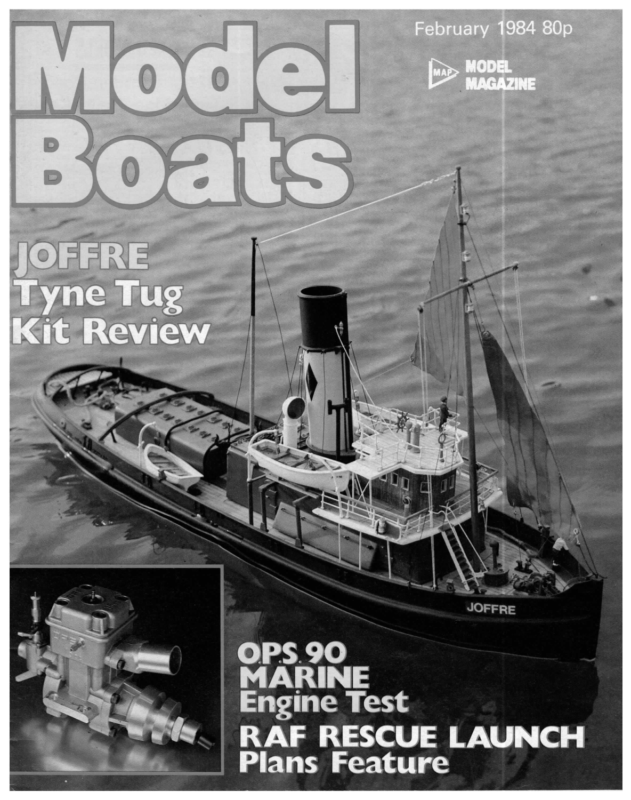

MARINE Engine Test RAF RESCUE LAUNCH Plans Feature

SIKRTING IN SAILIN Vic Smeed takes a /ook at leads, their design and construction NE THING that is near enough a certainty is that any model yacht will carry ballast, and it is rare for itto be anything but lead. Since the subject is yachts, immedi- ately up pop exceptions: multi-hull craft often use no ballast, and the 575 kit in- structions suggest sand/cement. The Starlet design often years ago(stilla popular non-class radio model and in fact a class in the U.S.A.) when first published offered cast-iron ballast — some 100sets werecast for us by a local foundry and snapped up ina matter of two or three weeks — but only because iron was a quarter of the price and there is a local foundry. However, the normal conventionally mono-hull yacht carries lead ballast and moves are afoot to ensure that lead is about the densest material that can be used. There are people who can obtain exhausted up for the width of the saw-cut. This piece was then used as a pattern for casting the lead. Two vertical lengths of brass or bronze studding, or rods with screwed ends, were often cast in, of a length sufficient to pass upper fin through the remaining laminations, to secure the lead in place and reinforce the upper laminations. An alternative was to drill two holes through the lead, with counterbores on the sole, and pass through two rods with cones or nuts brazed to their bottom ends, the cones or nuts being driven into the counterbores and the sole made good with filler. Rule modifications in the 1960s eliminated specific bans on bulb keels and they began to appear in, notably, the Marblehead class, although initially the approach was simply to concentrate the lead ina ‘torpedo’ attached to the bottom of a fin of ment, there is positive pressure on the leeward side andaslight pressure reduction on the opposite side. Thus there is a tendency for leakage to take place from high and low pressure, mostly round the bottom of the fin. Exactly as in sails, this biases the flowlines on either side, downward on the high pressure and upward on the low pressure side. The waterstreams meeting at the trailing edge are thus travelling in different directions, the result of which is a series of vortices and considerable extra drag. A bulb on the fin end eliminates or restricts the leakage, resulting in less drag, greater resistance to sideways movement and greater overall efficiency. There willstill be some leakage, but the higher the aspect ratio (i.e. the deeper and narrower the fin) the less will be the vortex creation and thus the lower the induced drag. Initially bulbs were of streamlined sym-: metrical form and circular cross-section, but assymmetric profile bulbs with inverted kite-shaped sections offer a slightly lower CG than circular bulbs and are thus sometimes seen, despite the greater difficulty of pattern making. There is to some extent a tendency for Mto 10ryachtstocarry obvious bulbs, but those of A, 36R and 6mdesignsto blend in more subtly to the fin. This is probably a matter of thin, high aspect ratio conventional profile and draught. fins on the former two classes and fatter, restricted, boats, where moulding the lead disallowed. A rule brought in now would Gradually, as experience was gained, fins became narrower and deeper, though extremes of depth were not reached until affect very few boats, in fact only one of the radio boom of the mid-7Os. It was not which we know. long before 10-raters were also sporting uranium or would be prepared to use mercury bulbs, but the vast majority would prefer such exotic/expensive materials shorter into fins one on plain the bulb other, might draughtproduce unacceptable width. In recent years views on aesthetics have changed and aplainbulb onthe end ofa flat, wide fin onanAor 36Ris rules covering concavities of shape, though bulb keels and the effects, on fin efficiency, sail-carrying abilityand comparative ease of construction, began to influence the other two major classes, the draught-restricted A it was also possibly a question of following and 36Rs. essential in the early days, and it is now full-size style. Even when the full-keeler Most people find it fairly obvious that carrying the lead in a concentrated |lump lower down will make a yacht stiffer, and that the further it heels the more effective the righting couple becomes. Increased fin efficiency is not, however, quite so obvious. It arises because the bulb acts as a hydrodynamic ‘fence’. When a yacht is beating it quite normal to see an uncompromising The ballast used always to follow the shape of the yacht; bulb keels were banned in most classes, either specifically or by evolved into the fin and skeg configuration, the lead fitted the fin shape. The effect of this was to position the C.G. of lead much higher than is normal today, especially in classes such as A, 6m or 36R where draught is restricted. Gradually the ballast/fin shape developed into athickened bottom, allowing the weight of lead to be concentrated lower down and thus lowering the ballast C.G. This form of fin is still occasionally used, though not often nowadays on competition yachts of any class. The traditional method of construction was to laminate makes leeway, i.e. there isa sideways component to its movement through the water, and it is this sideways movement which the side area of the fin is intended to limit. As it moves sideways but resists such move- the piece brought back to size by adding thin slips to the sawn faces, to make 90 chunk of lead of streamlined form in plan view, but cut off flap top and bottom. This shape is used on some full-size designs and does not seem to lack efficiency, while it is certainly easier for pattern making. The writer’s approach has been rather to use flat sides with a streamlined profile, in the belief that a flat top and bottom may affect pitching forces (in some way) while flat sides basically extend the anti-leeway function of the fin. If the nose and tail of the bulb are smoothed off into gentle curves, turbulence arising from the slightly angled movement movement laminations being horizontal solid timber. detached Bulb shapes have departed somewhat from the all-streamlined conception felt through the water (the resultant of forward complete fin andcarve tofinished shape, the The lead area was then sawn off and the not considered unattractive. and leeway) minimised, whereas a Below left: a modern streamlined bulb on John Cleaves new RA. Right: the traditional shape of fin/lead on a 1980s design now used for RA sailing. should be pitching hull with a flat top and bottom lead may well be up- setting the waterflow continually. Arguable

perhaps, but all aspects of simplification should be examined. Provision of the lead in its final forms is what puts some people off the idea of building a yacht, but really it is not the probably the better bet because of lower cost, though it will smell a bit when melting and all the impurities will rise to the top and will need to be spooned off before pouring. It will of course be necessary to have a filling with lead slivers or chopped pieces there is bound to be quite a proportion of ‘airspace’ — actually to be filled with polyester resin or similar — so that with the most careful packing, the volume required insuperable obstacle some people imagine. close idea of what the final lead weight must will be perhaps It is possible to buy lead bulbs in various be, which is no problem if building to an casting. There is an alternative if care is weights from such firms as Nylet Ltd., or established used, several of the individuals who supply yacht shape, size and weight. If the design is moulding fittings, or in some areas there are small original but close topublisheddesignssome (which might bea tube fora bulb) registering foundries who will run a single casting if guidance can be had by measuring theleads in provided with a pattern and an adequate of the existing plans as they appear reduced water. Small amounts of molten lead canbe design which will indicate a and 15-20% more than one solid that in board is to place water with which the hollow its top opening otherwise covers the amount of lead scrap. Clubs usually have a in lead poured in, allowing time between pourings member or a contact who will do the same, volume must be calculated (lead can be for everything to cool down. The successive pourings will not blend with each other, but magazines etc. Otherwise the or it may be worth checking with metal taken as 6.40zs. per cubicinch) whichcanbe working staff or pupils at a technical school: alittle tedious ifan unusualshapeischosen. remain as separate layers, but they will fill often making castings is part of the syllabus An alternative is to carve a pattern, which the moulding completely, without spaces. It and there is an attraction in producing a can be in wood or clay or even polystyrene, should casting which will actually be used rather and fill a large tin to the brim with water, or, dripping into water is not the safest thing, be self-evident that molten lead than going for remelting after checking and better, toa nail hole in the side, near thetop. but if care is taken an excellent result canbe weighing etc. The pattern, mounted on a wire, is then obtained with noill effects from excess heat immersed and held until on the g.r.p. moulding. Casting at home is not at all difficult in no more water Bob Underwood, who evolved this lead, but if it seems a lot of work, there are overflows, when it is withdrawn. The water other ways of making an acceptable ballast is now topped up with a measuring jug to technique, considers about 2lb. of lead ata weight without having to heat the metal. just overflowing, and the amount of water time a maximum for an Aclass lead (around Modern epoxy adhesives allow lead sheets added to be laminated, despite the natural slight displacement of the pattern. Convert it to and greasiness of lead, orahollowfinorbulbcan cubic inches and multiply by .4 to establish perhaps half that would be wise with a 10- be moulded in glass-fibre and filled with lead weight in pounds. 12Ib. lead. lead slivers or even lead shot. Builders’ merchants can will thus be equivalent to the Making a laminated bulb of any real total supply lead weight means a lot of cutting. For the little 35lbs. or so), but with a smaller moulding less surface area to dissipate heat Lead can be melted over a gas ring or electric radiant plateinalarge saucepan. An sheet ‘off the roll’ since it is still used for BBC yacht, one sheet of lead stuck eachside iron flashings and damp courses on better class of the fin was enough: for the Panache additional work. The usual thicknessis about ¥,,in. ora design four or five sheets each side were choice, but a thick aluminium one can be shade less, and at this thicknessitcanbecut needed. used. Jumble sales and junk shopsare likely with an old pair of scissors. It buckles and require curls as ,it is cut, but is easily flattened really be applied no more than three or four A 10lb. 30-40 symmetrical laminations, bulb and will should one is preferable, and one with an sources. grip opposite the handle for A spout is useful, and can be hammered into an aluminium pan. The lead between two flat boards by tapping or just at a time with slow drying epoxy. The total can squeezing quickly ina vice. A brief rub with weight should be several ounces more than dropped in with the heat full on: once one or coarse abrasive each side cuts through any required, two surface grease and provides akeyed surface smooth. Not a job for the impatient, but it for the epoxy. to enable the bulb to be filed be cut into pieces start convenient to run the pieces and remainder follows quite rapidly. Grease and foreign does get the job done. A pair of flat boards bodies will create some smoke and smell If there is any doubt about epoxydoing the should be covered with polythene sheetand and dross will rise to the surface. An old job, it may be worth mentioning a nine-year- each set of laminations left to set overnight spoon, (from the same source as the pan?), old yacht which has been sailed in very in the vice. Two stout (in.) brass rods (or should be used to skim the crust from the rough conditions as well as fair weather on thinner stainless steel) can be set through lead. many occasions which has an 11lb. bulb the laminations and if holes are drilled in It is possible tooverheatthe lead anda few epoxied_-to a ply fin with only about 4sq. ins. each board and each lamination, a greater short sticks of clean firewood should be of contact each side and no other fastening: number can be stuck at one time without prepared. a lot of paint has been chipped off the bulb, fear of slipping. Final burring over the rod temperature but ends will help to hold the whole assembly lightly chars. Pouring should be smooth and together in the unlikely event of an epoxied steady and continual, since interruption to it has never shown any sign of loosening. An alternative is to buy scrap lead from a scrapyard, which is likely to be cheaper, joint giving way. The lead when a is at the stick poked right into it pouring allows the poured surface to chill A hollow moulded fin or bulb will need to and subsequent lead will not bond to it. This though the surfaces will be dirty and will be rather larger than would contain a lead can produce a bulbwith anapparentcrackin need casting of the desired weight, since when it which will in fact separate. Inside a hollow wire brushing or glasspapering to expose clean and solid metal. It is possible that thicker sheet can be obtained in this way, for example by buying a length of 2in. lead pipe and sawing down one side, then flattening it. For casting, scrap lead is Flat top and bottom leads on two competing boats at this year’s RA Championship. Right: deep, high aspect ratio typical of modern RMs. Continued on page 93 i j f | | {

A quick dunking in a bucket is all that is required to moisten the glue, and it will slide easily into position, just overlapping the tape in front. The natural process of shrinkage appear. | makes had this join originally almost thought dis- that it would be necessary to applya second layer, but it turns out to be completely super- fluous in terms of the job it has got to do in the formation of a simple plug. By way of interest on the subject of hulls made totally from sticky paper, | received a letter some five years ago, from a man who had madea five foot hull of a Victorian paddle ship, which he had sailed many times, with great satisfaction, ballasted with pots of homemade jam! There seems to be reason to think sealed with waterproofing that my model, no good properly agents, could not have been skinned in the same fashion. The disappearance of the bones under the covering of brown paper is a big visual step forward. For the first time, one can actually see the smooth hull form and check it for abberrations of one sort and another. Where these occur, the brown paper can be cut and repaired very easily which is another big bonus. I’m happy to say that not too much of that had to happen and, of all the operations undertaken sofar, applying the gummed paper strip has been by far the easiest. Next month: plating the hull The application of the strip reveals the emerging shape of the hull. All photos by the author. 4n apt phrase, perhaps, is ‘skin and bone.’ ‘STARTING Left: wooden and metal moulds. Above: castings from blockboard moulds use on author’s Gosling 36R. Brass screws not essential. periphery has chilled. This liquid lead forms a reservoir from which the main castingcan draw an additional supply to make good any loss on contraction. Flat top and bottom leads can also be cast in an open topped mould, but the mould * offers more difficulties in that usually the ES. aie me hell this will not be important, but a bare or ainted bulb could come apart at any time, ven if it seems sound initially. Patterns for casting can be carved from mber and painted, or shaped from clay or laster. It has been suggested by casting xperts that when making a mould the type giving shaped profiles with flat sides, leading and trailing edges of the bulb are since the shape required need only be sawn raked. out of timber of the thickness needed for the shape with an Abrafile type blade, but it It is no doubt possible to saw this lead. The timber is then nailed to.a backing might be simpler to make up a mould by board and, provided the timber is dry, the silver-soldering the ‘side’ part toa flat base, lead can be poured straight in. It pays either or even cutting the ‘side’ shape withflanges to make the moulds say gin. deeper than the that can attern surface should not be greased, as finished lead or to pour until a meniscus b6éttom plate. Any small gaps would leak a tis can leave aninflammabledepositonthe off and dress the surface of the casting. A anger. In making plaster moulds we have rises above the timber surface The reason is that molten lead contracts quite markedly as it solidifies andin this type vax polished the pattern and used a of mould will leave a concavity on the upper establish the shape required tobe cut for the mear of petroleum jelly, but allowed the surface; a little extra lead enables it to be ‘sides’ to give the required fore and aft rake. vould several days to dry out in gentle heat filled or planed flat yside mould surface, with consequent light be bent, cut and bolted to the little lead, but it would be simple tochop this little experiment with card would soon Space is running out and we have not yet efore running a casting, without problems. The simplest médulds to make are tally, a fairly wide gate is needed so that the return to the subject to cover sand and ndoubtedly the constant-thickness wood lead in the centre remains liquid after the plaster moulds in the near future *ebruary 1984 In pouring into a normal mould, inciden- touched on conventional moulds, so we will 93

LOGBOOK Model Yachting Association News . IDDERS FOR the copy of ‘Model Racing Yachts’ offered through this column to the highest bid (proceeds to M.Y.A. funds) will be astonished and delighted to hear that a bid of £250 was received. At the moment it is not clear whether the bidder prefers to remain anonymous, but his cheque has duly been passed tothe M.Y.A. with a Suggestion as to how it might be applied in a way from which model yachting could well derive considerable benefit. We are sure that all M.Y.A. members would wish to join in a big thank you for a very generous gesture. Thanks, too, to the several unsuccessful bidders whose names are recorded so that if any further copies come to light they can be put in touch. One copy has already been offered, in fact. Marblehead (Vane) European Championships, 24-27 August Graham Bantock writes: The venue Spaarnwounde, a recreation area by the North Sea Canal 10 miles outside Amsterdam, has the benefit of a nearby site (and sailing club bar!), a 60 x 120 metre water with adjacent cafe and toilets, and a central location with easy access to England and Scandinavia via the ports and the rest of Europe via the motorway system. More importantly the local clubs, VZ78 and Spaarnwoude have sufficient keen and able members generous enough to donate their time and effort towards staging an event. Unfortunately however, the first ever European Vane Marblehead Championship attracted only sixteen entries from four countries, a disappointing entry both for the organisers and the entrants. Although not ideal for vane sailing (and | haven’t seen one yet) the pond is rectangular allowing 95% of its length to be used and the somewhat unusual NNE wind which blew for the first three days gave a long leg beat with some gyeing and a spinnaker run back. The race committee decided to save time by not measuring boats, thusa practice race was held on Tuesday, 22nd and the race plore? started on Mark Dicks with a new 247 hull under the old rigging, succeeded in winning 10/13 beats but only 4 runsand commented that the heavily raked keel did not seem to affect gyeing. Messieurs Bertoux and Dole Robbe settled down to improve their scores somewhat but at the end of the day Alex on 89 and Michel, 88 were clear of the field. Day three brought more wind with some boats changing to C rigs and the prospect of completing 3 rounds seaward a possibility. The runs became more testing with increased likelihood of broaching. Two other chine boats began to show promise downwind. Jean-Pierre, Dale Robbe’s deep, narrow, fine-ended and near vertical sided own design and Alexander Varheus’ wider and flatter creation. Both lacked directional stability, the latter probably as a result of insufficient keel area and absence of skeg. John Bush found sailing conditions suited Viraeity (on charter from Walter Jones) and capitalised on its ability to plod on steadily when others broached, scoring 59/75. Although not scoring so heavily the sister ship sailed by David Potter continued to clock up points. Only Alex had a better day getting 14/15 beats and 11/15 runs. A complete change of weather for the last day brought virtually no wind. Progress was slow until windspeed picked up to a couple of knots. The two top boats continued to do well in these conditions too, Michel just having the edge, sea- wise. Resails were completed by 3.30p.m. and after short speeches by the officers the prizes were presented. As in all model yacht races about half the entrants competed with no real hope of making the prize lists. Without them there would have been no race and it is to their credit, in this case, that the greater proportion of sportsmen (and women) present came from their ranks. For most of the four days they had to put up with a greater than usual degree of ‘bleating’ from some of the more experienced skippers who found themselves disqualified for breaking rules they should have learnt to abide by a decade previously. in the hope that it will improve the performance of the lower placed entrants in future races the following observations are included. It was apparent that they consistently lost races, often by only small margins, for some or all of the following reasons: vane gear not moving freely, inability to perform a ‘long gye’, poor rigging not allowing sail trim to be properly controlled, and attempting to race with only one suit of sails and/or spinnaker. Only the last of these ‘faults’ costs money to put right, the others simply require observation on the way the experts do it and save time and effort to achieve the same. Make it more difficult for the ‘experts’ in the next European Championship! Results were: 1. 2. 3. 4. Alexander Austin Michel Lahure 175 pts. 154 pts. Alaxis Own Design John Bush Bertoux Martin Roberts Peter Clark Jean Pierre Dole Robbe Mark Dicks Denis Lagarde Alexander Verheus 140 pts“ 133 pts. 130 pts. 130 pts. 170pts. 107 pts. 85 pts. 82pts. Vivacity Dave Potter 5. 6. 6. 8. 8. 10. 11. 12. Michel Bayard 13. Claude Lagarde 143 pts. 61 pts. 44 pts. 44pts. 40 pts. 13. Marielle Thorbecke 15. Joost Thornbecke Vivacity Bloodaxe Heartbeat OD 247 Bloodaxe OD Geme Pterodacty/ Mr. Jens Brandt from Denmark withdrew from the championship. * Graham Bantock * * Other observations on the event suggest that some of the bleats arose because none of the officials (other than the O0.0.D.) had experience of vane racing and thus tended to apply rules to the latter rather than, say, giving the benefit of the doubt to the skipper. Since they were technically correct the 0.0.D. would have no option, but to uphold their decisions, but sailing strictly to the book without the .1 per cent of ‘ease’ or the quiet warning to which experienced vane skippers may be accustomed would be a little strange. This does not suggest that vane sailing is usually slack on rule application, but old hand officials know when deliberate advantage is sought or gained by bending a rule and will crack down officially only in these circumstances or when transgressions are blatant. Perhaps this points up a difference in approach between vane and radio racing — in vane the rules are there to Wednesday morning. The coincidence of one of the entrants ctreining his back and the scheduled 0.0.D. finding he would have to miss one anda half day’s racing led to the writer being invited to officiate at rather short notice, literally half an hour before the start! On Wednesday, those who had then used tall suits and the prevailing conditions puta premium on the ability to gye effectively. A somewhat large number of competitors were disqualified, mostly for not poling or re-trimming correctly but also for pushing. Three boats started by getting 15/15: Michel Lahure’s narrow and light double chine own design (sailed with a remarkably wide sheeting angle to windward, but nevertheless, fast), the prototype Heartbeat requisitioned by Peter Clark and Alex Austin’s A/axis. By the end of the day Alex had 36/40 after taking 5 from Michel, 32, David Potter had 31, Martin Roberts 28. followed by Peter Clark and John Bush, 27. Day two brought progressively stronger winds with everybody in working suit by the afternoon. 96 Second place boat at the 1983 European Vane M Championships at Spaarnwounde, Holland. An interesting hard chine design by Michel Lahure. Model Boats

The successful skippers at the Europeans. Left to right: 1st Alex Austin, 2nd Michel Lahure (France) and 3rd David Potter. this reason, he’s got to be more careful the rest of the time. The other says if he sailed badly enough to attract disqualification, then he should carry the penalty into his total score. Logic seems to suggest that a competitor can take chances in the former case, either. hoping to squeak by without disqualification or that if one is awarded it’s in the last heat or two, whereas if he knows he can’t discard penalty points he’s going to sail a bit more reasonably throughout the event. Allowing a discard for a poor score (baulked by a rabbit?) or a_ battery going down in a race, or a shroud snapping etc. seems fairly sensible though there are people who say that this is the rub of the green and all scores should count. Below, the winning boat. Alex Austin’s Alaxis, pulls out from the lea bow position of windward boat. Monsieur Bartoux of France. All photos by Graham Bantock. ensure a fair result, but in radio they must be inflexibly applied? Anyway, all credit to the Dutch radio skippers who were prepared to devote a week of their time to helping to run the event. Charles Seabrooke Older model yachtsmen will be sorry to learn of the death of Charlie Seabrooke in March of this year at the age of 83. Although he had not been active in model yachting since the early ‘60’s, he was the man who re-established and held together the 1.M.Y.R.U. in the immediate post World War li years and was a tireless worker in the cause of model sailing. He and Mark Fairbrother were largely responsible for the M.Y.A. end of the Model Maker Trophy’s establishment almost thirty years ago, incidentally. 1.M.Y.R.U. Board Meeting Most newsworthy item from the November | M_Y.R.U. Executive meeting was the result of voting on the proposed M and RM ruie changes. Of the 22 member countries, 16 voted — 8 forthe new rules and 8 against. In terms of votes (proportional according to registered boats per country) the figures are 58 for and 71 against, but comment accompanying voting returns indicates that with only one or two minor amendments most countries would be prepared to accept them. Since the Executive Board has been charged with the task of introducing the amended rules, the next step must obviously be to particularise those areas which proved unacceptable and see what additional modifications can be made to achieve majority acceptance; it is probably true to say that unanimous acceptance will be virtually im- possible. Even the most severe critics were prepared to admit that the present draught is a considerable improvement on the existing rule. A final report on the European RM Championship in Sweden was not yet to hand, but this meeting showed up the very real diversion between those who favour fleet sailing and those who think that tournament sailing is better. Itwas a highly successful event; one outstanding feature was the totally passive judging by national and international full-size judges, whose only utterances were ‘Contact’ or ‘Buoy touch’. It was then upto skippers to decide if the judgement referred to them and whether to make penalty turns (instantly — no waiting for a favourable moment) and/or protest. Largely as a result of this meeting, but also of other comment, the EB. reconsidered the matter of how sailing should be run and decided that for the moment organisers can elect for fleet or tournament, as they prefer. February 1984 There are two distinct schools of thought on the subject generally, one wishing to see sailing at different levels, so that all the experts are in A or at worst B fleet, sailing against skippers of similar ability, The other view is that this will eventually lead to only the experts entering and the less skilled skippers will drop out. The only way the latter are likely to improve is by sailing against better skippers, and there have been many go home happy to have stayed within a couple of lengths of a top boat during a tournament heat, whereas fleet entrants are likely to feel disgruntled at having been stuck in the bottom fleet all day. Most people sail for pleasure and enjoy the chance of a tilt at the experts, which they get in tournament sailing. it would be interesting to hear how proponents of fleet racing answer this? Similar divergence of view occurs over discards, especially should a competitor be allowed to discard a disqualification? One side says if he’s had to use up @ discard for Brief points from the EB meeting include the new German association affiliating to the full-size Deutschen Segler Varband, New Zealand regretting that it will not be able to proceed with the Pacific Regional Championship they’d hoped to run in 1984, the West Germans hoping to run 4 European RM Championship in West Berlin. the possibility of a World Championship in San Diego, California in 1985, the possibility of an EC12 register {perhaps to allocate all numbers outside North America?) and the acceptance of the American Model Yachting Association as the US. affiliated authority (after 12 years quite intensive negotiation) in place of the M.YRA.A. The latter was a founder member of the |.M.Y.R.U. but is now about a quarter the size of the AM.Y.A. and most of its members are also members of the A.MY.A. The Union’s next General Meeting will be an all-day affair on August 4 at Gosport. This gives the opportunity for delegates if they wish to sail in the A class Championship, or to arrive in time for the Championship dinner and prizegiving, and it is also hoped that an invitation RM race can be held on the Sunday with RMs on loan to any delegates who would like to sail, but do not wish to transport a boat.