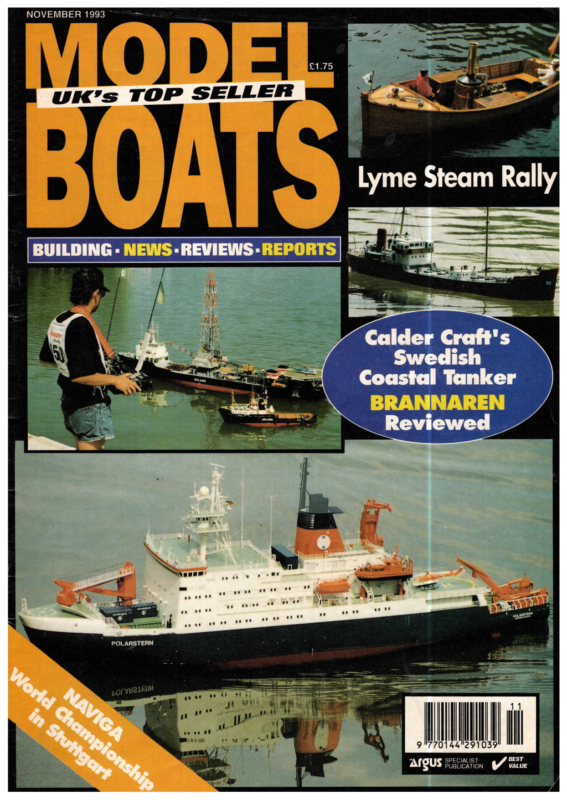

UK’s TOP SELLER _€¢ a = ~Qem Calder Cresft’s _ Swedish Coastal Tanker BRANNAREN Reviewed

Exclusive Full-size Superplan for a competitive R/C One Metre yacht by a top designer and manufacturer which won the National Championship in 1990 SUPERPLAN PROJECT Robert Vice poses with his model of Rhythm, built Jrom the Superplan. Au photos: Ray Brigden. Owing to the large size of Introduction this model in Making a start in R/C model yachting can be a daunting experience. There are so many decisions to make; size/class of model, kit or scratchbuild, new or secondhand, model shop or mail order, relation to the maximum allowable etc. published size Undoubtedly, the best piece of advice is, find your nearest local club and pay a visit. They can show you what’s available, where to get it from, and most important, the classes they are operating. There isn’t much point to making a race-winning ‘XXX’ class boat if they only sail ‘YYY craft! To seek out the club, try the local library if you are of our Superplan format, this month, the Superplan contains one aware of a sailing group in your area, otherwise a call or letter to any of the model boating magazines will bring the necessary info. Telephone the Secretary and go along to their next meeting. If there is no local club, but two or three of you gather together to sail, then contact the MYA Information half of the main yacht drawing plus the Sail Drawing. The Officer (address at end) for more other half of information. There are a large number of classes, currently seven ‘major’ and about the same number of ‘minor’ categories. It is generally considered that the newcomer the yacht was published on another Superplan last month, and on the reverse was the Rig Drawing. 32 GRAHAM BANTOCK’S Rhythm should make a start with a 36in Restricted or a One Metre. The physical size and relative simplicity of the latter, plus the fact that it’s spars must be of aluminium ally or wood, rather than exotic materials, means that a competitive yacht can be scratchbuilt from wood construction and not be outclassed the moment it hits the water; MODEL BOATS NOVEMBER 1993

if built and rigged well, it may be expected to remain competitive for some years to come. Maximum and minimum figures are set for draught and fin/ballast weight and there is a minimum total displacement. No more than two channels of control are permitted and exotic materials are prohibited from the hull construction. The construction requires no building jig; planking is not involved and hard chine construction is relatively straightforward, and the materials are commonly available at model shops. Background to Rhythm Sails Etc., of which Graham Bantock is the owner, initially produced the Rhythm kit in the late 80’s as a five panel hard chine design hull. No building jig was required to construct the kit as panels were supplied to shape. Rhythm won the first One Metre National Championship in 1990, and continued its success over the years at open and club events around the country, including a hotly contested MYA Ranking Regatta. The kit was withdrawn from sale last year and replaced by Jazz which features a grp moulded hull. Sails Etc. have now decided to release the Rhythm plans with the aim of maximising the potential boost to the number of One Metres and model yacht club members. What better way than by reaching 20000 readers through our pages! So if you have always wanted to get into R/C model yachting without spending a fortune on exotic materials, here is the golden opportunity. Why not take it now? For further information concerning the Model Yachting Association, write with an sae to the Information Officer, 115 Mayfield Avenue, London N12 9HY. This month, ROBERT VICE completes his build of Rhythm from the Superplan, and Graham Bantock provides instructions for the Sail Drawing Fittings From this point on the fitting out of the hull will depend on your fittings, I will describe how.and what I fitted, but you can do things cheaper using alternative items. T fitted a Bekabe ball-raced pulley block at the aft end of the winching loop. This is an expensive item at around £6, but the plan assumes that you will use this item. I must add that for your £6 you do get a superb reduced friction fitting. Seal with sealant and screw into place, bend the sheet guide eye from wire and push into holes. Do not bond this eye in place as the deck patch will go over the holes. Install the winch according to the MODEL BOATS NOVEMBER 1993 supplier’s instructions and servo and run the wires into the pot round the back of the fin box. At the forward end of the winching loop I used a through deck sheet lead. By simply drilling a hole for the sheet lead, and with a slight adjustment the returning sheet is fed correctly onto the winch drum. Alternatively make your own fitting from a piece of small diameter brass tube. The aerial on my yacht is fed into a thin PVC tube in the pot which emerges at the transom through a 4mm hole. Knot the end of the aerial to keep it taut and seal the pot hole with Blu-Tack (a Bostik product). The push/pull servo/tiller arm connecting rod was made from a length of 4.8mm diameter alloy tube with a servo connector at on end and a piece of bent wire bonded and cramped in place at the aft end. This then connects with my tiller arm. The fixings used will obviously vary from one item to another. Adjust the geometry of the servo horn, connecting rod and tiller arm to give 60 degrees – yes 60 degrees!! – movement each side of centre. Tighten the fixing bolt. A PTFE ring was used for the mainsheet fairlead suspended on three adjustable dacron cord lanyards from deck eyes J3 & J4. Adjust the winch (see maker’s instructions) to give sheet travel of 270mm. Then fit the dacron cord sheet to the lower part of the drum, bring it aft and through the pulley onto the deck. forward and down the tube and back onto the upper part of the drum. The system I used was a continuous loop of dacron cord with an elastic band to tension the loop. However the second half of this continuous sheet, that returning to the drum, could be made from fishing elastic (available from all good fishing tackle stores). A moulded bumper is available from Sails Etc. This item has to be made from elastomeric material to conform to [YRU Class rules. It may require trimming, if so do it with a sharp cutting knife and glue into place with either the silicone caulking compound. Trim the mast tube to length and fix in place using silicone sealant (not glue) complete track to the hull. Also avoid Fablon and Contact, etc., as they become brittle with age and cold. Most yachts sinking these days use this type of deck patch materials! Warm set adhesive materials are the most suitable although more costly. If there is one thing that people forget to give a new yacht, it is a drain hole, so drill a hole in the bow to avoid this shortcoming. Bungs are available from most of the normal outlets. The hull is now ready for rigging, and that is whole different ball game. (See accompanying article. Ed.) Sailing The boat hit the water for the first time at a club meeting before it was fully completed, but I was too impatient. The wind was a strong 2nd suit. This might not have been the ideal wind for a launching, however the Rhythm showed a clean pair of heels to all the others there. Despite suffering from a tendency to nose dive, she remained stable under heavy gusts and always popped up after the gust had passed. This proved the wire loops in the deck to be plenty strong enough for the job as indeed were all the fittings. The boat did have a leak but I put that down to not being fully finished. Before the next race she had to be measured and registered so a trip to my friendly measurer was called for. This didn’t throw up any problems and this is proof enough of the accuracy of the plan. Two weeks later she was out again for her first real competition; the wind this time was totally different, a very light top suit. Again, Maroon-ed as she is now known (due to her colour), held her own. When my other yachts were standing still she never stopped dead in the water. These are said to be Rhythm’s worst conditions due to being a chine design, but still ended the day with a 3rd position. Since then I have sailed in three more races all in top suit, and as yet I have not been disappointed with her performance. Now I have the worst choice of all; which boat do I use in the Nationals this year? In Conclusion to make a watertight tube for the mast. Cut the deck track to length and drill 2.5mm diameter holes where shown on the plan for the retaining screws. Drill the deck to match. Abrade the underside of the deck around the holes for the track screws and, after waxing or greasing the screws, assemble the track to the deck. Mix a small amount of resin and stiffen into a paste and apply around the nuts under the deck. Allow to cure and remove the screws and track. Thus when the track is removed the fixing I think that the tone of this review shows that I have been very impressed with the design, that was never in question. The plan is done to the highest of standards as all of Graham’s plans are. I had no problems in building the boat, and she went together very quickly. The keel position shown allows the yacht to float smack on the design water-line, and the mast position gives very good performance on all points of sailing. WhenI build a boat I like to get results it easy to re-fit the track. Self adhesive deck patches are the most commonly used method of covering the deck cut outs. One piece of advice from me would be to replace these patches each time they are removed, rather than re-stick them as you don’t want them to let you down! Fit three 6mm eyebolts and the track slide and eyebolt to the track and attach the very quickly get a hull and within a week or so, you can have a completed boat minus rigs. The design is very fast but a little tender when hard pressed, however it remains stable under most conditions. When it boils down to it, it is the person on the sticks that makes any boat win, and the Rhythm will certainly win more races in the future. nuts are located below the deck making quickly. With this building method you 33

And now, the sail drawing lines. 1.3. Cut out the sail profiles carefully with scissors or a cutting knife and metal straight edge. Lay-Out of Sail Profiles on he drawing shows the sizes and construction for the three permitted IYRU One Metre class suits of sails. They are suitable for use on the Rhythm and any other IYRU One Metre class yacht. Introduction Although high quality sails will never make a basically slow yacht into a winner, it is true that poor sails will prevent an otherwise perfectly good yacht from achieving its true potential. Many builders of the Rhythm will want to purchase ready made sails from one of the various model yacht sailmakers. Some will do this because they want to save time and trouble and some will do so because they have heard that sailmaking is regarded as a black art and there is no chance of them being able to replicate the experienced sailmakers’ products. However they should be aware that very well shaped sails can be achieved by people with no previous experience and using commonly available materials. The instructions below will take you through the steps necessary to produce well shaped sails each made from a single piece of cloth. If made carefully they will be at least as good as ‘average’ panelled sails and will certainly not hold back the performance you obtain from your Rhythm (or any other One Metre) until you achieve a high level of sailing skill. Instructions The instructions assume that all three suits will be made at the same time. The plan is in four main sections: Sail Profile Offsets – plotting the sail profiles onto paper; Lay-Out of Sail Profiles on Cloth – transferring the sail profiles to sailcloth and cutting; Sail Reinforcement – adding the reinforcement tapes, battens and eyelets; Size and Position of Sail Numbers, National Letters and Class Insignia – adding the identification marks to comply with the class rules. Sail Profile Offsets – plotting the sail profiles onto paper The sail profiles are described by giving the position of five points for the jibs and fourteen points for the mainsails relative to two base lines drawn at right angles to each other. The x and y base lines and the points on the sail profiles are given in diagram 1. The tables give the position of the various points in the same way that a map reference indicates precisely one single position on a map. Thus point J4 of the No 1 jib is 688mm from the y base line and 199.5mm from the x base line. Point M2 of the No 1 main is 404mm from the y base line and 10mm from the x base line. 1.1. Plot all the points for each sail onto a piece of plain paper (lining paper is a good inexpensive source). 1.2. Join the adjacent points with straight 34 Cloth -transferring the sail profiles to sailcloth and cutting 2.1. Use the patterns to mark out the sailcloth economically. One lay-out is shown. You will need to purchase circa 2 linear metres of standard width (914mm/36in) sailcloth if all the sails are to be made from one piece. 2.2. The No 1 suit would normally be made from 2.2 oz (100 g/sq. m) cloth, the No 2 from 3.00z (140 g/sq. m) and the No 3 from 3.5 oz (140-160g/sq. m). 3.0 oz cloth is an acceptable compromise for all three suits. Many sails are now made from drafting film sold by drawing office supply shops. The major problem with this material is that, when sold in roll form, it has an in-built curvature, caused by being rolled, which adversely affects the shape of the sails. The best way to buy this material is in sheet form when it is generally flatter. Unfortunately sheets large enough to cut One Metre sails in one piece are not commonly available. This solution is really only viable for panelled sails which are beyond the scope of these instructions. 2.3. Position the sail profiles so that the leech (trailing edge) of each sail is parallel to the long edge of the cloth (warp). Small deviations will adversely affect sail life and performance. 2.4. Mark the profile using the same points plotted onto the paper patterns. 2.5. Make a hot knife cutter by sharpening the tip of an electric soldering iron (25 to 75 watt) to a blade. Use it to cut out the sails using the metal straight edge, held down firmly, as a guide. Always cut on the waste side of the line and use the plywood or hardboard as a cutting surface. 2.6. Alternatively use a very sharp cutting knife to cut the cloth and rely on the reinforcement tape to reduce the inevitable fraying of the cut edges. Sail Reinforcement – adding the reinforcement tapes, battens and eyelets 3.1. Cut some small pieces of scrap cloth to make the 2nd and 3rd layers of sailcloth and glue (Bostik Clear) to the head (top corner) of each sail. 3.2. Add the reinforcement tapes to the luff (leading edge) and foot (bottom edge) of each sail. Use 12mm wide Scotch 3M Magic Tape sold in 33metre rolls by good office supply shops, or purchase self adhesive sailcloth tape from Sails etc for this purpose. If using Magic Tape it should be applied to both sides of the luff. 3.3. Tape each sail to a smooth flat surface by the head and clew (lower aft corner) so that the leech (trailing edge) is stretched quite tight. Now apply the 1 2mm Magic Tape with as little tension as possible along this edge too. If the sail is not stretched enough before applying the tape wrinkles will MODEL BOATS NOVEMBER 1993

appear along the leech and the shape will not be improved. If you can’t apply the tape without getting these wrinkles in the sail then omit this step. 3.4. Add the corner reinforcements by applying 1 2mm Magic Tape (if using self adhesive sailcloth tape less additional pieces are required) to eachside of the sail in a radial pattern. Take care not to exceed the 120mm radius (rules permit a maximum radius of 125mm). 3.5. Make battens by cutting 1 mm plywood into 6mm strips and coat with epoxy resin to stiffen. Alternatively use Plasticard or purchase the carbon/epoxy sheet sold for the purpose by Sails etc. Tape to the sail with 19mm Magic Tape (12mm will do at a pinch). Note the position of the battens. The mainsail battens are positioned exactly at the cusps of the leech profile and the jib battens are placed to divide the leech (accurately so that the class rules are complied with). 3.6. The jib luff is best finished by taping small brass ferrules (available from fishing tackle suppliers, or small crimps from Sails etc) to the luff at regular Size and Position of Sail Numbers, National Letters and Class Insignia – adding the Identification Marks to comply with the Class Rules 4.1. When you start racing, even at club level, you will need to be able to identify your yacht by adding the registration number (allocated by the MYA when you have registered the yacht) to the sails. The size and position of the jib numbers, national letters ((GBR’ for the UK) and class insignia are all tightly controlled by the class rules. The basics are given here but if you purchase your numbers, letters and insignia and follow the notes on the plan you will almost certainly get it spot on. 4,2. If you want to cut your own identification marks ensure you study the class rules carefully first. intervals (10 or 12 are required). Alternatively pierce the luff at similar intervals and tie the luff to the forestay wire as shown on the Argus Lo Tech One Metre Rigging Plan. 3.7. Usé the point of the soldering iron to make suitable sized holes in the luff of the mainsails and the corners of all sails for the eyelets. Dressmakers’ suppliers sell eyelets and punches suitable for, the corners (look for real brass rather than rust resistant ones). Suitable eyelets for both applications are available from Sails etc. Suppliers | Kits, Hulls, Fittings, Sails, etc Sails Etc, 141 High Street, Kelvedon, Essex CO5 9AA. Tel: 0376 571437. Tony Abel, Highnoon, Petersfinger Road, Salisbury, SP5 3BY. Tel: 0722 Beant, Swan Models, The Bungalow, New Barn Park, Swanley, Kent, BR8 7PW. Tel: 0322 666363. Housemartin Sails, 51 Edinburgh Drive, Birkenhead, Merseyside, LAS Materials Required To complete the sails you will need the following materials: Qty 2metres 1 Item Description _ Dacron sailcloth, 3.0 oz is suitable for all suits 1 1 1 1 1 33 metre roll, 12mm wide Scotch 3M Magic Tape or 15 metres 1 2mm wide self adhesive sailcloth tape 33 metre roll, 19mm wide Scotch 3M Magic Tape ORJ. Tel: 051 608 8252. Mac Fit, 1 Lakeside Court, New MY . * tube Bostik Clear contact adhesive batten material, 1 mm ply or Plasticard or carbon/epoxy sheet for battens pack medium eyelets and punch pack small eyelets and punch pack small ferrules * * * 4HS Brighton, Wirral, 145INS, Tel: 051 639 7106. i Cast Lead Bulbs . — Ken Butler, 10 Leaholme Gardens, Stourbridge, West Midlands, DY9 « – | + Fe ‘windWinches,49 Aberdale ] Road,Leicester, LE2 6GE.Tel: 0533