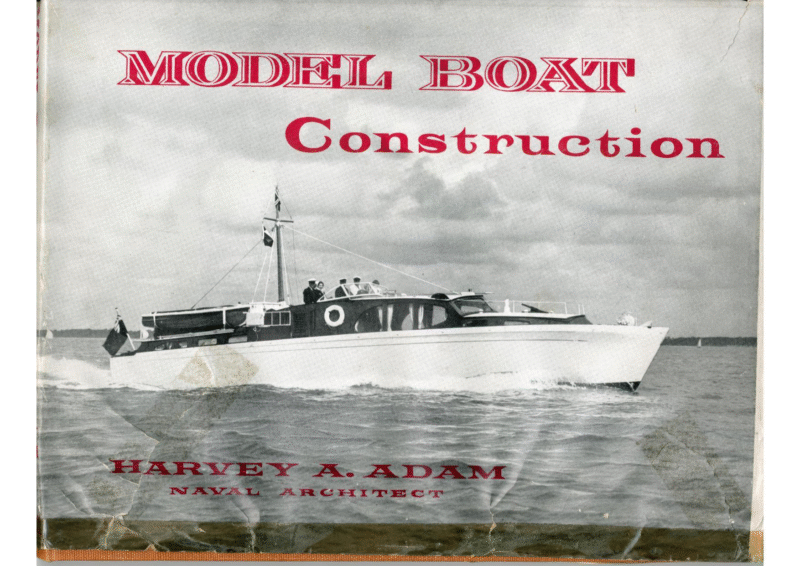

This book is primarily intended as an aid for the newcomer to model boat building. In taking the stage by stage construction of a typical model power boat, from the drawing board to completion, the book intends to present the fundamental principals of model boat building so that the novice will have no difficulty in constructing any of the models which have been dealt with in detail in the latter part. It is also presented to the experienced modeller as a reference book and as a summary of the author’s own model boat building experience during the last 25 years, and while some of the methods described are not new, their adoption has been the result ofa constant striving for simplicity and ease in the construction of working scale model boats.

- Chapter One: General Discussion

- Chapter Two: Choice of Materials

- Chapter Three: Metal Fittings

- Chapter Four: Engine Bearers, Exhaust Systems, Fuel Tanks, Couplings

- Chapter Five: Propellers, “P” Brackets, Rudders, Simple Steering Device

- Chapter Six: Scales, Drawing Instruments, Transfer of Drawings, Power Units, Construction of a Typical Model Motor Cruiser

- Chapter Seven: Painting and Finishing Model Boats

- Chapter Eight: A 16-in Sharpie

- Chapter Nine: An 18-in Clinker-Built Dinghy

- Chapter Ten: A 20-in Ventnor-Type Hydroplane

- Chapter Eleven: A 30-in Cabin Cruiser and 30′ Runabout

- Chapter Twelve: 71-ft 6-in British Power Boat M.T.B. and 80-ft Elco P.T. Boat

- Chapter Thirteen: Navigation and Sailing of Model Boats