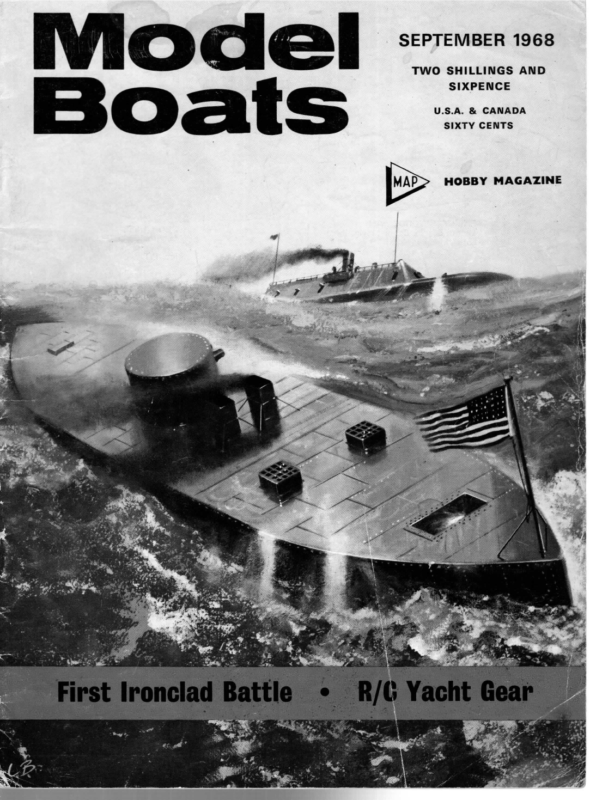

Viocdel Boats SEPTEMBER 1968 TWO SHILLINGS AND SIXPENCE U.S.A. & CANADA SIXTY CENTS HOBBY MAGAZINE

IMVODEIE BOATS Rudder and Winch Actuators for R/€ Yachts Part One By C. Robert Jeffries operation. This latter design has been successfully used on proportional equipment, both analogue and digital. For this purpose a feed-back potentiometer is required, and this has been included in the design. Considerable trouble was taken to find a suitable eae motor. There are many excellent government surplus HE writer is of the opinion that the sport of sailing radio controlled yachts has been held back by the lack of suitable rudder and winch actuators. There are many excellent boats with first-class radio equipment, but the actuators leave much to be desired. Usually these are an afterthought and made from odd bits of bent metal and gears that happen to be in the junk box. The result is a mess at best; it does the job but is crude, inefficient and unreliable. Strangely enough there are no suitable actuators available professionally, so the writer set out to design and make a set that would give him the results required. The prototypes have now been in use for over three years, being used most week-ends in the ‘Q’ class yacht Electra and following the success of these first units a total of three dozen have been made for fellow members, so the design is no drawing office dream, but a sound, workmanlike approach that has been thoroughly tested. The basic design is for operation via relays, but to some this is a dirty word (I don’t know why) so modifications will be given which have been well tested for relayless units available at a fraction of their original cost, but usually they are for 24 volt operation and the supply is somewhat haphazard. A motor has been found that is entirely suitable for both rudder and winch and is of British manufacture. The firm that makes these motors does not, however, supply retail, but happily negotiations have been concluded to make them freely available to readers of this journal. It will be necessary to have a considerable gear reduction from the motor spindle to the rudder arm or winch drum. Fortunately, a source of well-made machine cut gears exists, and the gears are available at a competitive price. In both units a worm has been included to prevent back operation. It will be of no use if after winding in the sails we find they pay out as soon as the control is removed. Good motors and well made gears are of no use unless the assembly is firm and rigid. Towards this end an aluminium casting has been included and here again a source of supply has been assured. The remaining components, switches, screws, wire, plugs, sockets etc. are all standard parts available from any radio shop that sells components. It may be mentioned here that although the design is for use in the larger model yachts, these units would be equally suitable for use in larger model power boats. The description of the rudder unit will be made first, but as there are so many parts that are common to both units, builders may prefer to build both units simultaneously. As the casting is the basis of both units we will start with that piece. The builder is expected to have the usual collection of hand tools, but a lathe will be of great assistance. It would speed up the construction and make for greater accuracy. If a lathe is not available perhaps the assistance of a fellow model engineer with a lathe might be sought. A promise of a go at sailing the finished yacht should be a sufficient incentive! Heading shows the author’s Electra Q class model sailing. Left is the complete R/C pack removed from the model, showing the actuators fitted to the box ‘lid’. 366

1968 SEPTEMBER OETAIL 6 MOTOR TYPE K5ST DETAIL 4 DETAIL 3 eee Sa — ee | HOLE TAP 3a” DIA x32 TPH DETAIL 4 DETAIL | A ite { he” |. Cas Doon 4 The T DETAIL 2. DETAIL | tid by} i DETAIL DETAIL DETAIL 13 |. ALUMINIUM CASTING ky aay t x¥e’RD. HO. BRASS SQL! SCREWS 8 WASHERS oe pt ay T — she DETAR 2_ 1. a ASSEMBLY toe – TAP Ye”DIA. x 32 TPI p CHAMFER EACH END SCREWS & WASHERS ~——1% II SLIGHT A x% RO HO BRASS 6B ! 10 DETAIL DETAK. 6 ° lo a } 16 SCREWS – t e DETAIL 15 8 BA % | Aaah + —+ 14 DETAIL 9 | re) T —-—_. 5g ——— —2 %” ——__—______— – ~ Me” DIA { ita . jal ZS 0 Pity ne Me Me a | i DETAL 5 | VERY 3 ~ y = 8 HOLES TAP 6BA BRASS _ —~ 5g – ROD AF ees OF RUDDER ACTUATOR — — ¥ DETAIL 4. OFF 2 BRASS i The castings as received are clean and only need trimming up with a file. The large hole for the motor may either be bored out in the lathe, or made by drilling a ring of small holes, removing the middle and cleaning out with a half round file. Although the casting may be completed it would be better if the hole for the countershaft is left undrilled until such time as the other components are available and the spindle centres may be actually checked. Detail 2 is the main spindle. Brass is quite satisfactory, but if you are very fussy it could be in stainless steel. The bush detail 3 and two nuts detail 4 are quite straightforward. Care should be taken to see that the threads are quite square. The gears are available from Bonds Ltd., of 357 Euston Road, London N.W.1. Detail 5 is made from a 108 tooth, 48 d.p. pinion. As received it will have a small boss. This should be pressed out and a larger one to the dimensions shown in the drawing should be fitted. I prefer silver soldering for jobs like this, but if carefully done soft soldering should be suitable. The motor as received has a 3/32” dia. spindle which fortunately fits the worm of a 40/1 64 d.p. exactly. This is ! x S2TPI –—} F SCREW DIA | DETAIL_3. = a ! am Ya” BRASS Three views of the rudder unit are given below, with a g.a. drawing above left. Note that all dimensions are included in the detail drawings, enabling the builder to go straight ahead. assembled with the plain part of the worm nearest to the motor. Fitting may be done by drilling and fitting a 1/32 in. pin or alternatively the spindle and hole may be tinned and the whole soft soldered, care being taken not to get the shaft too hot and damage the plastic case of the motor. With the motor fitted to the casting and the steering quadrant assembled, the position of the hole for the countershaft may now be checked. Don’t be dismayed if the mesh of the gears is not to your liking. Drill out the hole in the casting to, say, 3/16 in. and fit a brass bush with the hole for the spindle drilled eccentrically. By this means a perfect mesh is possible. The gears should work freely and without backlash or any tendency to bind. 367

MODEL The top plate is now made to detail 9. Drill the fixing holes first, then check the position of the hole for the main spindle. Again the shaft should work freely. Next drill the | hole for the countershaft. Again if there is any error this | Boating for Beginners hole also could be bushed as.described for the casting. The countershaft assembly detail 14 may now be com- pleted. Drill and pin 1/32 in. dia. 48D0P get lost Ls. | 4 i ‘” Sot f ’ ‘ ” eee Yet +e SILVER SOLDER ———”| DETAIL 5 BRASS reer S D a] K] \ mT 1 V2 DIA TAP 4BA yy 7 SILVER STEEL DETAIL Shiela ey 4 BA SCREW 23)| Eee A REAM Ya DIA oS x peo 4g Ye”DIA PINION ~ BRASS “ne its a5 : + ai Bj een Ya” a e Te ae “DIAHOLE Ly FIT 4BA TAP 6BA GRUB SCREW ay TAP 4BA ee ae b-——1 %e’—-+{ REAM ‘a”DIA Ye” HOLE L Pile Bs DETAIL 6 BRASS ve See y+ ae } DETAM 11 BRASS Parts list for Rudder Unit. Frame casting, 1 offAluminium C. R. Jeffries, 17 Colemere Special Motor. 6 volt type KST. Gardens, Highcliffe on Sea, | off Hants. 40/1 Worm & Wheel. | off 12 tooth 48 dp. Steel pinion | off Bonds Ltd., 357 Euston enon 48 dp. Brass pinion. Road LondonN.W.1. off. Limit switches. 2 off “Radiospares’ Micro Connecting wire. 7 different cols Switches (Lever type) 9 pin Plug type B.9.A. 1 off through any radio shop. 9 1 a of . Valveholder type B.9.A. M.Y.A. REGATTA DATES Sept. Ist 10R Eastern Dist. Champs. Dovercourt Sept. 7th & 8th ‘M’ National Champs. Hove Sept. 22nd 36 in. Northern and Dist. Champs. ko Tat Sept. 29th Sept. 29th Oct. Sth Oct. 6th discuss the wood-constructed version of ‘Hammerhead’, 36 x15in. offshore racer HIS month it is necessary to digress a little to cover, briefly, the wood version of the Hammerhead design. As we mentioned last month, the primary purpose of using this model in this series is to discuss generally the fitting out of a glass fibre hull; in wood form the model is not ideal for beginners, mainly because of the shape of the bow and the change of the chine from an ‘outside corner’ to an ‘inside’ angle, as shown in the cross-sections. However, beginners working from plans of any sort can run into trouble in using the plans, so we can mention a few points which may be of help. The usual building procedure is followed, i.e. cutting and assembling the keel, cutting the bulkheads, and fitting to keel, followed by chines, inwales and skins. Do not | cut the keel drawing out from the plan and paste it to the ply —it distorts in cutting and stretches and distorts even more when pasted. A difference of 2 in. in 36 in. is quite easy if this is done. Use kitchen greaseproof paper (or drawing office tracing paper) and pin or tape it over the plan, then trace the shape with a softish black pencil —a 2B lead is what we use. Remove the tracing and pin or tape face down on the ply, then draw over the lines from the back. On lifting the paper, the lines will be seen to be quite strongly transferred to the ply, though usually it is best to run over them again to make them bold. An 6 BA by 3 in. Rd. Hd. Brass screws. 8 off. 6 BA by + in. Rd. Hd. Brass screws. 4 off. Local ironmongers or 6 BA Washers Brass. 12 off. D.1.Y. Shop +in. sheet Bakelite. | piece Sundry Brass Rod & Sheet, as required. Sept. 28th Digressing a little this month to Leeds and Bradford ‘M’ Northern Dist. Open Team Race y Scottish M.Y.A. Fleetwood 10R Met. and Southern Dist. Champs. Hove ‘M’ East Dist. Junior Champs. Dovercourt ‘A’ Plant Cup Witton, Birmingham alternative is to lay the tracing in place and pin-prick through the lines, joining the pin marks with a pencil line after lifting the paper. Where straight lines are involved, this method saves a lot of time; it can be done without tracing, or carbon paper can be used under the drawing itself, but you cannot see through the plan, and thus have to make a bigger allowance between parts, which wastes a lot of ply. Where half-parts are drawn, lay the half tracing face down and pin-prick the centre line. Draw this in before transferring the tracing. Turn the tracing back over to transfer the second half, and take care to line up accurately. Before cutting, check on ply thickness where notches fit. Ply varies considerably in actual thickness, and if yours is on the thin side the structure will fit sloppily instead of sliding nicely together. Try to plan the cutting to enable a small tenon saw to be used on straight lines, with a fret-saw only where essential; few people can fret a long straight line. Leave a shade for cleaning up with a coarse glasspaper block, and when sanding, try to leave a flat, square edge, unless, of course, a chamfer is needed. Tack the keel parts down over the boat’s profile and ‘A’ Mid. & Dist. Champs. _,, Fa glue the doubler pieces on the exposed side. A most Exhibition convenient glue is Evo-Stik Resin W, but this is not enEnfield D.M.E.S. will be exhibiting at Enfield Show, in tirely waterproof and if water ever does soak into the wood, the joint could fail. More trouble, but completely the Town Park, on Sept. 20/2Ist. A 2-lane slot marina and a rail/sea containerisation demonstration at 1/32 | satisfactory, is Aerolite 306, which experience, both fullscale are among the exhibits, plus a 4-lane slot car layout, size and model, indicates is the best easily-available 5 in, gauge railway, and other interesting items. | adhesive for wood joints in boats. 368

SEPTEMBER The Metropolitan and Southern District ‘M’ Team Race With the kind permission of Hove & Brighton M.Y.A., the event was sailed at the Hove Lagoon on the 28th April with Guildford & District M.Y.A. the host club, ably directed by Mr. F. Jennings of Brighton, the O.O.D. Entries were received from 6 Clubs, Danson, M.Y.S.A., Highgate, Hove & Brighton, Clapham and Guildford. It seems that the Stollery design glass fibre boats are becoming very popular with a line-up of 7 ‘submarines’ in the 12 boats entered. Wind was S to SW at the start, force 2 to 3 giving a reach in both directions. A start was made at 10.15 a.m. with some very close racing and exciting finishes. Lunch scores after 6 heats: Guildford 34 points, Hove & Brighton 34 points, Clapham 30 points, Highgate 20 points, Danson 14 points and M.Y.S.A. 10 points. The wind gradually veered after mid-day to SE to E increasing, to force 4 giving a beat and a run but scoring remained at 2 points each way. Clapham forced the pace in heat 7, improving their position to Guildford 40, Hove & Brighton 40, Clapham 38 but could not keep up the pressure. The afternoon was noted for a considerable amount of ‘brinkmanship’ on the run with spinnakers and some excellent guying and pole work. Points were gained literally by inches. Notable races were, for example, in heat 9, C. Colsell beat C. Dicks on the beat by approximately 6 inches only to lose the run by a similar small margin. In peat 10, D. Bateup lost to C. Jackson after a very thrilling nish. Guildford finally emerged the winners by 4 points but there was no clear superiority of design with White Rabbit 32, March Hare 30, Mad Hatter 30, Fantasie Impromtitude 30. Club Entrant Boat Danson’ R. Seager G. Clarke Wayfarer Wayfarer Doormouse White C. Jackson Mojo Clapham _ C. Dicks Fantasie Design Rabbit March Pts. Ttl. 30 22 20 10 52 30 Hare Guildford F. Shepherd B. Brewster Highgate Hove& Brighton A. Marquis K. King D.Bateup March Hare 30 White 32 Rabbit Tamerara Witchcraft 8 Moonraker Witch 14 Manito Mad 30 C. Colsell Narang Hatter March Mad Mays Hare Mad 8 Toboggan 8 M.Y.S.A. F.Shattock C. Robertson Hot Stuff Hatter 28 62 22 58 16 Northern Area R/C Steering Championships The Northern Area R/C Steering Championships were held at Walton Hall Park lake, Liverpool on the 30th June. They also included qualifying rounds for the Pilot Championships and the Bulgaria Team for 1969. At the same regatta a Ladies’ Competition was held, and the trophy was donated by Hull Model Club. The prizes were presented by Mr. W. Fox, Treasurer of the Northern area M.P.B.A. R/C Steering Championships (28 entries) Ist D. North (Featherstone) 2nd _L. Townsend (Featherstone) 3rd L. Proctor (Ossett/Horbury) 137.2 points 135.5 points 135.4 points Top to bottom, F. Shepherd, B. Brewster, D. Bateup, and C. Colsell, at Hove. 389 1968