC, all those who attended the, regatta, especially as some had travelled long distances, such as London, Leicester and Coventry, to mention but a few, in weather which was more suited to building than sailing. It was nice to see so many entries from the Southern and Midlands Areas. — you for helping to make the event a worthwhile Position A A A the outright winner. The interest in this event was such that entries came from as far away as Fleetwood, Leeds & Bradford and South Wales, as well as Basildon, Leicester, Andover, Guildford, Woodley and, of course, the host club, the New Forest MYC. The result as far as the host club was concerned was a disaster. Experts like David Waugh with his Teacher’s Pet (Nationals winner 1974 and 1975) and Derek Stevenson (Nationals winner 1976), and other New Forest ‘stars’ came just nowhere. It just shows the competition that now exists in the ‘RM’ class. Two competitors tied for second place — D. Hollam of Leeds & Bradford sailing his Ashanti design Eskimo was just able to nudge in front of D. Andrews of the Leicester club, who also was sailing an Ashanti design, Zulu. In fourth place again there was a tie between C. Eagle of Basildon, sailing his Red Venom, who just managed to hold off N. Curtis sailing his well known, single sailed, Bloodaxe design Tango in the resails. The OOD was Bob Jefferies who, at the completion of the event, was able to introduce Mr D. Upton of Wellworthy Ltd, the donors of the Trophy. Mr Upton, after presenting the Cup and other awards, mentioned he had no experience of controlling such small boats. His 732

1976 DECEMBER Boat Name J. Curtis D. Hollom D. Andrews C. Eagle Frantica Eskimo Zulu Red Venom L. Thompson J. Cleave J. Clark JS. Knut Aeolian D. Priestley G. Coombes Icanga Red Wolf N. Curtis D. Waugh Tango Woodley Teacher’s Pet New Forest Sea Witch Panic Bloodhound R. Gerrey J. Foster J. Wild Yimkin — Pabri Southerner Margo Midnight Oil Moonracer Ultra Violet M. Oxlade V. Cooney D. Robinson T. Fuller E. Forbes A. Oxlade T. Able N. Hutchins Teazel Mrs E. Andrews Flying Saucer Margaret T. J. Cohen J. Thomas His One Benita Jonda Sally Ann —_— Jildi D. Stevenson D. Voss J. Ayles T. Brown I. Harrison A. Wood Club Fleetwood New Forest New Forest New Forest Woodley Woodley Woodley New Forest New Forest New Forest Woodley Guildford New Forest Leicester Woodley South Wales Basildon Andover New Forest Andover Leicester New Forest Poole Southampton Southgate Amarind G. Wyeth Two Too Many C. Wyeth A. House White Rabbit 42 38 20 28 26 26 14 30 33 41 28 26 28 17 21 C.Edmondson I. Taylor 18 21 Vulture Scimitar I] Hai Karate M. Peppiat P. Strickland J. Buttigieg 16 5 35 28 9 21 Own design Sea Horse 38 38 19 21 22 26 24 24 25 — 28 Squiblet _ Bewitched — 18 16 8 4 Did not start Did not start 23 26 27 28 29 — —_ 36R National Championship 1976 at Leeds & Bradford Twelve boats were entered for the °76 Championship, and the Club having spent weeks organising the event were slightly disappointed with the entry. Nevertheless the event turned out to be very successful and everyone seemed to enjoy their weekend’s sailing at Larkfield Tarn. The OOD, Peter Maskell, had decided to sail two rounds and he made this point clear in his ‘welcome’ speech. He also pointed out that for the first time in years there were ee planks missing from the duck-boards surrounding the ake! Saturday Racing started soon after 10 o’clock on the Saturday morning. The wind was blowing from the top end of the lake in a south westerly direction. The wind strength fluctuated throughout the day yet it remained on the strong side, most had their smaller rigs on. Spinnakers were used on the run and there were quite a few spectacular runs. Racing continued at a steady pace up to dinner; Ist 3rd ZT On Sunday, 19th September 1976, the Scale Section of Sedgemoor Model Boat Club held a ‘sail in’ for scale type models on their water provided by the Burnham on Clubs in the surrounding area were invited and 31 models and owners arrived at the waterside. An excellent assortment of models took part, naval, cargo and fishing 17 34 34 32 30 without becoming too highly competitive. 2nd Sedgemoor Model Boat Club Sea Council, at Highbridge. 13 14 40 40 of this club contact Tony Mounsdon at 46 Homefield, Locking, Weston Super Mare. The aim of the section is to promote scale models and meetings of scale models Score Round Round Posi1 tion Black Rabbit Luncheon Vulture Lorandus Ryde R. Seager A, Austin R. Stollery 46 42 40 This was an exploratory event to seek out the possi- by 4pm. C. Dicks Bewitched — Bloodaxe bilities of similar and more frequent meetings next season; by the response this would seem a very real consequence. If anyone in the area would care to join the Scale Section The wind was very fickle and light all day, the direction varying between NE and SW and mainly from the SE. Despite the lack of wind good progress was made and by 7pm one round and one heat of a second round had been completed. The presence of some weed in the lake made an additional hazard but did not dampen enthusiasm. At the end of the day the Clapham team had established a lead of 26 points over Poole team, their nearest rivals. A 9.30 start was ordered for the Sunday and with a SE breeze most yachts were down to their working rig within three heats. This freshening gave more interesting sailing and enabled the second round to be completed Major ‘B’ Bloodaxe 5 6 Th were electric powered. at Gosport. Guildford 4 vessels, tugs and pleasure craft. Because only electric, steam or sail power is permitted on this water all models ‘M?’ Class Team Championship 1976 Skipper 1 2 3 9 10 Bewitched The entries for this event were all from clubs within the Metropolitan and Southern District. Six teams of two yachts each came to the start at 10am on 18th September Yacht — 46 Position 60 56 50 50 48 46 — that were satisfactorily solved. Illusion 60 _ — Throughout the whole day there was not a single case Aeolus 70 — Bewitched _Moonracer Bewitched of radio malfunction, and there were only two protests Team 68 68 — — Ark Royal. Clapham Points Bloodaxe — Ghibli Squiblet — a New Forest New Forest New Forest experience of such things was limited to the rather larger Scores and positions were as follows: Design Ashanti Ashanti Modified Aquaplane Woodley Leeds & Bradford Leicester Basildon boats doing well at this stage were Batman 25/25, Mickey Finn 22/25 and Ariel with 18/25. The rest of the field were well behind the three leaders even at this stage. The afternoon racing was also very enjoyable, despite a few showers. The first round was completed and the OOD announced that he would do one heat of the next round and start early Sunday morning. Resails were taken, and then the first heat of the second round was sailed. This left 10 heats to sail on the Sunday. The position now was, Batman 49 pts, Ariel 43 pts, Mickey Finn 42 pts. A successful fish and: chip supper was held at the Armour household on the Saturday night. Sunday Unfortunately the wind had swung slightly and was now under the influence of the factory. This meant that there was a dead patch over the finishing line which was occa733

MODEL BOATS sionally ‘attacked’ by unexpected gusts which had great effect on boats in the area! The racing again was enjoyable, the three leaders continued their battle at the top and the lead changed hands quite a number of times. Four heats were completed up to dinner and the position with 30 pts still to sail for was — Batman €2 pts, Ariel 61 pts and Mickey Thanks must go to the club for a very well organised event; the hard working canteen ladies, the officials and an extremely efficient OOD, Peter Maskell, must also receive praise for their efforts. Also thank you all the competitors for making this championship so memorably enjoyable. Finn 60 pts. During the afternoon Mickey Finn only dropped three more points which gave him victory. Mike had sailed the boat very well (especially on the Sunday in very difficult conditions) and was a deserved winner. Second came Ian Taylor (Batman), Ian had also sailed very well, as had Walter Jones (Ariel) who was third. It is ahead of the rest of the fleet (pointwise) as Arie/ had 80 points and was third while Pyjarmours had 59 points and was 4th. HMS MOHAWK (continued from page 710) mine. The two half wrecks were towed away to Chatham to be later joined together with a new mid section and after six months’ work was recommissioned as the Zubian. This ship was credited with sinking a U-boat by depth charges in February 1918. Taken all in all, this class of ships was successful in that it more than fulfilled the requirements laid down for them. The shortcomings highlighted during their service life were rectified in later classes. The high fuel consumption was reduced in subsequent classes with the intro duction of the more efficient and lighter geared turbines and better designs of oil-burning boilers. This lighter machinery also permitted more displacement to be given over to armament, light armament being another deficient aspect of the Tribals in later years. But in their day the Tribals were still a large step for- 7th 8th 9th 10th \ith 12th 1145 1079 1069 1081 1146 1140 Big Red R. Hatfield Piglet G. Griffin Puddle Thumper H. Briggs Sku Wiff A. Whitely | Nogginthe Nog C.Thompson Mr Trimble C. Williams 1124 Hermes M. Harris I. Taylor W. Jones T. Armour S. Armour M. Armour Bournville Southgate Birkenhead Leeds & Bradford Leeds & Bradford Leeds & Bradford Welwyn Cleethorpes Cleethorpes Welwyn Leeds & Bradford Dovercourt 87 82 80 59 55 53 52 43 42 40 34 33 crank. 5. Hull can now be sealed internally and externally with sanding sealer. Aircraft tissue can be applied to the outside of the hull and decks also inside of access hatch. I find that tissue and sealer provide a much tougher surface after applying several coats of sealer than a non-tissued surface. 6. Details and deck fittings. This ship is a cowlmaker’s dream and it is up to personal preference as to which method is used to make the 29 ventilation cowls required. For the large cowls I used medium hard balsa blocks and carved from solid as shown on the plan in ward in Destroyer design. stage drawings. The medium sized cowls were carved from dowel which was rather hard work, and brass tube The model shown in the photographs is 24in. long but to give the ship a more reasonable size and carrying capacity for radio the drawings were scaled up to give a model size of 37in. long by 3}in. beam and a displacement of 3lb 140z. Total Mickey Finn Batman Ariel Pyjarmours Krab and fo’c’s’le deck in thick card or in. sheet balsa. Fill any gaps in hull sides and finish sand. 4. Fix propshafts, motor mount and motor in position, checking for correct meshing of gears before finally fixing propshaft centres. Add rudder and if to be fitted stl aa rudder post should be fitted with 90 deg bell- The Model Weight distribution should be: Hull and ancillaries 6 x HP2 batteries Electric motor .. Radio and gear. . 1089 1147 234 1113 1098 6th interesting to note that these three boats were a Jong way T.A. Ist 2nd 3rd 4th Sth was used for the smallest cowls. The ship’s boats were carved from block balsa and after having several coats of sanding sealer were hollowed out; seats of card were added later. The trick of success- fully hollowing out thin wall balsa parts like cowls and ship’s boats is in using an extremely sharp knife and taking 250z 21oz 40z 120z many small cuts which break up the balsa to be removed without overstressing the remaining shell. The funnels were made from gum paper strip round a former, but should be made of sufficient thickness to withstand rough 620z treatment by pondside helpers. As can be seen from the slightly crumpled No. 2 funnel in the photos, mine were not! The deckhouse and bridge can be made from +,in. plywood or card. The guns were cut from dowel and As can be seen the hull weight has to be held as low as strength will allow and the use of metal fittings should be kept to the minimum. Construction 1. Cut out main deck, bow and stern planks and bulkheads } to 5. Cut out access hatch from main deck Mark out and fix bulkheads and deck stringers to deck, forming curve of deck as shown with yin. and tin. packer strips. Glue bow and stern planks to A, B, C, etc, together in bread and butter fashion and fix to hull assembly, aligning as shown with an +in.sq. strip under deck at joint with bow plank assembly. Fix tin. square stringers along bulkheads and shape bottom edge of stringers to be flush with bulkhead bottoms. 2. Attach }in. sheet balsa hull sides, trim to be flush with hull bottom stringers. Slightly bevel centre edges of tin. sheet balsa hull bottoms before fixing in position. Similarly with stern hull bottom sheets after cut up point aft of bulkhead 1. Cut slots for prop tubes on centrelines as shown on.-hull lines view. Add half bulkhead 1}. 3. Carve hull to shape and check form with card templates of hull sections. Before final sanding add lower deckhouse, cut out recesses and fit curved hull sidescreens pinned on balsa mountings. Trials As the model in the photographs is only 24in. long, as stated earlier, the trials are not entirely relevant to this model, but are interesting if only to further illustrate the care needed to obtain good stability results when building light displacement narrow ships. The displacement was ‘carefully’ calculated at 360z which allowed for an Orbit 605 motor plus 6 HP2 batteries arranged in torch fashion. Upon placing the destroyer in the water at the pondside I was rewarded with the sight of the ship heeled over at an angle of 30 deg from the vertical. This disappointment was soon overcome when upon switching on the motor the torque reaction from the twin props tilted the ship upright; that was one problem solved! The ship was also lying more than Hin. below the designed waterline and behaved like a submarine when running at full speed. To reduce weight I replaced the 6 HP2 batteries with 6 HP11 plus 1 HP2 734

DECEMBER which made up to the same length but weighed 740z less. My only qualms now, were, would the reduced weight of batteries make the ship more unstable? I was just reading up on metacentric height calculations when I was struck by the fact that HP11s were lin. dia, and the HP2 batteries 1in. dia. Therefore the C of G of the second set of batteries was –in. below the first and although the hull would ride higher out of the water the C of G was still 1976 reasonably low. This general observation was proved when both battery layouts were tested and appeared to give the same degree of stability. Sources of Information British Destroyers by Edgar J. March ARINA — published by Seeley Service & Co. Warship International, Volume X No. 1 1973 page 113, 114. KRISPIE (continued from page 707) Follow these by positioning the first pair of inwales, glued at $ and 8, and when dry add the second pair, which are cemented all the way along to the first pair but not to the shadows (except 4 and 8). The frame now begins to look quite attractive! Many modern designs used a heavily flared bow or a built-in knuckle which provides extra lift at the bow when running downwind. This feature is incorporated in a simplified form in Krispie, by fitting in a knuckle strip and planking up to it. The strip on the prototype is made from three laminations of card, but it could be +in. ply if preferred. If card, glue the laminations up and leave to dry under pressure, then slide into the slots in the shadows and glue only to the keel and to 4. Make a last check that everything is fair and you are ready to start planking. Cut your collected cornflake packets into strips say gin. wide; they will need to be about 10ins. long at the widest part. It may be as well to save some uncut, as narrower strips, or even tapered strips, might be useful as you progress. Make sure the edges are straight, which means cutting them with a knife and straightedge rather than scissors. Start planking around section 4 and work forward and aft; each ‘plank’ is cemented only to the keel, stringers, and inwale and not to the shadows. At first the forward planks will cover the knuckle strip, but when the card wants to bend over it, start butting to the strip and use a separate piece to cover between knuckle and inwale. When 4 and 8 are reached, the planks can be cemented to them and any overhang trimmed off. Try to wangle the card strips to abut closely and lie reasonably flush with each other; the second layer will tie them neatly together. (To be continued) ii The Secretary Writes…. ae issue sees the completion of another year, one of mixed fortunes, derived from the weather principally — hot and dry all summer with the historic water shortage eliminating much boating at the height of the season. It is to be hoped that the current wet weather will provide enough water to keep us out of trouble all next year. Of course all activity in the open air has not yet finished, and symptomatic of the trend to get as many boating days in as possible is a note from Ian Boyle of Stevenage with details of a new event to be held on 21st November. Of course by the time you read this the event will have been held and I hope to be able to report on it next month. Rather unique in respect of several factors, this event perhaps heralds a new phase in the top end of multiracing and proves the need for the economy class even more. Entry is being restricted by invitation only and is for ‘B’ and ‘C’ class boats. The ‘Southern Classique’ has M.P.B.A. International Secretary, Jim King, on various model marine matters. Whatever opinions are formed, I look forward with interest to watching the contest and indeed have accepted an invitation to present the winner’s trophy. My comments on the Cygnets Scale Regatta seem to have upset a few people andI received a letter from some well-known people in the scale world protesting at my comments. Since a copy was sent to the Editor asking for publicity and I already had arranged to comment on it, nothing could be better than to print it here as received. “Dear Sir, only one prize — a trophy valued at £180 plus a cash prize of £100, and I anticipate that the racing will be in the ‘no holds barred’ category. As Ian Boyle says in his covering notes ‘a few eyebrows will no doubt be raised’ but with all the interest in multi-racing, there is a place for such a ‘Grand Prix’ even though the entrants could be classed as professional. Maybe competing in such an event could be used as a bar to their entering a Marine 20 event? October 1976 Model Boats It really is too bad of you to be continually sniping at the only ‘legitimate side’ of the hobby; I refer, of course, to the scale modeller. Fortunately, it can be said that we, as a group, are not overtly bothered by your disparaging remarks, we only question their necessity and motive. Incidentally, your articles are read, not to heed your pontifications, 735