Of all the many and varied branches of model-making, model boat construction must surely be one of the oldest, and certainly one of the most intriguing and romantic.

The designing and building of model power boats has much to offer to both young and old, for it combines indoor and outdoor activity in a manner which is both healthy and instructive. The construction of a model indoors when perhaps the weather is unsuitable for anything else, coupled with all the outdoor activity of operating it when completed, makes model boat building the ideal hobby—a hobby which calls for very little initial outlay—a hobby that will fire the imagination of young and old alike and help recapture on a small scale that old adventurous spirit of the sea.

- Introduction to the Hobby

- Theoretical Considerations

- Planning and Design

- Motive Power—Internal Combustion Engines

- Model Power—Electricity, Steam, and Jetex

- Hull Construction

- Superstructures and Deck Fittings P

- ropellers and Transmission

- ‘Fitting Out’ and Finishing

- Constructional Kits

- Rules and Specifications

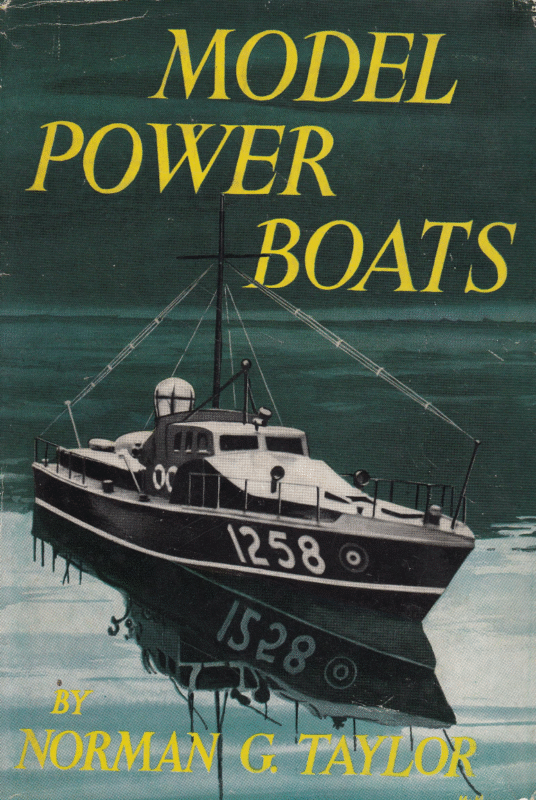

This authoritative guide to the building of working model power boats covers the three basic groups— scale models, semi-scale models in which modifications are made to simplify construction and increase efficiency, and functional models in which appearance is sacrificed to obtain the utmost speed. An early chapter is devoted to the essential theory behind the design of power boats; then follows instruc- tion on how to design a model and how to draw up full-size working plans. A section on power units covers the various types of internal combustion engines, electric motors, steam engines and Jetex motors avail- able for use. Subsequent chapters deal with the construction of the hull in wood and in metal, and the fitting of the superstructure, the problems of transmission and the correct use of propellers. The closing section covers the use of constructional kits, and provides detailed specifications and a glossary of technical terms. 18/- NET

Sia SSS See eres meebo ie ee go ee ee ere eee 2S BE Ss SHIGE seayerece terse ee SESS aoa iee se snecenenee So zee SSS Serene = Ee reretere aero Eaisceratstse SS SSS SSS SSS SSSSS SSS Se Ens sees Siusstafetsttateeercereteeiecemtenss as Setar = aera ee aspera ie ee ee eS oe See Serge eee SSSI E acgee ape ieee sates tecas ee eestor aes eases otra arnrorete! tat wetg rt

MODEL POWER BOATS

BY THE SAME AUTHOR Mopet AEROPLANES Mopet Moror Boats Mopet Racine Cars Move. Racine YaAcuTs Mopet MaKeER’s WorKSHOP THE Complete Book oF THE MopEL AEROPLANE

.1.—Always popular—a typical 33 -1n. scale model of an Air Sea Rescue Launch bu i It_by Mr. H._ N. Taylor from plans by Norman G. Taylor oe Fi oe

MODEL BOATS POWER by NORMAN G. TAYLOR With 211 illustrations in the text LONDON

CASSELL & CO LTD 37/38 St. Andrew’s Hill, Queen Victoria Street London, E.C.4 : and at 31/34 George IV Bridge, Edinburgh 210 Queen Street, Melbourne 26/30 Clarence Street, Sydney 24 Wyndham Street; Auckland, New Zealand 1068 Broadview Avenue, Toronto 6 P.O. Box 275, Cape Town P.O. Box 1386, Salisbury, S. Rhodesia Munsoor Building, Main Street, Colombo 11 Haroon Chambers, South Napier Road, Karachi 13/14 Ajmeri Gate Extension, New Delhi 1 15 Graham Road, Ballard Estate, Bombay 1 17 Chittaranjan Avenue, Calcutta 13 P.O. Box 959, Accra, Gold Coast Avenida 9 de Julho 1138, Sio0 Paulo Galeria Gittemes, Escritorio 518/520 Florida 165, Buenos Aires 5 rue Henri Barbusse, Paris 5e Islands Brygge 5, Copenhagen – First Published 1956 COPYRIGHT 1956 BY NORMAN G. TAYLOR MADE AND PRINTED IN GREAT BRITAIN (TAYLOR GARNETT EVANS & CO, LTD.) F, 1055 BY GREYCAINES WATFORD, HERTS

PREFACE THE preparation of this book dealing with the art of model power boat construction has given me much pleasure, because my ‘first love’ was model boat building when only a schoolboy, and since those happy days I have always gone back to the hobby whenever my other model-making activities permit. Of all the many and varied branches of model-making, model boat construction must surely be one of the oldest, and certainly one of the most intriguing and romantic. The designing and building of model power boats has much to offer to both young and old, for it combines indoor and outdoor activity in a manner which is both healthy and instructive. The construction of a model indoors when perhaps the weather is unsuitable for anything else, coupled with all the outdoor activity of operating it when completed, makes model boat building the ideal hobby—a hobby which calls for very little initial outlay—a hobby that will fire the imagination of young and old alike and help recapture on a small scale that old adventurous spirit of the sea. Only those who have actually built such a craft can know the fascination of operating a good scale model power boat on the sparkling waters of the local pond or lake. In presenting this book it is my sincere hope that the advice contained herein on constructional methods, power units, design and many other matters, will be the means of recruiting many more enthusiasts to the ever-increasing ranks of model boat builders. I would take this opportunity of gratefully acknowledging my indebtedness, and of extending my cordial thanks, to the following organizations for much help and information, and for their kind permission to reproduce many illustrations which appear in the following pages: The Model Power Boat Association, Messrs. Bassett-Lowke Ltd., Northampton; Model Maker Plans Service, Watford, Herts. ; Norman’s Model Supplies, Wimbledon, S.W.19; Model Aircraft (Bournemouth) Ltd., Bournemouth, Hants.; A. A. Hales Ltd., London, N.11; Taycol Ltd., Bournemouth, Hants.; Electronic Developments (Surrey) Ltd., Kingston-on-Thames; International Model Aircraft Ltd., eee]

PREFACE London, $.W.19; Davies Charlton Ltd., Barnoldswick, Lancs.; Amco Model Engines Ltd., Alperton, Middlesex; The Ever Ready Co. Ltd., New Malden, London, N.7; Venner Accumulators Ltd., Surrey; Chloride Batteries Ltd., Manchester; Wilmot Mansour & Co. Ltd., Totton, Hants.; and The Model Shop, Newcastle-on-Tyne. A book such as this would be impossible without such help and co-operation between friends. WIMBLEDON NORMAN G. TAYLOR be.

CONTENTS PAGE CHAPTER I INTRODUCTION TO THE HoBBy II THEORETICAL CONSIDERATIONS 20 Ill PLANNING AND DESIGN 40 IV Motive PowER—INTERNAL COMBUSTION ENGINES Vv MortitvE . Power — ELecrriciry, STEAM VII VII IX XI AND 86 JETEX VI 63 Hui CoNnsTRUCTION 111 SUPERSTRUCTURES AND Deck FITTINGS 138 PROPELLERS AND TRANSMISSION 167 ‘FITTING Out’ AND FINISHING 7S) CONSTRUCTIONAL Kits 194 RULES AND SPECIFICATIONS 203 GLossARY OF TECHNICAL ‘TERMS All INDEX 222 3 [e4

To my Sons BRIAN AND RICHARD

CHAPTER I INTRODUCTION TO THE HOBBY ANYTHING that works has more than ordinary appeal to the general public, as witness the crowds at any of the important model power boat contests and regattas, or even the vast number of people (both young and old) who gather so rapidly around a model when it appears at the water’s edge! A model power boat combines the fascination of the miniature, with the allure of the thing that ‘goes’—it has life and motion and makes a decided appeal to the eye and ear, especially when it is one of the ultra high-speed spark or without a regulation silencer! glow-ignition boats running Types of Models Working model power hoats, as opposed to any other class of working model boats such as yachts, cutters, etc., may be classified into three basic groups, these being (1) scale models, which should include true to scale replicas and representative models of all types of full-size vessels and also those in which slight modifications have been made below the water-line in order to increase ‘displacement’ and provide sufficient space for fitting the power plant, at the same time maintaining the true ‘full-size’ appearance as much as possible when afloat; (2) semiscale models, in which modifications are made both above and below the waterline in order to simplify construction and to make for increased all-round general efficiency; and (3) the purely functional type of model, i.e. speed-boats, hydroplanes, and other free-lance designs, in which appearance is sacrificed for the utmost speed and efficiency. Figs. 2 and 3 illustrate two typical and excellent scale models on which a great amount of time may be spent in getting every detail and fitting of the full-size prototype correct to scale. Models of this type are usually fitted with an electric or steam power plant. By far the most popular class of model at the present time is the semi-scale, this no doubt being due to the fact that ample power to give models of this type a realistic and interesting Fee

MODEL POWER BOATS Fig. 2.—Scale modelling at its best—a superb exhibition model of the cross-channel ship ‘Falaise’ by Messrs Bassett-Lowke Ltd. performance is now readily available in the form of the small compression-ignition (‘diesel’) engine which, in the past few years, has done so much to popularize the hobby. The models shown in Figs. 4 and 5 are typical of their class, and could easily be two of the many hundreds which may be seen in action on any of the model boating ponds throughout the country on any fine week-end. Model speed-boats and hydroplanes are what one may call ‘functional designs’ and in nearly all cases, especially for speedcontest work, appearances have to be sacrificed for utmost performance, speed, and general handling qualities; although let it be put on record that there are many speed-boats which have both good looks and performance. A model of the hydroplane type is shown in Fig. 6. When watching models of this type performing it will at once be observed how they travel “on the step’ when a certain speed has been reached. On Choosing a Model When first starting model boat building it is of the utmost impoitance to choose the correct type of model for your requirements and one which will also appeal to you. The newcomer to the hobl-y is strongly advised never to be tempted to commence with one of the more complicated types until a little practical experience has been gained by constructing and operating two or three simple models intended for beginners. There are many small hinis and tips which may be learnt in this way by [12]

INTRODUCTION TO THE HOBBY eee ee Fig. 3.—Craftsmen assembling a model of the ‘Norge’ built to the order of Messrs. Camper & Nicholson by Bassett-Lowke Ltd. progressing from the more simple types to start with—such little things as the best method of construction, painting, engine starting (in the case of internal combustion engine powered models), and handling the model in the water. Then, when you are ready, the larger and more complicated models may be tackled with complete confidence. ~ Facilities for operating your model whenit is completed should always be taken into consideration when deciding on the type you are going to build. Itis advisable to make a point of visiting all local ponds or lakes, and to inspect them at first hand to discover which is the most suitable for model boat operation. For the exposed waters of natural ponds or lakes, models of from 30 to 39 in. are usually the most suitable; of course, a smaller model than the size just mentioned may be constructed, but generally speaking, nothing less. than 30 in. is really practical on anything like exposed water. On the other hand, where there is calm unruffled water available, such as may be found in many artificial ponds, which are usually sheltered by their steep banks, the really small type of model (12 to 24 in. in length) may be operated quite successfully. [13]

MODEL POWER BOATS Fig. 4.—Typical semi-scale cabin cruiser for electric motor or ‘75 to 1-5-c.c. diesel engine. Length: 31 in. Beam: 84 in. From the workshops of Norman’s Model Supplies, Wimbledon Storage space and method of transport are usually the two governing factors when deciding on the general size and overall length of your model. It is surprising how much space a large model of, say, about 48 in. or more will occupy in that spare room! Hence the popularity of the 30-in. and ‘Metre’ (39-370-in.) classes, both of which are quite easy to carry and transport. For anything larger than the ‘Metre’ size, the use of a car or a Fig. 5.—‘Lorelei’ designed by Vic Smeed and built from plans supplied by the Model Maker Plans Service. This is a simple cabin cruiser for small diesels or electric propulsion. Length: 34 in. Beam: 7} in. E14]

INTRODUCTION TO THE HOBBY cycle trailer is really necessary for getting the model to the water, unless, of course, you are lucky enough to live very near a suitable pond. If you are constructing a speed-boat or hydroplane, transport difficulties should not -worry you unduly, because this type of model is very rarely more than 39 in. in length. At the outset, success in the building of a model boat depends on just three things: knowing beforehand just what type you want to make, obtaining the right power plant, and then getting started right with the construction. Once you have an accurate full size plan the rest is comparatively easy. Considerable experience of designing and building is necessary Fig. 6.—A typical diesel-powered Hydroplane at speed before one is able successfully to produce working drawings in detail for a model which will be really satisfactory and efficient on the water. For the beginner, by far the easiest and cheapest way of making a first model is to purchase one of the many excellent constructional kits which are now on the market, and to follow exactly the detailed building and operating instructions which are usually included therein. The chances are that your local model dealer is an enthusiast, and he will always be pleased to give practical advice and help in selecting a suitable type of model and power unit. By purchasing a constructional kit you get the advantage of having all the basic materials from which to build the model selected in the correct quantity without having to ‘over buy’ on the many small items which go to the making of a model boat. Another advantage gained by the beginner who starts with a kit is that all small and intricate parts (such as bulkheads, formers, and superstructure parts) are usually clearly printed on wood of the correct type and thickness in readiness for cutting out. Many kits contain all parts [15]

MODEL POWER BOATS pre-cut ready for assembly, all of which is a great help for the beginner and ensures accuracy. Fundamental Requirements For successful operation the model power boat must possess certain well-defined characteristic. These main practical requirements may be listed as follows: (1) The hull must be of sound practical design, and it must be of sufficient size and strength to accommodate the power plant required, with suitable provision for mounting the machinery and the fixing of propeller‘shaft and rudder assembly. (2) A vessel will, when placed on the surface of the water, ‘displace’ an amount of water equivalent to its total weight. Hence it will be seen that small heavy models should be avoided, and that weight should at all times be kept down to reasonable proportions. (3) A model should be fitted with a power plant capable of giving it a realistic and also reliable performance. Choosing the correct type of motive power is a matter of great importance, and is discussed in detail in following chapters. (4) An accessible switch for starting the electric motor at time of release must be provided, or, in the case of models employing other forms of propulsion, good accessibility to the power plant for starting, refuelling, etc., this usually being achieved by having a portion of the superstructure detachable with a quick and. ezsy ‘snap on’ method of fastening. (5) General finish and appearance are two items which should not be overlooked. When afloat, the model when seen from a distance of 10 to 30 ft. from the shore should look like the real thing. Even at this short distance all the small details are lost to view, and it is because of this that the utmost care should be taken suitably to. proportion and dispose the masses, i.e., superstructure, funnels, deck-houses, masts, etc. By so doing it is surprising what a semblance of reality and scale appearance is obtained without bothering too much about the smaller details and fittings. The most important feature of any scale model boat should be fidelity; it should convey to the beholder a sense of the magnificent appearance of the original, both when in dock and when cruising across the water. Minute detail should be studiously avoided, as it has a tendency to make a small model look clumsy and out of scale—this does not apply to large scale models of small size prototypes. tie)

INTRODUCTION TO THE HOBBY Fig. 7.—Models such as this fine cross-channel ship are ideal for electric or steam propulsion. Note how only essential details of superstructure and deck fittings give neat appearance Effect of Scale on Size One effect of building a model to a fixed length is that the scale of the boat varies according to the length of the prototype. Thus a ‘metre’ model of a 600-ft. liner would have a scale of 40/7200 or be 1/180 full size; in other words, 15 ft. equals 1 in. If, however, a river launch or some other boat of, say, 60 ft. in length were taken as prototype the model would be to a scale of 1/18 full size, or 14 ft. equals 1 in. Thus the size of all the deck fittings varies considerably on models of fixed length but representing different prototypes. Consequently the designer and builder of any mcdel should first determine the length of the model, or the scale; and arrange. everything accordingly. Practical Utility of Models Lest anyone should think that model boats are merely toys, it may be well to mention that hundreds of thousands of pounds are expended annually on scientific experiments and tests with models of intended ships. In fact, the basis of naval architecture is practical experiment with ship models, and the knowledge so gained has done very much to perfect the modern ship. Useful Tools An elaborately equipped workshop is certainly not essential for the construction of a model, except perhaps for the most B | Wy]

MODEL POWER BOATS advanced exhibition types, some very fine examples of which may be seen in the Science Museum, South Kensington, London, and in the offices of nearly all large shipping companies. But very few tools are necessary for building the more simple working types—in fact, many excellent models which are built are in the ‘kitchen table’ class. Modern methods of construction and the increased use of balsa wood and plywood have done much in reducing time, skill, and tools required to build an average working model. Surprisingly few people realize how suitable balsa wood is, and to what extent it can be used, in model shipbuilding. It is easy to cut and handle, the medium grades being suitable for formers, bulkheads, etc., while the harder and heavier variety with its very high strength/weight ratio may be used to great advantage for planking hulls and the construction of deck-houses, superstructures, etc. Of course, it is obvious that the facilities of a small workshop are an advantage, but many of us lack the necessary space for fitting out a special room just for building models. With this in mind, it is suggested that the following may be found to be the most useful tools for the beginner to obtain, these being listed in order of importance: 1, First and most important is a workbench, strong table, or building board (which really serves as a portable workbench) on which all the actual construction will be done. A draughtsman’s drawing-board makes an ideal building board, and is_ generally made of pine, a soft wood which is not liable to warp, and into which pins can be easily knocked without bending. For a small model of anything up to 30 in. in length, a piece of good-quality timber approximately 32 in. by 9 in. and 1 in. thick will serve quite well as a building board, providing always that you choose a length that is absolutely straight and free from knots. Remember that small pieces of unpainted wood show up better against a dark background, so it is a good idea to water-stain your building board a dark shade of brown to facilitate working with very small parts. 2. High up on our list of essentials must come a means of cutting the timber which will form such a large proportion of the completed model. Most of the wood used is obtainable ready cut in the small sections required, therefore our saws need only be quite small. The most useful would be a brass-backed modelmaker’s tenon saw, a fretsaw frame with an assortment of fine, medium and coarse blades, and a small coping saw. [ 18 ]

INTRODUCTION TO THE HOBBY 3. Next follows a group of three inexpensive basic tools. These are normally to be found in most households: (a) Small hammer. (6) Pair of small pliers. (c) Small and medium screwdrivers. 4, A 12-in. steel rule is always useful, not only for measuring, but also for use as a straight-edge when cutting paper, thin ply, and thin sheet balsa wood. 5. Hand brace and set of twist drills (J;-in. to }-in. diam.). 6. Small wood rasp and spokeshave. 7. Selection of chisels and gouges. 8. Pair of good-quality heavy-duty wire cutters. _ 9. Carpenter’s and metal-worker’s set squares. 10. Sharp knife for carving stem and stern pieces, etc. 11. Half-dozen woodworker’s cramps (small). 12. 4-,4-, and 2-in. flat and half-round files. 13. Sandpaper,Pers des 0, 1 and 2. Suitable sanding block. 14, Two or three dozen brass drawing pins. 15. Packet or box of onary household pins (steel). 16. Assorted panel pins (4-, 3-, and 4-in.). 17. Assorted wood screws ($-, 3-,$-, ou 2-in.). Nearly all the above mentioned tools are een for building various types of models of up to medium size. Individual requirements vary to such an extent that it is quite impossible to lay down any hard and fast rules concerning the selection of tools. The enthusiast will soon want to make further additions to his equipment; other useful acquisitions are a good strong vice, an electric soldering iron and equipment, and a treadle or power operated fretwork machine which will save a lot of time and hard work when cutting out both large and small -3-ply and other hardwood parts. For further detailed information regarding the selection fad use of tools, the reader is réferred to Cassell’s Model Maker’s Workshop in the “(New Model Maker Series’’, price 4/6d. [ 19]

CHAPTER II THEORETICAL CONSIDERATIONS PrAcTICAL modellers are sometimes disposed to scoff at the mere word ‘theory’ and deny its usefulness; others adhere slavishly to the idea that by calculation, formula and algebraic conjuring it is possible to evolve a stupendous success. Both are wrong, because the theoretician and the practical exponent can each learn something from the peculiar knowledge of the other; therefore, the ideal must surely be to combine a reasonable amount of theory with the results of practical experience in all models designed and built. Aim of the Theoretician The theory-man accumulated merely experiences endeavours of the past, to and co-ordinate by the analogy, by accurate deduction and by inference, to look forward into the future. Further than this, theory can and does enable the practical man to attain his ends or produce a better result with the minimum of labour. After all, there must be a reason for every happening, and so-called theory aims at giving reasons and stating laws which govern them. Furthermore, it attempts, with no small degree of success, to enable the naval model architect to design a model boat to fulfil stated conditions. Primary Considerations The student of naval model architecture finds that there are manifold difficulties to be overcome in the design of a successful model power boat. Stability indicates the need for a broad boat and the correct placing of the ‘metacentre’, the demand for speed necessitates fine lines, while other requirements such as radio control and steering qualities may well introduce fresh factors. To overcome all difficulties and produce an harmonious design is the aim of all naval architects. This chapter is intended as far as possible to show how and why the utilized. differing factors in a [ 20 ] boat design can best be

THEORETICAL CONSIDERATIONS Why a Boat Floats Primary attention must be given to grasping the fundamental principle of buoyancy, or the power a ship possesses of floating in water, while at the same time maintaining proper trim and stability. At first glance it seems impossible that a model constructed of metal should float. That a boat can do so is due to ‘displacement’ or ‘buoyancy’—that is to say, when a boat is floating in water it displaces or pushes away a volume of water equal in weight to the otal weight of the model. Displacement of Water For example, if a bowl of water full to the brim contains six pounds weight of water, and into this a rectangular block TOTAL WEIGHT IO Ib. [| TERED LE Ze 2210 cub inODE Fig. ae and displacement diagram of wood weighing exactly one pound is introduced, it is obvious that a certain quantity of water will overflow. If the wood is removed and the amount of water remaining in the bowl is again weighed it will be found that it now weighs exactly five pounds, thus showing that one pound weight of water has been displaced. Volume of Displacement The first thing when designing a model power boat is to ensure that the volume of that part of the vessel to be immersed in the water shall displace a weight of water exactly equal to the total weight of the boat. This principle is the most vital of the many involved when designing a model boat. For a boat to be able to float, its immersed volume, i.e. the part of the hull that sinks into the water, must displace a volume of water equal in weight to the total weight of the boat. A model that weighs 10 lb. for example, must displace 270 cub. in. and [ 21 ]

MODEL POWER BOATS leave some portion of the hull above water; because 27 cub. in. of fresh water weighs 1 Ib. Fig. 8 represents a model boat hull weighing 10 Ib. floating in water. The immersed portion of the hull displaces 270 cub. in. of water—in other words the volume of displacement is 270 cub. in. The weight of this quantity of water being 10 Ib. the boat is able to float. Note that the volume of displacement of the boat is due to that part which is immersed, or in the water. The total volume of the hull is greater than 270 cub. in. because there must be sufficient ‘freeboard’ or above-water portions of the hull on which to erect the superstructures. Correct Flotation It is not sufficient for a vessel to float but it must float in an upright position, and not be unduly liable to capsize; in other words, the vessel must possess stability. Stability may be defined as the property a vessel possesses of returning to the upright position after having been slightly inclined from it. Conditions of Equilibrium Having grasped the fundamental facts of displacement, it is necessary to consider the manner in which the volume of the immersed portion of the hull has to be arranged to ensure the boat floating at a pre-determined level. The placid state of flotation is known as equilibrium and the three primary conditions of equilibrium of a floating body are: (a) The weight of the body must equal. the weight of the water displaced. (6) The centre of gravity and centre of buoyancy must be in the same vertical line. For a vessel to float in the desired upright position the third condition is essential: (c) The metacentric height must be positive. Fundamentals of Stability A body possessed of bulk and mass has weight, and located somewhere in that body there is a centre upon which it could be balanced, were it accessible. The balancing point is called the centre of gravity. The [ 22 ]

THEORETICAL CONSIDERATIONS force of gravity always acts vertically downwards through that centre, no matter how much the position of the body may be changed in respect to a plane of reference, such as the surface of water. The centre of gravity is usually referred to on plans and diagrams by the letters C.G.; and the position of this centre never alters in a boat unless some of the weights in it are moved. Buoyancy A body when floating in water possesses another property known as buoyancy, which is virtually the reaction due to gravity. The immersed surfaces of a model boat hull floating at rest in water may be considered as experiencing pressures . perpendicular to them, and the sum of these pressures must equal the weight of the vessel. The centre of buoyancy is the centre of gravity of the immersed volume of the hull, and is that point at which the buoyancy pressures are concentrated. When the model is upright, the centre of buoyancy is in the longitudinal middle line, but when inclined or heeled, the centre of buoyancy moves to some new position dependent upon the immersed form of the hull. Transverse Stability The power to resist heeling, or an inclining force tending to tilt the hull sideways, is known as transverse stability and is chiefly conditioned by the form of the hull, the height of the metacentre, the ratio of depth to beam, and the relative heights of the centre of gravity and centre of buoyancy. At this stage of the investigation of a model boat hull floating upright and at rest in water, the following conditions or properties are known, and their magnitude can be ascertained by calculation: (a) The weight and volume of water displaced. (b) The C.G. is on the longitudinal central plane of the hull. (c) The centre of buoyancy (C.B.) is vertically beneath the C.G. This knowledge can be usefully employed in several ways; for example, when the total weight of an intended model is known, the appropriate volume of displacement can be ascerng weight in Ib. by 27. Obviously, theretained by multiplyithe contrive an immersed hull form which must designer fore, the will have exactly that number of cubic inches of volume. [ 23 ]

MODEL POWER BOATS Determining Permissible Weight Conversely, if the hull is designed first, the volume of displacement can be ascertained, and this divided by 27 will give the total permissible weight of the boat Fig. 9.—Centre of Buoyancy and Gravity pee CoP Poe accessories. gl Provided the conditions of equilibrium are complied with, such a hull will float at rest and upright; but it is most important to determine its stability, which can only be done after further investigation, Conditions of Transverse Stability These can best be studied by means of some simple diagrams . The first, Fig. 9, represents a cross-section of a model boat floating in water in a normal upright position. at The centre of gravity is shown at C.G., the centre of buoyanc y C.B.; the forces acting through them are in equal and opposite directions. Now if a horizontal force applied to the vessel causes it to incline to the right and assume a position shown in Fig. 10, the centre of gravity of the hull will be unchanged, and still remain at the same spot, C.G., on the centre- line of the boat; but the centre of buoyancy will move over to the right. There are three forces acting on the hull, one due to gravity or the weight of the vessel acting downwar ds through the C.G.; the second force also equal to the weight of the vessel, acting upwards through the centre of buoyancy and due to the flotational powers of the vessel. The third force is that which causes and maintains the change of position, and may at present be disregarded. Righting Couples Two equal, opposite, and parallel forces are termed a couple, and when they act together to maintain a stable condition of the hull they are ee known as a righting couple. Fig. 10.—Forces acting on Hull when inclined [ 24 ]

THEORETICAL CONSIDERATIONS _is the product of either force The moment of the couple into the perpendicular dis- tance between them. Thus the length G—Z ~< \ : y (used to distance) CGe multiplied by the weight of Cpe designate this the boat, is equal to the a moment of ‘statical stabil- = ity’. The length G—Z is also known as the stability lever. By inspection of Fig. 10 < . ‘ Fig. 11.—Neutral Equilibrium it will be observed that the centre of buoyancy acting upwards and to the right of the centre of gravity, through the agency of G—Z (the stability lever) exerts a righting force on the hull, causing it to resume the upright position; in other words the vessel is stable. Upsetting Couples If the hull were inclined to a much greater angle, as indicated in Fig. 11, until the centre of gravity and centre of buoyancy coincide in the same vertical plane, the vessel would remain in this position, the righting moment having reached zero. Should the vessel be heeled still further, the centre of buoyancy will travel to the left of the centre of gravity, and by augmenting the heeling force will cause the vessel to capsize. Such a couple is known as an upsetting couple. The Metacentre The word ‘metacentre’ is applied to the point where the vertical line of action through C.B. when the boat M is inclined cuts the original vertical central the boat. plane of This point—denominated M—is a fixed point for all small angles of inclina- tion, say up to 15 degrees or thereabouts. The relative positions of C.G. and M determine Fig. 12.—Method of finding position the stability of the model. of Metacentre When M [ 25 ] is above G, as in

MODEL POWER BOATS Fig. 12, the vessel is in a stable condition. When M and G coincide, that is to say, when the metacentric height is nil, the vessel is in equilibrium. When M is below G, the vessel will be in unstable equilibrium, and will capsize. Metacentric Height The height of the metacentre depends upon the immersed form of the vessel, and is quite independent of the length of the ship. The height is most conveniently ascertained from a drawing similar to Fig. 12, showing the vertical line through the centre of buoyancy, and extending it to cut the inclined line representing the original vertical central fore and aft plane of the ship. The distance between C.G. and M is known as GM and is equal to the moment of inertia of water plane area about the middle line, divided by the volume of displacement; and is strictly proportional to the of the breadth, and inversely proportional to the square depth. Metacentric Moment of Stability For all angles of inclination up to about 15 degrees or so the righting lever is equal to the height GM multiplied by the sine of the angle of inclination from the vertical. The moment of the restoring couple is equal to W x GMsine O, is displacement; where W GM is height of metacentre above C.G.; O is angle of inclination. For moderate angles of inclination the moment of stability is obtained by the above formula. Hence the conditions of sideways rolling of a model boat are governed by the height of the metacentre. Metacentric heights in real practice are approximately 20 ft. for a shallow draft flat-bottomed boat; about 5 ft. on a battleship; 3 ft. on light cruisers; about 24 ft. on tug boats; 14 to 2 ft. on T.B.D.s; from 6 in. to 2 ft. on passenger boats and liners. These heights reduced to appropriate scale will be useful A high metacentre makes a as a check on model boat designs. boat stiff or jerky in action, a medium or small metacentric height produces a boat with a low period of oscillation, that is, a boat that has a long, slow roll. [ 26 ]

THEORETICAL CONSIDERATIONS Effect of Ballast The addition of ballast, or a weight low down in the hull, alters the designed metacentric height and consequently affects the transverse stability. In general it tends to make the boat stiff and roll badly. The important point to grasp is that stability depends fundamentally upon the distance between C.B. and C.G. and the distance GM when the boat is inclined; and further, that the action of the boat amongst waves is markedly affected by the metacentric height and by the length of the stability lever. Hence the addition of ballast to introduce others of. worse character. correct one fault may Form of Immersed Hull The best design for a given purpose is that which has the most appropriate under-water hull form. When the boat is heeled the shape of that part which is in the water is different— in respect to the water—from what it was when upright. This new form determines the whereabouts of the C.B. in the heeled position and thus affects the stability and action of the boat. Action of Boat amongst Waves When a model power boat is travelling through a series of waves, so that, for example, one side of the hull is supported by the crest of a wave and the other side rests in the trough, a heeling force is imparted to the hull, and momentum carries it farther in the same direction until all these forces are balanced. As the boat passes out of the wave the forces diminish and the boat comes back to a normal plane of flotation. When the wave system is continuous at regular intervals, a rhythmic series of oscillations is set up and the boat continues rolling. The duration and periodicity of such rolling can be determined, or predicted, by rather intricate calculation; the model boat designer is therefore advised to confine attention to the general results obtainable from characteristic hull forms and changes in the length of the stability lever. Longitudinal Stability The longitudinal stability of a vessel is the power it possesses of resisting changes of trim, that is, variations of level in fore and aft direction. Actually, the same laws apply as those governing transverse [ 27 ]

MODEL POWER BOATS stability, but they are customarily dealt with separately. In one respect the problem is not so pressing because it takes a much greater force to affect the longitudinal stability. Disposition of Hull Weights Practically it becomes a matter of correct disposition of the weights in the hull when trimming a model for maximum longitudinal stability, as their position determines the fore and aft position of the C.G. and this must in any case be in the same vertical line as the C.B. But as the position of the C.B. is determined irrevocably by the shape of the immersed portion of the hull, it follows that the weights in the hull must be moved backwards or forwards until C.G. is in the vertical plane of C.B. The correct placing of the weights in the model calls for extreme care, as it should be apparent that when the position of C.G, alters, tlie boat must change trim until the immersed portion of hull, forwards or aft of the normal centre of buoyancy, displaces a sufficient amount of water to restore equilibrium. This shows the necessity for correct placing of weights, and proper proportioning of the forward and after bodies, as the portions of the hull ahead of, and astern of, the midship section or centre of gravity are termed. Reserve of Buoyancy To retard ‘pitching’, or sinking by the head, a good flare is needed at the bows, and as far as possible, a reserve of buoyancy aft to counteract the evil of ‘squatting’, or sinking at the stern. Beam to Length Ratio The proportion of beam to length of hull is known as the beam/length ratio; and this in conjunction with the beam to depth ratio has a marked effect on stability, speed, and the action of the boat amongst waves. A narrow boat with a fairly deep body is usually unstable; a broad, shallow boat, is very stable until considerably heeled. Various general types of hull have gradually evolved as the best for specified purposes: broad shallow hulls for racing; a rounded body for an easy seaboat; a rectangular section for maximum carrying capacity, and so forth. The ‘sharpie’ or box form hull has the maximum initial stability, and a circular section possesses a very low stability in a sea way; hence to reconcile compromise is often necessary. [ 28 ] these differing factors a

THEORETICAL CONSIDERATIONS The foregoing remarks apply particularly to boats of normal form, or those generally called displacement-boats; the conditions governing the action of hydroplanes, or small craft adapted to skim over the surface of the water, are in a somewhat different category. Brief consideration will show that there must be a critical speed beyond which it is impossible to drive a displacement type of boat through the water, because it will clearly take a definite time for the water to be pushed aside to allow the hull to pass, and a corresponding time for the water to flow back again. When a displacement type of boat is driven at higher speeds the hull is forced out of the water at the bows or stern and will ultimately sink outright. Hydroplanes A hydroplane is a boat intended to rise bodily at its critical speed, until it is partly out of the water; this obviously reduces skinfriction and therefore allows much higher speeds to be attained. Two separate states or conditions require to be considered; first the ordinary laws governing displacement boats, such as the displacement, initial stability and so forth, which must be adequate when the boat is at rest and apply until the critical speed is reached. At and beyond that speed the boat exhibits a new property, which for convenience may be termed dynamic stability. The phenomenon of dynamic stability is exemplified by an ordinary bicycle. This, when at rest, will not remain unaided in a vertical position, but when set in motion it acquires the property of stability, and safely and vertically supports the rider. Dynamic stability is imparted to a model hydroplane by reason of the form of the hull and the relative solidity of the water at high speeds. A graphic understanding of the forces acting on the usual double flat plane type of hull can be appreciated from the diagram Fig. 13, which shows in profile a typical hydroplane hull. Balance of Opposing Forces Suppose the fore and aft position of the centre of gravity is located at G., and the centres of pressure on the two inclined surfaces are located at A and B; it follows that the pressure on the forward plane will exert a turning effort about G., and the pressure upon the after plane will act similarly but in the contrary direction, [ 29 ]

MODEL POWER BOATS Complete dynamic stability is only obtained when these forces acting through A and B exactly balance one another, as under that condition the hull will then tend to rise bodily and will moreover be remarkably steady when running at high speed on smooth water. as =e — Fig. 13.—Forces acting on a Hydroplane Hull RESISTANCE AND PROPULSION The word resistance is applied in a general sense to the sum © of all the forces acting upon a model boat which retard or entirely prevent its passage through water. These resistances are due to several separate and distinct causes, and so far as they apply to displacement boats can be subdivided into five groups, which in order of importance are called skin friction, eddy making, wave making, the wake, and air resistance. Skin Friction The frictional or skin resistance is caused by the friction of the water on the immersed surface of the ship. The laws governing it have been enunciated by the researches of the late Dr. W. Froude, who found that the resistance varies with the nature and the length of the surface in the direction of its motion; and approximately as the square of the speed. The experiments enabled the skin friction to be accurately determined, and for all practical purposes the resistance per square foot of wetted surface taken as a mean over the whole surface of the hull can be fixed at the following values: Varnish Paraffin Wax -Tinfoil ah a a as — “41 Ib. “38 s ue 30 4, ,, Coarse Sand .. = se 110; These results were obtained at a speed of 10 ft. per sec., which equals 5-92 knots, or 6-8 m.p.h. [ 30 ]

THEORETICAL CONSIDERATIONS Average Resistance of Model The approximate resistance of a model power boat is about +25 Ib. per sq. ft. of wetted surface at a speed of 6 m.p.h., and ina metre model of average form would be in the neighbourhood of 4 lb., assuming a surface of 280 sq. in. immersed, at a speed of approximately 7 m.p.h. It should be noted that the resistance varies considerably according to the nature of the surface; hence the practical ship modeller will endeavour to secure a perfectly smooth hull surface. Increased Resistance at Speed The foregoing figures for skin friction were taken at a speed of 5-92 knots, but the resistance varies with changes of speed. Skin friction varies as the 1-83 power of the speed. The calculations are intricate, consequently the following table of values (Prof. Sir H. J. Biles) should be of help to the designer. FRICTIONAL INDIE EL, : RESISTANCES V=Speed in knots IM [es (<5 ) We \ 1-83 oe 1-15, 1 0386 3°45 OPS 3 3 2883 7341 7 1-359 10:3 8-06 5 Dell sy 12-6 11 3-107 es 13 GePNG) 17-27 1S 5-482 1955 17 6-893 268 19 8-448 24-1 29:33 21 22 11-048 26-4 25. 11-985 28-78 25 13-961 31-09 27, 16-071 34-5 30 19-489 38-0 33 wes 35 232202 25-841 42-60 37 28-606 46-04 40 322993 [ 31 ] 10-146

MODEL POWER BOATS The formula for the calculation of frictional resistance due to skin friction is: RF=FMxMxs RF=Frictional resistance in pounds. FM=Mean resistance in pounds per sq. ft. of wetted surface. V = (sz) \1-83 S=Surface of immersed hull in sq. ft. The table is used in the following way: Suppose, for example, that FM equals -41 lb. per sq. ft., and the model has 24 sq. ft. of wetted surface, then FM equals 1-025 lb. at 6-8 m.p.h. To find the resistance at any other speed (either in knots for example, 25 m.p.h.; under column V or m.p.h.), say, equals speed in m.p.h. opposite 25-33 read 11-048 as the value of M. Substituting values in the formula; RF equals 1-025 x 11-048 ==11103)2 ily. This enormous increase of resistance with increase of speed is one of the chief reasons why so much more power is needed materially to increase the speed of a given model boat. It should also be remembered that skin friction imparts a velocity to the water in the immediate vicinity of the hull and partly causes the zone of frictional disturbance and the frictional wake, and to some extent distorts the stream lines, or energy flow, around the hull. Eddy Making Eddies are disturbances of the water caused by partial aeration and internal movement of the water. Eddy making caused by appendages such as shaft brackets, rudders and sudden changes of hull form is not a serious energy loss, except at high speed when it becomes imperative to take all possible steps to eliminate eddies. The practical remedyis elimination of all such changes of hull form and a careful streamlining of those which cannot be dispensed with. Wave Making Lord Kelvin defined wave making as an “orderly progression through matter of a state of motion,” and as “‘the progression of a displacement.” [ 32 ]

THEORETICAL CONSIDERATIONS oe . Fig. 14.—A selection of ‘Solid’ Glass Case models built by Norman G. Taylor to a scale of 100 ft-1 in. Reading from the top these are: ‘Britannic’, ‘Strathnaver’, H.M.S. ‘Repulse’, H.M.S. ‘Hood’, ‘Queen Mary’ and ‘Normandie’. These models are fascinating to construct, and make excellent ornaments for studio or ‘den’ Cc E33]

MODEL POWER BOATS When a model boat is at rest the hull surfaces are, practically speaking, subjected to uniform hydraulic pressure. When the boat is set in forward motion, the distribution of these forces is disturbed, and this change is accompanied by a corresponding. alteration or increase of pressure in one part, with a diminution of pressure in others. The surface pressure due to the weight (Hire | —— ——= —_—— Cc | =e cost = —_ = | = — .B — eer! — ———d ee Fig. 15.—Wave Making Systems of the atmosphere always remains constant, consequently differences in level become apparent and these differences of level are known as waves. Bow Wave System As the boat moves forward, the normal stream lines at the bows are disturbed and a system of ‘bow waves’ as at B in Fig. 15 is generated. At the stern a similar disturbance takes place, the decreasing speed of the stream lines being accompanied by an increase of pressure, and the formation of a stern wave system as at S. The bow system is caused by the passage of the body and is a regular wave of translation; the energy needed to generate it is entirely lost. Parallel Middle Body The middle portion of a boat is usually more or less parallel and causes little or no extra wave making resistance; the only practical resistance of the middle body at ordinary speeds is due to skin friction. The increased efficiency of large vessels over properly proportioned smaller models measure explained. [ 34] is thus in some

THEORETICAL CONSIDERATIONS Stern Wave System The conditions around the after body and stern of a model boat when in motion are largely conjectural, but in addition to the diverging stern wave system S it is fairly certain that a series of transverse waves as at ‘I are generated which appear to follow the ship, together with the wake, as at W in Bigs 15, Some of the transverse wave system T is due to the frictional disturbance, and some of the energy in it may be returned, as may some of that from the diverging stern wave system. Wave making is a necessary evil and cannot be entirely eliminated, although much can be done in this direction by a clever hull designer. At low speeds of 1$ to 2 m.p.h. wave making is practically non-existent, except with very small models. Wave Making by Hydroplanes The wave systems associated with hydroplanes and boats with ‘steps’ are of various forms, dependant chiefly on the hull form. A characteristic form at the critical speed is sketched in oe if aaeeeaes Ss 1 ee Pp ee —— Se —— eee fis eS ESS ae, e—= ———— Se T — ae 1 ee ' WwW ' ————— 4 —- a ——d«sP=— ee — Seen eee, Som an | ZA i) Gees + B — —— oe =< og — E ee ae Seria Ss —— ——— a — Fig. 16.—Wave Making by Hydroplane at Critical Speed Fig. 16. Usually there is a small bow wave system as at B, a narrower stern system S, and a closely associated duplex system E—P generated by the step. In a well-designed boat this duplex system may be eliminated —or practically so—by arranging that one damps out the other; the result is then a particularly efficient and clean-running boat. [ 35]

MODEL POWER BOATS The Wake The resistance of the wake is due to the water being set in motion in a forward direction, thus resulting in a loss of energy and speed. Some: of it may be regained by suitable propeller arrangement. Air Resistance Many model boat designers pay very little attention to the losses due to air resistance, although a relatively large portion of a model power boat hull is exposed to air currents. Air resistance is only -005 AV (A equals area exposed in square feet; V equals speed in feet per minute), but it increases as the square of the speed, and at the high velocities now attained by model boats becomes a factor that should be reckoned with very seriously. The effect of a head wind is enormous. A model moving at 6 m.p.h. in a calm, with an air resistance of only :540 Ib., experiences an air resistance of 1:5 Ib., against a head wind of only 4 m.p.h. The only practical remedy for reducing air resistance is good aerodynamic design of all cabins, superstructures, etc., and of course good hull design. Total Resistance The sum of the foregoing resistances constitutes the total resistance to the motion of a boat through water; or more properly to a boat that floats on the water; the case of a submarine when submerged is quite a different matter. One of the greatest problems is to ascertain accurately the value of the total resistance at the required speed, as without such knowledge it is impracticable to determine with precision the power that must be developed at the propeller to overcome drag. Power Needed to Drive a Model The energy that must be expended in overcoming the total resistance of a model power boat at a given speed cannot be calculated with absolute precision; all that can be definitely stated is that. the thrust of the propeller must equal the total drag, or resistance. The practical difficulty of ascertaining the necessary power of the engine(s) is due in part to difficulties of propeller design. [ 36 ]

THEORETICAL CONSIDERATIONS A very close approximation, however, can be arrived at for boats of normal form and reasonable speed, by application of the following formula: TH eo FMxV s0000 ~ where T is effective power at propeller, FM is total skin friction in Ib. at the appropriate speed, V is speed of the boat in ft. per minute. Take as an example a metre boat with 2% sq. ft. of wetted surface, then FM will equal 1-02 x 6-89 at a speed of 20 m.p.h., equal to 1,773 ft. per minute. Substituting values in the formula: oy 1:02 x 6:89 x 1773 33000 12460-28 ely eee oe This figure is the power required at the propeller, and to ascertain the total power of the power unit an amount must be added to compensate the losses in engine and propeller shaft friction and any other mechanical losses. Transmission Losses This amount may vary from 25 per cent to 70 or 80 per cent according to the efficiency of the plant. A reasonable average is 40 per cent, consequently from the foregoing example the total power is: 40 x -307 100 = 1924-307, giving a total of -429 h.p. Taking another case, that of a high speed single step flatbottomed boat, running at 42 m.p.h. The skin friction at this speed will be greatly reduced owing to the small area immersed. Taking this at 2/3 sq. ft. gives, from the table on page 31, a value of 16 Ib. at 42 m.p.h. Substituting values in the formula gives: 16 x 3600 33000 = 12 hp. at the propeller. Theory of Propulsion There are various ways of driving a model power boat through the water, of which three are commonly used; these [ 37]

MODEL POWER BOATS are the jet system, the use of revolving wheels with plates or ‘floats’ upon them, and by means of a rotating device known as a propeller or water-screw. The Jet System This method is employed to a limited extent on real boats, and is extensively used in a modified form on many small commercially made models. Essentially it consists in forcing a jet or stream of water in a sternwards direction; the reaction of the moving column of water drives the model forward. (This method of propulsion is in no way connected with ‘Jetex’ jet motor propulsion). Paddle Wheels By the paddle system, a pair of comparatively large diameter wheels are mounted on a shaft directly driven by the engine(s), and placed athwart-ship at about the middle of the length of the boat. Floats or vanes are attached radially to the wheels; the whole is so arranged that only the lower parts of the wheels are submerged, and the floats thereon move through the water in a contrary direction to that of the boat. Forward motion is attained partly by the direct pressure of the floats upon the water and partly because the water is set in motion in a sternwards direction. Originally, it was supposed that the paddle-wheel acted in the water in a similar manner to a pinion in a rack. Actually, however, it is the setting in motion of a column of water which is forced through the adjacent and relatively still water, that drives the boat forward. In some cases a single wide wheel is placed at the stern, but the principle is the same in either case. The Screw Propeller Marine screw propellers are divisible into three groups: (a) those which rotate in air and can be termed air-screws ; (b) those which rotate partly in the water and partly in air, and generally called vane wheels; (c) the totally submerged water-screw or propeller. The first two groups are not extensively used for model ship propulsion, although in certain circumstances they have sundry practical advantages. Except where stated to the contrary the [ 38 ]

THEORETICAL CONSIDERATIONS term propeller is here taken as applying to the fully submerged screw propeller, now almost agrcrsaly employed for marine propulsion. Fundamentals of Propulsion The action of any form of marine propeller—while the boat is in steady motion—is fundamentally dependent upon the sternward projection of a column of water called the propeller race. The change of momentum of this water, per unit time, is equal to the thrust of the propeller, and is balanced by the resistance of the boat. The basic problem of propeller design is therefore to devise _ an instrument which will force a sufficient quantity of water in a sternwards direction, and at a sufficient speed, to equal the resistance of the boat at the given speed. So far the submerged propeller has produced the most satisfactory results. [ 39 ]

CHARTER ITt PLANNING AND DESIGN Ir is essential to have a clear and accurate plan to work to when constructing a model. If you are designing your own boat it is obviously fairly important to have the necessary equipment with which to create the plan; this equipment need not be elaborate, suprisingly few drawing instruments being required for making a full size pencil (or ink) drawing of your proposed model. The majority of model boat builders only require a plan which is full size and accurate enough to work to, and which may be kept for future reference—the elaborate ink drawings on tracing linen for reproduction purposes being left to the professionals! Drawing out the plan for a model is quite easy providing you take a reasonable amount of care, and it is well to remember that should you wish to improve your knowledge of draughtsmanship, the local library will usually be able to provide a number of useful and instructive text books on drawing office practice; by reading these you will soon get acquainted with the fundamental requirements of accurate drawing, the laying-out of plans, and the correct use of drawing instruments. The Drawing Board First and foremost must come the all-important question of the surface on which you are going to draw. A good quality drawing board measuring, say, 42 in. x 29 in. may cost quite a considerable amount of money, but if you can afford to purchase one you are strongly advised to do so. A point worth remembering when purchasing a drawing board is to see that it has a number of slots at the back so that any further shrinkage of the wood will not cause the board to crack on its working surface (see Fig. 17). All good quality boards are made with this feature incorporated. There are, of course, alternatives to a drawing board. In many cases a piece of perfectly flat 3- or 4-in. plywood about 42 in. x 24 in. will do almost as well. If a board of this type is used it is important that the left-hand edge be made perfectly | 40 J

PLANNING straight and true, so AND DESIGN that a tee-square may be used with accuracy. On the other hand, if a flat-topped table is available then this will do quite well for drawing on—a few sheets of paper spread over a table with recesses in its upper surface will prevent the pencil digging through the drawing paper—but in any case the left hand edge should be checked for straightness, and if found to be uneven a strip of perfectly straight timber should be screwed in position (the screw heads being countersunk) - to give an accurate bearing for the tee-square stock to run on. Fig. 17.—Rear surface of good-quality Drawing-Board. prevent workings surface from cracking Slots Drawing Board Sizes Half Imperial .. Be 0 223 1M. Imperial a 2 - 32m. X23 in, .. hous Double Elephant .. Be 2 42m 29m: ANOINTING os i Of Ii. O21: Extra Antiquarian SS -, 60 in. x 36an. Hamburg = 5 . (52 wn, 22 ie, = Drawing Instruments It is surprising how important a straight line designing and laying-out the plan of a model! is when Implements which allow the drawing and positioning of straight lines are: (1) Tee square—Usually made of pear wood with a teak or composition inset bevelled edge. 36 in. is a useful length for the model boat designer. Lat

MODEL (2) (3) POWER BOATS Rule or Straight Edge—Hardwood for drawing, or steel engineer’s type which can be used for drawing and also cutting cardboard, thin ply-wood, etc. 12 in. is sufficient for most purposes. Set squares—A 12-in. 45-degree and a 12-in. 60-degree set square will be of real value. All the above-mentioned items are illustrated in ie; lice reference to which will show how horizontal lines parallel to each other are drawn with the tee-square, and how vertical lines are made by using a set-square in conjunction with the tee-square. Fig. 18.—Tee square, rule, and set square on the Drawing Board Quality before quantity should always come first when purchasing drawing instruments. The essentials are shown in Fig. 19, and consist of the following items: 1. Plain compasses; 2. Plain dividers; 3. Spring-bow compasses; 4. Spring-bow dividers; 5. Protractor (for measuring angles). Inking-in attachments for these instruments are shown, but these will not be required unless reproduction drawings are to be undertaken. Special Drawing Instruments Items not usually found in the mechanical draughtsman’s kit are a set of ‘ship’s curves,’ which are pieces of thin pearwood cut to curved shapes based on the parabola and found by long experience to be generally useful; also a set of ‘French curves’ E42|

PLANNING AND DESIGN Fig. 19.—Basic Drawing Instruments required. Reading from left to right: plain Compasses, plain Dividers, spring-bow Compasses, spring-bow Dividers, Protractor are extremely useful. Splining battens—long thin slips of lancewood, rectangular in cross section and tapered as regards their length—are absolutely essential for drawing long flat curves. A spline is comparatively expensive because a good one can be uniformly curved without forming a bump or hollow; it should be handled carefully, and when not in use should be suspended from one end by a clip. Batten Weights Splines or battens are held in position on the drawing while curved by means of heavy lead weights with a wooden base, generally shaped as shown in Fig. 19, where the method of using a spline is clearly shown. If special batten weights are not available a few domestic flat irons can be used as substitutes, but they are not so efficient in use. Use of Splines and Ship’s Curves To draw a curve with a on the drawing a spline, it is necessary first to mark series of small spots through which the curve is to pass. ‘Then lay the spline on the drawing, and place weights at each end—carefully adjusting until the spline takes a fair easy curve through all the spots; it is then held in that position with the aid of batten weights (see Fig. 20.) [ 43 ]

MODEL POWER BOATS Charge the ruling pen with Indian ink and holding it almost erect, run it over the paper, guiding it by the edge of the spline. Ship’s curves are used in a similar manner; the usual method being to indicate on the drawing the whereabouts of a series of spots on the path of the desired curve and then apply the ‘curves’ to them, until a satisfactory shape is indicated—the pen or pencil is then run around the edge of the curve and a neat smooth line is made upon the drawing. An alternative method—used by many modellers—is to draw all the curves lightly in free hand, using a soft pencil, and afterwards to perfect them with the aid of the ship’s curves. This method tends towards spontaneity and freedom, but often necessitates the use of several ‘curves’ to ink in any one section. When blending one curve into another it is imperative to do so without changing the character of the curve. This should be clear from Fig. 21, where two unsuitable curves have been joined at A, the illustration being exaggerated to emphasize the faults. By comparison with B it will be seen that the first curve is jerky, whereas the latter is smooth, although both pass through the same fixed points C, D, E, on the original drawing. Completing our list of “Drawing Office’ requirements we come to the expendable items. Pencils should always be carefully selected; a good quality HB being used for writing and drawing in details, and the harder F or H grade employed for drawing Fig. 20.—Spline and Batten Weights in use [42 |

PLANNING AND DESIGN lines which must always be clear and thin. Good quality drawing paper is quite an expensive item, and need only be used for drawings and plans which are going to be kept for reference purposes. For plans on which you are going to work (and therefore probably spoil) thin cartridge paper will do, or even a roll of white ceiling paper. Carbon paper has a great many uses, for copying and making reverse drawings of templates, etc., and a few large sheets should always be kept handy—be sure to use a hard thin-pointed pencil when tracing over carbon paper. Fig. 21.—Good and Bad Curves Preparing a Set of Hull Lines A model boat hull of any type can only be completely delineated by means of three separate drawings, these being known as the sheer plan, the body plan, and the half-breadth plan; collectively, these drawings are known as the hull lines. The sheer plan shows the vertical longitudinal shape of the hull, and is projected upon the vertical longitudinal centre plane. A series of vertical lines are also drawn upon the sheer plan and these indicate the position of sundry vertical planes at right angles to the centre line of the ship. The half-breadth plan is one that shows the horizontal shapes of the boat at different levels or water-planes, the relative positions of which are shown by the horizontal lines on the sheer plan. For ease of reference it is usual to draw the halfbreadth plan immediately below the sheer plan, with the vertical lines on that drawing projected on to the half-breadth plan. As a boat is symmetrical about the longitudinal centre plane, only one half need be drawn. Lastly we come to the body plan; this drawing is an end [ 45 ]

MODEL POWER BOATS Fig. 22.—An experienced model builder, Mr. Tilley, trying out his model of a steam trawler on the boating lake in Abington Park, Northampton Fig. 23.—An ideal prototype for the scale model enthusiast— ‘Cullamix’ of the Cement Tug Fleet. Plans for building a superbly detailed model (Length 394 in, Beam 10 in.) are published by Model Maker Plans Service. Suitable for Radio Control and the installation of steam power plant as prime mover, or for larger internal combustion engines [4]

PLANNING AND DESIGN Fig. 24.—One-tenth scale replica of the full-size cabin cruiser ‘Deglet Nour’ built from Model Maker Plans Service drawings. Length: 36 in. Suitable for Radio Control with either I.C. or electric power view of the hull and shows the shape of the cross sections of the planes indicated by the vertical lines on the sheer plan and the corresponding lines on the half-breadth plan. In practice, the body plan is often superimposed on the sheer plan or halfbreadth for economy of space. ‘The three drawings above mentioned are intimately related and should be thought of as one drawing. A graphic representation of this inter-relationship is given in Fig. 25, where a typical boat hull is shown as if cut asunder through some of the planes mentioned above; while three sheets of paper are shown parallel to the planes they represent. The sheer plan is shown at A, the body plan at B and the tar

MODEL POWER BOATS half-breadth plan at C, the latter being in a horizontal plane; the body plan B is vertical and at right angles to both C and A, while the latter is vertical to C and its plane is the centre of the Fig. 25.—Inter-relationship of Hull Lines boat as represented by the centre lines DE on the half-breadth and body plan; the dotted lines show how the various planes are projected from one to another. Setting out the Hull Lines The procedure when setting out the plan of a model is to draw first the L.W.L. (Load Water Line) on the sheer plan, and at a convenient distance below it, draw the centre line DE on the half-breadth plan. Then draw the centre line DE and the L.W.L. on the body plan. Next, draw the horizontal water line W on the sheer and body plan and then draw the vertical section lines 1, 2, 3, etc., on the sheer and half-breadth _ plans. ‘Then on the sheer plan draw an outline of the hull, and on the body plan draw a trial midship section, noting that the height H on the sheer plan must be transferred to the body plan. Similarly the depth below the L.W.L. must be marked on the centre line of the body plan. The next step is to draw a trial L.W.L. on the half-breadth plan. This will be a curved shape, somewhat as indicated in the [45]

PLANNING AND DESIGN illustration Fig. 25, at L.W.L. The only guide to the breadth of this line is the dimension F, which should be transferred from the body plan to the half-breadth plan, and the L.W.L. must cut the cross section line, in this case No. 4, at this spot. The Trial Load Water Line The trial L.W.L. on the half-breadth plan now cuts other section lines as at 1, 2, 3, etc., hence the widths at these points can be set off with dividers along the L.W.L. on the body plan, and other trial cross sections drawn through them. From these cross sections the half-breadths on the horizontal line W can be transferred to their corresponding sections on the half-breadth plan and a curve drawn through them which will be the shape of the water plane at the level indicated by the horizontal lines W on the sheer and body plans. Hence from one line, the drawing is gradually built up, and as each fresh line is drawn on one plan the corresponding Fig. 26.— Positions of Buttock and Diagonal Lines dimensions are transferred to the others as in Fig. 25 until the whole is complete. While the drawing is actually being made it will soon become apparent that to get all the curves into harmony will necessitate altering them from time to time to preserve absolute accuracy on all three plans—a process known as fairing-up. D | as)J

MODEL POWER BOATS Fig. 27.—First class exhibition model of Vessel No. 1813 ‘Helix’ built by Messrs. Bassett-Lowke Ltd., to a scale of { in.-1 ft. It is very tempting to make one curve look nice and not to bother to correct all the other places which are affected by the alteration, but unless this is done and the three drawings kept absolutely accurate at every point where a cross reading can be taken, it is worse than useless as a working drawing, because every error on the drawing will be reproduced on the actual hull. Setting out the Buttock Lines A hull drawn and faired-up as described above might seem to be perfectly accurate, but on reflection it will be seen that vertical planes parallel to the central longitudinal plane can be shown on the drawings and they will check up the shape at a different series of points on the hull surface. Such lines are known as buttock lines, and they are graphically shown in Fig. 26 at B and B! under similar conditions to the same hull illustrated in Fig. 25. as Actually the buttock lines show a great deal to the practised eye, particularly the speed qualities of a hull. The vertical distances of the buttock lines from the L.W.L. at each station [ 50 ]

PLANNING AND DESIGN _ Fig. 28.—Admiral’s Barge. Length: 33? in. Beam: 9} in. Plans by Model Maker Plans Service. Designed for Radio Control have to. be set off on the vertical buttock lines on the body and sheer plans. ‘The points at which the water lines on the halfbreadth plan cut the buttock lines thereon have to be transferred along the horizontal W lines on the sheer plan. The buttock lines then appear as curved lines on the sheer plan and aight lines on the other two plans. Accurate instruments and draughtsmanship are essential to success when making these drawings, it being interesting to note that some saving of time can be effected by cross-projection, i.e. by projecting by means of a T-square the various points of intersection between one drawing and another. This method is particularly helpful when the half-breadth plan is beneath the sheer plan and the body plan is at one side. Diagonal Lines An inclined plane can be taken longitudinally through the hull and the boundary of this plane will appear as a curve and is actually one that exists on the surface of the hull at that plane. The relative position of this plane and the inter-related lines on the drawings are graphically shown by the lines D in Bist 26, The diagonal is generally shown on the half-breadth plan, and the diagonal distance J, on the body plan, is set off along [ 51 ]

MODEL POWER BOATS the section lines (as at 4) on the half-breadth plan. The points obtained in this way are spots on the path of a curve which should pass evenly and harmoniously through them all. The diagonal Jine does not, as a rule, appear on the sheer plan. Diagonal lines are most valuable in the final fairing-up of the hull, and several such lines may be drawn if a very exact piece of work is being undertaken. Moreover, these diagonals indicate to the trained eye the characteristics of the volumetric displacement or rate of change of volume of the hull. General Conclusions When the lines are thus completed in pencil, they should be carefully inked in, or a tracing made of them and the original preserved for future use or reference. In addition, the whereabouts of the various centres, the distinguishing numbers of the sectional lines, the value of displacement and any other useful data should be recorded on the drawing. Drawing the Superstructure and Details The various upper works, cabins, funnels, deck fittings and other details should be shown on a separate drawing, and it is generally sufficient to show the hull from the L.W.L. upwards and to give a deck plan. One half of this may show the positions of deck fittings, etc., and the other half can show details of con- struction of the cabins or other parts. One or two cross sections are desirable. The propulsive machinery need seldom be shown in full detail, the foregoing plans usually being sufficient. The power unit can be shown in outline only, and salient dimensions given, such as propeller shaft centres, engine mounting position, and any others that are essential to the proper fitting out of the hull. When space in the hull is restricted, a number of cross sections should be taken showing the thickness of the hull to ascertain that the power unit will go into the space available, as this information cannot be gleaned directly from the previous drawings. Designing a Representative Model The foregoing hints on the method of making a drawing are quite distinct from designing, and having thus cleared the [ 52 ]

PLANNING AND DESIGN way, the following notes are intended to indicate how the various centres can be determined, how to ascertain the displacement, and various other matters of a like kind. At the outset it must be realized that theory and calculation alone will not produce a really successful boat; the human element of ‘knowing how’ which is gained solely by lengthy experience cannot be dispensed with. Furthermore, it should be noted that the methods advocated are not the only ways of accomplishing the desired results; there may also be better ways, but experience has proved them to be good methods, hence they may be followed by the novice until sufficient experience has been attained and the novitiate becomes the practical exponent. Preliminary Considerations The first thing to do is to settle the leading dimensions or scale of the model; if the hull length is fixed, the scale is governed by it; but if the model is to be to a specified scale, the length will be fixed according to that scale. The next step, and a very important one, is to decide upon the motive power and its approximate weight, then to add sufficient weight for the hull, decks, and fittings, and thus arrive at a trial displacement value and a general comprehension of what is required. All that follows applies equally to any kind of representative ship model of normal form, but for convenience it will be assumed that the hull is 1 metre (39 in. approximately) in length, the displacement about 10 lb., and the boat a model liner or cargo boat. Allocation of Weights As the design work progresses so the drawing is carried out by showing upon the lines those parts which have to be settled by calculation, consequently the L.W.L. and centre lines are drawn in ink and the overall hull length marked in pencil. The estimated total weight of 10 lb. is made up as follows: machinery (with allowance for radio-control equipment) 5 lb., propeller and transmission with rudder 4 lb., hull and deck with superstructures 24 lb., deck fittings 14 lb., paint and varnish 3 |b. [ 53 ]

MODEL POWER BOATS Determining the Area of Mid-section The next thing to do is to determine the area of the midship section, which is done by the use of certain coefficients, of which the first is the block coefficient. This is the ratio of the volume of the under-water body to a rectangular block, whose length is equal to the load water line, breadth equal to the beam, and the depth equal to the mean draught of the model in question. The cubic area of the underwater body divided into the cubic area of the block gives the block coefficient. The load water plane is taken as being the top of the block. The average block coefficient for model battleships is -6 to -65; for cruisers -5 to -55; model T.B.D.s :-45; for model racing boats of extreme type 35 to -45. Cargo boats and other bluff boats have a coefficient as high as «7 to °8. The Prismatic Coefficient This is the ratio the volume of the underwater body bears to the immersed area of the midship section multiplied by the length of the water line. The ratio may vary from -45 to -84. Typical values are: tug boat -45; T.B.D. 55; cruisers -71. The third coefficient is the mid-section, which is the ratio of the immersed midship section area to a rectangle having the same beam and draught as those at the midship section. Average values are -75 to -8 for fairly fast boats and -85 to ‘9 for boats with broad flat floors. The length of the L.W.L. being known (say 38 in.) and the displacement (10 lb.) the area of mid-section is calculated by dividing the displacement in cubic inches (270) by the L.W.L. in inches (38) and by the prismatic coefficient. 270 ‘Thus 38° equals 7-1. This divided by -8 equals 8-9 sq. in., and with this as a guide a trial mid-section can be drawn after selecting a reasonable beam and draught. Determining Draught and Beam Knowing the approximate value for the area of M.S., the area of a rectoid equivalent to the product of beam multiplied by draught can be determined by dividing by the mid-section coefficient, which in general has a value of about -85. [ 94 ]