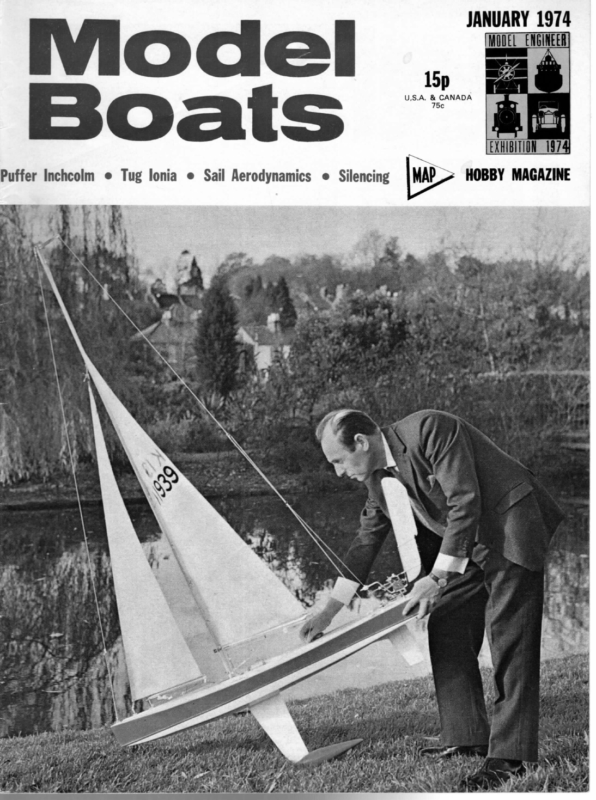

Vode S Puffer Inchcolm e Tug lonia © Sail Aerodynamics @ Silencing ae y “4 reblog 3 wok . Z . – JANUARY 1974 |MAP > HOBBY MAGAZINE

JANUARY 1374 In the Tideway The New Forest R/C M.Y.C. reached its first birthday in September and is a thriving concern with 20 members, all active, on the books. The use of Setley Lake in the forest is a major factor, and the Verders are very helpful — the notice photographed week! The world energy crisis casts something of a shadow even over modelling activities. We hear on the international grapevine that methanol is likely to be virtually unobtainable in the U.S.A. for some months, and many by-products of oil refining that we take for granted will be in very short supply everywhere. Yachtsmen can at least count on adequate supplies of their motive power (on most occasions, at least) but travel to events is going to be more difficult and/or expensive. Some clubs already have contingency plans to get models to regattas while the owners travel by public transport.’ This is all happening at a time when some exciting events are planned — the World Championship for multi-boat endurance racing at Keighley in August, the first British R/C Marblehead Championship at Elstead in September, and, further ahead, the big international meetings to be staged in Britain in 1975. The first real international meetings for R/C M and R/C 10r yachts are to be held at Gosport, coincident with the Naviga Championships at Welwyn, in August 1975, and there is talk of a World Championship for vane As and Ms at Fleetwood at around that time. Let us hope that current problems have eased in time for these functions at least, or we shall all be oiling our bikes! Lifeboat Model Top picture shows the model lifeboat built by the 9-11 year olds of Romford and Dagenham Boys’ Club, at its dedication service at the local Salvation Army Citadel. Boat and trailer will be in the next Lord Mayor’s Show procession and at _ other functions, raising funds to add to the considerable amounts already collected for the R.N.L.I. by these keen youngsters. was not requested, it just appeared one Experience has indicated that some of the older designs are superior to later types for R/C use. The club fleet includes 8 Bewitched, four with bulb and four with conventional fins (a good all-rounder, they say), two Sailplane II, much modified with snubbed bow and turtle deck (a very good design), two Fivon (cheap to build and very fast), a Tucker Duck (fantastic, won the May open meeting at Guildford), the Soling described in September MB, and a Stollery Here Today, Goon Tomorrow, which is good in windy conditions. Since the Duck design is over 20 years old and the Witchcraft 10, these comments will undoubtedly interest non-R/C yachtsmen, could it be that radio weight is less of a percentage of a 234 lb. boat than of a modern 18 lb. design? If any visitors would like to go along, the club sails every Sunday afternoon and the contact is either A. B. Abel, 8 Saxon Road, Salisbury, Wilts., or you could ring C. R. Jeffries on Highcliffe 4438. A new secretary for the Off-shore Model Racing Association — D. Hill, 46 Somerset Road, Farn- borough, Hants., GU14 6DP. Just time to see an exhibition of industrial modelmaking, including marine subjects, which closes on January 5th. It’s at the Design Centre, 28 Hay- market, London SWI. R. Mogg, Raefield, Glencot Road, Wookey Hole, Wells, Somerset, tells us that his son’s electric Corker model was stolen in Cornwall (St. Just Lane) and if anyone sees it would they let him know. It’s a vacuum formed hull with false clipper bow and bowsprit, dark blue hull, white deck, Gem 1+1 main masthead and navigation lights working from a single bulb and Perspex light guide. Should be easily identifiable. Transfers A couple of years ago we offered some small waterslide transfers of the name ‘Model Boats’, which people were pleased to have on their models or model boxes. We have a few more available to first-comers and you can obtain a pair free by sending a stamped addressed envelope marked ‘M.B. Transfers’. Forestry Commission Model Yacht Sailing ease do not disturb – model sailing area when in use by Club

JANUARY 1974 a GENIE Part two of Vic Smeed’s simple Marblehead for vane or radio Early trials with sails borrowed from another boat; perhaps it was as well the wind was light, as we hadn’t had time to make a hatch cover! Daughter Michele acts as mate, so the camera can be used. When all is set, the ends of the planks can be trimmed back flush with the stempiece and transom, just to tidy things up, and attention can be turned to the deck beams. First chisel/plane/sand the inwales and side top edges down flat, so that a ruler laid across sits fairly on each side. Check that the sides follow a smooth fair curve in profile, best seen by squinting along from one end. Plane off any high areas and check equal height each side by placing the hull on a table and sliding a length of timber, placed athwartship, along, measuring the WE now have a ply shell with firm joints, held together at the extreme ends by the stempiece and transom but capable of changing the shape of the open top. Left to itself, the top edges will tend to spring inward, giving a deck beam of only about 9 in., but the edges can be pulled apart to make this 12in. or so. The effect of allowing the beam to reduce is to force the rocker (fore-and-aft curve) in the bottom plank to flatten slightly, but whether this would have a noticeable effect on sailing is con- jectural. Since altering the curves must put some height of each end from the table at various points. Use the same piece of timber, wrapped in glass- strain on the joints the recommended temporary cross-piece should be kept in place while work paper, to sand both inwales at once. A proceeds. The next job is to fit the inwales, and for these we simply selected a good dry and clean 8 ft. length of + x 1 in. prepared deal (which measures } x ¢ in. actual) at a local timber yard and an obliging gent ran it over a saw to give two lengths } in. sq., near enough. These are cut and fitted into the hull and epoxied in place, ensuring that the outside top corner is flush with the outside corner of the hull side. That means that the inwale fits inside the side, but since the top edge of the side is going to be bevelled, its inside corner is going to be reduced. It might be thought that the edge could be bevelled beforehand, but until the inwale is there it is not very rigid, and anyway the inwale is going to have to be planed down, so it might as well all be done in one operation. As the photograph shows, clothes pegs are used to clamp the inwale while the glue hardens, and the temporary spacer is in place to ensure that the right curve is maintained. It is best to work both inwales together, since if one is fitted ahead of the other, that side will be stiffer and the other side may therefore bulge out and produce an asymmetric deck plan. This would not make much difference to the below-water shape, which is now fixed, but on heeling there could be a slightly different effect on opposite tacks. The hull as lifted off the building jig; rippled effect is only grain pattern, Far right, hull interior after taping; compare with photo on page 27, when slimmer, unwedged effect will be apparent. 25 little care at

MODEL BOATS this stage will result in a much nicer-looking hull. Pin a straight strip of wood, or a string, from to transom centre. Mark the deck you are building for vane sailing, only the handle is needed with no hatch, surplus water being drained out through a # in. hole in the transom. If for radio, the hatch is essential, but there is less need for a handle; the fin must extend through to secure to the deck beam, but cutting away surplus means easier access, even though it is still recommended that the radio be split into two boxes, one each side. In either event, the two hatch edge members, shown as +s x } in., should still be included for deck support, which is also the function of the one full deck beam of this size timber; this one carries no load but prevents that sinking feeling which a large 2 The fore-and-aft beams, or carlings, are halved into the cross-beams in a similar way, except that the lodgements can be cut right across the latter, i.e. a % in. sq. X ve in. deep piece is cut out. Before “5G MRE OOK FITS 1K DRILLED HOLE IW BOOM crea STRUT From ‘SECTION AL OR S7e \ sit! ea ’ Pe ee SPINNAKER BOOM ‘e’s “ spRUCE ETC 3 | we i centre beam positions on one inwale, measured from the plan, and use a square aligned with the centre strip or string to mark the opposite inwale correspondingly. There seems little point in having a cambered deck on the boat, so the deck beams are straight; if you fancy rounded beams, by all means have them, in which case shape the inwales to the appropriate slight angle. For flat beams, simply cut ? in. sq. to lengths + in. shorter than the overall hull beam at each position, angling the ends to follow the hull shape. Cut a 4 in. x } in. step x in. deep in the inwales at each junction (knife and chisel) and cut the underside of each beam end to fit, i.e. each 2 in. wide beam will lodge } in. into the inwale and the beam and lodgement are cut to ysin. depth so that when the beam drops in place it is flush with the inwale top and a snug fit across the boat. Since the inside face of the inwale is angled, the beam must be cut at a corresponding angle to be a nice fit. Hy stempost fitting these, it is as well to consider whether they will be in the right place if you intend to use other fittings than those on the drawing. To save time, we used a number of commercially available fittings on the prototype (available from J. Roberts and/or W. Jones, details later), but the only alterations needed were to fit a central fore-and-aft member running from the bow aft about 9 in. and a small block between the two fore and aft beams about 14 in. aft of the mast. Our prototype is slightly inconvenient in that it has both a handle and a hatch (this means the hatch has to fit round the handle) but it is intended that if

JANUARY unsupported area of deck might otherwise have to endure. The next stage is to mark and cut out the fin, skeg, and rudder. Although 4 in. ply is adequate for the last two, it may be convenient to cut them all from = In. exterior or marine grade ply; it is not very important provided one is enthusiastic with the glasspaper. The fin must really be ? in., unless you prefer to use Tufnol or one of the other plastics or laminates of similar strength, when it could be thinner. Clean up the cut pieces, mark on the exposed areas, and chisel or plane/rasp/sand to Sheet 1 of the two-sheet plan is reproduced here. Drawings are all full-size (except sail plan) and show fittings based on Stollery/ Shepherd = simpli- city. copies sheets) MM1175, The complete hull with deck beams ready for the next step, fitting the fin and skeg. We feel it better to cut the slots for these after assembly of the hull, just in case there is any misalignment. Clothes pegs (bulldog clips too, if you have them) clamp the _inwales in place while the epoxy sets. Noite spacer wedging hull to correct deck beam. Full – size (both available, price £1.10 inc. V.A.T. and post, from Model Maker Plan Service, P.O. Box 35, Bridge Street, Hemel Hempstead, Herts HP1 1EE. ae ee ORRL & SCREW (/hi 24 ON © BRASS! EVE FOR BACKSTAY (EACH SOC) The bow deck- beam layout; note epoxy fillet between inwales immediately behind stempiece. Beams in mast and hatch area. Having a flat deck with only sheer curve makes it all very easy. mI 1974

TT eee MODEL BOATS The fin in position, together with the mast step on its block on the hull floor. Note additional block in mast space to take screws of commercial mast slide. round the rudder tube as in the photograph. Also cut and fit the two triangular fillets which reinforce the joint between the fin and the deck beam, visible in another photo. Glue a block to the hull floor ready to receive the mast step and drill a ~ in. hole near one upper corner of the transom to use as a drain, and the interior work on the hull is complete. Give the interior two thoroughs coats of varnish (or paint if you prefer) remembering to brush it under the inwales and all round the deck beams, before moving on to the next step, which is the deck. More about the design nest berets Ranier section. This is a bit tedious but symmetrical rites with straight sharp edges are worth striving or. Probably the marked centre line of the bottom plank has survived so far, but if not, re-mark it carefully and measure off from the transom the positions of the skeg and fin. Check your marking before cutting out the appropriate slots; these are sare cut in the ply plank by means of a modelling nife. Both fin and skeg can be epoxied in place, taking particular care that they are both truly vertical and absolutely in line. Both have a notch at the top which locates on a deck beam. Because of the flat bottom plank, it is possible to check with a trysquare or set-square (check both sides), but you should also stand away from the model and sight the two components as an additional safeguard. Leave to set off thoroughly. It is probably as well to fit the rudder tube (or trunk) as a next step. This is a length of 4 in. brass tube which epoxies to the rear of the inside part of the skeg and should finish up flush with the outside surface of the bottom plank and the deck, i.e. it will need to project zs in. above the deck-beam level to allow for the thickness of the deck. Drill a hole say vs in. through the bottom, hard against the skeg, and open it with a rat-tail file to accept the tube. A slight concavity in the after edge of the skeg can be worked in at the same time. The tube can be epoxied in place and held with Sellotape while the epoxy sets; while mixing, make enough glue up to run a fillet round the inside joint of fin and skeg. If a Roberts upper pintle is to be used (or any similar fitting) cut a small block to fit It is already clear that we should be seeing a lot of boats built to the Genie design since orders have been flowing in since publication of our last issue. One comment from an experienced yachtsman is that the jib was perhaps slightly smaller than currently used on Marbleheads. In recent years there has been a tendency to have a much greater proportion of the area in the jib, but in_some cases this has been found a slight handicap with radio control models. Some reference to the disadvantage of a large jib was made in our May issue last year. We have heard of devices fitted on some. North American R/C yachts called ‘jib twitchers’, the function of which is to put the jib over to get the boat’s head round quickly when tacking or rounding a mark. Since Genie is likely to attract many beginners, complications such as this, involving a third servo etc., seem undesirable and we have therefore kept the same sort of area relationship between jib and main as was common in Marbleheads four or five years ago and is indeed still used in perhaps the majority of boats. Naturally anyone building the model with strong ideas on the subject is per- fectly at liberty to change the sail plan, but so far the indications are that the sails as drawn are a happy combination with the hull. Despite the light weight of 15} lb, the use of a bulb and a 133 in. draught makes the boat reasonably stiff though it would probably be necessary to change from the high aspect ratio rig to the working suit perhaps one or two m.p.h. windspeed sooner than a heavier and more powerful boat. Against this must be offset the good acceleration and quick planing characteristics of our model. An interesting point is that at about 10 degrees of heel, the ‘first chine’ forms a straight keel line angled at about 34 degrees to the true centre line. The effect of this has unfortunately not been fully checked out — the prototype was finished after the end of the season and has not sailed against a competitive boat — but it can be expected to tend to steer the boat into the wind and the quite normal couple of degrees of weather helm, often used, should therefore produce a very positive trim, i.e. there should be no tendency to wander. Observation so far bears this out. Incidentally the prototype will be on show at the Model Engineer Exhibition (January Ist to 12th), together with the prototype of the 36 in. Gosling design, so that any reader tempted towards either of these models will have an opportunity of seeing them in the flesh before making up his mind. Interior of skeg fixing. Note beam for screw-on top pintle which shows through deck. also clear in blocks fore and aft of deck and projection of rudder tube Halved beam/inwale joint is this photo.

JANUARY Adjustable Trim Tabs TRIM bea | \ By K. T. James The arrangement sketched here a particular model is probably If simultaneous depression or raising of the needed, a further servo would be needed, unless movement is arrangement required to push-rod, it on the servo harmonised with ‘e gee PORT provides differentially con- RAIL corporate simultaneous change of trim with different throttle settings. The trim servo is connected to a pivoted bar from each end of which runs a push-rod to a crank arm on each tab. Swinging of the bar by the servo obviously will raise one tab and lower the other; for sensitive adjustment the further the servo arm is attached from the pivot point, the smaller the angular movement will be, and exactly what for RUDDER STBD trollable trim tabs using the third servo of a three-channel radio outfit (or ‘trim’ servo of a 2+1) and can also in- movement is needed matter of experiment. 1974 throttle opening, tabs the when coe TRIM BAR BOLTED TO PLATE PIVOT. : SLIDING PLATE PLY «+ a a OR ALUMINIUM |< is RAIL tab the bidOOD If the sliding plate is could be as sketched. move in the opposite direction to the throttle isa simple matter to use a double-ended arm with a push-rod on each end. RAIL TRIM SERVO 3rd FUNCTION —}____= THROTTLE Readers Write... Dear Sir, | read with interest about the Crystal Palace Dinghy Exhibition in the June issue — and read with interest also that Mr. Carr had expressed his views about one-design class sailing to the skippers of the MYA. Since I followed in Mr. Carr’s footsteps as the Secretary/Treasurer of the AMYA, we have had numerous conversations regarding one-design class sailing and | have also had a one-design class boat. Much of what Mr. Carr contends about one design class sailing would be true if all boats were identical in construction and were tuned identically! However, it would be a tremendous task to achieve this. Let me illustrate: While the model | was sailing was a one design class boat, there was a tolerance on the beam dimension of plus or minus .50 inches. When a boat was built to the minimum — or with a 11.00 inch beam — the displacement came out around 22.00 pounds. And when the boat was built to the maximum — or with a 12.00 inch beam — the displacement came out around 26.00 pounds. This variation in displacement occurred so the designated load waterline length of 42.5 was held. Also, since most of the sail control units were homebuilt, the weight of the R/C installation varied from 1.00 to 3.00 pounds. Now — due to the variation in overall displacement and_ variation’ in weight of the R/C installation, the lead ballast would vary from 17.00 to 23.00 pounds, This meant that there were great variations in the _ ballast/displacement ratios of the boats. There- fore were some boats tender. were stiff and some In conjunction with made from # oz, 2.2 this, sails were oz and 3.00 oz Dacron and suits varied in the degree of fullness suited for -—- so light some _ air and suits others were for heavy air, This meant that on a given day that some boats had a suit of sails that were well suited for the prevailing air while others had suits of SERVO CLIPS SERVO FOR USE WITHA 2+ 1 SYSTEM OR UP TO SIX CHANNEL THOUGHTS ON ONE-DESIGN TO ENGINE sails that were not. The net result of this variation of construction and tuning was that there was a vast difference in performance of the boats. Some were simply a fast boat while others would sit ‘glued to the pond’. The summation of all this is that when two boats are built from the same design — regardless of whether or not it is a one-design class boat or an open design class boat — each boat will have its individual characteristics and both boats will not necessarily have the same characteristics performancewise. While it would be nice to think that all boats built to a set of one-design class specification would have the same performance characteristics — i.e. the same speed over the water at a given point of time — there are simply too many variables that enter into the picture to achieve this goal, However, this is not to say that a group of beginners would not benefit from the building of a fleet of boats off the same design. For if this is undertaken and the performance of each boat studied from a design standpoint -final ballast/displacement ratio, cut of sails and weight of sail material, finish of the bottom, weight of the rig, etc, — much valuable information de- signwise can be learned. As you know, there is a_handydandy formula that says the maximum hull speed is equal to the square root of the waterline length in feet — this speed being in knots. (This maximum speed is sometimes multiplied by a factor.) Now, if this group of beginners will study all of their boats to see what must be done to each boat so this maximum hull speed is indeed reached, many valuable lessons will be learned by the group. These lessons can be learned regardless of whether you sail long enough so the boats will have a sufficient length of run to achieve maximum hull speed. 29 Mention was made at the conclusion of the article on the types of classes that should be gone into — whether to establish new one-design classes or to stay within the framework of established classes. | think that Vortex Model Engineering has taken the wise course with their Santa Barbara and their new Soling. The Santa Barbara is established as a one-design class — but the boat meets the Ten Rater class rating rule — so the skipper can sail in one-design and open design competition. Likewise, the Soling has been established as a one-design class — but the boat meets the 50/800 class rating rule — so the skipper can sail in one design and open design competition. | think the Vortex choice of design and sponsorship is excellent in all respects. Whereas skippers of boats in other classes had to find other onedesign boats of the same class to sail against, competition for those boats was limited to the areas those boats could be found, but the Santa Barbara and Soling can find competition — either one-design or open — wherever they go! : Therefore, | would suggest sticking within the framework of an open design class but establish one-design class sailing on a local level — or national — if you desire to, But — keep the design open for a bit until the de- sign is developed into a good boat! Too many AMYA one-design classes froze their design before the bugs were worked out and skippers lost interest in the classes and membership suffered. In closing, | would i like to : mention that it has been my good fortune to have MYA’s John Lewis as a guest in my home many times these last few months and the experience has been most rewarding to me both as a skipper and a designer. Greenbelt, Maryland Ben A. Hogensen

BOATS MODEL \\ More on Low pressure Sail Aerodynamics Some additional notes by the Editor post people can quite easily accept that the wind blowing into a sail produces a force which will drive a boat along. You have only to hold a sheet of card or a tablecloth out in the wind to realise how much force there is. This is, of course, what is driving a boat along when it is running, i.e. sailing downwind. However, the drive when the boat is reaching (across wind) and, particularly, beating (into wind) is less easy to grasp, since the boat is clearly being drawn along rather than ‘pushed’. The answer, without being too technical, lies in Bernoulli's Law. Stated in simplified terms, this is that energy of motion plus the energy of pressure plus the energy of weight add up to a constant; if one in- creases, One or both of the others must We are, of course, dealing with low-speed aerofoils on these courses, but we are handicapped in that they are flexible structures which have to be able to reverse their form for sailing on the other tack. Most model classes also have restrictions on battens and the like which limit the variations in shape which can be achieved unless a range of sails of different cut is carried. Changing the flow of a sail can produce changes of trim due to a change in the position of the centre of effort, so that anyone with an assortment of sails would have to be very methodical to be sure of what was likely to happen with which suit. One area in which there is always lively interest is in the elimination of the interference caused by the mast. An article last month mentioned the apparent greater efficiency of the jib, due to the absence of ob- decrease. Since considering air, we can assume weight to remain unvarying, it follows that if motion increases, pressure must decrease. Looking at a sail, Fig. 1, we see that air flowing from ahead of it parts to pass it, and rejoins at the leach. Because the sail is curved, one stream of air has further to travel and in order to avoid an area of low pressure where it rejoins the other stream, it speeds up, 1.e. its motion increases. From Bernoulli we know that this means a pressure decrease, and a decrease of only 1/100th of an ounce per square inch will provide a force of + lb. on a Marblehead, most of which is translated into forward motion. Try towing a boat with a spring balance and you will be surprised at how little force is needed to move it. The sail actually bends the airstream, upsetting direction and pressure distribution over quite a large area. In the conventional Bermuda rig, the jib bends the airstream and the mainsail thus works at a different angle of attack (assuming the sail booms are parallel, Fig. 2). The correct relationship of jib and struction to the airflow along its luff. To go into this we must first consider the flow over the sail, which can be laminar or turbulent (Fig. 6). At the speeds with which we are concerned, we can learn a lot from, particularly, model sailplane enthusiasts, many of whom use ‘turbulators’ to induce a turbulent flow across their wings. Experience indicates that very tiny rolls of turbulence across the upper surface (Fig. 7) tend to ‘stick’ the airflow to the aerofoil for more of the chord than might otherwise be the case; this has the effect of increasing the lift (by bending the airflow more because of the greater effective distance) and reducing the drag, by reducing in size the turbulence rolls in the breakaway area. Turbulators take two forms, either a thread cemented to the aerofoil surface just behind the leading edge (the position is quite critical) or a nylon monofilament carried on tiny outriggers ahead of and above the leading edge; again, the position is critical airflow is thus vitally important. The extremes of trim are usually clearly visible; either the boat sails on the jib alone, with the main obviously contributing no drive, or the main can be seen to be blown out of shape by the bend of the airstream off the jib depressing the curve of the main, known as ‘backwinding’. (Figs. 3 and 4.) On a reaching course, both sails are providing ‘lift’ independently, as far as they can, since there must be some interaction between the higher pressure on the aft face of the jib and the lower pressure on the foreside of the main (Fig. 5). On this course, the lift or thrust of the sails is most nearly parallel to the centre line of the hull and, all other factors being equal, the boat should be at its fastest. 36

1974 JANUARY cambered aerofoil can create an area of turbulence beneath the leading edge at speeds above about 5 m.p.h.; filleting this section in with a blister smooths the flow and greatly increases the efficiency (Fig. 10). Some of the best performances nowadays are achieved with a Jedelsky wing (Fig. 11) which is of this general form and operates excellently at speeds of around (Fig. 8). The diameter of the thread or nylon is 1 mm. 15 m.p.h. The final sketch shows a symmetrical mast or less, yet its effect is very noticeable. The effect of fairing (rotating on a tubular core) which would prob- a mast of + in. diameter or more may be imagined. Wing masts and double-luff sails are both methods used to try to eliminate the harmful interference from a conventional mast. A further method of improving efficiency is to bury the sail luff in a groove in the mast to prevent any leakage of air from the high to the low pressure sides through the gap which usually ably produce the most efficient mast/sail shape for beating and reaching. Whether it would also be worth giving the jib a similar section (remembering the weight disadvantage) could only be determined in practice; provided the weight was kept to a minimum and a powerful hull was used, it should be well worth trying. exists between mast and sail with conventional rigs (Fig. 9). A double-luff sail also eliminates this air leakage and also goes some way to streamlining the airflow behind the mast. However, it leaves something to be desired as a leading edge shape for an efficient aerofoil. A wing mast has some advantages aerodynamically but can be slightly difficult structurally and is bound to carry the penalty of unwanted weight high up. Its advantages can be lost if the mast and sail together do not make a smooth aerofoil shape, or if it cannot rotate as easily as the sail can flap, but designed, made, and operating properly, it should show a worthwhile gain over a conventional sail. Experience with single-surface aircraft wings suggests that air striking the sharp edge of an under- EO (- le FIG. 11 =. Jedelsky section c e FIG, 12 SE ROUND THE REGATTAS — and other club activities JASON Very attractive tug model entered in R/C scale at the St. Albans weekend. Though we hung about, we failed to make contact with the owner. Nice, though. ro WELSH INTERNATIONAL OPEN WATER REGATTA, PORT TALBOT DOCKS, 26th AUGUST, 1973 The weather was warm and sunny with a nice breeze making conditions perfect over the three and a quarter mile course. With a total entry of 52 covering the three 6 20 secs.; 2nd, B. Minton (R.R. 3rd, M. Bray (Gwent up to 35 c.c.: 1st, M.B.C.), N. 6 min. Morris (Port EASTBOURNE M.P.B.C., 9th SEPTEMER, 1973 The weather was fine, sunny and very little wind, Water was calm, very unusual for this lake. 22 competitors took part in the day’s events. First was the Ald, F. Taylor Trophy for steering, There was some very good steering which was on the Naviga course, John Bennett being the winner with 141 points, Second place resulted in a tie between young Peter Palmer and J. May with his very Results and details as follows: Class A 0O to 5 c.c.: 1st, K. Harrison (R.R. Derby), 7 min. 17 secs.; 2nd, J. Pallett (Stevenage), 7 min. 58 secs.; 3rd, lan Boyle (Stevenage), 8 min. 38 secs. Class B over 5 c.c. up to 10 c.c.: ist, S. Harris (Gwent min, secs.; Class C over 10 c.c. giving. 6 31 Talbot), 6 min. 26 secs.; 2nd, D. Hill (Kingfisher), 8 min. 5 secs.; 3rd, lan Boyle (Stevenage), 8 min, 8 secs. Concours Cup: P. Allen with Cat-o-three tails. Ladies Prize: Sandra Harris (also fastest time of day). classes, three boat heats were run continuously to bring the event to a close at five thirty resulting in an overall win by a lady competitor, Sandra Harris of the Gwent Club, and leaving a lot of red faces amongst the men and cries of ‘women’s lib’ from the other ladies during prize- M.B.C.), min. 32 secs. Derby), 37

JANUARY 1974 interested in model yachting of any sort in the South Wales or Bristol area should contact the secretary Courtney Coleman, 128 Ael-y-Bryn, Llanedeyrn, Cyncoed, Cardiff, who will be pleased to tell you about the South Wales Model Yacht Club. At the Model Maker Trophy each year the furthest travelled get a special prize. The M.Y.A. has no such prize, so a special mention should be made of Gordon Keeley’s keenness in travelling all the way down from Newcastle to help man this exhibition. The publicity officer would like to take this opportunity of thanking all those who took part. (The M.Y.A. would also like to thank the Publicity Officer, R. Stollery no less, to whose flair and effort much of the success of the stand is owed. The stand was beautifully laid out, really professional in its pre- sentation, and lost nothing in comparison R.Y.A. stand alongside. Well done indeed.) to the R/C Yachts at Birkenhead Early in the past season, a visit to Birkenhead M.Y.P.B.C. was made by the Warrington club, who sail radio-controlled 10-raters, and quite a few vane skippers, including visitors from Midlands clubs, had their first taste of radio sailing. Birkenhead members were interested in going in for radio, and partly as a result of this visit some six or seven radio Marbleheads are on the way. Conversely, the Warrington members were able to pick up a lot of ideas for improving their boats, and this club has now affiliated to the M.Y.A. Obviously a valuable bit of co-operation between the two clubs; everyone enjoyed it immensely, even though some spoilsport stopped a wellknown skipper from walking off the bank into the lake, so great was his concentration! The photograph, top right, shows one of the Warrington Red Herring type boats. The other picture was taken during the Birkenhead Parks Committee Cup race; Walter Jones watches his mate Bill Perry field Black Tarquin, while in the background Spinaway is lifted out. The latter retained the Cup, against quite hot opposition. (Photos M. E. Browne) Constant-position Buoys Competition enthusiasts will like this idea for constant-position buoys from the East German magazine Modellbau. A is plastic bottle part-filled with sand and tied to the eye of a pulley block B. The anchor weight C carries a line which passes over the pulley and is wound on a plastic spool D. Clipped to the line by a safety-pin type clip is a weight not exceeding one-third of the anchor weight; the line needs to be locked on the spool once the right amount has been unrolled. Non-critical to set up and easy to re- trieve; neat.