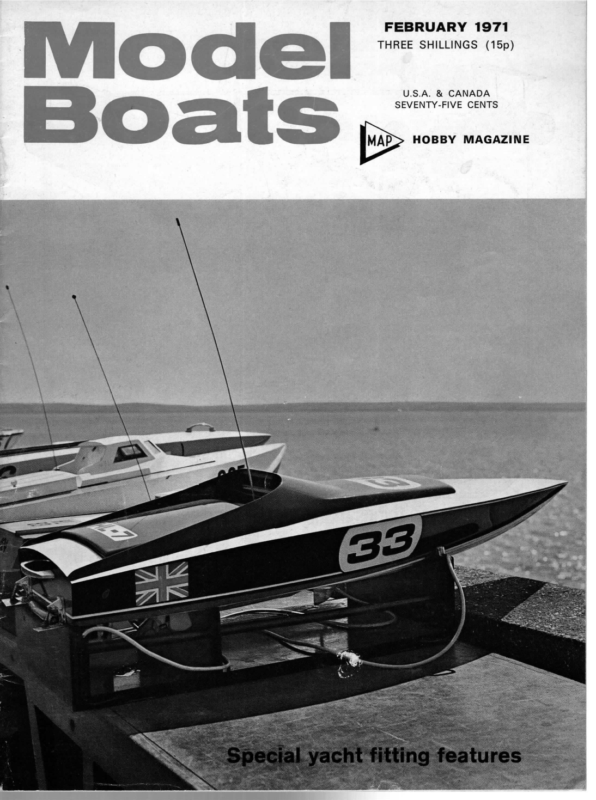

FEBRUARY 1971 THREE SHILLINGS U.S.A. (15p) & CANADA SEVENTY-FIVE CENTS HOBBY MAGAZINE

FESS UABY 1377 the Tideway to their fancies. By the way, only Bic pens may be used, plus a limited number of accessories to be specified. £ he words are written amid the hectic early hours of the 40th Model Engineer Exhibition. As we mentioned last month, marine entries were high, with more miniatures and period ships, and having now seen the entries, we can say that the standard is also high. A full report and results must await our next issue, alas; in the meantime, we shall be photographing and making notes on some of the outstanding models for the interest of readers unable Ship modellers pop up all over the place, and are of every race and creed. This model of the P. & O. cargo liner Strathardle was built by one of the ship’s Leading Maintenance Hands, 53 year old Wong Wing from Kowloon. Construction is basically papier maché and building was spread over a year. The ship is one of the P. & O. fleet of ten cargo liners which operate three regular freight services between Europe and the Far East. Off-shore to reach the Exhibition. We are asked to mention that St. Austell club will be running an off-shore event on May Ist and 2nd. at Charlestown, Cornwall; full details will be appearing next month. Novel Competition One-Design Yacht An unusual competition which will intrigue many of our ingenious readers is announced by the Biro/ Bic company. The idea is to encourage creativity in what would otherwise be discarded items, viz. used Bic pens. Eligible pens are the two types of ‘stick’ pen, the fine point, yellow-barrelled or the medium point, transparent-barrelled. Any part or parts of the pens may be used, and any number can be built into a model. There will be two categories, Senior and Junior, the latter for under 16-year-olds. Heat moulding will be allowed in the Senior class, but not in the Junior. Prizes of £25, £15 and £10, plus consolation prizes, will be awarded at three-monthly intervals, and prizewinners will be eligible for the National Championship, judged at the end of the year and bringing the prize-money up to £250 plus a Championship Trophy. Full details will appear in March issues of our journals, but we thought that early notification was useful, as you can start collecting discarded Bic pens. One pen is sold each year for every man, woman and child in the U.K., plus several million more, so there are a lot of pens to be found. Perhaps you know someone in a large office who would help collect; you may make a model from only nine or ten pens, but if two models tie for a prize, that containing the greater number of pens will have the advantage. Early experiments indicate quite a range of possi- bilities, and we hope to show pictures of some editorial staff efforts, as well as future winners, to inspire other builders. We are sure that many readers will find this competition a challenge that will appeal An ‘unofficial rumour’ is going round to the effect that the M.Y.A. is considering the introduction of a one-design yacht class, probably around Marblehead size, from which it seems logical to assume that glass fibre hulls would be available. This is a splendid idea which would give yachting a considerable boost. If everyone is sailing the same design, results would clearly be dependent on care in fitting out and skill in sailing, plus, no doubt, the usual small element of luck. Is it too much to hope that any such design will incorporate the one feature sought by so many would-be model yachtsmen-— grace ? This basically means overhangs, surely not a rating problem with a standard hull. An immediately obvious additional advantage of such a model would be its appeal as a one-design radio model; indeed, this could prove the answer to the pressure for a practical R/C yacht class smaller than the Q. We rarely report rumours unless the grounds for them are strong, but in this case, if this is a proposition being considered, we feel it important to stress the necessity of yacht-like appearance and suitability for R/C use, as these two factors would do more than any other towards wide acceptance and an infusion of new M.Y.A. members. Incidentally, in the U.S.A. a new national R/C yacht association has been formed by enthusiasts who felt that the established M.Y.R.A.A. was not taking notice of R/C yachtsmen. It would be a pity to see such splintering off become widespread when modellers with a common interest benefit by mutual co-operation. Se eo Gl Mit WT in sail could eV Heading Picture

FEBRUARY 1971 Racing Model ~ TOP MAST SPREADER BAR Yacht Construction WING MAST SPREADER BAR hee \-_—————_———— BACK STAY Part Nine — fittings a \ +} \ \ is By C. R. Griffin ——— BEATING SHROUDS \ \ pe \ JIBSTAY MAIN SHROUDS ‘ \ ys this and ensuing articles, when describing the \ construction of various fittings it must be under- stood that, where metal surfaces have to be soldered, silver soldering is the only acceptable process. Plumbers’ or tinman’s solders are too soft for this category of work. Silver soldering using a 7 pencil FIG. sufficiently keyed (deep scratches are needed), how- To date, experience with model racing yachts has shown that the most practical and efficient rig is the Bermuda sloop. This is the simplest rig possible, as it consists of a triangular (Bermudian) mainsail and a see Fig. 60. It is generally accepted that a tall rig has greater driving force to windward but, due to the higher centre of gravity, the stability is adversely affected in strong winds. By lowering the height of the sailplan but maintaining the surface area of the sails, the same hull can be sailed at its designed angle of heel in high winds. Therefore, in competitive sailing, it is necessary to have more than one suit of sails, usually two suits of maximum sail area but with different aspect ratios, and one suit of a lesser sail area. Sail aspect refers to the ratio of the height to the foot of the mainsail, e.g. 78 in. height 12 in. foot is 6.5:1 and is classed as a high aspect ratio, 62 in. height 16 in. foot is 4:1 ratio or low aspect. \» 60 RIGGING FOR A RACING YACHT The designer of a model yacht can only give the approximate position of the mast and rig on the hull. This position is adequate in the constructional stage, but to enable the yacht to be tuned to give her best performance it is essential that the fore-and-aft position as well as the rake of the mast be adjustable. This adjustment is accomplished by a mast slide at deck level and a mast heel on the backbone within the hull. Alternatively a deck-mounted mast heel can serve both purposes, Fig. 62A. This need to alter the sailplan and to maintain as rigid a mast as possible has a direct bearing on the type of mast to be fitted and the matter of rigging. There is the constant conflict between the slender mast with complicated rigging and the stouter mast with little rigging. Too much rigging can cause excessive windage whilst too thick a mast can disturb the flow of air over the mainsail. The weight of the mast is also of importance, especially when high aspect sails are used. By reason of the high position of the centre of gravity of the mast above the waterline, any saving in the weight of the mast means that approx- The Mast Heel and Step This consists of an offset stainless steel peg, about 4 in. diameter, screwed into a Tufnol or aluminium ‘button’ which locates into holes in a brass or Tufnol plate. The plate or mast is fitted either inside the hull on the backbone or on the deck, see Fig. 61. This type of fitting has an advantage in that the mast can 61 ; . em ~ imately four times that weight can be added to the keel. Today there seems to be little doubt that aluminium alloy tubing is the first choice in material for the mast. Provided that the tubing is of an adequate diameter to prevent bending, the thickness can be as low as 22 gauge to save weight. It is a matter of personal opinion whether an adjustable single mast and main boom is fitted or whether each mainsail has its own mast and boom; each method has its devotees. There are, however, features that are common to both, i.e. each mast requires a jib stay, a back stay, a pair of shrouds, a mast heel fitting and a gooseneck for the main boom. Personal preference, and in some instances the size of the yacht, can require the addition of a mast-top forestay and beating shrouds. ever, it can be joined by the use of low temperature brazing rod such as ‘Eutectic’. (jib), Vata —— MAST HEEL is applied at the proper point. ‘Easiflo’ flux can be obtained in paste form and this does assist in making a strong, clean joint. Brass to brass joints should present no difficulties; bronzes require greater heat to enable the solder to run and fuse. Stainless steel can be troublesome, especially if the surfaces are not headsail 4 ae \ coco flame blowlamp, particularly one of the butane type, is reasonably simple. It is only necessary to ensure that the metal surfaces are clean and adequately ‘keyed’, that the correct flux is used and that heat single \ TT

MODEL BOATS WOOD OR TUFNOL FERRULE ALUMINIUM OR TUFNOL BUTTON 10G STAINLESS STEEL RIVET V/8 O.D. STAINLESS STEEL —— PEG At yi eal fcc: ee ee ee ee | 0.07040; 0 0 0 8) ? 3/8″ Ed 1 (e ©. ft « MAST STEP IN MAST STEP BRASS OR TUFNOL IN BRASS vw @ IOIMICILILILIL ri HOLES 9/64″ DIA, FIG. 6|_ 3/8″ BETWEEN CENTRES & HOLE” “PEG FIG, MAST HEEL & STEP & SLOT” MAST HEEL & STEP 62 “NOTCH COUNTERSUNK HOLES 16G.S.S. PIN 18G BRASS OR FIG. 62A 20G STAINLESS STEEL DECK MOUNTED MAST HEEL 20G. STAINLESS STEEL /e” DIA, HOLES DECK PLATE COLLAR TO BE CLEARANCE FIG. 63 MAST SLIDE FIT ON MAST SLIDE be rotated through a few degrees either side of centre deck plate without being slack. The slide is approximately 1 in. longer than the deck plate with a hole through the centre over which is silver soldered a ferrule or short tube to form the mast collar. The collar should not be a close fit on the mast but should have enough clearance to prevent scraping the mast and to allow for any rake (usually no greater than 3 deg.). The slide has a series of 1/16 in. dia. holes drilled at + in. intervals on either side of the mast collar to coincide with a locating pin hole drilled in the bent-over edges of the deck plate. To provide a fine adjustment, the holes in the slide are offset to each other. Four countersunk holes to accept } in. x No. 1 brass screws provide the means for securing the deck plate. As an alternative to the use of brass or stainless to assist the flow of the mainsail. Alternatively the mast heel may be in the form of a slot or notch to fit over a slotted mast step, see Fig. 62. A metal rivet fitted from side to side prevents movement. ie The Mast Slide 2 1/4″ MAHOGANY The traditional mast slide as shown in Fig. 63 consists of a deck plate which is screwed to the deck. The mast hole is wide enough to clear the mast and is about 23 in. to 3 in. in length to allow movement of the mast in a fore-and-aft direction. The edges of the plate are bent over to form recesses for the slide. It is advantageous to bend the edges of the deck plate over a piece of metal of a slightly thicker gauge than the slide. This allows the slide to move freely in the 1/8″ THICK TUFNOL (tp [ 7 UPHAUL MAINSAIL HOIST 24 GAUGE STAINLESS — STEEL WIRE “SWISH” NYLON CURTAIN RAIL JIB HOIST —–4 /lé” THICK TUFNOL \ 8BA CHEESEHEADED FIG, 64 MAST SLIDE IN PLASTIC SCREWS ark tyan “2 r) FIG. 65 MARKING OFF THE MAST FIG. 66 JACK LINE DETAILS. \ ~-F— WORKING HEIGHT HOLE TO SUIT DIA, FIG, 68 PUNCH & JIG OP MAST P-P— DECK LEVEL MINIATURE BOTTLE SCREW 62

FEBRUARY 1971 66. Another method of fitting the jack-line is to thread it through a series of 5/64 in. holes drilled in the mast, see Fig. 67. The task of threading will be made easier if the holes are drilled at approximately steel sheet tor the mast slide, the fitting may be constructed using various plastics, see Fig. 64. ‘Swish’ nylon curtain rail provides the side pieces by cutting as indicated in the inset. The deck plate and slide are 30 deg. to the mast as indicated in the diagram. The lower end is fixed by an 18 gauge stainless steel wire cut from 1/16 in. and } in. Tufnol or Paxolin re- spectively, whilst the mast collar is cut from 4 in. Tufnol and is epoxied and riveted into position on the mast slide. hook whilst the upper end is turned back on itself and ‘tied off’. A third method of running a jack-line is to make a series of indentations at intervals up the mast. This is accomplished by using a round-nosed rectangular punch, 14 in. long and } in. wide. The The Mast The sizes of aluminium alloy tubing that are most commonly used for the various classes of yachts are 36R — 4 in. dia.; Marblehead — + in. or 2 in. dia.; 10R —% in. or } dia.; A— jin. or 1 in. dia. Cut the tubing to the required length, i.e. height of mainsail plus werking height plus mainsail uphaul allowance plus underdeck allowance. The latter amount is not required if a deck-mounted mast is mast is held in a split clamp, see Fig. 68, and the punch is driven through the locating slot. Holes } in. dia. or small saw cuts made before punching help to form the indentations. Thread the jack-line wire up the inside of the mast through the slots formed by the punching. Secure the lower end by a soldered ‘knot’ and the upper end by an 18 gauge S.S. hook, envisaged. Fit the mast heel, then put the mast in the see Fig. 69. MAINSAIL UPHAUL 24 G. STAINLESS STEEL = WIRE e} FIG. 70 —— ° 20G. BRASS OR oT 22G. STAINLESS STEEL EYE FOR MAIN SHROUDS on 5/64″ DIA. HOLES JIBSTAY ALLOW CLEARANCE FIG. 69 FOR JIBSTAY AND SPINNAKER —~_ HOOKS a RECESSED JACK LINE SECTION THROUGH A Al = — 24G STAINLESS STEEL WIRE _ = 8BA BOLT O— SOLDERED “KNOT” \ POP RIVETS FIG, Z70A | 18 G. $5.8. HOOK MAIN MAST BAND Should it be the intention to use double luff sails there is no need to fit a jack-line. slide, locating the mast heel on to the mast step. Mark the mast to indicate deck level and remove from the hull. Measure from the deck level the working height of the main boom, usually 4 in. to 5 in. Mark a distance equal to the hoist height of the mainsail, i.e. working height plus height of mainsail. Main Mast Band The purpose of the main mast band is to provide a means of securing the main shrouds (and beating shrouds, if fitted) and the jib stay to the mast. Some variations of this fitting are shown in Figs. 70 and 70A. In the former type the band is clamped to the mast by one or two 8 B.A. screws; however, care must be taken when making the fitting to ensure a tight clamping action. If this is not done the band may slip down the mast under the tension of the shrouds. Pop-riveting or a tapped screw helps to overcome this problem. Add a further 1} in. to 2 in. to allow for the uphaul of the mainsail, cut off any excess. Mark the hoist height of the jib above the deck level, see Fig. 65. At this point consideration must be given to the type of mainsail and its rigging. If traditional ‘hooked’ luff sails are to be used then a jack-line has to be fitted up the after side of the mast. Check that the hooks on the luff of the mainsail are evenly spaced Top Mast Spreader Bar This fitting enables the back stay to clear the mainsail without being so far aft as to restrict the move- and mark off their approximate position on the mast when the foot of the mainsail is about + in. above the working height mark. Run the jack-line, 24 gauge stainless steel wire, through the slots of 8 B.A. ment of the vane gear. When the yacht is running before the wind the vane gear or the vane feather carriage is streamed into the wind, i.e. turned through 180 deg. so that the feather is towards the bow of the yacht. If the back stay is placed too far aft, the cheeseheaded brass screws which have been tapped into the mast. Pinch the heads of the screws to nip the wire and hold it in position. Tension the jack-line by using a miniature bottlescrew or turnbuckle, see Fig. feather of the vane gear will be fouled. 63 MS pea) sol

I – 16 G BRASS TUBE 5/32″ ©. DIA, POP WOODEN TOP MAST RIVET [#E \/4″ THICK ALUMINIUM THINNED TO 1/8″ | ALL HOOKS BENT FROM 18 G.S. S. WIRE Ve 9 tf—|/4″ O DIA, ALUMINIUM NK eae FLAT BOW SIE OO) FORESTAY MAINSAIL UPHAUL TOP 1/8″ DIA, $.S, ROD “ARALDITED” INTO TUFNOL BLOCK ALUMINIUM TOP MAST TEE X SECTION BRASS OR ALUMINIUM a pa ES i _ | “TUFNOL BLOCK “ARALDITED” TO MAST. BACK STAY \ G . 72 MAST WING SPREADER BAR HARDWOOD PLUG Fig. 71 gives a few variations of this fitting and allows for different types of top masts. to the 22 g. brass mast band, and a 4 B.A. clearance hole is drilled vertically through the lug. The shank of the swivel pin is screwed to accept a 4 B.A. nut or locknuts whilst the upper end of the pin has a Mast Wing Spreader Bar To prevent the mast from bending under the strain of the shrouds and the mainsail uphaul, especially when using high aspect ratio sails, it is useful to fit a wing spreader bar, Fig. 72. This fitting allows two 24 g. or 26 g. stainless steel rigging wires to be run 4 in. square by 5/16 in. long block silver soldered to it. A jaw is cut in the block into which is fitted the tongue of the main boom ferrule, made from 22 g. brass. 8 B.A. screws provide the pivot for the jaw block and also clamp the mast band to the mast. A ee from the top of the mast to a point approximately halfway down the mast. A hook secures the upper end of the wires whilst a flat bowsie and a hook tensions and secures at the lower end. similar fitting, accurately aligned to the first, pro- vides a swivel for the kicking strap adjuster (a turnbuckle). The second version, Fig. 73B, utilises Tufnol rather than metal for the ‘mast bands’. A hole, of the same Gooseneck for the Main Boom In order that the main boom and hence the mainsail may move in both a vertical and a horizontal direction, it is necessary to fit a gooseneck. Basically this is a form of toggle which joins the mast band to the mast band to the main boom ferrule. In the first version, Fig. 73A, a lug is silver soldered diameter as the mast, is drilled through } in. thick Tufnol whilst the other four holes shown are + in. dia. (these are for the pivot pin of the spinnaker pole). A % in. wide ? in. deep jaw is cut in the block into which fits the rectangular toggle block. Two + in. dia. holes are drilled at right angles to each other through the toggle block. Two 20 g. stainless steel 6BA BOLT Me SPLIT PIN ii x 3/8″ x 5/8″ TUFNOL © K) “22 G.S. STEEL 3/4″ TUFNOL BLOCK 20 G.S. STEEL WIRE FIG 73 B_ GOOSENECK -+—— |/8″ DIA, S. STEEL ROD at e e m” ty so Z FIG. 73A_ GOOSENECK FOR ALTERNATIVE PIVOT PIN— MAIN BOOM UD shige HOLE TO FIT MAST lo iH T 6BA Vs” DIA, HOLes SCREWS ARE STAGGERED 64 | i J TD i A

FEBRUARY 1971 plates are screwed to a wooden main boom 3 in. wide in section, or riveted to an aluminium tubular main boom ; in. o.d. The lower band of 5/16 in. thick Tufnol is also drilled to fit the mast and a single ¢ in. dia. hole is drilled in alignment with the hole in the jaws of the upper block. Both bands are epoxied and riveted or pinned to the mast. A length of } in. dia. stainless steel rod is bent to form the pivot pin. A retaining collar is silver soldered at the lower end of the straight portion of the pin to provide a smooth bearing area, whilst the upper end has a washer and a 1/16 in. split pin fitted. The kicking strap adjuster is fitted on to the angled section of the pivot pin. The variation illustrated in Fig. 73C has stainless steel mast bands to which are soldered 4 in. dia. pivots. Note that the bands do not extend completely around the mast and that they are pop riveted into position. The shanks of the pivots are 3/16 in, dia. tapped 4 B.A. internally, the swivelling collars are a slack fit on the shanks and are held in place by 4 B.A. cheeseheaded screws. Brass lugs, 1/16 in. thick, are silver soldered to each of the collars and have 1/16 in. dia. holes to accept 16 gauge stainless steel pivot pins. The main boom ferrule fits tightly into the 2 in. o.d. 22 g. aluminium alloy tubing main boom and is held in place by an 18 gauge double-eyed pin. The kicking strap adjuster consists of a 1 in. long 2 B.A. cheeseheaded screw with a 9/64 in. dia. hole drilled centrally through its length. This screw fits into a 14 in. long, } in. dia. 2 B.A. tapped barrel which has a 1/16 in. wide by ? in. long jaw to fit the lug on the lower swivel collar. The 16 gauge stainless steel kicking strap has a ‘knob’ silver soldered on the lower end, is pushed through the screw, and then has the upper end bent to fit into either a hole in the main boom or a vee-hook attached to the main boom. Fig. 73D shows a gooseneck fitting constructed mainly of 22 gauge stainless steel. Two U-shaped brackets, ¢ in. wide, have } in. dia. holes drilled in the centre of each face. A + in. dia. stainless steel pivot pin fits through four of the holes whilst the remaining hole is used to pop rivet each of the Ubrackets to the mast. The minimum distance between the brackets is 3 in. and it is essential that the brackets be in true alignment with each other. One end of the pivot pin is screwed 4 B.A. to accept a locknut whilst a 4 in. dia. 5/16 in. long stainless steel block is silver soldered to the other end. The Ubracket which carries the 3 in. o.d. aluminium alloy main boom is silver soldered to the pivot pin block. The kicking strap adjuster is attached to a lugged collar working within the lower U-bracket. Either 5 B.A. or 4 in. Whitworth screwed stainless steel rod is used for the adjuster screw. The knurled adjusting wheel, ? in. dia. + in. thick, works within a frame constructed from + in. wide 22 gauge stainless steel. Secured to the eye on the adjuster screw is a length of 20 gauge stainless wire to form the kicking strap. 3/8″ O. DIA, 22G. ALUMINIUM TUBING _b MACHINED FROM 3/8″ DIA, BRASS POP RIVET 1| ROD p o=Sfn [f—3 Oo 18G or 6G S.S, WIRE KICKING STRAP ADJUSTER KICKING STRAP ADJUSTER 2BA SCREW I/4″ DIA, BRASS ROD FIG 73C GOOSENECK MACHINERY FOR STEAMERS (cont. from page 82) the square root of the scale but I do not know how this equation applies to the characteristics of scale steam engines. For smaller models height is at a premium; if radio control is contemplated, self-starting and reverse must be provided. Self-starting may come from two double acting or three single acting cylinders; reverse is probably best provided by one of the radial valve gears. Single acting engines may be built lower than double acting ones and they also have the advantage of being more easily designed and constructed without the need for castings because the valve chests may be mounted on the cylinder heads, leaving the cylinders as little more than plain tubes. If the valve spindle is designed to be at the side of the cylinder the thing cries out for Hackworth gear and almost designs itself! Not much like a full-sized marine engine but at least a design with some consideration of model requirements. One thing is fairly certain. Engines for model steamers require much more careful construction than they seem to get in many cases today. Valves, ports and valve settings require precise attention and all rubbing surfaces should have the benefit of a lapped finish. That oily pool of sludge which fouls the inside bottom of most model steamers is the hall-mark of leaky pistons, joints and glands. All the best looking model marine engines live in glass cases and never come to life by driving a model ship. Unkind Doubting Thomases wonder whether they could! Nevertheless, these glass-case jobs represent a lot of fine craftsmanship; is it perhaps too much to expect the same person to have equal interest and skill in the mysteries of hull construction and all the other problems presented by the challenge of achieving for model steamers an approach to parity with the excellence of the best models of other examples of engineering? a |||

JIB BOOM AND KICKING STRAP LIFTING Tube flattened in vice and then drilled to take sail hook drilled V6″jibhole fited a; JIB FITTING Hole for kicking strap hook ony F & & between handle cnd deck ~0K front Pin passes through slide and engages in series of holes in deck it 4BA Pintle \ – for mast adjustment _, ,ocrew to locate jib fitting on deck 4BA. topped — MAST SLIDE 4°x 7 1/8 hole for jib lutf hook Bose made from Tufnol sheet 1/4” ® thick Vertical post of 5/IG’thick Tufnol a Loop one end, push through, loop opposite . A 4BA : Wer VIS hole = sheet etc. size to suit mortice , Me through deck. Fitted before deck is glued into place angle of bend in wire to suit thot = Se AF Araldite of jib fitting bose pa hoes ond pus wires through *. ~~? >> ¢ Stainless wire 16g projecting 7 to deck , ‘ Bessa ar ge R | 7 . ba igp ( ‘@ Ae in bottom of Turnbuckle bet SL ©) | hook: Aa with /2° ladle wide PVC. tape 5 24g Stainless Dural mast foot glued into tube oe fo form tiller Made from 18″ thick sheet stainless steel rod boom , fe) |RUDDER ASSEMBLYTMS 1/4″ YD brass tube projecting 1/8″ below hull & WACKLINE AND: SHEETING LAYOUT | Fai knotted = main jockline ain \ ir she in ph wire or cord loop 5)” Ringing bbowsie | | ‘ | SHEETING BOWSIE LAYOUT jib sheet 5/16″ tufnol ae : main jockline ek \ =) to rudder pr lope int ite skeg , | Topped_ BBA 8BA clearance To main\ boom sat S & \ = Araldite ~Rudder post glued | \. To jib boom and angle a/d, it is characteristic of a sector having a large SR (1 to 4 or more) that the angle of the L.E.C. will be greater than one for a sector with a low SR, and in the former case there will be a high F at the extremity, and in actual practice an F two or three times greater than the theoretical one is found; with a small SR the theoretical and practical F are nearly the same. In either case the theoretical and practical L.E.C.’s will be in close SPEED WATER PRESSURE the proportions of the sector, or varying its position, to a very low level; and in these cases F will represent the force needed from either of the other two factors to achieve a change of course, and should be a low figure. The force level at any distance from B is easily determined by proximity in the regions of R and B. had s It has been mentioned in a previous article that the drag from a thin sector appears to be practically negligible irrespective of its depth, and it is considered that for a sector to be truly effective its depth if possible should be about one and a half to two times the depth of the hull. If the sector is considered fundamentally as a rectangle, then the best proportions for one having a small SR would be length twice or three times the depth. In the case of x angle a/d=F. 2 _In figure 7, a symmetrical keel achieves success by virtue of the sector’s centre being in close proximity of point B, resulting in a low F and efficient rudder. Should it be desired to increase the area of the keel to compensate for windage, etc., while retaining the existing behaviour, if the following factors, F of the existing sector, and also point B, S and angle a/d of the proposed sector are known, finding the position of the new sector is simply large SR it should be either a square or one having a depth that is equal to twice its length. In the latter case, increasing the width will result in a lesser F and F smaller SR, and in this respect SR1-2 appears to be 2 the minimum; any further reduction (of SR), irrespective of depth, will result in an inefficient sector, while increasing the depth of SR will result in a angle a/d (where F is equal to that of the old sector.) If a sector of any shape or area has its centre at point B, then F is zero; in many ways this would appear to be an ideal position, and in view of the water pressure and drag around the rudder and the motive power needed, it might well repay some yacht designer to investigate this point more fully. more effective one. The shape of a sector can be important. In figure 5 it might be thought that because of the shape of example B, this would allow the model to run easily and, at the same time, allow the model to work to windward satisfactorily. Of these two asymmetrical keels example B will not result in a better performance than A; in fact, it will show all the characteristics of a large SR with the attendant disadvantages such as a poorer performance when working to windward due to the lack of water along the keel which combats windage and leeway. It is not in- (To be continued) FIG 7 ke cas aay BS a 73 a |