- Festive, Part II of W. J. Daniel’s Marblehead Yacht (Plan available in US VMYG Store)

- History & Development of Model Yachts, By Bernard Reeve

- A New Vane Steering Gear, By S. Elphee

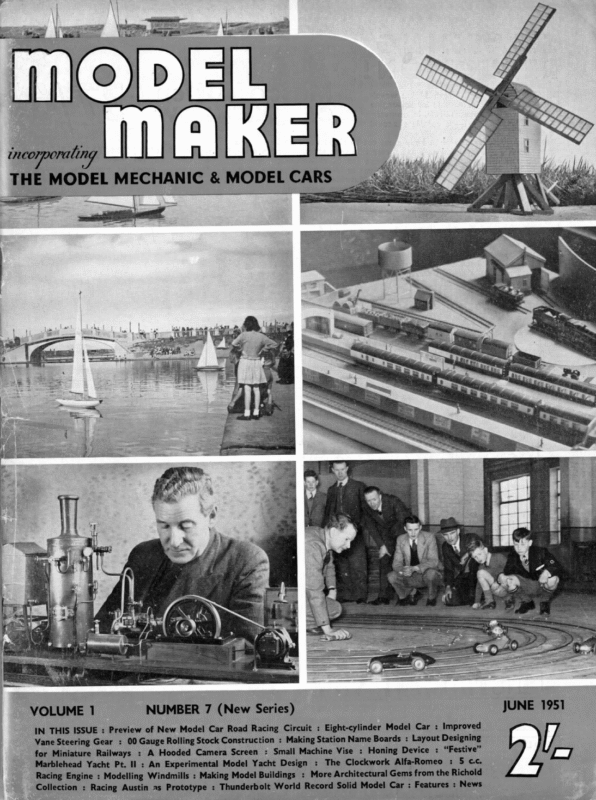

R E K A m be oe THE MODEL MECHANIC & MODEL CARS VOLUME 1 JUNE 1951 NUMBER 7 (New Series) IN THIS ISSUE : Preview of New Model Car Road Racing Circuit : Eight-cylinder Model Car : Improved : 00 Gauge Rolling Stock Construction : Making Station Name Boards : Layout Designing Steering Gear VaneMiniature Railways : A Hooded Camera Screen : Small Machine Vise : Honing Device : “Festive” for Marblehead Yacht Pt. Il : An Experimental Model Yacht Design : The Clockwork Alfa-Romeo : 5 c.c. Racing Engine : Modelling Windmills : Making Model Buildings : More Architectural Gems from the Richold 2 Collection : Racing Austin as Prototype : Thunderbolt World Record Solid Model Car : Features : News ee es eee {/LJ

PART Il OF W. MARBLEHEAD Owing to the heavy commitments of J. DANIELS’ YACHT ao 62 our modelmaking department in completing special models for the Festival of Britain, it has not been possible to provide step-by-step building pictures for this instalment of ‘‘Festive’’. However, Part III will be enlarged and contain detailed closeups of all points of difficulty encountered in the light of correspondence that we have received. FESTIVE OU will notice that on the cross-section plan that Now set off the width that the plank is to be at each mould and draw a line through these points. A hard- lines have been drawn at various angles crossing each section. These are used by the designer for ensuring the fairness of the curves around the hull as by setting off at each section from the centre line the distance of each inter-section and testing whether a true curve can be drawn through each point. These lines will also give the builder an idea for the run of the planking. It will be seen that by starting at the garboard that the first plank will be wider at the ends than at the centre. Take a piece of the planking of sufficient length and width to reach the recess in stem and stern piece, one edge of which must be dead straight, and fit it in position. It will be found that the angle at each end can be marked and cut to fit into the rebate. It will overlap the underface of keel, but this can easily be cut down to the level of keel after fixing. The plank for the other side can be marked out using the first as a template. Having made the first planks they can now be fixed by glueing and pinning as before described, with fine copper nails with cardboard washers under the heads. This will enable the pins to be withdrawn after the glue has thoroughly set. The rest of the planking must now be determined. The most economical way is to have a wide board and cut each plank separately, and proceed as follows. Mark off from the cross-section plan the point at which the diagonal lines cross each mould, and taking a strip of planking about 1 in. wide, make one edge straight and tack it lightly on each mould at the lower diagonal position. This is known as the spiling plank. You must determine how many planks you will take to cover up to this point. Measure each distance and by dividing these by the number of planks you have decided to use, you will have the width of each plank on each section. If you bend your spiling plank round the frame so that it lies flat on each rib you will notice that the inner edge will not lie parallel to the edge of the plank already in position. Take your dividers and setting them at the widest gap prick off points on each mould from the edge of the first plank to the edge of the spiling plank. Place the board from which you are going to cut your planks on a flat surface and draw a line through these points and cut to the line. wood spline % in. x } in. will take the curve nicely. You now cut to this line. You have now to fit it to the angle at each end to set properly in the rebate, and after repeating it for the other side glue and fasten each in position as before described. It should be arranged that the last plank of the topside is wider that those below it for appearance. Having completed the planking there will be a gap between the top plank and inwhale between each rib. This gap should be filled in with strips, the same depth as the inwhale at each point. The fin is the next job. The simplest way for the beginner and for the expert also, is to take pieces of timber of the same thickness as shown on the design slightly longer than the length of each layer, which will be noted, are as long as from the top of the forward end to the top of the lower face aft. All these pieces should be as wide as the largest cross-section dimension. You now arrange them on your drawing so as to cover the outline of the fin and mark off each section all round both faces and sides. Gauge a line down the centre of each piece and either number or letter each for identification. On the top face of each lay off the shape. Square off the ends to the sides of each piece and placing them together so that section lines coincide, draw the outline of the fin on the side. Cut out square to the profile. The position of the bolt holes should now be marked and drilled before glueing. Two bolts of ys in. drawn brass rod will be sufficient. Now cut the widest waterline piece to the shape. It is best to saw about 4 in. from the line and trim down to it with chisel or small block plane. You now place this piece face downwards on the next one and mark the shape of it, care being taken that the centre line and cross sections are in correct position. This layer can now be sawn, care being taken to keep outside the line and then trim the upper face to its correct shape. The reason for this procedure is obvious, as if you saw to the shape of each upper face the under face will not be wide enough to cover the one beneath it. This procedure is, of course, only necessary in the case of a bulb fin. Having cut each layer for the keel appendage they 394

MODEL MAKER PHOTOGRAPHIC CONTEST HIS interesting little International Class Dinghy, built to a scale of one-twelfth, is one of two excellent pictures entered by Mr. A. W. Bennett, of Maidstone, in our photographic contest. The technical quality of the print is beyond criticism, in fact, our problems would all be solved if contributors would maintain so high a standard! But, for the benefit of our entrants, we are sure Mr. Bennett will have no objection to our using his picture to point a lesson. On the left-hand side it will be seen the background is dark and without shadow, but on the right there is a certain obtrusion from the brickwork. Had the whole boat been moved about 2 ft. to be directly in front of the dark doorway a far more pleasing picture would have resulted. Normally, our art department would air-brush the undesirable background to a neutral tint; a process which, carried out forty or fifty times, makes hard work of an issue! The moral of this picture then, is choose your backgrounds, and get them well out of focus to avoid any jarring note. Dark doorways for light subjects, or low angle pictures to get sky backgrounds for darker objects can usually be found without any need to put up any special backcloth. HISTORY AND DEVELOPMENT OF MODEL helm control, (b) main sheet control, (c) jib control, quite independent and progressive in action. The jib control should be capable of holding the jib a’weather to assist going about which is the usual practice when sailing full-size boats. Let me take a concrete example of the advantages of radio control as applied to model yachts. On my own sailing water the prevailing wind and a belt of trees make it very difficult to sail a triangular course without coming ashore five or six times for a re-trim and re-set of the Braine gear. Consider how much more interesting it would be if we could sail this same course as if we had a live crew on board. : The effects of every increase in wind pressure, every variation in direction and every deflection owing to the presence of belts of trees could be met and corrected with precision by means of radio control. Each buoy marking the course could be rounded, controlled gybing turns executed accurately and the model brought over the finishing line between two predetermined points. If radio controlled yacht racing is to come into its own, as it surely will, it must be possible to race several boats one against the other. Single boat sailing is only a stunt. ~To do this, each model must be controlled by a YACHTS separate wavelength. (Continued from page 399) Now watch these boats racing for the first buoy, jockeying for position under perfect control; they gybe round off on a fresh tack and away to the next buoy on a close-hauled beat, round they go and then on a broad reach to the finishing line, each skipper at the controls jockeying for posi- tion avoiding foulings with his fellow competitors in exactly the same way as if a live crew were on board. How this three-point control is to be arranged I must leave to the radio expert. My suggestions may be revolutionary and not acceptable to the purist, but I maintain that progress in this direction cannot be long delayed, and one day, perhaps in the near future, we shall see upon the Round Pond itself, or at Fleetwood, a radio controlled yacht making rings around a 1951 International Champion. If I have succeeded in arousing interest in a proposed XP Class vessel, fully radio controlled, I shall be very well satisfied. My Editor has warned me that I must be prepared to be thrown to the lions for my temerity in voicing my opinions upon this absorbing subject. So be it. I have had my say and now await judgment and criticism, but please let it be constructive even if hostile. 396

June 1951 History & Development of Model Yachts il. PART BERNARD III REEVE, 2A SCLS Ses! M.S.N.R. SHEER PLAN FUTURE SECTION. THRO” DESIGN & RADIO CONTROL NOW what of the future, both as re- aveeeg gards hull form, shape of spars and sails, and control of the model as a whole. This is a highly controversial subject 16, and many of the views expressed herein may not be acceptable to some of my more experienced, and may I be per- mitted to add, conservative readers. RUDDER ————— uwr. DEPTH j Ss Fusvcnwas) et PL pele DECK PLAN 60 Inches 56 INCHES 1174 INCHES MAX BEAM 12!/2 INCHES the way to the production of better and faster boats. Most model yachtsmen will agree that exe =F W’D END SECTION THRO’ KEEL I fully realise that I am open to be shot at by those who may have a greater grasp of the subject than I have, but this FIG. is all to the good for if my critics will propound their theories constructively in reply to this article I feel we are well on Te MIDSHIP | SECTION SUGGESTED AT A.A. DESIGN FOR X.P CLASS MODEL YACHT our existing rating rules, excellent Le CENTRE PLATE——— though they be in many respects, do not allow for progressive development. In point of fact every class of model yachts, FIG.2 HULL SECTIONS TYPICAL with the possible exception of the ““M” Class, are so hedged about by such a rigid set of rules as to debar the designer from indynamics, unfettered by any rating rules, until the corporating new ideas into hull form or shape of sail. design had been proved in practice and accepted by I am not quibbling over the stringency of the a panel of experts appointed by the M.Y.A. for that present rating rules as such, as any highly competipurpose. tive sport, especially one of international status such At the end of each season an XP Championship as yacht racing, must be governed by inflexible rules Race would be held open to all approved boats and if the sport is to be kept clean, and no useful purpose the improvement incorporated in existing class, or would be served by altering the existing rating rules existing rating rules altered to allow such improveunless it was to improve the breed as a whole. ment to be incorporated in future models, after In order to foster the spirit of competitive design, agreement by the panel of experts. whose sole object would be to improve upon existing A Utopian dream maybe, but I maintain this is models, I would suggest to the M.Y.A. that they the only way to improve, if such a thing is possible, sponsor the creation of a special experimental class the existing types of model racing yachts. to be known as the XP Class open to boats whose I know only too well the thinness of the ice upon only restrictions would be 4.5 beams to a length, which I am skating and inviting the wrath of the such length not to exceed 60 in. L.O.A. This would M.Y.A., if they deign to notice my remarks. Neverbe necessary to exclude the freak type of craft, theless I feel sure I shall be upheld by many model either the once popular, but short-lived “plank on yachtsmen who feel, as I do, that our designs are edge” vessel, or the ultra light displacement skimstagnating, and who really have the advancement of ming dish type, for we are not after speed at any the sport at heart and that their healthy and conprice, but are aiming to produce a healthy type of structive criticism can do so much in the interest of boat capable of putting up a maximum performance improved design, so now let us get down to facts. under any set of normal conditions; a model emdodying the latest ideas in hydrodynamics and aeroHULL FORM.—We have two points to consider

MODEL MAKER in arriving at the shape our experimental hull is to take. Firstly, it must be sailed upon the longest possible water line when heeled to obtain maximum speed. Secondly, as the wetted area of the fin and skeg is approx. one-third of the underwater surface of the model, we must ensure that the fin and skeg are of the correct shape, have a fine entry of about 45 deg. to the water line, and must also be made as smooth as possible, for we must bear in mind that this fin and skeg nearly always travels through the water at an angle, varying with the degree of heel, and is capable of setting up many eddies unless it is carefully streamlined — another argument in favour _ of sailing upright. We must also remember that the fin and skeg have a considerable bearing in keeping a model upon its course, and these underwater appendages must be true to the fore and aft centre line otherwise the boat never will perform satisfactorily. The next important point for consideration is the sectional shape of the hull, and ignoring for the time being those vital factors in design and forward entry and the run aft, we will concentrate on the midship section. I have set out below the salient features of the midship sections illustrated in Fig. 1. Fig. la—The old-fashioned round-cheeked hull. This will give a comfortable type of craft, slow but stable. Fig. 1b.—A hull with shape of hull is usually associated with the sleek graceful lines of the fast yacht. An easily driven hull with quite good seakeeping qualities. Fig. lc—A hard chine hull known as a “sharpie”, sometimes built with a double chine, easy and cheap to build. A boat with a hull of this shape must be sailed more or less upright as if the chine is buried a heavy resistance will be set up and the boat becomes sluggish. Under favourable conditions the hull will rise and plane over the surface of the water. Fig. 1d.—This is the hull form of the International Dinghy type, made famous by that great designer and helmsman Uffa Fox. It is known as the hard bilged type. This is an excellent racing type of hull which must be sailed upright otherwise it becomes dangerous. If heeled beyond a-certain angle stability quickly goes and wind pressure on the weather side of the hull assists the inevitable capsize. They are always fitted with buoyancy tanks and their crews adopt almost circus-like antics to keep their boats sailing. They are exciting craft to sail, but do not make good models. Our problem is, therefore, to design a hull with a fairly flat floor with most of the support in the fin, with no fore and aft overhangs so as to give a maximum water line and, with all underwater parts carefully streamlined. In many models the fin is of bulbous form, but I contend that this is a mistake. A fin should have a 398 very fine entry with its thickest part two-thirds from the fore end and not tapering until the after end of the skeg is reached; the final taper, which should be abrupt, being at the trailing edge of the rudder. Actual towing tests have proved that this form of fin, skeg and rudder causes less disturbance than the blunt nosed keel, and as disturbance or eddies denotes resistance to be overcome by effort we must eliminate it insofar as lies within our power. Most rudders have parallel tapered blades, but here again tests have indicated that such rudders are apt to set up undesirable eddies under the hull. To overcome this the rudder should be slightly bulbous in a vertical plane, thin at the top, the cord increasing towards the base of the blade where it is at its maximum. This shape of blade gives a greater turning effort at a lesser angle than the orthodox shape like an elongated letter D. As our model must be sailed heeled when beating we must avoid burying the lee coaming, as in this condition a very great resistance is set up. To overcome this I have shown the experimental hull with a hogged sheer. Much controversy has been caused in the yachting press by the adoption of this reversed sheer by some designers. It is said to be ugly, to spoil the grace of line, to serve no useful purpose, and many other accusations are made against it. Doubtless at first sight it is a little startling and certainly unorthodox, but so are all innovations. Prejudice dies hard and many years ago quite a number of well-known yachtsmen were against the introduction of the Marconi mast with its high aspect ratio Bermudian sail, predicting broken masts, and labelled the whole rig as dangerous in the extreme, giving it but a few months of life. How wrong they were! We now have to decide upon the actual midship section of our hull, and I have compromised between sections B and D, which should give a fast powerful hull of light displacement, easy to drive, yet stiff and stable, and capable of planing under favourable conditions. Let me make it quite clear that the profile drawing shown in Fig. 2 is not put forward as a scientifically designed hull, but is given to form the basis of a design and to illustrate the ideas and theories I have been discussing whose sole object is to lay the foundations of a suggested experimental hull. SAILS.—The gaff rigged yacht is as dead as the dodo, its place having been taken by the Bermudian sail with its high aspect ratio. A certain amount of efficiency is lost, however, with this type of sail as the last few inches at the peak have little driving power. This loss can be partially overcome by the use of a bent mast, i.e. one whose tip curves towards the leach of the sail. But this does not entirely do away with this loss as I will explain later. The M.Y.A. limit the bow of the leach and the length and numbers of battens used in the leach. This detracts from the efficiency of the sail in no small measure. 5

June 1951 As we are going to ignore all rules in the search for efficiency for our XP model we must alter the shape of our existing type of sail while still keeping to the Bermudian basic shape. Before doing so I must digress for a moment, and explain the action of a yacht’s sail in relation to the wind. The uninitiated is apt to think that wind pressure on the weather side of the sail provides the driving force. This is partly true when running before the ANGENTICAL LEACH PRESENT DESIGN LEACH, wind, but not on other points of sailing. It is a building up of negative pressure on the lee side of the sail caused by air flow over the sail that exerts the greatest force as any of my readers who may be interested in model aircraft can testify, for after all a yacht’s sail is, or should be, a true aerofoil set in a vertical plane. AEROFOIL LEACH BATTENS FORE STAY A perfect example of this theory can be seen in many of our full-size racing yachts whose Genoa jibs are sheeted home well abaft the mast, in some cases as much as three-quarters the length of the main boom. This causes a very large area of low pressure to be built up with a subsequent increase in speed. As Lt.-Col. C. E. Bowden, A.I.Mech.E., so ably points out, Nature has provided a splendid example of the aerofoil in the shape of an albatross wing. Given a wing of this shape in a vertical plane and we have the ideal high aspect ratio sail. FIG.3 SUGGESTED — BATTEN SECTION OF MAIN BOOM. SAIL PLAN FOR X.P CLASS MODEL YACHT How are we to achieve this ideal? By scrapping existing rules and shaping our sails as I have shown in Fig. 3. In order to preserve the curvature of H-RECESS FOR JACK LINE the leach and to allow the sail to arch in the centre we must make use of full width battens, thin in the centres and FIG.4 thicker at the ends. There should be plenty of lift in the main boom to prevent the lower portion of the sail being blanketed by the hull when the model is heeled in a breeze. So much for the main sail. To obtain maximum efficiency in the jib SECTION OF STREAMLINED MAST Many of my model yachting readers will recall that on August Bank Holiday of last year the Radio Controlled Models Society held a Regatta at Fleetwood and demonstrated radio control as applied to model yachts. An “A” Class vessel negotiated a buoy-marked course with accuracy and under perfect control. we should arrange for it to overlap the main boom for a quarter of the main boom length: the foot of the jib being one-third of the length of the main sail. Unfortunately we are unable to do this as we have I know that the purist views with horror any form of mechanical control as applied to model sailing yachts, but they cheerfully accept the Braine steering gear and the vane self-tacking gear. Surely no crew on board to pass the clew of the jib around the fore side of the mast when going about. A slight gain in efficiency can be obtained by shaping the main boom as shown, this will assist air flow, and by streamlining the mast and recessing the jackline in a groove on its after side, again improving the air flow. these are mechanical devices, especially the vane gear with its present complicated train of gears. RADIO CONTROL.—Before I commence to air my views upon this very vexed subject I wish to make it quite clear that I am no radio expert. Much . of what I shall write may be pure nonsense, much may be impossible for I can only state what I expect My contention is that if we are to reach perfection we must emulate as closely as possible the effects of human control, and-the only way to do this is to instal radio control of helm and sheet. But such controls must be progressive, i.e. capable of fine adjustment over the whole range of movement, not just hard over to port, central and hard over to starboard. radio control to do and leave its practical application to the experts. The ideal would be a three-point operation: (a) (continued on page 396) 399

MODEL A New Vane Steering Gear Bs inent member mingham of Club the Bir- offers this well tested design of vane ‘gtouniie gear, which with its simplified construction should appeal strongly to all would-be vane ‘exponents. y VISIT to the pondside these days will reveal that many model yachts are controlled by vane steering gears. There are many designs, all using the simple lever principle. These vane gears are lightly constructed and delicately balanced. The major diffi- © TO Et PF See culty with this type of vane gear is to construct one that is self-tacking without obtaining the necessary reacting force to operate the rudder from a weight. Another point about these vane gears is that they have to be set by the sailer for each different course sailed. The vane gear I wish to introduce to readers does not require to be set independently by the sailer, the setting is done automatically when the main sail of the yacht is adjusted. It is self-tacking by using a rubber gye acting upon the main boom in the normal way. As will be seen from the drawing this gear is robust and not easily upset. This vane gear has three bevel gears (1), (2) and (3). Gear (1) is fixed to the rudder post by means of a grub screw. Gear (2) engages with gears (1) and (3) and is free on a shaft carried on a distance piece (4) which is in turn free to rotate on the rudder post (5). A collar is fixed at the top of the rudder post (by Ya’ ota SUIT Ye” out RBH ‘ ig tk @® BRASS. {pe DIK i Ey GS 7 od = ae ‘ ag 7 TAP 4 BA. SOFT _.__ — SOLDER. LENGTH TO SUIT. MMMM ye 4 THICK. 7ZZ i —|| 3/4 y* —*o1a DIA a The author who is a prom- So re| %” oa 2 a %a eC © z SOFT SOLDER. TT TAP 6BA. BRASS. ASS. 9 Vo” RAD , Ye erass CORD FIXED. ne .. * COPPER TUBECUT a Ge ‘ :-. — 1 HALF AFTER SOLDERING. HATCH COVER. PLAN. 1 SCALE GA- 4 FULL size, DETAILS-FULL size. 400 Yy, y A Ya” | pta. 4 SOFT SOLDER, curr ©

June 1951 means of a grub screw) to keep the gears in mesh. The grooved pulley (7) is mounted on the rudder tube (6) and is free to rotate. A pin anchored in the distance piece (4) engages in a hole on the pulley (7). Now we come to the goose neck, which consists of a length of tube (8) soldered to a pulley (9). This assembly is free to rotate about the mast and is kept in position by means of a collar (10) fixed to the mast. The boom is free to pivot up and down on pins (11), its movement being restricted by the kicking strap (12). A length of cord is fixed to pulley (9) and running through guides (13) and (14) is fixed to pulley (7). Guides (13) are used to tension the cord. To set the vane gear, the boom vane and rudder should be central fore and aft. From the drawing it will be seen that any movement of the boom is transferred through pulley (7) to gear wheel (2), which (if you hold the rudder central) will rotate gear (3) and the vane. Now if you hold boom (as when sailing) you are holding gear (2) in its new position, but since gear wheel (2) is free to rotate about its own axis, it is possible for the vane to transmit any movement to the rudder. In other words, the relative position of the rudder and vane has been altered, still leaving the vane to operate the rudder. This type of vane gear corrects two sets of conditions presented when sailing a model yacht. Vane steering is becoming more and more the fashionable gear for contest sailing. Here is seen R. Pilling’s “Westwind” (644) third prize winner in last year’s “Daily Despatch” contest, and on the leeward board J. Anyon’s ”Marion” (315) both so equipped. 1. The amount of helm required due to the position of the centre of effort of the sails tending to turn the boat into the wind when reaching and running. This I term permanent helm. helm required for running and proportionally less when beating, until the boom is amidships, when you get none. This set of conditions is open to debate, but the writer maintains that it is more consistent than can be obtained by the average sailer setting an independent type of vane, and certainly saves time when retrimming. 2. The helm required due to the relative speeds of the wind and the yacht. ‘ The helm required for condition (1) at different angles of sail position is obtained by pulleys (9) and (7), being of different diameters. The helm required Since this type of vane gear has more friction losses than some others a balanced rudder is used and the vane gear area increased. It is only necessary to balance the vane itself. for condition (2) is obtained in the normal way, direct from the vane through gears (3), (2) and (1), the main sail holding gear (2) in position, and the vane and rudder reacting upon it. A few notes on construction. The gear wheels may be of any convenient diameter approx. # in., and should be of brass with fairly fine teeth. Care should be taken in the length of distance-piece (4) so that the gears do not mesh too deeply. (This causes friction or binding.) When designing this type of vane gear, the ratio of the two pulleys (9) and (7) is perhaps the most tricky to arrive at. The writer’s prototype is fitted to a model, the mast position, angle of rudder, and boom when running being known. With this information one can arrive at the gear ratio required to rotate the vane 180 deg. (plus the angle of the rudder) when the boom is moved to the running position. Now since gear wheels (1), (2) and (3) are of the same diameters the gear ratio between gear (3) and distance-piece (4) which is connected to pulley (7) is 2:1. Therefore when the boom is rotated to the running position it has to rotate pulley (7) 90 deg. plus half the angle of rudder The distance-piece is of hard brass, the connecting arm being screwed and soft soldered in position. The pin for gear wheel (2) should be of stainless. steel screwed into the distance-piece with a small split pin and washer to keep it in correct mesh. A highly polished stainless steel rod 4 in. dia., should form the rudder post (5). A hard brass thrust washer between gear (1) and the stern tube may be fitted instead of a pintle. It is important that all parts are a good running fit without too much play. The pulleys can be made without the aid of a lathe as shown in detail drawing. Detail dimensions of the goose neck assembly are not given as they will differ with each boat: required to run the boat before the wind without using a spinaker. To do this the centres of the holes in cord guide (14) should be less than the diameter of pulley (7). It will be seen that when the boat is set for a reach, that you now have half the permanent 401