MAY 1971 15p (3/-) U.S.A. & CANADA SEVENTY-FIVE CENTS HOBBY MAGAZINE

ee) A HLH ——_ —_— — Racing Model Yacht Construction TEMPLATE DECKLINE Part Eleven me Erection of mast, horses, rudder and deck 22 GAUGE STAINLESS STEEL FIG. By C. R. Griffin fittings, spinnaker boom, etc. 79 RAKE OF MAST Ot THE ERECTION OF THE MAST. It has been said previously that the designer of a model yacht can only estimate the position of the mast on the hull, and the exact position is found by a tuning-up process. However, it is necessary to have a starting point, and therefore the mast slide or the deck mounted mast step is placed centrally over the designer’s estimated mast position. Measure from the plans the two positions of the jib stay, i.e. the high and low aspect, and site the jib fitting so that it can be moved to either of the positions, preferably with additional movement fore and aft. Check that the jib boom will not foul the mast. Decide which sailplan is to be rigged and put the jib fitting in the appropriate position. Rig the mast to suit this sailplan and, from the plans, calculate the angle that the mast should make with the deck. If not indicated, use an angle of about 874° to the waterline with the mast raked slightly aft; note that the angle to the deck will need to be calculated from the plan, see fig. 79. It is useful to make a plywood template of this angle so that it can be repeated at will. Fit the mast into the mast slide or onto the mast step, rig the jib cn and adjust until the mast is at the correct degree of rake. If the chainplates were not built in with the hull, fit these now. Two types of chainplate are illustrated in fig. 80 and 80A; the type shown in fig. 80 is constructed from 16 gauge brass or 20 gauge stainless steel sheet. Cut the chainplate 3” in length and 3” wide, and drill 4” holes at 3” intervals to accept the shroud turnbuckles. Silver solder three feet, 3” long and 5/16” wide, to the drilled strip. This fitting is secured by screws through the deck into the inwale. Fig. 80A shows a chainplate made from 22 gauge stainless steel and is fastened by screws into the inwales both downwards and sideways. “40 2″ Troe RIVET 22 GAUGE STAINLESS ao 2″ | e | 1/16″ COPPER we 4 a el 22 GAUGE STAINLESS STEEL 3 1/4″ DIA, HOLE 2″ DIA. 4″ THICK PLASTIC OR TUFNOL COLLAR v2″ U5 4” DIA, POST || rT FIG. 82A._ “TRIANGLE FOR OPERATING MOVING CARRIAGE VANE POP RIVET FIG. 828. ‘TRIANGLE’ 186 Measure the distance from the hounds to the chainplates and secure 20 gauge stainless steel wire of the appropriate length to the eyes on the mast band to form the shrouds. Alternatively, if no mast band is used, make hooks from 16 gauge stainless steel wire, secure the shroud wire to the hooks and insert the hooks in appropriate holes in the mast. It is advisable to use turnbuckles to connect the shrouds to the chainplates prior to and during the tuning-up process. This allows the mast position and rake to be altered more easily. Open the turnbuckle to the mid-position and hook on to the chainplate at a point approximately 1” behind the mast position. Measure from the mast band eye (or hook eye) to the eye of the turnbuckle on both sides of the hull, calculate the mean distance, measure off both shroud wires and bend over. Secure the lower end of the shroud wire to the turnbuckle then check that the mast is vertical when viewed from the bow. Ensure that the rake of the mast has not been altered during the operation. Tighten the turnbuckles so that the shrouds are reasonably taut but do not overtighten as this will bend or distort the mast between the hounds and the deck. THE JIB HORSE is fitted to provide an anchorage point for the jib boom sheet and, depending on the type of horse used, allows the jib boom to move about 10° either side of the central axis of the hull. Any further movement of the boom in a horizontal plane is controlled by the jib sheet. Fig. 81A illustrates the traditional jib horse and traveller and should not exceed 3” in length. Ideally, stainless steel should be used throughout but a good compromise would be partial construction in brass, preferably with the horse bar of stainless steel. Whatever material is used the bar should be silver soldered into the posts, and similarly the feet should be silver soldered into position. The triangular uprights shown in fig. 81B have advantages over turned posts in that there is less likelihood of the jib sheet becoming entangled and they are simpler to make. If the jib horse is to be on lines similar to that illustrated in fig. 81C, it is essential that two collars are soldered on the horizontal part of the bar to prevent the traveller locking on the corners. The traveller illustrated in fig. 81B requires less intricate bending of 22 gauge brass or stainless steel sheet than the one shown in fig. 81A. Both function in the same way utilizing }” diameter rollers operating on 8BA axles. The stainless steel deck eye shown in fig. 81D replaces the jib horse when synchronous sheeting of the jib and main booms is desired. Fashion the eye and the ring from 16 gauge stainless steel wire, silver soldering the joint in the ring and the loop to the plate.

MAY THE MAIN HORSE, if fitted, performs the same function for the main boom as does the jib horse for the jib boom. Except for the extra length of the bar, which is approximately 44” long, there is no difference in construction. Modifications have to be made to the traveller if it is required to operate a moving carriage vane gear; however, this aspect will be dealt with when vane gears OLLERS POST IN BRASS OR S, STEEL FIG. BIA__JIB HORSE AND TRAVELLER y4 ” are Dy \_- 1/8″ DIA. BRASS ROD e FIG. BID ‘JI8 HORSE” DECK EYE SYNCHRONOUS SHEETING e STAINLESSS STEEL RING 4/16″ . ©, DIA. . STAINLES Soa e V5 5/6″ INES (a nih 5/\6″ DIA, BRASS COLLAR . 5 _JIB HORSE FIG, BIC HORSE 81C_1B FIG. shelLo a74″-o| ier ar oe brass or curtain rail and located in a saw cut in the bottom of the skeg as in fig. 83A. Silver solder the stainless steel pintle pin to the brass plate then epoxy and rivet the fitting into position. Alternatively, the fitting can be made from 1/16” thick brass sheet as shown in figs. 83B and 83C; this type of fitting has an advantage in that the pintle plate can be readily removed should the necessity arise. The lugs on the ‘shoeplate’ are made from 22 gauge brass sheet and are silver soldered into place. Two 7BA countersunk headed screws secure the pintle plate to the shoeplate which is epoxied and pinned into position. If a raked rudder is fitted, see fig. 83C, the end of the pintle plate, on which is silver soldered the stainless steel pintle pin, is bent to the required angle. To ensure that the rudder rotates on a constant axis it is necessary to fit either a deck mounted pintle, see fig. 83A, or a locating device in the form of a plate or a bush. The pintle shown in fig. 83A is constructed from 1/16” thick brass strip, the buttress piece being silver soldered into position. Actual dimensions vary according to the type of rudder tiller arm and the vane gear fitted. The base plate however, should not be less than a }” square and the pintle pin preferably of stainless steel. The locating plate shown in fig. 83B has an advantage in that there is no restriction on the movement of the rudder tiller arm. However, compared to the pintle fitting described earlier the locating plate fitting is more prone to interference by foreign matter such as sand and grit. Most materials can be used in the construction of the plate, the choice ranging from stainless steel to INSET I. { y ALTERNATIVE BRASS Y FIG. 818 JIB HORSE AND TRAVELLER ys” UPRIGHT IN STAINLESS STEEL 22G, in the previous type. LOCATING PLATE TRAVELLER G STAINLESS STEEL 22 THE RUDDER AND ASSOCIATED FITTINGS. The construction of the rudder itself has been described earlier; summarising what has been written:— chamfer the rudder post edge of two pieces of }” thick mahogany and glue together so that the chamfers form a vee. Ensure that the grain of the laminates are reversed to prevent warping. Shape the outline of the rudder and carve to the designed chords. Drill an appropriate length of }” or 7/32” outside diameter brass tubing to take ?” long No. 1 brass screws. Coat the vee with epoxy and screw the rudder post to the rudder. Allow the glue to harden, file off the screw heads level with the rudder post and either paint or varnish the rudder. The rudder is held in position within the rudder tube by a lower pintle on the heel of the skeg and a further fitment on the deck, either a pintle or a locating plate or bush. The lower pintle fitting is made from T-section POST Ole, RUDDER a” TUFNOL: P.T.F.E. ys” a” to a main horse operating a moving carriage vane gear, the vane gear can be operated by a ‘triangle’. Figs. 82A and B illustrate two versions of the ‘triangle’. In the first type, fig. 82A, the operating arm and the strengthening arm are cut from 22 gauge stainless steel sheet and pop riveted together at the forward end of the operating arm. A spacing collar of plastic or tufnol, 4” diameter and }” thick, is sited between the two arms, all three items being drilled with a }” clearance hole to accept the pivot post. The base plate of the pivot post is approximately 1” in diameter and 1/16” thick, the pillar being tapped 4 BA to take a flat headed screw. A 5/16” diameter ring of stainless steel or brass is secured to the forward end of the operating arm by a short length of terylene cord and acts as an anchorage point for the main sheet hook. The type shown in fig. 82B is constructed on similar lines but the side arms of the operating arm are made of plastic and are lengthened to enable guying sheets to be used. The operating and strengthening arms are cut from 22 gauge stainless steel and are copper riveted to the plastic arm. The pivot post is identical to that described oe alee fo} fo} > are discussed. A deck eye similar to that described for the jib is used for synchronous sheeting. As an alternative = ° 1971 UPPER PINTLE BUSH =s 1s 1/2″ O.DIA, BRASS TUBE —> 9/8″ O.DIA, BRASS TUBE UPPER PINTLE 3/4″x No… BRASS SCREWS LOWER PINTLE ( 1] ale SECTION THROUGH : cm, OF SHOE PLATE AND LOWER PINTLE i SHOE PLATE—s LOWER PINTLE FIG. 838 a 7B a CREW RUDDER AND FITTINGS 9/4″ x No.1. BRASS SCREWS SKEG AND PINTLE 7/32″ O.DIA, BRASS TUBE 7/32″ O.DIA. BRASS TUBE LOWER PINTLE SHOE PLATE LOWER PINTLE FIG. 78A SCREWS 83C RUDDER ANO FITTINGS 187 IMI FIG. 836A. RUDDER AND FITTINGS

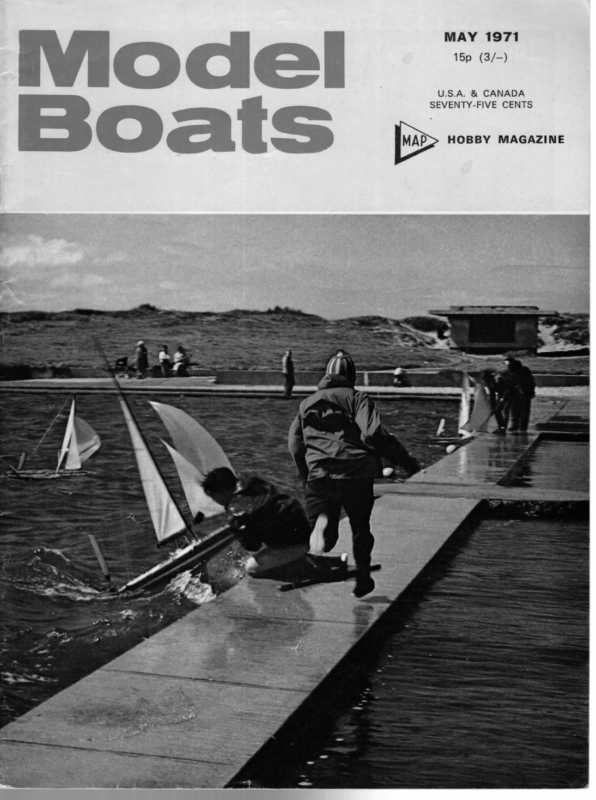

MODEL BOATS Details of triangle, upper pintle fitting, gunwale eyes, and other items of gear on two Marblehead yachts are shown in photos on left. perspex. When a raked rudder is fitted, the hole in the plate must be cut at the designed rake angle unless very thin sheet is used. Fig. 83C illustrates the use of a P.T.F.E. bush located in the top of the rudder tube. However, if this type of locating device is envisaged it is advisable to use a larger diameter rudder post tube, e.g. 4” outside diameter. There is no reason why a brass bush should not be fitted, provided that firstly, the bearing surface is reduced as indicated in inset 1 and secondly, some positive method of securing the bush is employed. GUNWALE EYES are used as anchorage points for the backstays, forestay and the spinnaker sheets. Fig. 84A shows a gunwale eye with three attachment holes which is used for attaching the after spinnaker sheet, the mast backstay and the guying jackline. Cut the baseplate and the upright 1/16” thick brass or 20 gauge stainless steel sheet. Drill 5/64” holes in the upright and silver solder it to the baseplate. Drill and countersink the base to accept 3” long No. 2 brass screws. The gunwale eye showh in fig. 84B utilizes “Swish” nylon curtain rail or medium gauge brass curtain rail. Hook attachment holes are drilled 5/64” in diameter and screw holes are drilled to suit No. 2 brass screws. Fashion the ring for the eye illustrated in fig. 84C from 16 gauge stainless steel wire and cut the baseplate from 22 gauge stainless steel sheet. Silver solder the ring into position. A loop rather than a ring is the main characteristic of the gunwale eye shown in fig. 84D. The type of eye fitted depends upon its designed use and its relative position to other deck fittings, e.g. guying eyes positioned on each side of the transom can be simply screw eyes. Fig. 85 gives a layout fy i k \ rie 1 2 3 4 ey A fi] = 8 9 D 5 10 eis a? ee jaar 6 don TWO EYED HOOE a ry bn cg ase 16 G.S, STEEL RING 22 G,S, STEEL BASE S.5. STEEL LOOP BASE a cpa 3 sect eo of fittings for an ““M” class; the pce is intended to show only the relative placement of each fitting and is not meant to be used as an ideal or standard layout. ’ THE SPINNAKER BOOM is a spar to keep one of the position. Under the ‘M’ class rules a spinnaker boom lower corners of the spinnaker sail in a predetermined must not be more than 15” in length measured from the centre line of the mast to the point of attachment. In the 36” restricted class there is no limit to the length of the spinnaker boom and both the 10R and ‘A’ class rules limit the length to that measurement not exceeding the base of the foretriangle. Fig. 86 shows a spinnaker boom constructed from }” outside diameter aluminium alloy tubing. The swivel pin shown in detail seats in a }” diameter clearance hole in the mast band. This swivel

MAY ff TOPPING LIFT ? . ” ; Ss Eun ae = pa 1971 a | vs Le ge ae The ‘Spike’ boom end fits into a 5/64” hole on either side of the mast and is held in place by a spring attached to a hook placed in one of two holes on either side of the mast. Unlike the spinnaker boom sheet in fig. 86, the forehaul and backhauls are separate but nevertheless, they function allows the boom to be set at any angle to the centre line of the yacht on either side of the hull. It is held in a fore and aft position by an adjustable spring or rubber tensioned forehaul and an adjustable backhaul. Movement in a vertical plane is controlled by a spring or rubber tensioned adjustable stay holding the boom down against an adjustable topping lift stay. The purpose of the tensioners is to allow the spinnaker to move slightly thus preventing violent reactions in gusty winds. Make the attachment eye from either a 16 gauge stainless steel wire ring silver soldered to a brass plug or bend 18 gauge stainless steel wire to form a double eye. The spinnaker boom illustrated in fig. 87 is made from in exactly the same manner. The various types of spinnaker sails and method of construction will be dealt with later. HOOKS, BOWSIES, etc. Fig. 88 shows various types of hooks, woggle hook and bowsies, most of which will be needed in the rigging of a yacht. Stainless steel wire, either 16 gauge or 18 gauge, is the best material for hooks and either tufnol, perspex or hard plastic can be used for bowsies. It is hoped that the drawings are self-explanatory. 2” diameter hardwood with boom end ferrules as detailed. One Man’s Models Reader John McCloskey sends a couple of snaps of recent work (XHESE pictures show some of the models built by John McCloskey of Liverpool, and include a Lorraine, a Pathfinder, a 36R yacht Lady Betty, a Remora, and two models of Joshua Slocum’s Spray. The larger Spray, shown separately, was scaled up from drawings in Captain Slocum’s book ‘Sailing Alone Round the World’, and is about 2} times the size of the little model which was published as a full- in. oak keel member, and the deck is spruce-planked and natural varnished. Masts and spars are yellow pine, deckhouses ply, dory 1/32 in. ply, casks from broom handle, anchors oak and brass scrap, and dead-eyes plastic wood. Oak was used even for the ship’s wheel. The model sails well. bread and butter yellow pine halves glued to a 5/16 Mr. McCloskey mentions that he built it at the same time as the Pathfinder, as he likes to have two models going at the same time. In the picture, Pathfinder is lacking guard-rails due to difficulty in finding a supply of four-ball stanchions. Season’s starting. Are you licensed? size plan in Model Boats in January 1966. Overall length is 35 in. and beam 12 in., displacement 13 Ib. of which about 44 lb. is lead. Construction is two Are you insured? 189 Are you silenced ?

aaa Sunn MODEL BOATS O my great surprise I find that the design of High Tension is dated April 1964 andas far as I canremember this is the latest design of mine to be published. A lot has happened to the 10-Raters since that time and we are now starting a new generation of development. I think it is true to say that High Tension was the first design to 10-RATER show that 60” LWL was a good proposition but even so, it was only several years after publication that the design longer and lighter boats than before and bulb keels are a must. Therefore, my new design is longer and lighter the limit of development within the rules as they then stood. That is, unless one exploited the rules in such a way that fortunately has been prevented by the revision. However, although I was tempted to go one stage heavier it was without conviction, as the only way to make real Let us look at it. The 65” waterline is not unreasonable and a displacement of about 24 lb. seems to me to be caught on to any extent. To me it probably represented progress seemed to be to go lighter, but I didn’t want to lose power to windward and I didn’t like the extra wetted surface of bulb keels. Model yachtsmen of my age, and older, can remember the plate and bulb keels of the late twenties and early thirties and how they fell from fashion as the full “power” keels proved superior. There was therefore a natural reluctance to reintroduce them into the 10-raters. However, the outdating of the old plate and bulb keels was probably more to do with the plate than the bulb and I would still never consider a flat plate as any good for a fin. The main reason being of course that the flow of water over a flat plate when going to windward will break down at quite small angles of incidence and the drag will increase sharply together with a distinct drop in the force which is resisting leeway. This phenomenon can be seen in some modern designs where the fin is of very thin cross-section. Particularly in the “M”’ class. At about this time I met Dennis Hardwicke and together with Denis Lippett they wanted a new 10-rater design. As the two boats would be racing together quite frequently and we should in any case test sail them to evaluate their performance, I designed a hull similar to High Tension but three pounds lighter. On the one for Dennis Lippett we put a “‘conventional’’ all lead fin and on the other we put a bulb keel and prognathous fin. Tocutalong, sorry story short, the bulb keel version was the faster under all conditions. This model also was fitted with a highly sophisticated rig and deck gear developed by Dennis Hardwicke which contributed a lot to the performance, but I think he will agree with me that the keel design difference also played its part. Roger Stollery wrote to me a very friendly letter trying to jolt me into designing a few M class and also pointing out that I was ignoring the bulb keel developments in the 10-raters. I was glad of this correspondence as it cleared my mind of old prejudices, although it is true that I had been working on a full-scale project incorporating bulb keels, so it is only with respect to 10-raters that I admit any prejudice. The next step was a 60” LWL 28 lb. short overhang design for myself which was really a resurrection of an early attempt at 60” LWL about 10 years previously, but of course this time I put on a bulb keel. The lead ballast jutted out in front of the leading edge of the fin, but the fin was raked in the conventional way. The boat has not been raced very much but the performance, although good, is not exceptional and no conclusions can wn. Now we come to the changes in the 10-rater rules and 1 do not propose to debate them and, in any case, as I was im favour of the change, my comments are bound to be baased. | have watched with interest the new boats that have been emerging and there is no doubt that performance has been stepped up. The classis now going to produce 198 than anything I’ve done before and it has a bulb keel. JOH! about optimum at this stage with 14” draught. I am reluc- WELCON close to the surface. The very first 10-rater I owned was 24 Ib. displacement and about 47” LWL. This boat, designed and built by Lance and Brookes, taught me that light displacement 10-RAT tant to go deeper as so many pools have the bottom this Full-size copies of the CRACKER 10R designed by \ The Model Maker Plans Service idge Street, LL LOA DISPLACEMENT BALLAST DRAUGHT MAX BEAM SAIL AREA Hemel Hempstead. TO Al drawing below consist of full-size body plan ar available from Model Maker Plans Service, 13-35 Br M9) J. Lewis. \ MA Herts

MAY ‘CRACKER’ LEWIS ESA can be very good in heavy winds, certainly very exciting to sail. The hull form of Cracker is that with which I am familiar and which has proved to be very satisfactory on all points of sailing. I have seen nothing yet which con- = RETURN vinces me that I need to make a radical change in this /ANCED department. Of course, the reduced displacement, 10 Ib. less than High Tension, and the increased waterline, pro- R DESIGN § quce a hull which is very narrow and fine. There is nothing to stop it travelling very fast and she should plane very well too. lead, half-size sheer and waterlines, and quarter-size sail plan. They are 3 St., Hemel Hempstead, Herts, price 65p post free. PROFLE 6 WATERLINES 1971 The lead bulb is of reasonable thickness/length ratio and this is appropriately placed under the C.B. of the hull. It only remains to fill the gap between the hull and the bulb with some sort of a fin. I am coming to the conclusion that the shape of the fin is not critical. It can slope forwards or backwards, it doesn’t seem to matter. What I am fairly sure about is that with this type of model it is a good thing to have the sail plan as far aft as possible, particularly as we are going to have a big spinnaker to carry. Therefore, it is helpful if the fin is drawn as shown and let the bulb ballast project forward of it. In fact, I would not mind if the leading edge of the fin sloped from the bulb aft to meet the canoe body at station 6. This would move the rig a further 3” or so aft. Please note the section of the fin, i.e. do not use a flat plate. One thing I do like about bulb keels is that you do not have to design the fin with excess lateral area in order to be able to accommodate the lead. In a year or two we shall be able to judge better just how small a lateral area is permissible. In the meantime we will go (continued on page 206) PLAN SCALE HALF FULL SZE SECTION SPACED 6.50° WL. SPACES 100° fui 199 MM

MODEL BOATS Building the GRAUPNER ‘OPTIMIST’ Bob Jeffries writes a two-part report on building and sailing this 41 in. R/C model yacht ([SHERE are no doubt many readers of this journal who have the ability to build a R/C yacht, but who have been deterred from the attempt because they are afraid that having spent much time and money, the design they have selected may prove unsuitable for the needs. The ‘Optimist’ kit has arrived on the market at an opportune time, as it offers a really suitable design, in a suitable size, and a sufficient amount of skill is required to construct so that the builder will not feel when he has finished assembling it that it is just another plastic kit. The demands on workshop facilities are modest, and are I am sure, available to any potential yacht builder. For those builders who like to make every part, it must be borne in mind that it is now current practice in full scale to use glass fibre hulls and superstructure, and “Optimist” is just following this excellent trend. The design of ‘Optimist’ follows closely on the full scale design of the ‘One Ton Design’ that won important events in Europe and America in 1968 and 1969, so the prototype had the success that I am sure its small scale replica will follow. The model is 41 in. long, 104 in. beam, 50 in. to top of the mast. It weighs 11 lb. without the radio equipment, and when one bears in mind the weight of the keel is 7 lb., the keel /displacement ratio is most satisfactory. The sail area is 640 sq. in. and for a boat of these dimensions should give a sparkling performance. The specification states that the all up weight should not exceed 13 Ib., and this allows 2 lb. for the radio, batteries and actuators. Normally this is ample, but as my flotation tests show, at this weight the boat floats somewhat above her waterline, and an extra 1 lb. or so should not cause concern. The kit arrived in two parts. Firstly the postman arrived complaining bitterly of the weight of quite a tiny parcel (the keel) and later British Rail arrived with a huge parcel weighing almost nothing. You can’t satisfy. everybody. However, when the parcel was opened, it contained what appeared to be a frightening amount of material, including a finished plastic hull, plastic cabin top, skeg and rudder. The keel was of cast iron and the remainder was in precut balsa, mahogany and what appeared to be spruce or similar. The material was of very good quality and finish, except that some. of the mahogany was twisted and warped, and needed treatment before use. The set of metal fittings was complete, and well made and finished, and in no small way contribute to the finished appearance of the yacht. My main concern over the construction was that the excellent instruction book enclosed was only available in German. This book was well illustrated with stages of the construction, and this and the three large plans enclosed with the kit made the order of construction clear. Some time was well spent on a close study of these drawings and the material before anything was commenced. (This was a _ preimport kit without English instructions—Ed.) A start was made on the keel. As stated this is in cast iron. It only needed a small amount of work with an old file to complete. I was a bit concerned that it was to be fitted with only one bolt. Perhaps if the instructions had been understood it would have said that the keel should have been cemented to the hull, but I prefer my keel detachable, so I added two extra 2 BA screws. Had I cemented it, perhaps the one screw would have been sufficient. The construction of the deck was somewhat complicated, but as construction proceeded, the whole assembly became clear. The construction consists of Top picture shows the basic kit, and left is the finished hull minus mast and sails. 202

MAY 1971 Modification to cabin top to provide access to gear without removing mast each time. Hatch is still adequate. a sub-deck in balsa over which the deck proper is fitted. This sub-deck follows current model aircraft practice as all the balsa parts were precut in the usual manner and caused no trouble until I started to add the spruce strips around the edge that form the joint with the hull. These strips started to distort the subdeck so badly that I decided to preform them in the steam of a domestic kettle first. After this, there was no further difficulty. Included in the kit was a giant tube of ‘Uhw’ cement. It should have been sufficient to complete the model, but perhaps I was over-generous, and I had to purchase another tube. If there is difficulty, clear Bostik cement is a good alternative. Before completing and fitting the sub-deck, the foot well for the cockpit was made and fitted. This was the material that was so distorted, and it was necessary to back these parts with thin, hard balsa, cemented on with the grain at right angles, and held under pressure whilst drying. The parts were assembled with the mahogany side outside, so on completion there is nothing to show that an alteration had been made. The hull is supplied slightly oversize and needs trimming down to a faint line moulded in. This is just a matter of patience; I used a fine, small tenon saw. Before fitting the sub-deck, I decided to fit the keel, rudder and skeg. Again the plastic parts had this fine trimming line moulded in. The rudder and skeg are in two halves, and the design calls for the skeg just to be cemented edge to edge with the hull. I was not satisfied with this and added a piece of plywood of suitable thickness between the two halves before cementing together, and in the case of the skeg, this ply projected about an inch above the skeg and through a slot I cut in the hull. This was then cemented in and small packing pieces added inside. The result was vastly stronger and the increase in weight was a fraction of an ounce. The rudder has a brass tube cemented in, and the rudder shaft passes through this tube. It is necessary to drill a small hole right through the rudder, tube and shaft and fit a suitable pin. Take care over this, as I broke a drill in, and had quite a job in getting the bits out. One of the large sheets of drawings shows the radio installation, and shows an arm fitted to the rudder shaft. This was not included in the kit, and had to be made and fitted before the deck assembly was fitted. After the rudder assembly was completed the two bulkheads were fitted. These were duplicated, as presumably it would have been difficult to precut them in the thickness required. They were cemented together before assembly. Before fitting the sub-deck it was waterproofed with a coat of polyurethane clear varnish thinned with about 10 per cent white spirit. At the same time the deck was also varnished, on the underside to waterproof it and on the top to prevent the rather attractive printing of deck timbers being marked with fingerprints or cement during assembly. The sub-deck was then cemented to the hull. A generous amount of cement was used to ensure a strong, waterproof joint. There are several slots in the Hatch top in place, also mast and rig. Model is nice looking and a good performer. 203 sub-deck and domestic spring pegs were used through these slots to hold the joint closed between deck and hull whilst the cement dried. The cabin top is made in the same plastic material as the hull. It needs the top cutting off, again to the faint lines moulded in. The top was then taped back with adhesive tape to hold everything in alignment whilst the lower part was cemented to the subdeck. The correct placing was found by fitting the deck over whilst the cement set. There are various hardwood pieces, battens etc. to be fitted before the deck is finally fitted; make sure that all is done because once the deck is secured there is no possibility of getting to them. The various precut pieces of mahogany that make the trim and cockpit are now fitted. It is a help if these are sanded down with very fine glasspaper before assembly. This is a lot easier than afterwards. With the completion of this part, it was given several coats of clear polyurethane varnish, carefully rubbing down between each coat until a satisfactory finish was obtained. Attention was then paid to the mast and deck fittings. The mast is worth comment. It follows full scale practice as it has a proper runway to take the luff of the mainsail. The main boom has a similar runway for the foot. When cementing the parts of the mast together, care has to be taken that excess cement does not get in the runway and impair the movement of the sails. I found a length of metal rod that closely fitted the slot did the job nicely, and removed any excess cement before it had a chance to dry. The sails are supplied finished in nylon. A cord has to be threaded through a pocket in the foot and luff (Continued on page 205)