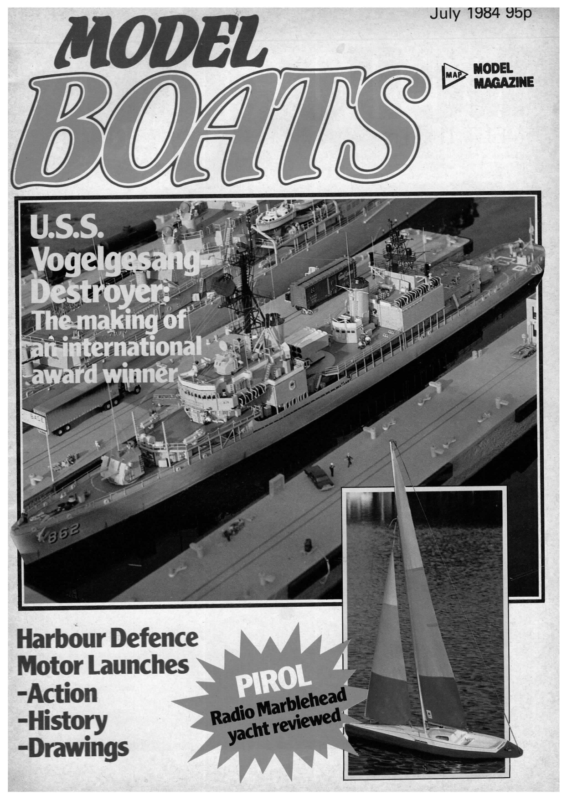

July 1984 Y5p MODEL MAGAZINE Harbour Defence Motor Launches -Action -History -Drawings

[ would be wrong for any reader to be under the illusion thatI am in any shape or form an expert on model yachts. For many years I have been (and indeed still am) a devotee of radio controlled model aircraft but like most modellers am interested in all aspects of modelling and the Readers will therefore appreciate that I was thankful not to be relying upon public yacht was really the fulfilment of a desire which I had nourished on andoff for several years. I was finally motivated, I think, by spending an hour or two at the canoe lake at Ryde on the Isle of Wight watching racing by the Isle of Wight MYC towards the end of last year. To me, model yacht racing was obviously akin to thermal soaring and although undoubtedly a lot of fun could be had by sailing purely for pleasure, it is the competitive element that produces the maximum excitement. So it was then that when I returned to the mainland I sought the advice of ‘Barry the Boat’ in ‘Avicraft’, my local model shop. He explained to me the various classes and the availability of hulls, masts, sails and other fittings whereby one could build a boat from scratch. However, I felt that as an absolute novice a kit was probably advisable and the upshot was that I selected the Robbe Pirol. Predictably the box was a fair size but unwittingly I had not bargained that I would have to also transport home a cardboard tube some 7ft. long containing the mast and also a much smaller package — but considerably heavier — some 5 or 6 lb. — containing the ballast. The Contents acquisition of a model radio controlled Left: ‘Goose-winging’ in the gentle conditions. Below: Pirol finding rough weather rather heavy going, and having only a working suit available did not help matters. All photos by the author. transport. I had, of course, already examined the contents of the box at the shop but the workshop was obviously the place for a much more detailed inspection. It was immediately apparent that apart from the usual items such as adhesive and paint the kit was complete. The hull is moulded in ‘Plura’ which although fairly light in weight — some 2lb. 10oz. is appreciably strong, quite rigid and pleasant with which to work. The shape is I believe of French extraction and has provoked the comment ‘interesting’ from those who know about such things! The moulding — the hull comes in one piece with openings for the hatch and at the bow, the latter being for access during building only — is nicely done and requires very little attention from the point of view of ‘cleaning up’. Indeed, I found that after a few minutes work with wet and dry paper the almost unnoticeable spots of ‘flashing’ disappeared and a smooth matt surface resulted ready in due course for painting. The instructions do emphasise that where gluing has to occur the hull should be ‘flatted off’. Obvious, of course, to those of any experience but also perhaps an indication of the thoroughness in some respects of the instructions which, incidentally, are printed in English. I would mention, however, that the plans which are very clear and nicely produced, do not contain an English translation but ope eine 392 Model Boats

more on this point later. The shroud and mast rails are easily affixed in their recesses, again using Stablit Express, but the fixing is reinforced by suitably sized brass nuts and bolts. Before fixing the ‘rails’ I decided to titivate them by giving them a polish to bring up the aluminium to a mirror like finish. This was merely for the sake of appearances because the extrusions supplied are quite satisfactory as they are. It is advisable to substitute a countersunk bolt in the centre hole of the mast rail as the ‘cheesehead’ one supplied the hull makes for a convenient carrying handle. Incidentally, my cautious nature dictated that the underside of the deck could benefit from being reinforced here by a piece of ¥, .in. ply, say 10cm x 5cm, with a small block of wood drilled to fit over the brass reinforcing tube glued in place when the keel had been aligned. The instructions suggested using set squares and a spirit level to ensure proper alignment of the keel but I found that this was achieved easily enough ‘by eye’. I did not fit the ballast at this stage because it occurred to me that the additional 5 or 6 lb. would make for difficulty in handling the hull during further construction. In any event the ballast is held on by a long bolt and so far this has proved successful in being the only means of support! Incidentally this was to prove to be an advantage when it came to rigging the boat. place on the ply plate using ‘Self-Stick Velcro’. I was in some dilemma as regards the aerial — all that ‘metal’ hanging around looked somewhat ominous to say the least. Impatience to set sail caused me to forget that the aerial was still neatly coiled up on top of the receiver and happily no disasters Radio Installation sheet on the ‘seats’ immediately behind the The time had now.come to give further thought to the installation of the radio equipment. From my experience with model aircraft, I had long ago appreciated that one cannot be too careful) when installing the ‘gear’ and consequently the somewhat casual arrangements .shown, on the plan. provoked raised eyebrows, to say the very least. Indeed, the placing of the batteries at the lowest point in the hull and the rudder servo and sail winch also fairly low down, inhibits the seating of the mast at this point. . seemed to me to invite disaster if the boat took on any water. At the same time, The opening left in the bow provides easy access for fitting the guide pulley here and however, I can appreciate the reasons for as this pulley has a very deep recess I did not wanting to keep the weight as low as bother to add any device that would ensure possible. I decided, therefore to install a in. that the ‘loop’ would stay in situ because, ply plate suspended across the hull and according to the instructions, which I had conveniently .accessible via the hatch read through two or three times before opening. This ply plate had cut into it starting work, this loop would be under suitable holes to take the rudder servo and sail winch. Incidentally, I obtained a sail tension in any event. more than 50 yards or so away. The aerial is now stretched along a piece of ¥,in. sq. balsa and located under the deck with double sided tape. No problems have been experienced at ranges of even 200yds. — which may be a commendation for my Skyleader gear — 27MHz of course!! In order to keep the sail winch out of harm’s way, the drum was thus too high to use the rear pulley mounted under the cockpit floor. I therefore overcame this problem by installing a piece of 18 gauge aluminium front wall of the cockpit and the pulley was mounted on this — the looprunning through two holes drilled in the cockpit wall. Again, see the photograph. I also decided to maintain the tension on the loop controlling the sheets by inserting four or five small elastic bands (rather than wind it tightly round. the drum as the instruction suggests and so far this has worked satisfactorily although I appreciate that the experts may tell me that there are better ways of doing this. I would have much preferred to have used the closed loop system employed on model aircraft for controlling the rudder but this Was not entirely practical and the brass wire rod/reinforcing tube system has worked satisfactorily, although I did use a piece of plastic tubing, cemented to the underside of the cockpit floor, as a ‘guide’ to prevent undue flexing of this push rod. You need, incidentally, about 35° rudder movement each way and therefore insert the push rod in the innermost hole but one on the horn (and the outermost on the servo arm). The opening in the bow could, of course, now be sealed but I delayed fixing the rubber ee ae On then to the assembly of the ‘parts which seal the deck opening’. At first glance, the instructions and the plan may seem a little confusing in this respect but a dry run, with the parts separated from the plastic sheet, makes all become very clear winch from David Andrews because apart from being more compact than the Futaba winch shown on the drawings it is also infinitely cheaper! A glance at the photo- occurred although Pirol did not venture mee Seals graph will illustrate the installation of the radio gear and batteries — which are heldin eR ee seit a vahnip a ae ee ON and cyanoacrylate is certainly the desired adhesive here. All of the parts fit together very satisfactorily and I found that my hatch cover worked extremely well from the outset and indeed has proved to be Pat remarkably watertight. The addition of the quite an attractive eee offers ean and date cabin roof provides the right degree of rigidity Although at this stage the instructions suggest the two flanges are affixed to the bow opening, because I had decided from the outset that a little more thought should, in my view, by given to the radio installation, I moved on to the next stage which was the assembly of the keel. The plastic parts fit very well and seat nicely in the recess in the hull, although the brass reinforcing tube does require to have some 10-15mm cut off the upper end so that it fits comfortably under the deck. The projection of the tube in July 1984 Papeete ite appearance. The roof, indicentally, is moulded in translucent blue plastic and if the windows are masked off when painting the end result is most satisfactory. The Keel “on reference to the instructions and parts list ensures that there is no difficulty. Having spent then a few minutes cleaning up and flatting off the hull, a wooden bulkhead is affixed behind the front wall of the cockpit, using Stablit Express (which would prove to be an ideal adhesive) and the flanged brass bush at the stern to take the rudder post. On my particular model this bush was found to be marginally too short but the problem was overcome by compressing the deck at the stern very slightly whilst the adhesive was setting. The most difficult part of this particular operation was ensuring that there was a good fillet of adhesive around the junction of the bush and the inside lower and upper parts of the hull to obtain a watertight joint. One does, in fact, need to be of extremely dainty proportions to work inside the hull — anda glance at the suggested installation of the radio equipment will endorse this — but The author’s method of installing the radio gear – the 7.2 volt winch pack (pencells) is next to the winch, and the receiver/ rudder servo pack is behind the receiver. Also note the aluminium plate carrying the pulley. Here the mast is shown at the centre of the rail – further trials have indicated that it should be as far back as possible. 393

buffer until painting was complete. This rubber buffer, although of fairly hard rubber, can be shaped quite easily by first trimming with a sharp knife and then rubbing with fairly coarse sandpaper. It is interesting to note that the lighter the pressure when using the sandpaper the more effective it is. I understand that the rules state that the ‘buffer’ must not exceed Yin. in thickness and therefore the offering in the kit needs to be sliced to suit. Mast, Booms and Rigging Attention was then directed to the mast, booms and rigging. Robbe offer quick link style attachments to the shroud rails and fore and aft eyebolts. I felt that whilst the quick link style attachments may work satisfactorily insofar as the fore and aft eyebolts were concerned, because of the angle of the shroud rails, tension would be likely to force open the quick links, notwithstanding the locking washers, with disastrous results. Consequently I purchased four shroud tensioners from Nylet who were most helpful in enlightening me generally on the intricacies of model yacht building and rigging. Thanks to the very clear instructions, the standing rigging can be set up fairly quickly and without any undue difficulty. Now, with a mast some 7ft. tall you obviously need a very high ceiling if you are to carry out assembly comfortably indoors. It did occur to me to carry out the erection of the mast on the landing, removing the loft hatch cover to give the extra few inches of height that was required. However, I did find that I could achieve this in the workshop by turning the stand which I had made (in accordance with the instructions) on its side and resting the hull, minus the ballast, on it. This gave me 2 or 3 in. of clearance at the top of the mast. Sails The Dacron sails supplied with the kit were what I came to know as a ‘high suit’ — | for calm weather. Bearing in mind that I Pirol laid flat by a gust – and that trough didn’t help but all hands were safe as Russell Potts was at the helm on this occasion. Sailing The instructions do not suggest any great difficulties should be encountered and that one should wait for a day with a light to moderate steady wind. According to the weather man on the day in question the wind was blowing 15 knots — gusting to 20! As directed, Pirol was placed in the water — and into wind. Would Pirol run out obliquely from the bank and pick up speed? — yes, she did. I sheeted in the sails a little and she picked up speed. So far, so good, until Pirol was heeling over at an angle of some 40 to 50 degrees — perhaps a little more. Also the bank was not far away. Therefore apply some rudder. By this time Pirol was heeling over even more and the rudder was acting very much like an elevator but Pirol did not climb — in fact, she did not do much at all apart from continue to head towards the bank. Now contrary to what I understand is the normal practice, I had arranged that the sails would sheet in if the stick was forward and out when the stick was_ back. Instinctively I ‘throttled back’. Pirol immediately righted herself and responded to the rudder — immediately — in fact, so immediately that she turned almost in her own length. A brief pause ‘in irons’ to think about things and then the sails were sheeted in and Pirol was on her way again, this time | expected to finish the boat during the winter / months — around Christmas as it so happens — I was not optimistic that there would be the balmy type of weather that one might (hopefully) expect on a summer’s evening and having regard to the fact that I on a different tack. Undoubtedly my experience of flying was, and indeed still am, a novice, I approached Nylet for their comments. They model aircraft has been helpful from the said that the high suit could well work point of view of orientation but nevertheless satisfactorily but I would no doubt in any Pirol has not so far proved difficult to sail. I event find that I required a‘working suit’ ifI am very much aware that her capabilities was to sail in all but the strongest winds and exceed mine as a skipper at the moment and in a fit of extravagance | ordered from them she has been sailed in moderate to strong a working suit. (These are available from winds now on more than a few occasions. Cougar Craft specifically for Pirol. — Ed.) When I get things right she seems These sails arrived promptly, were nicely remarkably manoeuvrable and will cream made and quickly installed with hardly any along quite rapidly. She has not yet been modification necessary to the existing rig, tried out against other boats. although the jib boom needed to be some 2in. longer than shown on the plan. Conclusions After a couple of sessions of rigging and To sum up then what are my conclusions de-rigging Pirol in the comfort of the workkit? First and foremost, all of the shop and the making of a sail bag on the about this items are of good quality — particularly the advice of amember of Danson MYC (whichI hull. The mast, of airfoil section with luffing have now joined) it was off to the pond for a groove, is reasonably rigid and attractively launching. I would explain that in my blue anodised. My limited experience has enthusiasm (or more correctly, impatience) me decide that a deck stepped mast, as to set sail I decided to go it alone rather than, made provided in this kit, is not as convenient nor, the in dictated, least at as conscience I think as efficient as a mast located company of someone who was well versed in through the deck and builders may do well the art of sailing model yachts. 394 to consider this modification. All nuts and bolts, etc., are supplied and are of brass. There are undoubtedly refinements which the experts would introduce and which would no doubt improve performance but Robbe obviously have in mind a kit for the average modeller, if not the absolute beginner. I would say that in my view anybody with only a moderate amount of experience of building models would not encounter any difficulties. No sophisticated tools are required although a drill press would undoubtedly come in useful in drilling the mast and booms, etc., to take the various fittings. The hull could, I suppose, be left unpainted — in my case] finished the model using car cellulose which adhered splendidly to the ‘Plura’ having, of course, given the hull three coats of ‘grey primer’. The ballast, thought by some to be somewhat light I am told, seems quite adequate and my Pirol, ready to sail, came out at just under 12lb. Whilst I am convinced that I did the right thing insofar as using my own ideas for the installation of the radio gear is concerned, Pirol has proved to be an extremely dry boat, notwithstanding my, on occasions, inexpert handling. Due to over confidence on my part, Pirol rammed the bank rather hard on one occasion and due to the pendulum effect of the ballast, the keel fractured very slightly at the trailing edge just below the bottom of the hull. This was easily repaired but for good measure I have added a length of 2mm brass rod let into the trailing edge of the keel which is secured (with Stablit Express throughout) inside the bottom of the hull as reinforcement. I am convinced, however, that this slight damage would not have occurred ifI had not been careless. Overall then I can say that I was well pleased with my Pirol kit and it has enhanced my enthusiasm for model yacht racing. What I need to do now, of course, is improve my skills to match Pirol’s abilities! Price at the thick end of £130 Pirol may be thought rather expensive. Possibly one could build a ‘Marblehead’ from scratch by buying the hull and other components separately more cheaply, but equally, for the novice, the saving might not warrant the inconvenience and possible dilemmas that might be encountered due to lack of experience and know-how. My Pirol has recently been rigged with a ‘groovy mast’ from Graham Bantock, (whole rigging drawings are a great help) to suit the ‘working’ sails, the original mast taking the ‘high suit’ supplied with the kit. Pirol is distributed in the United Kingdom by Cougar Craft. Model Boats

= ‘ Or: painting starts, everything needing painting should be ready, but so far we haven’t made a rudder. Two are shown on the plan, depending on whether the model is to be used for vane or radio. For fun sailing either rudder could be used in either mode, but experience has shown that for maximum performance (at least with the smaller classes) a skeg should be used for vane sailing and a spade rudder for radio. The skeg will be built permanently onto the hull, preferably jointed into a slot cut into the backbone and with a ‘finger’ extending up to the centre deck stringer. In order to achieve maximum efficiency from a skeg and rudder, as small a gap as possible must exist between the two surfaces. This is achieved by hanging the rudder on a stock, usually a length of brass tube of a diameter nearly the thickness of the rudder, rotating inside a second tube (the trunk) which passes through the hull (Fig. Brass block 1). The trunk is cut away where it emerges from the hull, leaving half the tube, which fits into a groove on the after edge of the skeg. Usually a bottom bearing is provided and attempts are made to keep this as friction-free as possible. A small bracket bearing a vertical needle-pointed pivot is screwed to the bottom of the skeg, the needle entering the rudder stock into which has been epoxied or silver soldered a stub of brass rod with a dimple for the needle tip SECTION OF LOWER PINTLE (Fig. 2). Sometimes a bronze or stainless bearing ball is driven into the tube in place of a dimpled rod, but in this case the base of The tubes are drilled and quite deeply countersunk for screws to hold them to the skeg and rudder, the heads of the screws then being filed smooth and flush. Solid timber is usually used for both skeg and rudder or each can be two laminations with the grain slightly angled to obviate any chance of warping. The thickness does not increased convex side is a turning force, with less turbulence than is created by a sharp angle in a thin set-up, or in other Se on —_—_ ae [a Cut away trunk el ae Rudder stock J Skeg AS Lower pintle 3 4 Fig. 1 July 1984 ib Rudder Buoyancy Fig. 5 iness of the rudder to appreciate how important this is in racing. For general fun sailing, where a response SECTION OF LOWER PINTLE Fig. 3 within two or three degrees is acceptable, there is no need to go to quite such extremes. A ¥,,in. rivet as a bottom pintle, in a ¥.in. id. rudder stock, would work reasonably well if the bottom of the stock was smootheda rotate easily on the skeg bracket. On to 4). (Fig. used is thick section tend yacht the weight of the tiller and stock will r small rudde n Buoyancy of the woode the g makin would partly offset the buoyancy of the to make it rise in the trunk, if the contacting corner of the lower bearing less effective and possiblyr rudder so that rudder was hard and polished there would n between the upper edgeo words the same turning effect may be produced at a slightly smaller angle of deflection but in any event with less drag ifa a \ Ball SSSss appear to be critical, since one school of thought believes in thin and flat and another in thick and streamlined. In the latter case the suggestion is that the hydrodynamic effect of a drop in pressure on the Sa V_s_{g_/’ { {ASFAaNaiasy stock centred (Fig. 3). ) the needle needs to be big enough to keep the creating a frictio corner of the rudder and the hull. A top bearing is therefore customary, to hold the rudder in correct vertical position, and this is usually a similar needle bearing to the bottom one, the needle being mounted ona single cantilever arm or in the centre of a bridge-piece (Figs. 5 and 6). be little friction. In such a case the upper bearing could be a small circle of brass or Formica drilled to clear the stock easily, then countersunk on the underside to forma circular knife-edge bearing plate screwed or glued on the deck (Fig. 7). Avoid oil or grease, which you might think would reduce friction; it goes sticky in water, particularly All this may seem a little elaborate, but things worse. the reason is that the force available from salt water, and makes A spade rudder usually uses a solid rod for the vane gear is small, particularly at small no support at the lower angles of deflection. A well-made vane is, its stock, since with are considerable. As forces ng bendi within to the nly end certai ive, sensit howeer, superess steel or in. stainl ‘4in. little mum, is mini there a and one degree of adjustment, but silver steel d, mende recom its is if rod brass point in using such a precise device r is removed periodicadvantages are to be dissipated by the use of can be used if the rudde ed. The buoyancy a rudder which is not equally sensitive. You ally and the stock ,polish , but the force course of exists a still n em betwee probl ence differ have only to see the is greater servo st weake the from stickble availa well set-up yacht and one witha slight 395

With either rudder completed, painting can proceed, with the rudder getting a coat Fig. 6 and a rub-down in step with the hull. The time has come to make a stand for the model. This is often a bit of a bind, diverting time and effort from the model itself, but it makes subsequent work and pondside operations very much easier and more convenient, as well as aiding storage. There are various possibilities, the easiest being a aaa: : : 8 small folding stool of the fabric seat variety, either with an aperture cut in the fabric to accept the fin or two webbing straps substituted for the fabric. An alternative is an open-topped box with upward extensions at the corners, straps being attached to the extensions; the box provides storage for smaller containers of spare rigging and fittings and, provided care is taken over keeping things dry, the transmitter, spare batteries, etc., in the case of radio models. A temporary stand can be made from a deepish card carton with appropriately shaped cut-outs in the top edges at the ends. Brass or Formice Fig. 7 than that from a vane gear and friction is not therefore quite so serious. However, the hydrodynamic forces on the rudder are higher than beginners realise and most conventional servos are unable to turn a flap rudder (one hinged at the leading edge) through much of an angle on, say a Marblehead or larger yacht, and if they can they are having to work very hard. Extra work means extra current drain which means less sailing between charges. This is the reason for using ‘balanced’ rudders, where instead of the whole rudder behind the pivot turning into the waterstream on one side, a proportion of its area ahead of its pivot moves to the opposite side. The resistance of this area balances some or most ofthe resistance of the rest, so that the force required to turn the rudder is reduced. Taken to extremes, if the resistance on each side was exactly equal, virtually no force would be needed to turn the pivot. Unfortunately it isn’t as simple as that, since the centre of pressure of the rudder moves as the angle it makes to the waterstream varies. It might be around 35% back from the fore edge at small angles and only 20% or even less at large angles. More than one builder has put his stock at 33% and found the rudder wrenched round, with the linkage slipped, over-centred or even bent, when he applied a lot of rudder to the boat when it was travelling at speed. The answer is to set the pivot line (the stock, or as it is now often called, the rudder shaft) at a position where no more than 25% of the area is ahead of it, which means that the servo has to exert a little more force at small rudder angles where the loads are light anyway, but the imbalance decreases with larger rudder angles so that the servo and/or linkage do not become overloaded. Using a moderately long tiller arm and matching servo arm will reduce the risk of over-centring; the servo arm normally has 45 degrees movement either side of neutral and it should not be necessary to use more than 30 degrees of rudder, though a little more can be useful to take the way off the boat while turning to avoid collision. Rudder construction can be two angled laminations of, say, /in. timber or a balsa or foam core with glassfibre skin or 0.8mm ply or thin melamine either side. Light but stiff is the object, but bearing in mind the forces which can affect it, adequate strength is 396 essential. Extending the rod right The development of this is a wooden box 25% “ini Deck Fig. 9 ES _ Foam or balsa Ply, resin etc. Fig. 10 through is likely to make it unnecessarily heavy, but it is normal to run it down to about one-third depth. Where possible the hole for the rod should be ‘built in’ rather than drilled after finishing the blade, as resulting in a more accurate alignment — you did fit the tube in the hull vertically? If epoxying the rod into the hole as a last stage, make a pinhole through the side into the bottom of the hole so that air can be expelled as the rod and epoxy are pushed in, or you will find that most of the epoxy remains outside due to air pressure in the hole. The section for a spade rudder should fall into the general ‘symmetrical airfoil’ category, with reasonably sharp fore and to aft edges and a centre thickness adequate accept the stock. The pivot line can be vertical to the waterline or angled to suit the angle of the run of the hull. No-one has yet demonstrated a particular advantage toa particular section or angle, as far as is known. (usually ply sides and ends with corner fillets) with the ends extended upwards and cut out for the hull. Or, if a box is not needed, vertical end-pieces can be securely fixed toa moderately heavy baseboard, with cut-outs at the top. The cut-outs can be traced from the relevant hull sections and an allowance made for some form of padding; split plastic or rubber tube hose, some forms of double glazing strip, draught-excluder strip, or even split tubular foam heat insulation for water pipes are all easily-obtained possibilities. They will probably need to be glued to the stand (even self-adhesive types) and ifa tendency for a wet hull to stick to the padding emerges, a wipe of wax polish on the contacting surfaces may be needed. Some form of location for the bottom of the fin is desirable in a yacht stand, to stop the hull slipping sideways, and this need be no more than a block of wood secured to the base either side, though fore and aft location can be useful. Some form of padding is again advisable, to prevent chipping or scratching of paintwork. Combined with a fairly substantial base, say lin. blockboard or similar, a vertical yacht will stand reasonably safely in a breeze, especially if head to wind, but one which is already leaning may blow over more easily. The only major step remaining, apart from making the mast and spars etc., is the lead, but before this can be tackled a tot-up of the weights is needed. When the design was considered a figure of 1000z. was thought to be a reasonable target, i.e. a shade over half the permitted weight for the class, two thirds of the weight of some existing R36Rs, and */,lb. heavier than the 30in. Panache design which had proved an entirely successful radio sailer despite its limited draught and beam. The hull as first drawn ‘fell out’ at a whisker over 960z. and the lines had evolved sweetly, so rather than seek the odd ounce or two it was decided to leave it; in design, when all clicks apart from a relatively unimportant variation from an arbitrary target, one doesn’t argue! If we allow 1Ib. for hull and fin and 1 |b. for rig and radio, which are quite achievable, plus say a spare ‘/,lb. for deck and paint, we need 3°/,lb. of lead. Built light and carefully, this could be as high as 4lb., orif things have come outa bit heavy, perhaps only3¥,lb.The radio weight assumes a lightweight winch such as a Whirlwind or at most a Talisman or Sanwa SCU; you cannot expect to stick a Model Boats

couple of pounds of radio equipment in this little boat. The best course is to weigh all the completed parts plus other items such as the mast and spar tubes (cut to length), i.e. everything possible, leaving a minimum to be guessed, and to subtract the total from 6lb. The balance is then what is a permissible maximum for the lead. Naturally, for vane operation the. radio weight is omitted but two or three ounces should be allowed for the vane gear; this could mean 4%4lb. of lead. It is not essential to cast a lead, if you don’t mind the slightly tedious job of cutting out the lead profile from sheet lead a dozen or so times. This is in fact partly why the lead is drawn with fair side area, the other reason being that if simple casting is undertaken all you have to do is cut the shape twice (one left, one right — it’s not quite symmetrical) from *%in. ply, tack the ply ‘holes’ on a dry backing board and simply pour two pools of lead. Those wanting maximum efficiency and prepared to make a two-piece mould could make an inverted kite section or torpedo lead of similar weight but lower centre of gravity, which would allow the yacht to carry larger sails. lead) is completely dry. When the ply outlines are nailed to the backing board (Fig. 13) it is worth pinning in Laminating the lead is really best done with new lead bought from a builder’s merchant and cut with scissors. Cut enough laminations to weigh slightly over the target weight, sand the mating surfaces, epoxy and leave clamped ina viceorundera board weighted with bricks for 24 hours. The extra few ounces of weight will leave a margin for cleaning up and filing the edges round, etc. It is simple enough with this method to cut the centre laminations to fit round the fin bottom; on completion a couple of small holes can be drilled through all the laminations and the fin and a pair of brass wires slid and epoxied in, for additional security, although if the lead surfaces are properly cleaned with glasspaper the epoxy will hold them quite adequately. two pieces of thin ply or timber, each half the thickness of the fin and shaped exactly to the fin profile. This will mean that when the castings are shaken out they will be recessed to fit on the fin and the rest of the inside faces will fit closely together. Otherwise it would be necessary to fill the gap between them with ply, in which case the fin profile might as well have been cut to include the lead area. If it is intended to register the yacht as a 36R youmay like to lay it on its deck, wedged so that the fin is vertical, and holda straight strip of wood llin. off the bench top by holding the strip against two rulers or marked lengths of wood, rather in the fashion of a set of goalposts. The ‘cross-bar’ should pass over the lead, just, and if it It may be possible to pick up sheet lead of greater thickness ata scrapyard, even if this is in the form of a pipe which needs sawing through on one side and flattening. A spot of enthusiastic sanding will remove grime etc. from the surfaces, down to clean metal and naturally if it is thicker fewer laminations doesn’t you will have to filea small amount 3/8″ply will need to be cut. Scrap lead is perfectly suitable (and somewhat less expensive) for casting purposes, if you don’t mind the smoke and smell when it is melted. An old metal bucket, or part of an oil drum, with holes punched in it, can be used for a brazier so that the entire job can be done out of doors. In fact a good barbecue fire will serve to melt lead, using an old ve YY “ July 1984 NN Fig. 13 to squeeze a hair’s breadth more draught, saucepan (preferably iron), though thickish but remember under the new rule the fin discussed fairly recently in this column, but is in any event not a complex matter in this instance provided everything (including the rubbing down now lie ahead, before we start aluminium can be used). Casting was WoSAILING WHERE ARE YOU 70 TEST (GareSTUrMOD EL! MY LATE Backing board must touch the bottom of the box. Several coats of paint and plenty of on the fittings next time. 5 HELLO MALCOLM! OFF 70? off the bottom of the lead. In fact, since the hull can be tilted in the 36 x 9x 1lin. box and this boat is well under the 9in. beam dimension, seekers after the last micron might like to draw the 9 x llin. rectangle on tracing paper and twist it about over a drawing of the mid-section and fin. It might be possible +4. 70, hay:eeninke CLEANING A Y ? WHAT WH YOU GOING TO FEST ?