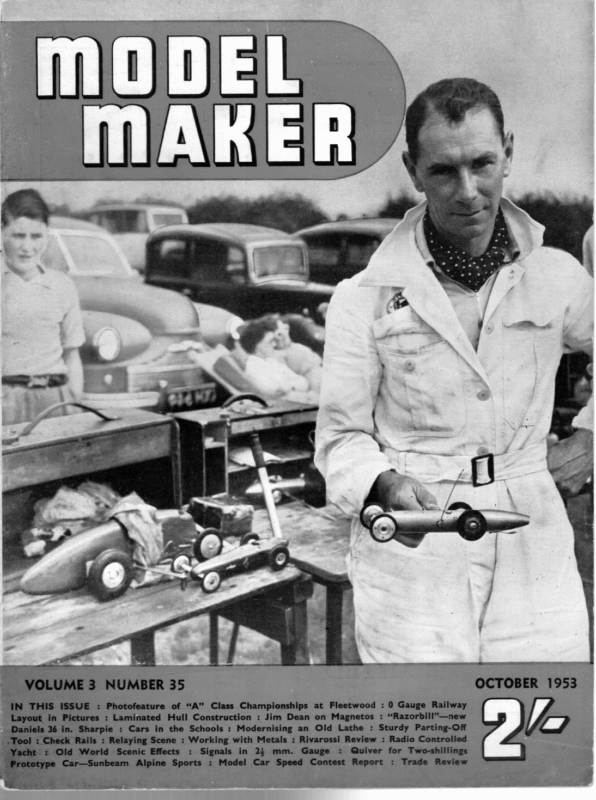

MODEL 4 MAKER- National A Class CHAMPIONSHIP AT FLEETWOOD ARABESQUE WINS LARGE ENTRY FROM REPORT BY VIC SMEED of holiday-makers who had followed the week’s sailing with keen interest. In this connection AV EN His Worship the Mayor of Fleetwood officially started the first pair of boats on the accurate and enlightening commentary over the P.A. by Mr. N. Frith deserves special mention. The prevailing conditions tended to favour the heavy-weather boats, and the lightair skippers spent much of the day consoling themselves with the thought that next year will see the Championship held once- more in the gentle zephyrs of Gosport! In order to shorten proceedings to a manageable length, the fleet was divided into two groups of 22 boats and on Thursday evening the leading six of each group were moved into the final. The two smaller fleets sailed on alternate mornings and afternoons, getting through the programme in excellent time. Much the first board of the 1953 British Open “A” Class Championship on Sunday, August 16th, over one and a quarter tons of model yachts (Class “A”, assorted) were assembled around the magnificent lake built by the Fleetwood Corporation especially for model yachting. With an entry of 44 boats from 30 clubs, the meeting required only excellent organisation and good weather to make it memorable; the first of these was certainly available in good measure, and so, for the greater part of the regatta, was the second. The breeze was fresh and from the west, along the length of the lake, for four of the days; on the Tuesday it backed to southerly and died a little, while on Wednesday it almost disappeared and the only serious rain of the week fell. Saturday saw a near-gale of about 42-45 m.p.h. blowing from due west, which caused cancellation of the second round of the finals, though seven hardy souls raced for the benefit of the thousands 1, Embassy and Pandora, neck and neck. Every entry used vane gear. 2. Well-filled spinnakers bowl Yeoman and Celeste down the lake, Celeste slightly ahead. 3. Susie J] takes a run from Vanity Fair. 4. Picture II going the other way— Yeoman leads Celeste on the beat. 5. Grenadier and Fantasy—note the duckboard walk at the down-wind end. 6. Vanity Fair leads Celeste; in the distance two preceding boats go about. 7. Celeste looked a favourite at one time. 8. Fantasy gets very close to Helios’ stern. 9. Westwind’s husband and wife crew, Mr. and Mrs. Pilling. 10. Shalimar fairly boils along to win a run from Revanche. 11. Embassy was built by designer Bailey in 1938. 12. N. D. Hatfield (Fantasy) dresses for the weather. 13. The Fleetwood clubhouse was straining at the seams with three rows of boats like this. 14. Kai Ipsen brought his clean-decked Above is the Fleetwood clubhouse and flagpole, gay with the burgees of thirty clubs. Below, left, is the winner, Arabesque, in the lead from Black Tarquin, the third-place boat. Right: Pandora sailed well to earn second place 1951 winner, Revanche 55

—— oA 1. Fanine, in the hands of H. Boussy, and Shalimar. 2. Shalimar and Embassy off under the watchful eye of assistant O. O. D. J. Pitt. 3. H. Boussy and his English mate J. (Pop) Metcalfe. 4. Black Tarquin leads H. M. Amlot’s BerttyXI. 5. Youngest skipper was Eddie Greenwood with his plastic Atlanta. 6. Winner Arabesque receives attention from owner/skipper J. Anderton, watched by builder/mate J. Levison. 7. On Thursday most skippers changed to second suit. 8. One of the newest boats was Coronation, sailed by W. Hugman. 9. Roy Bradley and mate Dobbs with Black Tarquin, which used tongue and groove planking. 10. Black Tarquin glides away in sheltered water at the beginning of a run. 11. J. Anderton favours a clear deck which suits Arabesque’s clean lines. 12. Pandora ministered to by J. F. Craker and mate Kirtley; this boat is designed for hard weather Left: The scoreboard at the close of the preliminary rounds Below: Some idea of Saturday’s conditions can be gathered from this view of Arabesque ‘arriving’ sympathy was extended to Mr. J. Bisset, who early on accidentally dropped Phantom and was forced to retire, thus creating a bye in his group. Welcome visitors were Denmark’s Kai Ipsen (1951 winner) and Jens Brandt, both of the Dansk Modelsejler Union, and M. and Mme. H. Boussy, of the Olympique de Billancourt. The Boussys’ journey, undertaken at the height of the French railway strike, was quite an epic, especially since they were accompanied by an enormous box containing Janine. Unfortunately, all three foreign entries were eliminated in the preliminary rounds, as were the five Scottish and three Irish entries. Possibly the most interesting boat present was a plastic-hulled entry, Atlanta, designed, built and skippered by Eddie Greenwood, who had turned out a most professional-looking job despite his modest 16 years of age. Some first-rate sailing was seen during the early rounds, and by Thursday the tension was almost tangible as skippers fought for the odd point or two which would carry them forward into the final. By six o’clock in the evening it was known that Shalimar, Grenadier, Cumbria, . Embassy, Fantasy and Vanity Fair from “A” Division and Black Tarquin, Pandora, Yeoman, Arabesque, Celeste and Helios from “B” Division (in those orders) had qualified for the final. Showery weather and a continuance of the fresh westerly breeze greeted the early starters on Friday, and seaboots and oilskins were the rig of the day. It was soon apparent that the windward starting berths had the advantage, since the lee boats had to be held on going about to avoid fouling; this lost precious seconds and decided several boards. By late morning Celeste and Vanity Fair were several points in the lead, but gradually dropped behind; Arabesque’s very fast hull was notching up a useful total of points, especially on the run. The day’s racing was followed by an excellent dinner in the Marine Hall, attended by the Mayor of Fleetwood and about 150 guests. Saturday dawned in torrential rain and a high wind, and, although the rain stopped, the wind persisted until it was obvious that sailing in serious competition would result in many damaged boats. One or two brave types tried the water—B. H. Priest with Yeoman was one, and another was a veteran builder who. with the aid of a “helpful” small boy and a handling pole between the feet, really went into the matter. It is true to say that Yeoman moved as fast under practically bare poles as any fully canvassed boat during the preceding six days, but the rumour that an odd bulge is a vane-feather growing on-Mr. A. Levison’s transom is authoritatively denied. After a consultation between officials, it was decided that Friday’s results would be taken as final, and the meeting thus ended without sailing the second round. (Results on page 589)

sone RAZOR BILL’ (w) DESIGNED OY WJ DANIELS MODEL MAKER PLANS SERVICE | 36 © we > CCK OLAMS 179° 90 CORYMONT OF CLARENDON WO) WATFORD ‘TOP SURFACE oF CUILOING a HEAT 2 570 4

October 1953 Rvecttith HERE are many with a desire to build a model yacht who are prevented from doing so by lack of facilities. A workshop is generally the difficulty and the idea of this article is to enable a model to be constructed with the least possible noise and annoyance to others. The model chosen is a sharpie and this should give just as good a performance as a “correctly designed” normal type. The method of construction calls for no hammering and no annoyance to other members of the household. The tools required are A HARD = only a chisel, small plane, small brass backed fine tooth saw, and a fret saw. A building board 39 inches long and four inches wide will be necessary, and this need be no more than 3 in. thick if of seasoned wood, free of cast or wind. Any saw mills will true a board up for you on the overhand planer for a few BY 36I1N. CHINE W. J. REST. SHARPIE DAWNTEtcS wy, of two pieces } in. thick, which arrangement not only makes the work easier but, if the following instructions are carefully carried out, will give a superior structure. The width of each piece is arranged so that by planing off the corner the correct angle of the floor is obtained. pence. Having prepared everything as per instruc- Lines should be squared off across the faces of the sections shown and pieces 4 in. x 4 in. prepared ready for fitting across the four inch tions, adopt the following procedure. Draw a centre line down the upper face of the building board and square a line round the centre of each of your #? x # pieces; fix each one in position. Those forward of the fore and aft centre of the model will have their after edge on the crosslines and those aft will be reversed. This will allow you to bevel off the floors and shadows so that the floor and topside planking lies on the surface fairly. The simplest way to do this is to hold each piece in position with two small clamps. It is best to first drill two holes in the building board, one on each side of the centre line on all positions, and screw through from the underside. The shadows can now be fixed in position by screwing to the cross pieces. in front of each cross line face at each station. A cardboard template should be made of the angle of the topside with the horizontal: it will be noticed that this is constant throughout the boat, as the most important thing the designer must avoid is a winding chine line. You will require a } in. board to make the shadows for each section station; these being all the same angle they can be marked off very economically by reversing them. If a parallel and the wood sawn between the two lines, work will be saved. The chine stringer will be 3 in. square in section so that the top face of each shadow will be parallel with the building board less 3 in., the height of the actual chine on each station. As the planking is to be one millimetre three ply (resin bonded) the topsides of each shadow and the floor timbers must be reduced on each side by that amount. These floors (which are the cross pieces that will rest on the shadows and remain permanently in the boat (must now be made and forward, and aft behind the centre. “Casco” cold-water glue or a similar casein glue should be used throughout. It is the general practice to cover the transom with a piece of wood the same as the planking. If it is intended to do this the transom shadow must be set in one millimetre, otherwise the model will exceed the length for the class. Before erecting the shadows carefully mark out and cut the slot to receive the inwhale to slotted as shown to receive the keelson. The shadow at the extreme stern will form the transom and the floor will not be separate at which the deck will be fitted. The inwhales will be 3 x 2 inches and the slot must be set one millimetre lower which will bring the deck to the designed height. Place each shadow in position and screw it to the cross pieces, ereat care being taken to centralise and fx them this point. The recess for the keelson is best done with a fret-saw. Before cutting out mark carefully the centre line. This should be done on each shadow. Accuracy in assembling will make things much easier in finishing the model. The stern piece must be prepared as illustrated together with the keelson. which will form the backbone of the yacht. You will notice that this is formed eee rr——— NEW hard down on the building board, starting at the centre and working to each end. Now && the stern piece, and place each floor in positaos. 571

IIL MODEL MAKER fixing temporarily with a pin at each end. Take one of the two keelson pieces and fix and glue into the slots provided, allowing it to take its natural bend. After the glue is set the second piece should be sprung over the first and held in position with small wooden clamps as shown. These are known as Bird Beak Clamps and are easy to make but must be of tough wood. When this is set the keelson can be chamfered off to the angle of the floor: The inwhales and chines can now be fitted and fixed. The latter are arranged to butt up against the ends of the floors and held in position with ordinary pins driven end on into the floors. Chamfer as shown forward so that the outer edge just leads into the rebate that has been cut in the stempiece. If you bend a spline round the floors or topsides it will be noticed that it only touches on the – edges of the shadows and floors except the centre one. It is therefore necessary to plane off the forward edges of the front shadows and the after edges ow the rear ones so that the floor planking and topsides lie fairly touching each point. The boat is known now as being in frame. You will require one millimetre bonded ply wood for the planking and also the deck. The floor of the boat can be covered in two pieces, as also can the topsides. Take a piece about 38 inches long the width of the greatest distance from centre to chine, and make a straight edge about 38 inches long of the same ¢ in. wood that was used for the keelson. Bend this lengthwise from the meeting point of topside and floor forward to the centre line of the transom, seeing that it lies flat across the floors. It will be found that the edge of the straight edge will be away from the centre of boat in the middle. Mark on your straight edge exactly the position of each floor and, using dividers, prick off on the straight edge the distance from its edge to the keelson centre line. Remove the straight edge and, placing it on the ply along the line already drawn, transfer with dividers the position of each shadow and the distances found; then take a wooden spline about 2 in. x } in. and draw a curve through these points. If, before removing the straight edge from the floor, you make a Before fitting the floor planking the chines must be planed to the angles of floors and topsides. This is not difficult as the shadows give you a perfect guide. The floor planking can be fixed permanently, being glued and screwed into position along the inwhale and centre with ? No. 1 brass countersunk screws, one screw in the centre of each floor being sufficient. Space screws 14 inches apart along edges. The outer edge of the floor planking can be glasspapered to the angle of the topside after the glue is set. The pieces for the topsides must be prepared in a similar manner. If the forward ends are are cut to the fitting angle of the rebate in the stem you need only run a sharp pencil along the chine and inwhale to give you a line to cut to. . The shadows at the fin location will butt against the fin, as the fin is carried up through slots in the keelson and engages the deck beams so as to take the side strain of the lead keel. Mark off the position of the slots and cut them out by drilling holes close together, opening them up with a small backed saw and finally finishing to take the lugs of the fin with a file. The thickness of the fin is } in. The skeg is fitted as shown. It is not necessary to do more than see that the skeg is dead in line with the fin as the stern tube will keep it true. The apex of the centre must be filed flat to form a seating in the skeg. The floor and topside planking having been finished, the edges are screwed and glued in position. The topsides will cover the edge of the floor planking at the chine. lin. No. 1 brass . mark on the floor where the straight edge crossed each, you can then in a similed manner mark off the chine line from spots from the straight line through each shadow position. You can then draw a curve through these and cut to these lines, allowing enough for final fitting. 572 countersunk screws will be sufficient, each hole being made with a suitable awl. If, however, the builder prefers nailing it is best to use copper pins. The spacing in either case should be 11 inches. The boat can now be removed from the building board. First take out all screws from the under face and then remove the shadows by twisting them. These could be used again for another model if required. The deck beams can now be fitted, after which the transom must be cut to the finished shape and the stern piece chamfered off in line of the topsides. The fin and skeg, of seasoned wood, should be arranged with the grain vertical. The fin must be cut to pattern. Pieces must be glued to make a recess on the underside of the deck beams that engage the top lugs of the fin; these will take the side strain. After the fin is fitted, pieces of half round section should be glued and screwed

October 1953 along above the hole of the carrying handle same firm as the fittings which will encure the correct material. The cloth should be pinned down on a flat surface. The leach of the sails should run parallel to the selvedge of the cloth. Measure this off and with a spline draw the curve as shown. The other two sides of the triangle can be drawn. The luff that goes up the mast must be straight but the foot of the mainsail as shown. After temporarily fitting the fin, mark on it with a sharp pencil the top of the keelson. Two holes as shown must be made to take the holding pins. The deck must now be prepared. The same 1 mm. three ply is used and this must have pieces glued on the underside to make sufficient hold for the screws where the sheet horses, mast plate, etc., are situated. The hatchway should have a frame arranged as shown to form a Seating for the hatch cover. A piece of 4 wood must be cut to just fit into the frame on deck. Glue a piece of } in. balsa wood on the underside to just fit the opening. Glue a wedge shaped piece to receive the mast step on the keelson so that the top face is parallel with the water line at the mast position. Make up the skeg, but, before fitting, groove the back edge to receive the stern tube. In fixing the skeg it is advisable to screw the stern tube in place temporarily. The underside of deck and inside of hull should now have two coats of varnish each. At the same time varnish the groove in skeg. After the varnish is set put the stern tube in position permanently. The rudder must now be made and fitted. The illustration shows the pintle, etc., on which should have an outward curve of parabolic nature. It will be found that after the edges are taped the mainsail will take an airfoil form, the amount of draught being in proportion to the amount of curve given to the foot of the sail. The jib is made perfectly flat and make its own airfoil if correctly sheeted. After cutting out the sails the leach must be machine hemmed and the other two edges bound with good quality tape. The latter should be 3 in. wide and should be creased down the centre by folding and rubbing over an edge. Start at the clew of each sail in binding, and fold in about half an inch of tape, placing the corner of the sail in the fold. Bring the needle of the machine down through tape’s inner edge and ensure that the edge of the cloth is right into the fold in the tape. A pull should be kept on the tape whilst doing this, but no strain put on the cloth. Bring down the presser foot of the sewing machine and the rudder pivots. See that the pin points up dead through the centre of the tube as the perfectly free movement of the rudder is abso- sew about four inches, keeping the needle down each time. Raise the presser foot and repeat until the whole is finished. In sewing the batten sleeves the opposite should be done, i.e., the tape should be slack and a slight pull given to the cloth. Hooks must be sewn on at intervals on the luff and foot of mainsail. The spacing is five inches on luff and three on foot, starting in each case at the gooseneck corner of main- gail. The wire jackstay along mast and boom must be arranged so that the hooks come lutely essential. A wooden pattern must now be made for the lead keel. This is simple and it will be found more economical to take it to a foundry as the two sides can each be cast from the same pattern. After finishing up the casting with file and glass paper it can be burnished with the back of a spoon or similar article. The hull can now be painted and the deck lined. How to do this has been explained already in this journal. The spars and fittings between the small screw eyes through which the jackstay passes. After painting, the lead keel can be fixed. and also deck coamings can be made whilst the hull is drying. Most of the fittings, etc., are not easy for the novice to make and are best purchased from specialist firms advertised A clearing hole must be made to take each screw. A hole sufficiently small on the inner face of the other half should allow the screw to make its own thread on the lead. Number in this publication. The fittings will consist of two sheet horses three inches long, mast plate and step, mast, ferrule, hounds fitting to take jibstay and shrouds, gooseneck, and also what- eight screws (brass) should be used. If the whole of the floor is left in the boat there will be an unnecessary weight of wood. If, however, you draw a parallel line as shown and, after drilling as illustrated, make a saw ever steering gear is chosen. The builder. however. will no doubt like to do as much as possible himself, and if the following procedure is adopted he will not find the making of the sails too difficult. The sailcloth and tape. etc., can be supplied by the cut nearly to the ends you can complete the cut and remove the surplus timber after the boat is removed from the board. The rough saw edge can be finished off with glass paper- 573 ee)

October 1953 Laminated Hull Construction PART ONE OF A REALLY DETAILED DESCRIPTION OF RIB AND PLANK CONSTRUCTION OF MODEL YACHT HULLS WILL BE OF VALUE TO THOSE ENTHUSIASTS WHO HAVE BEEN DETERRED IN THE PAST FROM A LACK OF STEP BY STEP INSTRUCTIONS B.. Ye. A. BOARDMAN Offering the backbone to the shadows. This is the essential first step after their erection—and almost inevitably will require additional chamfering and adjustment Take the body section and decide the width of planking you intend to use (Fig. 1) as a guide, the best width I have found is ? in. for “A” pe building of the hull of a model yacht has always been looked upon by the novice as extremely difficult, and for the builder the method of procedure may lead to much lengthy and involved description. Books on the subject of building, whether water-line, “Bread and Butter” construction or “Buttock” line building, are many and describe the processes fully for the novice, but when the intention is to build a yacht in the orthodox manner, namely “Rib and Plank”, a considerable amount of detail is required to explain the method, in order that the beginner may understand. boats; £in. for 10 raters and 50/800, and ¢in. for 36 in. The centre section being the largest is the best to work upon. We shall assume you are able to build an “A” boat and the planking will start at the sheer strake, with the closing plank in the garboard. The width of the planking has been decided by the body section and the thickness you decide for yourself, allowing 1/16 in. for clean- ing off, mainly at the joints. Now, take five planks and take long shavings from both sides. If they have been machined beforehand, they will only need to be sanded to act as a key to the glue which is to be used. The adhesive which I have found to be most suitable and convenient is Beetle “W” and I have built a number of racing yacht hulls, from 30in. to “A” boats, including the 6 metre and 12 metre hulls, and have often wondered how the beginner proceeds to set up his backbone when he has his forestem, afterstem, and garboard piece, as these three pieces -have to be set in one “dead straight” line. In explaining the method I now use for all my building I hope it will help the beginner over some of the difficulties of the old method. It is not original, but when one’s hobby is building hulls it is obvious that a more modern Rapid Hardener No. 6 (Orange) with rye flour added as a gap filler to the cement. Apply the cement to one face and the hardener to = FIG.1 | 10 RATER method should be employed where practicable, particularly when it proves both speedier and easier to adopt, and results in a hull as strong yet lighter than one built on the old method. The drawings of the hull you intend to build should be all to full size model scale before you start, and should be checked and re-checked in order that no possible error can result in the model. If possible, make a tracing from the original profile of the canoe body only, marking on all section lines. The backbone, which is to be laminated, DATUM should be formed in the following manner. 583 oaTuw

MODEL MAKER DETAILS FIG.2_METHOD NO.I OF SETTING OUT FORMER TO SHAPE LAMINATED STEM. MAST | | KEEL BOLTS done in order to give the required pressure all round the backbone and will produce quite a reliable and satisfactory result. The cement is now “going-off” (setting) and this will happen fairly quickly in a room of working temperature, but as the backbone is not required until later, there is no necessity to remove it. Cleaning up and marking will be explained later. Now for preparing the shadows. For this I always use 6 mm. plywood, interior gum, which is off licence and is cheaper than resin bonded. Taking the body section, you must decide at what point you are going to have your datum. I always work on 2 in. above the highest point (i.e. the forepeak (fig. 1) ). Take the tracings of all the shapes, including the diagonal lines and water lines and most important the datum line. Off-cuts of 6 mm. ply wood can be obtained in sizes which are suitable for shadows. Mark all your shadows with diagonal lines and deck lines and then complete the marking out. In marking out prepare all the pieces by “shooting” one edge straight, as this will be the datum edge or line. In the centre of each piece strike a line square off the datum edge. Place your tracing on the ply wood with the centre line the opposite face. Time must be taken in this operation to ensure tha the cement is perfectly eveny distributed. I have found a small hand roller ideal for this job. When the spreading is finished you have about ten minutes working time before the cement begins to thicken slowly, so it is wise to assemble the laminations together and fit them in the former (fig. 2) making sure that they are sitting right and ready. Then apply all the pressure that you can. The following alternative method may be employed in assembling the backbone without using the block former. Assuming you have a workroom or any place with a flat surface that will accept wood screws, you paste your tracing to this surface. Now for every 4 in. along the outside edge of the canoe body screw a piece of 1 in. x 1 in. x 3 in. Opposite these blocks (fig. 3) screw the same length of blocks in such a position that the distance between the two is slightly less than the width of the backbone which you are to build. This is of the body section over the line you have marked and the datum line on the line which has been “shot”, pin it down and trace with a carbon pencil or tracing wheel. All the lines for the shadow, including diagonals, and deck line, should be traced. Turn the tracing over and complete the setting out. When all the shadows are marked out, cut them to the outside line and check with the |LWL | Vi | he — RUDDER TUBE || | A | A ~ pee oes. | 584 il] DECK LINE | TRACING | OF THE PROFILE | mm ! | LWL TY its

October 1953 original drawing of the body section. All the shadows are now full size and must be reduced to a degree equal to the thickness of the rib and planks. In making the ribs for an “A” boat I use Aircraft Birch Plywood # in. wide and 1 mm. thick. This gives greater glue surface and therefore greater strength and lightness. Having decided upon the thickness of planks, set a marking gauge equal to the thickness of planks and rib and scribe round all shadows on the marking face only. Re-cut all the shadows to this line. Next comes the cutting out for the inwhale, which in an “A” boat should be of * in. x 9/16 in. close grain Red Pine tapering to $ in. x 9/16 in. fore and aft. Cut out your shadows accordingly, letting in the inwhale until it is flush. The backbone must now be let into each shadow and we prepare it in this manner. First clean off all surplus cement and take one shaving off both sides. Check it with the original drawing and mark off all sections on both sides, including position of the skeg and rudder, and a gauge line down the centre inside and outside. As this has to be let into the shadows and fit tight down, the method I adopt is taken from the original drawing. Mark the datum line on the profile drawing and the inside edge of the backbone. For each section measure from the datum line to the backbone on the profile and apply this distance on the shadow, which will give the depth the backbone has to be let in. (Fig. Photo 2). The width of the backbone is equalled on either side of the centre line on the shadow, marked, and cut out. As the angle of the backbone varies with both faces of the shadow they must both be marked. If the hull you are building has a transom piece, this must be fashioned and fitted. For FORE PEAK. DETAIL Fit all the shadows in their respective trenches in the building board with each facing inboard. All centre lines should be in line with the gauge line on the stick. When ready, offer the backbone to the shadows and fasten down to the building board. In fitting the inwhales the transom has been morticed to receive them and the block at the peak has been “chased out” for the same purpose (Fig. 4). When fitted and checked, they can be cemented and fastened with one screw holding them in the block forward until the cement sets, when the screw may be withdrawn. In order to check the shadows for alignment, take one plank and using it for this purpose; ease the shadows where they have been cut square, until the test plank sits flat. A file and a spoke shave are suitable for this operation. STOP PRESS! INTERNATIONAL RACING | Dean, J. … Be a 2 * Riva, F. (ex-Dean car)… 3 Stepan on ate 4 Petrie A es ae 5 Riva, F. (ex-Moore car) the forepeak, a block can be fitted up to the So far, we have dealt with the preparation 5c.c. of the backbone and shadows and must now be concerned with the building board or “stick.” This must not twist or “move” in any way and should be 5 in. x 14 in., and 6 in. longer than | 2 3 4 5 Benazzi … | Riva, F. (ex-Dean car) … es = 2 Dean, 3:34 3 { Breda 5 { Broglia Cooke, J. … TEAM RESULT | Great Britain in the setting up. In the centre of each trench drill a + in. hole and countersink it on the other side. All is now ready for the setting up 4 France 704 791 453 1,948 2 Italy 275.5 53 0 328.5 and final checking. . … … … … … Great Britain Italy… … France … Great Britain Italy… … 191.489 k.p.h. 189.474 ,, 189.474 ,, 187.5 es 186.5 ” Great Britain italy … Great Britain Italy … … … … Healy… 148.85 k.p.h. 148.76 ee 143.857 __,, 141.732 * Placed second on better average of two runs. CLASS Cooke, J. es a Riva, F. (ex-Dean car)… Cooke, J. … fe os Broglia 2x c.c. CLASS the finished hull. Mark on the gauge line both sides and all the section lines. On the section line cut either side to the thickness of the shadows (i.e. in this case 6 mm. to a depth of 4 in.). It is important that all these trenches are of the same depth as any variation will show CAR RESULTS — ZURICH 10 c.c. CLASS first shadow. (Fig. 4). MODEL … iw … «s 141.527 oso MRI SREE Se ssultaly…. … Great Britain 121.122 coe DIG I2Z9 .. Italy… ips _, 23, … Great Britain 116.127 ,, ses 436.5 618 Bil 3 Switzerland 1,865.5 5 Germany 7 0 39 46 Full Report with photographs will appear in our next issue. 585 2 125 259 393

vn REDLICH TRIES OUT – EST G. HONN 36in. LANCET WITH SINGLE CHANNEL RADIO CONTROL added complications at both transmitter and receiver of the mark/space ratio systems, it had to be some sort of sequence escapement. Sailing is a tricky business, an one cannot afford to go through many “unwanteds” to arrive at the chosen rudder position. Firstly, one has not the time, and secondly, my memory I therefore at least cannot cope with it. decided to alter an E.D. clockwork escapement to give the following positions in. sequence. Neutral, 4 port, full port, neutral, 4 starboard, Experiment proved _ this full starboard. unequal sequence to be the best. For example, [ one respect I am unfortunate. Because of my close association with radio control, I am always expected not only to give a faultless demonstration, but also to demonstrate only the most advanced equipment. Hence it was with some trepidation that recently I took down to Poole a 36 in. yacht fitted with a single valve, single channel receiver. The results, however, were rather astonishing. With rudder control only and a fixed position one at that, the yacht could be controlled in all of the three major positions, tacking, reaching, and running. Landfall was made every time at a predetermined spot. Before coming to the radio equipment, method of installation and control, let me show a little appreciation of Tommy Lance’s “ Lancet.” In a day of violent winds, the pool having one tree-sheltered end and one totally exposed, enabled this little yacht to be put through its paces under all wind conditions. Never once did a gust flatten it or turn it off its course, at the sheltered end it maintained enough forward movement to come about easily with its rudder control. I did not have to experiment with the rigging or mast rake; its balance was perfect from scratch. As usual with me, this was not just a hasty tryout, but a planned experiment. when tacking the 4 rudder gives course correction, the following full rudder puts you on the opposite tack where you may require opposite 4 rudder again. The 4 between full and neutral was eliminated as unnecessary and would have made an eight sequence job. The alteration to the escapement can be seen in the diagram. Three standard two position rotor arms are soldered together at the angles shown. The piano wire rudder drive is taken from the normal operating pin to a rudder arm which, in order to determine the amount of rudder movement, has a series of fixing holes. The angle of full rudder required to come about I found to be approximately 45°. This may, however, vary according to the sail 4 / i> & RUDDER FIG.I OM RUDDER POST ESCAPEMENT RADIO I obviously & BATTERIES LEAVE realised that single fixed-rudder positions would be of no use with a sailing boat. If the angle of full rudder were too small, one could not come about. If too large, then one could not maintain a chosen direction in relationship to the wind. Using the most simple, foolproof radio of commercial type, and without the PIANO DECK 588 LINE ETC. SLOT WIRE FOR a ESCAPEMENT

October 1953 On the left author G. Honnest-Redlich adjusts the receiver on his Lancet at the pondside. Right: Lancer sailing under radio control position. I personally fixed my sheets to a position between tacking and reaching. It is obvious that in this case one cannot sail as close to the wind as possible, and when running, steering is a tricky job, but as I have said before, this is radio controlled yachting by the most simple and inexpensive means. A fixed triangular course can be sailed with probably only a little more tacking than would be required with full sail control. Second most important in a R.C. yacht is the installation. Yachts are usually “ wet” boats with water often washing over the decks. Both radio, batteries and escapement were built into boxes with covers as illustrated. The boxes are let into the deck, slightly projecting, and the hatch cover overlaps like the light trap on photographic equipment. This very effec- tively keeps water out. The radio, in this case the new E.D. hard valve “ Boomerang” and the full amount of batteries with on/off switch, etc., fit in the box just aft of the mast. The aerial is the supplied length run up alongside the mast and held by rubber bands. The escapement box should be at least 6 in. from the rudder post, otherwise a very short piano wire link would give a distorted “track” due to unequal circles of operation. This would give differing angles of Let us hope. that we shall see an increase of R.C. yachts next season. The addition of radio is not just another newfangled mechanical gadget, it is a necessity, because for the first time you will be able to sail your yacht, not just see it sail. It requires far more skill than fixed point sailing and after all one quickly gets port and starboard movement. For tuning and operation follow the makers instructions, but this is important, finally tune and adjust with the yacht in the water. The mass of water in close proximity with the receiver, batteries and wiring has a detuning bored effect. ; Rapa riiet i eaof Page ce.i and : -details the leading Results with 5 Celeste er again i far from its 1 home water— etthat boat has tShalimar li 5 triumphed. With this encouragement we shall 10 doubtless be seeing. many more A Class boats from the Littlejohn board! j, Gumbrie i | Arabesque 54 | «56 | 1640 beam) beam 15 | Designed 15 | Littlejohn Vanity Fair i Built | Levison 544 | 50 | 1450 14 | 14 | Andrews | Sik 51 | 1689 | #17 | | 16 | Norsworthy | Bolton | 589 rt | Craker | Black Tarquin works itself, no skill Lei dasma 43 K688 R.A. Jurd Gosport 31 Kay Birkenhead 25 Birmingham 21 Fa. Peiece M.Y.S.A. olton # —aoele Kigs K600 Wi W. Dougine H. Jones _ Barrow Birkenhea K679. J. Meir| = “4 = GSS EurBieckehaw Wi Liverpool i ; a a Remarks ee 1952 IOR winner, early planer. Won every run in | Pandora “it K67I J. Anderte ,3 Ponies K682 J.R. F.Bradle Craker in K698 clea aoa Mate ha eradiny boats are given below. Last year a Littlejohn design was entered for the first time: this year— L.W.L. | Disp. Sail | Deck | W.L.| the required” hobby. final. pee ei m.d. penalties, hard bilge, flat floor, long measured ength. | First Norsworthy A design since 1933. Broad, flattish hull.