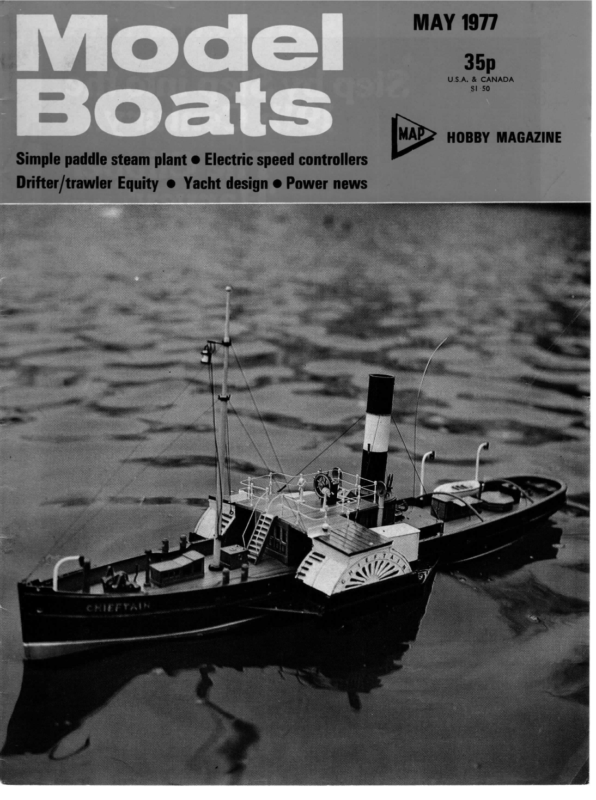

MAY 1977 | 35p U.S.A. & CANADA $1-50 HOBBY MAGAZINE Simple paddle steam plant @ Electric speed controllers Drifter/trawler Equity @ Yacht design @ Power news

MAY N One Approach to Yacht Design, April Model Boats, comment was made that good design should not be compromised for the sake of numerical value. And so it was when the lines were drawn for Tiny Tim. It was found that when a bit of area was added to the sections at Sta 4 and Sta 5 so that the beam at the load water line was increased, a stiffer hull would result. And, since there was a bit of excess area allotted to Sta 7 and Sta 8 to be used in the bustle, it was possible to add the area to Sta 4 and Sta 5 without increasing the displacement. The net result was a slight reduction in the value of the prismatic coefficient and the centre of buoyancy moved slightly forward. So although the calculations were altered, the intent of the design had not been changed — a ee displacement boat sailing on a 52-0in load water ine. While the method given in One Approach to Design is simple and easy to use, there is also another method that I use quite often. Daniels and Tucker in Model Sailing Craft (Rudder Publishing Company, 1932), suggest that once the dis- placement has been determined for a design, a portion of that displacement be subtracted from the overall displacement, the result be allotted to the canoe body, and the amount subtracted be allotted to the appendages (fin, skeg and rudder). When Derarro was designed for Rod Adams of Tasmania, this system was used as follows: the canoe body was drawn up with the 52-0in load water line specified by Rod, a master section that gave a 14-00in load water line beam was drawn in and the lines faired. After the canoe body was faired, the displacement and centre of buoyancy was calculated as follows: Sta. No. 1. 2 3. 4, 5: 6 Te 8. Area 000:000 5-375 21:250 39-375 48-460 41-230 28:590 12-74 XSM = Product 1 4 2 4 2 4 2 4 xSM = Moment 000-000 21-500 42-500 157-500 96-920 164-920 57-180 50-960 0 1 2 3 4 5 6 a 000-000 21-500 85-000 472-500 387-600 824-600 343-080 365-720 Sum of Products = 591-480 Sum of Moments = 2491.080 Displacement canoe body M omen tA = = = 92:0 591480 _ 1981 +146cuin 24:0 52-0 x 2491-080 85 591-480 = 27-375 : inches inches. Since the canoe body was designed to settle, giving a sailing length between 66-00 and 68-00, it was decided to could be very significant since it could be packed in soundproofing material. By far the most impressive of the three products tried so far is the exhaust connector material. Seven or eight years ago, I found no problem in making silicone tubing last a whole season on an exhaust system. Higher powered Schneurle ported engines at hotter temperatures, however, have shown that silicone rubber is no longer the best material. The teflon type material supplied by Racing Models shows none of the problems of burning or splitting characteristic of silicone, even if fitted over sharp edges of pipes. Three sizes are available and these can be stretched to fit the exhaust system by warming in a flame. All three of my i.c. multiboats were fitted with the new connectors at the earliest possible chance and problems of blown exhaust have entirely disappeared. Note that it is not necessary to use a clamp to seal the exhaust, as long as the 255 1977 A Second Approtch Another method of designing a yacht hull from predetermined values. by Ben A. Hogensen use the maximum displacement for the load water line length. The cube root for the displacement was calculated as follows: pis = 229 + 19= 11-40, max 5 The displacement in cubic inches for the whole model was calculated from the above root as follows: Displacement = 11-40? = 1481-544 cubic inches. By simple subtraction, the displacement for the appendages was found: Displacement del Displ. _ canoe body Displ. appendages = 1481-544 = 1281-146 ——_ . = 200-398 cubic inches. All that remained at this point was to draw in the appendages using the calculated displacement for them. And when this was done, the lines for the hull were complete. For the skipper who is interested in the 50/800 Class, this method is quite adaptable to the design of a boat with a fin and bulb keel. A suggested method is to draw the desired canoe body after finding out the displacement in cubic inches for the design and proportioning out how much is to be used in the canoe body and to be used in the appendages. The volume of the ballast — or displacement if you prefer — is calculated next using the following formula: Displacement ballast =Weight of ballast 0-411 Note: It is better to use 0-411 for the weight per cubic inch for lead than to use 0-400! Once the displacement for the ballast has been determined, the balance of the displacement can be allotted to the fin, rudder and skeg (if a skeg is used). Again, the offer is made, if I can be of further help, a letter to me at Box 218, Greenbelt, Maryland, 20770, USA, will bring a prompt response. silencer is prevented from being blown away from the manifold by the back pressure. The third item tested was a coupling consisting of two drive dogs and a plastic disc insert. (Apologies for the lack of a photo.) This is claimed to be quieter than the conventional ball and socket joint, although any difference would not be noticeable until the rest of the model was quiet. The coupling allows for some end play in the prop shaft and will therefore prevent thrust from reaching the motor which is highly desirable with some motors. Fitted to my K & B 40, the test coupling has worked very well despite a number of crunches, demonstrating a remarkable strength. A life of several years can be expected judging by the lack of any sign of wear. The standard sizes of drive dogs are for a plain 3/16in prop shaft and a tin UNF threaded crankshaft which covers a very wide range of motors. Other products will be reviewed in future articles.

MODEL BOATS KRISPIE Part Five of a 36in yacht made from inexpensive materials, the subject of our Christmas free plan. Deck fittings, mast, booms, rigging. by Vic Smeed i Is as well to leave the lead unsecured to the fin until the model is almost completed and can be subjected to flotation tests. It may be that a fraction of movement fore and aft will be welcome to ensure the correct waterline, depending on how your weight disposition came out, weight of a particular vane gear, or whatever. The four main deck fittings are the jib rack, mast step, and shroud plates, and all can be made from scraps of brass curtain rail or similar T or angle material; if in difficulty, sheet brass could be bent for the shroud plates, or flat plates used as an alternative. Two pieces of angle can be bolted or soldered together (preferably silver soldered) to make a T section. These four fittings are screwed (into the hull frame members) with 2in No. 2 screws. All remaining deck fittings are simply small screweyes, two on the centre line for jib and main sheets, one either side at the stern for the split backstay, and two to port of the centre line for the sheeting jackline. An optional one can be screwed in the stemhead for a forestay, but this is not really n z One other consideration arises with the hull, if a vane is to be fitted, and that is clearance for the vane feather when the boat is off the wind. In a 36in yacht the mainboom extends well aft, so that the backstay to the mast has to be u well aft, too, to avoid impeding the swing of the boom. Unfortunately this rather crowds the vane feather, and in order to give this a clear swing it is usual to have the pintle on which it pivots right on the transom, or even on an outrigger, which is allowed by the rules. The difficulty is that when the boat is travelling downwind, with the vane feather pointing forward, this is just the time when the backstay is needed. Havinga split stay, that is, one which divides into — as : — = two tails secured each side of the hull, eases the problem to some extent. A simple, basic vane, adapted from one we published some years ago, will be shown next month. This problem does not of course arise with radio installation, where a single backstay can be run to the:centre line at the top of the transom. The mast is a length of 4in aluminium or dural tube with a notch at the base fitting snugly over the mast step and a hole drilled through for a locating bolt; 8 BA is adequate. Immediately above the notch drill a small hole right through, form an eye on a short piece of 18g stainless steel wire, pass through the hole, and make off into another eye. The aft eye takes the lower end of the kicking strap and the sail luff tension cord, and the fore eye is either simply to prevent the wire pulling out or, for vane sailing, to attach the spinnaker downhaul. Moving upward, the gooseneck plate is a piece of Tufnol or similar plastic; if really stuck for material, a piece of fin ply could be used but would not last as well, though if wear was severe, brass tube bushes could no doubt be epoxied in the holes. If the appropriate area of the mast is roughened, epoxy should hold perfectly well, but as an additional safeguard a small hole could be drilled through the front of the plate into the mast, and a wire or fine screw epoxied in place. Moving to the top of the mast, the jumper strut is simply a piece of thick wall 3/16in tube or it could be a piece of T section aluminium, etc. It takes a fair strain when the wind is behind the boat and the backstay is in tension. The remaining jobs on the mast are simply small holes for the top and bottom of the jackstay and three 1/16in holes for the shrouds and jibstay, plus additional holes for the jibstays of smaller suits. The jackstay is a length of 28 or 30 gauge s/s wire which is threaded through a hole just above the gooseneck and “‘knotted off”. The upper end is poked througha similar hole a couple of inches below the mast head and also knotted off. If a friend can be induced to spring the mast slightly when finishing off the top end, when the mast straightens the jackstay will be drawn % a Photographs depict similar rigging arrangements used on a previous 36in yacht. Left, mast step, main boom gooseneck, kicking strap, Flattened jib boom end and shroud plates. Above, jibstay rigging and a luff hook on the sail, which runs up and down the jackstay. 270

MAY completely taut. It will later be secured by five or six against a wall it is possible to rig it without assistance, lengths of plastic tape wound round the mast to hold the wire tightly against it, but it is best to leave positioning these tapes until the sails are made or obtained and the simply by placing the mast on its step and slipping the appropriate bolt through, then leaning the mast against the wall while the four basic lines are attached. The backstay can be made of braided fishing line and should comprise a section of about four feet fitted with a hook at each end and doubled back into a bowsie. The top hook engages the jumper strut and the bottom hook in the centre of a length of line about 3ft in total length tied off to the two backstay screweyes at the stern of the boat. Wire is better for theshrouds, about 26 gauge being more than adequate for this model, and to avoid the expense of turnbuckles to tension the shrouds it is possible for the bottom three or four inches to be cord with bowsie adjustment. The top end of each shroud is made off into a V hook engaging in the appropriate hole in the mast, and the short cord is also passed through a hook which engages in the shroud plate. Unfortunately the mast will still not stand by itself until the attachment of the jibstay, and the jibstay hooks into the tack eye on the jib boom, so that it is necessary to form the S hook for the boom attachment, using for preference 18 gauge s/s wire. The jib sail must be bent to the boom in order that the stay can be tightened, and the backstay and es ad be marked out to fall between the luff hooks on e sail. It goes without saying that the jackstay should run centrally up the mast in line with the pivot hole of the gooseneck, which in turn must be aligned with the notches at the mast heel; the shroud holes should be accurately placed on either side and the jumper strut should also be aligned so that all is square when the mast is rigged. The next job is the booms for jib and main, and the jib boom has one end flattened in a smooth jaw vice and just over two inches from the tack end the tube is squeezed from top and bottom in turn in the corner of the vice to leave a flat area without distorting the straightness of the boom. A series of holes is now drilled in the flattened areas as shown in the drawing and a wire eye fitted in the tack end. If preferred, the tack end could also be squeezed in the vice for a short distance and a hole drilled through rather than a separate wire eye fitted. Similar treatment is required for the outer end of the main boom and an eye should be fitted as shown on the | © (ore. TOSTUD ACCEPT EX <> BRASS LAMP FITTING. PINNAKER PIVOT INTERMEDIATE TOPMAST aA BA es, envee nig GOOSENECK PLATE 1/4″ TUFNOL OR PLASTIC 3/16″ TUBE, EPOXY: EYE FO R NOTCH TO FIT OVER = 1977 HARDWOOD OR TUBE PLUGS ir iN ” * ae +. “JUMPER STRUT MaiNSAlL UPHAUL iit i JIB SHEET —=y drawing, together with a 1/16in hole beneath the boom for the kicking strap hook. The gooseneck end needs to be sawn and filed out to accept either a stout wire eye or a brass stud taken from a scrap electric lamp socket. The fingers left on the boom must be drilled and a wire or 8 BA bolt fitted through the fingers and the pivot pin. One other boom is required for vane sailing, for setting a spinnaker, and this can be made from a piece or spruce or similar timber with a wire pivot bound at the inboard end to slip into the side eyes of the gooseneck plate. The outer end requires eyes or wire loops to be fitted on all four sides to receive the four lines which control the spinnaker boom setting. Apart from hooks and bowsies this completes the basic fittings, unless you propose to sail the model under all conditions, in which case it would be necessary to make the mast length adjustable by having a plug-in topmast carrying the jumper strut and two different length intermediate tubes, also fitted with plugs, so that three mast lengths to suit the various sails may be selected. One difficulty with deck-stepped masts is that it often needs three hands to set them up, but if the boat is leant / shrouds then tightened up until the mast is vertical from all points of view. The sail has a hook to engage in the tack eye, and one in the clew to hook into one of the eyes at the outer end of the boom. Its head requires a short bowsied line and a hook which engages in the eye of the V hook fitted to the jibstay. The effect of this is that the jibstay tension pulls up on the tack end of the boom, which pivots through its S hook and puts the leach of the sail in tension, while the tension in the luff of the jib is adjustable by the bowsied line which secures its head. Hooks on the luff clip the sail to the jibstay. The mainsail has its clew hooked to the boom in the same way as the jib, and its head hooks into the small hole shown beneath the jumper strut, with a very short line. Its tack is hooked to a line passing through the gooseneck plate and through the bottom eye on the mast, returning to be made off in a bowsie, so that when the bowsie is pulled up the sail luff is tensioned. This may require a little adjustment to the short line attached to the sail head. As with the jib, it has hooks along the luff, which are hooked to the jackstay to secure the sail, but the tension on the leach is obtained by means of a cord and bowsie kicking strap. 271

MODEL BOATS Readers’ Ideas which may help your modelling, on sail, power T = and scale. VASBES enthusiast Guy Batho provides the first two tips on R/C yachting, both concerned with rudder linkages. On boats which have internal rudder operating gear, a hatch is usually provided over the rudder post to facilitate fitting and locking the rudder arm to the post. This extra hatch adds weight and may not be completely watertight. It is unnecessary, provided it is possible to reach with the fingers to the rudder post inside the hull via the main hatch. This is certainly possible with all RA and RM boats, but possibly not with the very long R10R class. Locking the arm to the post is achieved by means of a short length of rod with a knob at one end which can be turned with the fingers. It is threaded at the other end to engage with a tapped hole in the boss of the rudder arm, and is tightened against a flat filed at a convenient angle on the top half inch or so of the post, as shown in Figure 1. The linkage is, of course, attached to the hole in the arm before the arm is attached to the post. If no knob is available, the short length of rod can simply be bent at right angles to provide a handle. Plugmoulds from plaster and sawdust From Warrington reader, Mervyn Pugh, a hint for modellers who use plaster and paper balls to make plug moulds. One of the problems is the vast amount of plaster one needs and the fact that sometimes the paper balls or scrap will collapse, leaving holes which have to be filled. A method of making this type of mould which is cheaper, less likely to fail and has the advantage of easily obtainable material, is to use wall plaster sold in D.I-Y. shops in small bags for small repairs. This is normally fairly fast drying. With this plaster, sawdust is mixed about half and half when dry. Water is added in the normal way but the mould should be shallower by around Hin from the true line that you wish the finished mould to be. The last din is filled with moulding plaster or plaster of paris and finished in the normal way. You will find that wall plaster is cheaper than plaster of paris (you can get it in bigger bags), it is easy to obtain (D.I.Y.), and the sawdust can be got from the same place, at the most they will charge a few pence for a bag. LINKAGE BRASS BOSS SHORT THREADED | ROD < KNOB a= Fig. 1 os i of 1 ap LJ ‘TAPPED HOLE \ _ KNOB EASILY REA CHED VIA HOLE FOR RUDDER POST | ALTERNATIVE TO MIDSHIPS HATCH 2S z - 45° NIN BOSS Y RUDDER SOLDERED TO ARM KNOB The second tip may help skippers of R/C sailing boats, who are now fitting their steering servos close to the rudder post in order to avoid having a long flexible linkage from a servo in the usual mid-ships radio box. Guy learnt in the early days of radio controlled aircraft that it was customary to prevent the rather long linkages from bending, by lashing them with thin string to a length of tin square balsa. This added very little weight and can be protected by clear dope or varnish. He copies the idea and has used it on his RA boat with no trouble for many years. The advantages of having the steering servo inside a nice watertight radio box are obvious. It is not easy to make the servo itself waterproof and those who have to leave their boats in a damp garage or shed should bring a// radio equipment indoors when not in use. 274 ae RUDDER POST FILED FLAT - at Fuel Proof Finish A tip for power boaters using i.c. engines is Mervyn’s second offering. Most people when painting a wooden boat will proof it with one of the commercial mixtures, which can be expensive, if only because they use both paint and proofing. To keep the cost down and to cut the time needed for both paint and proofing to dry, one can use polyurethane based paints. They are very hard wearing and are proof against oils and fuels. There are more than enough colours and shades to satisfy the normal modeller and they will mix together if needed. These paints go under many trade names and can be bought anywhere, including the large chain stores. You might even have the odd tin left from the last painting job around the house.

MAY Another use for polyurethane paint is in the finishing of plug moulds prior to application of the gel coat. The plaster used in the moulds is of course porous and will need sealing. The paint will do this and an added bonus is that an excellent finish can be obtained ready for the gel coat, and hence that really nice shining hull. According to Mervyn, the polyurethane is not affected by the resin used in glass fibre work, but test it first by painting a bit of scrap wood, leave it to dry hard and then paint with resin. Silencer Cleaning Also for power boaters using petrol engines, Mervyn suggests a well tried method, used in the motor cycle world, of cleaning silencers and exhaust systems. Engines are in the main, two stroke, and they of course run on a fuel mixture of petrol and oil. After the oil has done its job of lubricating the engine bearing surfaces, the engine throws the surplus out via the exhaust system and a great part of this oil will collect in the silencer, where part of it will be burnt into carbon by the passing hot exhaust gasses; the remainder will lie like a gluey mass. This, together with the carbon, will over a period of time choke the silencer, making the engine run badly and in very bad cases even stop the engine from running altogether. The answer lies in the silencer; if possible fit one that can be broken down for cleaning or if using a commercial type then try and modify same for cleaning. The motor cyclist, who ran two strokes, used a solution of hot water and caustic soda. Place the silencer or parts in same and boil for half an hour, reboil in clean water before use, and remember that caustic soda in solution is very corrosive, more so when the solution is hot. Wear rubber gloves, and wash any splashes on skin copiously with water. The silencer will need to be taken out of the boat for cleaning, so remember when building to make the exhaust system removable. Book Review W: live in an age that has seen the growth of a cult of collecting, perhaps worship, of the past work of man. Allied with this interest in the past is the current fashion of reproducing by facsimile old copies of the classics, technical and other books. Having entered this part of the publishing industry with facsimiles of early volumes of the Model Engineer and Model Railway News, Argus Books of Watford have now reproduced Volume 1 of Ships and Ship Models. This journal was first issued in September 1931 and continued until April, 1940, when it was forced by war paper rationing to cease publication temporarily. After the cessation of hostilities, Percival Marshall replaced the magazine with another, Model Ships and Power Boats, the format, though on larger pages was very similar and indeed with the January 1954 issue, it reverted to the original title Ships and Ship Models. The Editor of the publication through the changes of title was Edward Bowness, AINA. The original page size and layout of Ships and Ship Models was the same as the sister Percival Marshall magazine, Model Railway News, and after resuming publication, page layout and size followed that of Model Engineer; Edward Bowness was a staff member of that publication. Never a best seller, publication ceased at the end of 1956, owing to the lack of support, bemoaned of course by 275 1977 It is hard to say how long a silencer can be run before it needs cleaning, as it depends on the fuel mixture, running temperature and oil type. However, as an instance, on a local lake there is a petrol engined boat that runs most Sundays. The engine is nearly new and has very few running hours to its credit, the fuel mixture has always been as per the manufacturers hand book, the silencer is home made and is in fact a very good copy of one sold by the manufacturer of another petrol engine which is of larger capacity. The silencer has one fault; it cannot be broken down for cleaning and this engine is already showing signs of the silencer being choked with unused oil from the engine. Perhaps the manufacturers of model silencers will get round to putting on the market, a light but not too large, break-down silencer suited to both the model boat and the modellers pocket. Until then we will have to remember to keep our pipes clean. Smoke Generation Finally, for the scale buff, Paul Sutcliffe from Tyne and Wear has found a quicker, easier and cheaper way of getting smoke to come out of a ships funnel, using a car lighter element and an oil drip, and would like to share the idea with other modellers. He bought some charcoal sticks which are used for hand warmers for fishermen and are lit and put into a case, the sticks of charcoal can be bought for about 50p to 60p. Simply break one into two or three parts, light with a lighter or match until it glows red and then blow on it. Then place them in a heatproof funnel and drop in a little 3 in 1 oil. There you have it, instant smoke for half-an-hour or more. To keep them going simply drop oil on to them again. If your funnel is a deep one, block it off about 14in in so the charcoal sticks are near the top and in the wind (which keeps them burning). An old car exhaust pipe was used by Paul for the funnel on his T.I.D. Class tug. all those who, during its lifetime, had not supported the publication. If the foregoing history differs from that printed in the reproduction then it can only be remarked that a little more research should have been forthcoming before printing. Designed to interest the ship modeller and follower of marine lore, there is much to interest them in this reproduction as items of curiosity, but since most of the modelling copy has been seen elsewhere, apart from this aspect, it has little more to offer. There are many items concerning the sea and ships that will be found of interest and the book is well made. The pages compare with the original well and the binding is good. The dust cover has a reproduction of the original cover with some advertisements on the back cover. It would have been vastly improved if the covers and adverts had been reproduced and bound in the volume. Comparing the reproduction with an original it was obvious that much was lost by not including the index and also a full set of supplements, only two of the latter being bound in. For those who would like copies of this first volume perhaps to fill gaps in a set, to see what pre-war ship model publications were like and are prepared to accept these few failings, the reproduced Ships and Ship Models will serve them well. Like all books today this is not cheap, being priced at £6.75 which, on the face of it, compares unfavourably with the bound volume price of 9s 3d in the August, 1932 issue. But is it after all? The price is almost 50p and prices have surely risen by more than twelve times since then. We understand that this is the first of a series and hope that the publishers include in all the following volumes the items omitted in the first one J.K.

MODEL BOATS many details were passed over to me, but this sounds interesting and as soon as more details are known I will pass them on. One or two people have made enquiries regarding the Dutch International, so for their benefit and any others that might like a trip, here are the details. The regatta will cater for classes F1V (all), F2A/B/C, F3E, F3V, FSR 15, FSR 33. The dates are 19th, 21st and 22nd May. Registration will take place each morning before racing starts. Entry is required before 28th April with 7.50 guilders senior, 4.0 juniors per boat per class. Valid transmitting and MPBA licences are required, only six frequencies are allowed and anyone interested can get entry form and condition of entry from me at PO Box 35, Hemel Hempstead. From all accounts the recent multiboat section meeting achieved most of the objects that its sponsors set out to do. Since I was not able to be present I rely on others to put me in the picture and this can be enlightening as one gets more than one view of the happenings. Like all similar meetings, much hard talking seems to have taken place and it is a good thing to give diverging views an airing. With all the enthusiasm generated, we hope that results of the efforts of the new section will be rewarding, and we look forward to hearing what they propose in the way of reforms, new ideas, etc., so that all those who were not able to be present at the inaugural meeting can study them and add their thoughts at other MPBA meetings, or express their feeling when propositions come up for voting by the membership at large. A policy for selection for the 1978 and 1980 World Endurance Championship was discussed and some firm ideas formulated. A registration date, Ist February, 1978, was agreed so intending contenders now know that they have to make up their minds before then. Almost a year but there will, as usual, be many still unsure on the 31st January. A series of two hour eliminating events will be held prior to the championships to select those who will represent their country in the championships. A good move, and I do hope that all those entering will be serious contenders in more ways than one. While not wishing to discourage anyone it needs remarking that only too often some people, without a chance, put their names forward and in so doing make life somewhat tedious for the other competitors and the organisers. Chairman of the new section is Roger Burrell of the Midland Area and Secretary is Paul Firmin, whose address is 53 Parkwood Road, Boscombe, Hants, and I am sure all wish them well in ensuring the success of this new venture. cea Jim King MICHAEL’S MODELS Saeed 646-648 HIGH ROAD, NCHLEY f N. FINCHLEY, LONDON N12 0NL BILLING BOATS Quality Plank on Frame Kits Fittings in Brass and Plastic All Kits listed are suitable for R/C Kit Fittings 32in. Progress, Northsea Trawler £12.75 £17.25 3lin. Zwarte Zee. Oceangoing Tug £13.95 £13.95 38in. Mercantic. Modern Freighter Rae £15.95 £18.75 22in. Krabbenkutter. Inshore Shrimpboat £10.75 £12.00 22in. Gina. Inshore Side Trawler ... we £8.50 £9.00 34in. Neptune. 1930’s Luxury Cruiser ... £10.00 £10.75 28in. Sea King. Modern Cruiser. ABS Hull ... £19.85 £5.55 Beautifully Illustrated Catalogue 85p post paid Most Billing Fittings available separately from stock Open Six Days a Week 9.00-6.00 MAIL ORDER — PARK OUTSIDE _ 011-445-6531 S.A.E. with all enquiries “ASHANTI” Chosen by both first and second place skippers and many more at the R.M. Championships. Displacement 14.3 Ibs and easily to-day’s most consistently successful R.M. Now available in the following packages, with instructions, to assemble into a complete boat in as little as a day. (1) (2) (3) Hull, fin and deck in one piece G.R.P. moulding with all internal stiffening, hatch with coaming and cover and rudder tube fitted. Colours: White, black, red, blue, green, orange and yellow: £48.60 inc. VAT+ P&P £2.50. Two tone with contrasting deck colour: £59.40 inc. VAT--P&P £2.50. Customised colour schemes including moulded-in name: Price by quotation. Also.now available in the above forms: Rudder G.R.P. moulding with stock fitted: £3.24 inc. VAT+ P&P 50p. Fittings, masts, booms and rigging. Complete set of fittings and rigging to complete RIOR “Eclipse” L.O.A. 69.3in. L.W.L. 58in. Disp 16.7 Ibs. the boat above deck level. De-Luxe for keel stepped mast Standard for deck stepped mast (4) (5) = = Specification £22.68 inc. VAT-- P&P £1.00 £12.96 inc. VAT+ P&P £1.00 Contact: Lead bulb. Cost with slot ready to fit to fin: £7.56 inc. VAT-- P&P £1.00. Sails by Number One Sails, superbly cut and panelled to give optimum flow and leach tension. High Aspect Rig 8lin. Luff: Working Rig _67in. Luff: Other rigs on quotation. £9.72 inc. VAT+ P&P £1.00 £8.64 inc. VAT-+ P&P £1.00 iy RL and prices on request. DAVE HOLLOM AT SEALPLAN LTD., DEPT M.B.3, ACRE MILLS, ACRE LANE, WIBSEY, BRADFORD 6, YORKS. Postage and packing complete kit less lead bulb £2.50. CE 36in Restricted Class “Jiminy Cricket” L.O.A. 36in L.W.L. 36in Disp 8.00 Ibs. Tel: 0274 492742 ee 278 i eh. en