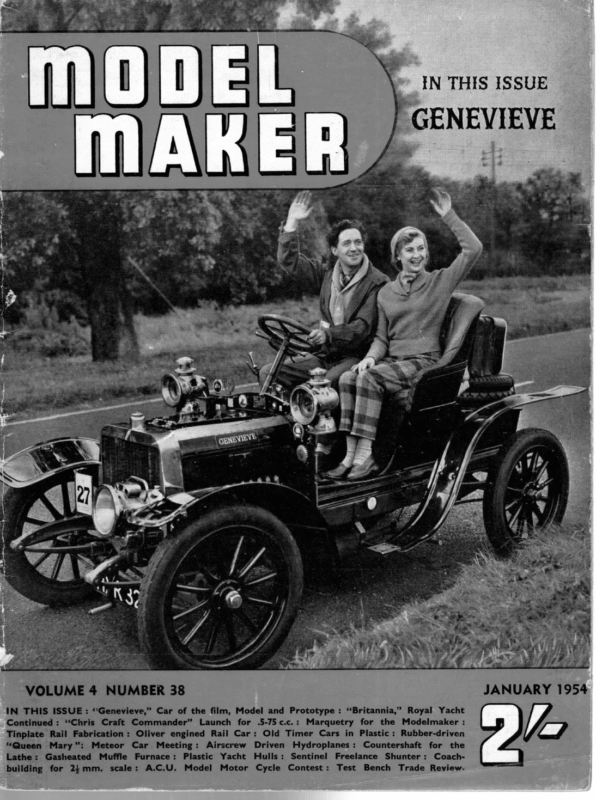

IN THIS ISSUE JANUARY 1954 VOLUME 4 NUMBER 38 IN THIS ISSUE: ‘“‘Genevieve,” Car of the film, Model and Prototype: “Britannia,” Royal Yacht Continued: “‘Chris Craft Commander” Launch for .5-75c.c.: Marquetry for the Modelmaker : Tinplate Rail Fabrication: Oliver engined Rail Car: Old Timer Cars in Plastic: Rubber-driven ‘Queen Mary”: Meteor Car Meeting: Airscrew Driven Hydroplanes: Countershaft for the Lathe: Gasheated Muffle Furnace: Plastic Yacht Hulls: Sentinel Freelance Shunter: Coachbuilding for 24mm. scale: A.C.U. Model Motor Cycle Contest: Test Bench Trade Review. a

PLASTIC HULLS Notes on the construction of a model yacht hull with glass cloth, fibreglass, and synthetic resin By E. GREENWOOD is lifted and the matrix removed. Now we are left with the two mating moulds with a space between them when in position, this space being pre-determined by the matrix. We are now ready for production. First, lubricate the male mould and’ treat with resin known as M.R.28C. Next, drape the male mould with Fibreglass and _glasscloth, and then lubricate the female mould in the same manner as the male. At this stage it can be placed in its compound position with Cea a strong and level building board several inches longer and wider than the overall length and beam of the finished hull. Next, cut out the shadows exactly as if building a planked boat with the exception that the allowance for hull thickness should not be more than 1/16in. for an “A” class boat. The shadows are erected in the usual way, but must be very securely fixed to the building board with the spaces between filled up with wood blocks or any other suitable light materials to about 3in. below the edges of the shadows, and this remaining space filled with Keene’s cement and finished off smooth to the correct shape of the inside of the hull. The top of the mould is finished off fiat to receive the keelson, which is made with two pieces of wood and secured to the mould with screws and plugs fixed into the cement, and the keelson is faired off to the correct shape as shown in Fig. 1. Paper is now pasted on the mould in layers until a matrix of a uniform thickness of 1/16 in. has been formed, and when completely dry, the surface is smoothed off with fine glass paper and finished to a high polish with shellac. After treatment of the surface of the matrix with wax, the outer, or female mould. is cast with Keene’s cement to a thickness which will give sufficient strength to the mould for handling. At the same time, suitable clamping brackets are set in the cement and it is also advisable to incorporate a wire reinforcement. In the top of the mould a steel, or brass, sleeve as shown in Fig. 2 is cast in to receive the pump connector. When the cement is set, the female mould the sight-glass and any other instrument fastened in place. Impregnation The impregnating of the glass fabric can: be done by one of two methods illustrated in Figs. 4 and 5. Let us first deal with the vacuum method. This is the method advocated by the makers of the resin, and its principal advantage is that it is impossible to get an air-lock. ; First, fill the trough around the base of the mould with resin, then extract the air; this will cause the resin to rise. About a 15 in. vacuum is needed to do the job. When the resin reaches the sight-glass the flow can be retarded by stopping the vacuum pump. It is essential that the height of the resin must always be sufficient to keep the edges of the female mould submerged. In the “A” boat Atlanta the second method was adopted (because it was thought that the minimum amout of resin would he used) and so. the process was completely reversed. Instead of fixing the vacuum pump at the top of the mould, an air-tight tank with a tyrevalve fitting was attached. It was found by experiment that plasticine would stop the flow of resin without softening unduly, so the bottoms of the moulds were sealed from after the forward and ends. The tank off, avart Heading shows Eddie with his very successful Atlanta. On the right, a photo taken through the deck hatch shows the odd effect of light shining through the hull where the paintwork has been rubbed away without damage to the hull itself

JANUARY 1954 having been filled with resin, air pressure was applied by means of a tyre pump, the idea being that when the resin had penetrated to the two open ends these would be sealed off and other points along the side would be opened up and re-sealed until it was seen that the resin had penetrated to all points. Final stages At this point, we can say that all the hard work has been done. All that. remains is to take the casting from between the moulds and trim the top sides of the bull. If marked properly the trimming can easily be accom- ; : plished with metal-working tools, thus com- fibres is bought in liquid form and is cured by mixing it with additives, the setting time being adjusted by increasing or reducing the amount of accelerator added to the mixture. Some of the features of this type of plastic pleting the hull. Obviously, a deck has to be fitted and this can be done in the same manner as a planked boat. Experience has shown that after a certain amount of consistent sailing, the inwhales absorb enough water to make them expand. The moulded hull will not absorb water and, therefore, will not expand are:— (1) The water absorption is about one per cent. to the same extent as a wooden huli:; the result of this uneven expansion is that it causes the deck to lift to such an extent that a crack shows around the edge. It can easily be seen that this joint will remain water-tight and the only fault is the bad appearance. The method I intend to try to prevent this will be to cut out the inwhale about 1/64 in. below the top of the plastic, thus giving room for expansion. +e used is named by the se > . ine makers as chopped strained mat”. This is treated in a similar manner as the glass cloth, but the strands are chopped into two lengths and rolled into various thicknesses. The reason for using glass mat is that it is cheaper to produce and it is very good for reinforcement as only one layer of glass cloth need be used on the outside. “ie eazecm: used. for impregnating the (Continued fig? on Fig‘ 3 ‘ page SHOW Ss Saka | Pius DETACHABLE COUPLING fEMALE MouLD — LIGHT TO WHICH lee Zieuhe, —wstaumenrs seme ARE SCREWED *— CONNECTION SIGHT VACUUM AIR-TIGHT 3 wna MALE MOULD FOR TANK METHOD Z SECURING NUT BALL VALVE VACUUM 42) VACUUM PUMP OR GLASS Fig 4 to way. 78 weeMALE MOULD eee BOARD up required, but if you require to paint the water-line this can be done in the usual ag! SulcouNe anything ull. Glass cloth is made with strands of glass which have been specially treated for lamination with synthetic resin. It is interesting to note that glass fibre has extremely high a and strength. tensile common use. The glass mat with (4) The finished hull does not need painting, as it can be pigmented to any colour Materials strength/weight ratio higher than any tensile material in compared 50 per cent. with a wooden hull. (2) It has a good impact strength, while the ultimate tensile strength is 45,000 lb. per square inch. (3) Although the specific gravity of the composition is greater than that of wood, a hull can be built to compare very ee aed in weight with a wooden , PRESSURE METHOD GAUGE => TO VACUUM euMP HOLES BORED To ALLOW = fir: v1S =. PlPS= TO SCREW CAP AIR FLOW AIRTIGHT PLASTICINE GLASS & CONICAL SLEEVE TO CAST IN CEMENT RESIN BEING by vacuum glass AN PUMP 7H G RESIN PEGS FOR KEYING TO CEMENT PUMPED BEING DOWN TANK CLOTH Mar