:. TTL tense reeen ee at ae ey t # fe bee *

MODEM MAHER HE tribulations of the would-be designer are many, and his troubles are even = 7 a : ae slat _ ee © F esl “ The story H. es when f0 he ven- the first line on paper he has a winner or a NP By B. more tures into the International “A” Class field. The very first and basic problem he has to contend with has nothing to do with design. It comes from the fact that very few model yachtsmen can look at a set of lines and dimensions and be able to say if the lines will produce a good ship. I have found that the average model yachtsman is not aware that from the moment the designer puts failure. The designer starting e 9 from scratch on the “A” Class rule will have to draw Priest, M.I.Mar.E. } , of the development of a highly successful string of ssp’? nek yachts ica the original Yeoman of 1949 (photo- graphed in third suit above) to the 1957 model Saxon in the drawing below. Fullsize copies of this drawing can as usual be supplied from our Plans Service in the normal way. SAXON Rast 12S PENALTY Meu DSSPLAcEMENT 565 LBS POMLTY MeL $a AEA S608″ out and scrap some three or four designs before he & ets his displacement ? balance and Q.B.L. correct. Having first produced real design his things | |

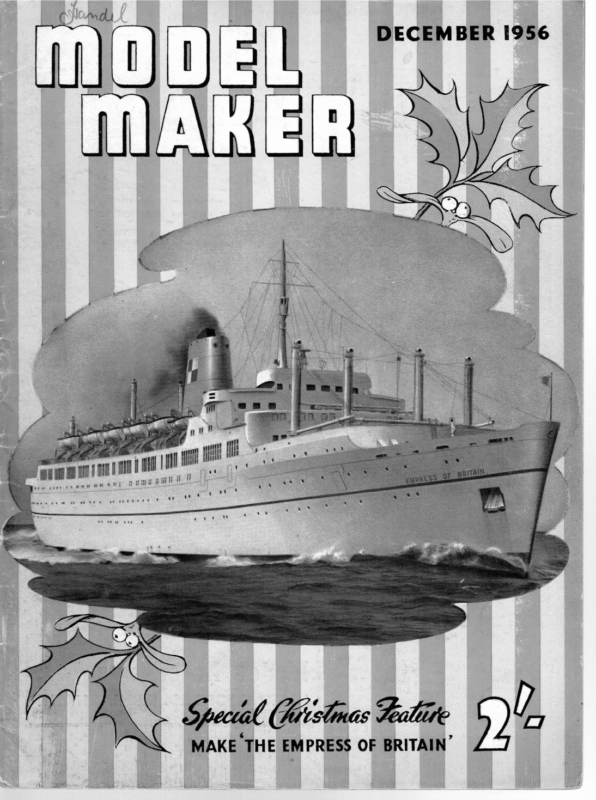

DECEMBER, are somewhat easier as he now has a basis from which to develop future designs, since if he splits his L.W.L. into ten sections on every design he produces, he can put one tracing over another and say one will be approximately sO many pounds more than the other, etc. Having produced the first real design a great deal of luck comes into it, because some good builder has to build it, and some good skipper has to race it. As I have pointed out, not many can say if a set of lines will produce a good boat and so it is very hard for a new designer to burst into top flight racing. The writer was extremely lucky when he produced his Yeoman design. Firstly, that it was a successful design, secondly that Mr. Boardman produced the hull and lastly that he could skipper the final product himself and so be able to evaluate its virtues and vices from first-hand information. The designer will, if he succeeds with his first design, now find he has a monster on his hands. There are a number of model yachtsmen who, when a winning design is produced, play safe and promptly ask for a set of the lines to build a full sister, or the more ambitious promptly request one to beat it. To do the latter every other year is where the poor designer’s troubles really start. When your Editor suggested a nice Christ- 1956 mas box for model yachtsmen, the writer decided to offer a design which, if correctly built (this point is made because some builders produce something which the designer himself cannot recognise and others, knowing more than the designer, decide to put in modifications of their own, usually with dismal failure), well tuned up, and sailed with more than just moderate skill, will be certain of very high placings in National and District Championships. It may be felt that this is a sweeping statement and so it is intended to take the reader step by step through the Yeoman family tree to Saxon. By this method and the data, facts, and results given, it is hoped to prove that she must be at least the equal of any in her family tree and has a very good chance of ~ being better than any before her. Yeoman came first as is shown on the family tree. Her mid-sections, bow and stern water line endings are shown on Fig. 1, complete -with her main dimensions. She proved to be at her best in a nice sailing breeze up to a limit top suit breeze. Under these conditions she could hold her own with any in the country. She liked to be driven hard with the main strapped well in. In second suit upwards she was not able to hold the Turner heavies with their 60-odd pounds, Arabesque with her great power or Pandora’s shallow powerful hull to windward, although she stood a 50-50 chance on the run with them. In light conditions she could not hold boats like Shalimar, Sharma or the Nash designs, either running or beating. In club racing Shalimar usually had the best of the encounters. Yeoman was designed to be at her best in the middle wind range but it had been expected that she would have been better than she was in practice in lighter winds. Her record, however, was quite impressive: 1950 National Championship is tus OTE 1951 National Championship 1952 National Championship ce fae .. oie). 6th L8E .. Ist 1953 National Championship Be 1951 Northern District Championship yen 2 oth An attempt was made in 1951 to overcome the weakness in light and heavy weather by redrawing Yeoman on 1 1/10in. water lines instead of lin., the idea being to give more weight for heavy weather and more square inches for light weather on the same beam. The idea, carried out in practice in Crusader, was not successful and the boat, although quite good, seemed to lack a certain amount of life and was not as fast on the run as Yeoman. Crusader has never been entered for a National 3 nt ahs mt BE a ae ae) ea ee

ai be [ < 4 ena ] Ze aot eae OB FIG" YEOMAN" LOA. LWL 79" 54-5" LW.L. BEAM 13-6" DISPLACEMENT 51-5 LBS. a Dats cea YEAR 1949 aa \ t\ a N cs ] Ze | zB) Cette A | SARACEN 1952" ope ROBERTA 1952 = 1 —e — N aN can /] Pd COMMANDO 1954 x FIG. 2."CAVALIER" ( ROBERTA) % FIG. 3. "COMMANDO" ay L.A. LW. 3 L.O.A. LW.L. a Q.8, PENALTY. 3" W] YEAR 1954 = Te eee SAXON 1956 -8o" 54" L.W.L. BEAM 13.5" 6. PENALTY <5" | DISPLACEMENT 50-5 LBS. SAIL AREA 15105" B YEAR 1952 Yeoman under these conditions. The design could outrun Yeoman under most conditions. A number of boats were built to this design -and the record is as follows :— (Roberta) (Roberta) (Aramis) 1955 National Championship éth 1956 Naticnal Championship 2nd (Serenade) 1951 Midland District Championship Ist (Roberta) In Saracen the Cavalier design was drawn on 1 1/10 waterlines instead of 1 in. and flare put into the ends to give extra reserve buoyancy for the extra displacement and so overcome the lack of life Crusader had seemed to possess. Saracen proved to have more life than Crusader but she still seems an inferior boat | fa 80" 54" LW GEAM 14:1 DISPLACEMENT 53 LES. SAIL AREA 15400" to Roberta. The writer can only conclude that the cause is the deep ‘body and that the ratio L.W.L. beam + body depth is too small. That type of hull form has therefore been discarded and development continued along the Yeoman/ Roberta line. The new problem was simply how to develop the Cavalier design so that it was a better allround boat. The reasoning went this way. To run faster meant a flatter floor to give more lift. Better windward work in heavy weather meant more weight and beam. To maintain an equally good performance in light weather over Cavalier meant more sail. From the writer’s data he concluded that 25-30 square inches would be needed if he increased his beam 4+ in. All this was carried out and the result was Commando (Fig. 3). Other minor modifications were made at the same time. The reasoning behind the design proved sound in practice as the boat is in fact a better all-round ship than Cavalier. On the run Calypso’s record run of 1.52 down Gosport lake in this The hunt for the answer was turned in another direction in 1952 and two designs were produced, Saracen and Cavalier. Yeoman’s maximum beam and body depth were on the mid-section. Her rise of floor, as seen in Fig. }, was rather flat; the after water line endings were rather flat and weak and the profile curve round the mid-section was rather tight. Accordingly, Cavalier was reduced to 54 in. L.W.L. and the tight profile curve was eased. The maximum beam was moved to 2.7 in. aft of midships. Her after water line endings were rounded off in a steeper curve, curve was put in her rise of floor, and extra power was put in Section No. 3 which meant taking a quarter beam penalty. The alterations can be seen quite clearly in Fig. 2. The design was very successful and proved a better “all-round” boat than Yeoman. The weakness in light weather was cured without any detriment to moderate weather performance although the new boat could still be outsailed on the beat in heavy conditions by those who could outsail 1954 National Championship 3rd 1955 National Championship 3rd SR Ee LESAN 1942 CRUSADER 195! r Reena 9 WT ee W) N or District Championship so it is hard to say just how good or how poor she is. a oy year’s International Race leaves no doubt as to her speed in this direction in a blow. In lighter weather Commando’s dead heat with Serenade would appear to prove the design slightly better running than the Cavalier design as in this very true test Commando was to leeward and each time she attempted to go ahead Serenade would take her wind, come up to her and go slightly ahead until Commando would get a free wind and the process would start all over again. It would seem to indicate that had the positions been reversed Commando would have won. In windward work the writer feels, after close observation, that the Commando design just has the edge in most conditions. (To be continued) 614

a, —— MODEL MAKER A GLASS FIBRE MODEL YACHT HULL This step by step description of the construction of— —da Marblehead will help many of those interested in this > coming medium to avoid some of the By A. G. Stainsby snags and pitfalls AE visitor to the Boat Show at Olympia cannot have failed to be impressed with the tremendous increase of interest in the use of fibreglass and resin for the construction of yachts and power boats. It is evidently one of the materials which future boat builders will be using, and it must thus be taken seriously even by the model builder who is keen on prototype construction. It was with this in mind that lL embarked on the construction of a Marblehead. The design was my own, also my first, based on the Circular Arc principle described in MopDEL MAKER in April, 1955. I mention this because there were features in the design which made construction in fibreglass very difficult, and others which made it particularly easy. My first difficulty was to estimate a table of weights. It is known that fibreglass is extremely strong, and that a small thickness will have adequate tensile strength, but what thickness is required for rigidity was not known. It was therefore assumed that the hull would be at least as heavy as a wooden one, but that one would save on the weight of paint. In fact, as will be seen, the hull came out lighter in weight than many wooden vessels. Not knowing what thickness of hull was required it was evident that it would have to be built inside a female mould so that any additional strengthening could be added in the inside. depending how strong the boat seemed. process was therefore to make a male The mould from which to cast a female mould in which the boat itself was finally built. This all seemed straightforward enough, the only decision that had to be made was on the fixing of the keel appendage. This I decided to do along a waterline rather than to fit it to the curved underside of the circular arc hull. This did mean there would be parts near the keel with negative curvature, but these turned out to be no more difficult to lay up than those with positive curvature. In this technique shapes corresponding to the body sections are set up on a base board as for a planked hull except that the shapes are the full size of the sections. The space between is filled with crumpled newspaper and then plastered over the top. There are several possible methods for making the mould for the canoe body. In essence, all that is required is a boat-shaped mould, and this may be made in any way that boats are made, i.e. breadand-butter, or planked. The cost is the main objection to the first, and the limited accuracy due to the It seemed 630 To obtain good accuracy, I took out 21 stations , they were thus about 23 inches apart which seemed a reasonable spacing. The shapes were made from resin bonded hardboard. I chose this because it has no grain, and there is no tendency for a scribed line to be unwittingly defiected from a true curve. Since all the sections below waterline were true arcs of circles, these could be marked out with dividers on the shiny side. The flare of the topsides could then be scribed by tracing from the body drawing in the usual manner. By rubbing chalk on to the surface the lines were very clear and fine. The shapes were then cut out and spokeshaved to the line. Then, since the hull is symmetrical fore and aft, one could place a fore section with the corresponding after section and check the accuracy of the work. This showed uD a slight lack of symmetry which I attributed to the fact that the lighting over my bench is not symmetrical. lL next proceeded with the keelTMappendage and the base piece of the canoe body, where the shape has to change from circular are to the keel giving the one inch minimum radius. This was a pece of wood three-quarters of an inch thick, and was going to be attached to the sections and form a the keel. The keel was built up location for bread-and-butter fashion. All pieces were the same width and the holes for the keel bolts were drilled in each piece. These were used as locating holes for all pieces and the section lines could be scribed along the sides when all pieces were clamped together. The shapes at The Male Mould thickness of the planking, to the second. that the method of plastering over crumpl ed news- paper had the merit of cheapness and great accuracy. each waterline glued together. was then were marked and The base piece of drilled for the the pieces the canoe all body bolt-holes and marked out for its sections. It was also decided to put in two dowel holes near the two ends of the keel to assist in location. The keel and the base piece were now accurately carved to shape using cardboard forms cut from the drawing to check the curvature of the base piece at the line of the sections.

DECEMBER, Flats were now cut on the middle section shapes to take the base piece. Four quarter-inch square slots were cut in all moulds to take longitudinal battens. All shapes were mounted on a T-section building board in the usual manner and the base piece was glued to the top of the shapes. Quarter-square longitudinals were glued into the slots to keep all sections upright. Before gluing, all sections must be carefully checked for alignment and the edges must be cham- fered away on the side further from the midsection, carefully checking the amount of chamfering with a batten. I later wished that I had mounted one longitudinal fore and aft along the centre line and also that I had made the batten along the inwales removable. The photographs show what the mould looked like at this stage. Dowel pins for the skeg are inserted at the correct position. If a batten has been put along the centre line they can be inserted into this, if not they must be screwed into the hardboard sections. All location and lining up is preferably done before the keel appendage is carved. Use can then be made of the parallel side of the wooden layers to ensure that the appendage is accurately aligned with the centre line of the male mould. The spaces were now filled with crumpled newspaper and the whole was plastered over. About 14 to 28 Ib. of plaster is required at this stage depending how close to the surface the newspaper is taken. It is better to err on the side of too great a thickness as it is infuriating to find newspaper protruding just when the rubbing down in nearly complete. The plaster is now carefully scraped away until it conforms to the right shape. The best tool for this is an old carving knife which is regularly sharpened on a scythe stone. It is no use using coarse glass paper as this does not rub away the plaster, wood and hardboard at the same rate, and unevenness is obtained giving flats between the stations. This is the real weakness of the technique and for this reason it is not wholeheartedly recommended. It may well prove easier, if a little more expensive, to build effectively a planked up hull but this is not likely to be so accurate since the wood is of variable thickness, and also the amount of rubbing down cannot be so accurately known. With the plaster method the size is exact since nothing is taken from the hardboard moulds. With many hours of patient scraping and checking wiih a batten. an accurate form may be obtained. This is rubbed down with fine glass paper, given a few thin coats of shellac until it ceases to be absorbent then rubbed again with flour paper and waxed. Simonize wax polish is very satisfactory. A very fine finish is necessary. At this stage one has to consider how to make the female mould. In one instruction sheet for the construction of full-sized boats it was suggested that this could be done in plaster with chicken wire as a 631 1956 strengthener. An attempt was made to make a plaster mould. The male mould was first coated with Teepol (soap is also good) and allowed to dry. It was plastered with a skin coat of plaster ‘then strips of hessian soaked in plaster were laid all over the top so that it looked like an Egyptian mummy. This was allowed some days to dry and then an attempt was made to remove it which was quite unsuccessful. A few holes were drilled in the bottom in case it was suction holding it on, but with no more success. Eventually the bow and transom were sawn off and the mould removed, but it had lost its beauty by then and was abandoned. One difficulty with my design is that it is a pram, L.e., it has a forward transom and I am sure that this was one of the reasons for the difficulty in removing the plaster mould. If the design used a conventional spoon bow and better still if the topsides were flared, I believe it might come away in one. However, at this stage it was decided to make a split mould with resin and glass eae which technique proved successful. Materials The stage has now been reached where some discussion of materials can no longer be avoided. To those unfamiliar with chemistry, it may seem a little baffling, but the instructions given with the material are very adequate and there is no need to do more than follow them. A little additional knowledge does however help if one wishes to exploit the resins to most advantage. (For this boat the resins were obtained from Automobile Plastics, High Street, Barnet). First then there is the resin itself. This is a fluid looking rather like golden syrup and will remain fluid for at least six months but not indefinitely. When the catalyst, a waxlike paste, is mixed in at the rate of four parts in a hundred, the resin will very slowly solidify; but no perceptible change takes place in 24 hours. When the accelerator, a pink liquid, is added at the rate of one to four parts in Photo at right shows the first concrete results of the method described, the basic framework ready to be plastered. Below is the ultimate stage in the mould – making phase, the completed female glass-fibre mould in which the elegant and highly finished hull in our heading picture was made.

— — . oe MOEN MAKER} a hundred, then things happen quite fast, depending how much has been added, and depending on the temperature. The chemical reaction gives off heat, thus a large quantity will get hot from the inside out and set more quickly than a small quantity. The solidified resin is not strong in itself, particularly in tension. It is therefore used to stick glass fibres together which are themselves very strong. The glass fibre may be bought either as a cloth in various thicknesses and weaves, or as a mat in which coarse fibres are loosely bound together in random directions, but not woven at all. If a lamination is made with glass cloth alone several layers may be put together and bonded with resin and they wiil form an intensely strong but slightly flexible sheet. If, however, the glass mat is used, a more rigid sheet is obtained but one which is more brittle since the glass fibres are much coarser and tend to break if bent. For a boat then, we need a bit of both and a single layer of cloth together with mat of 1 0z./sq. ft. weight seems to make a lamination of sufficient rigidity and more than adequate strength. The resin as stated above is a syrup-like fluid. If this is put on a vertical surface it will drain off, Particularly as there is a phase during the setting when it becomes extremely fluid. To overcome this difficulty, thixotropic resins have been devised. Thixotropic is a word which describes a substance which flows when pushed or brushed but stays still when little or no force is acting on it. Thus if the thixotropic resins are added to the standard resin one can brush the mixture on to a vertical surface and it will not drain away. The thixotropic resin is added at the rate of 25 per cent. to the standard resin when vertical surfaces have to be covered. It is counted as resin from the point of view of the proportions of catalyst and accelerator that are required. The resin as mentioned above is not particularly strong by itself, but on the surface of the boat we shall wish to have resin and not glass cloth in order to obtain a smooth surface. Furthermore, resin is not easily rubbed down since it easily picks up and fills the sandpaper. This difficulty can be overcome by using a filler which may be chalk, French chalk or pumice, depending on the requirements. This also gives a more opaque layer on the surface. French chalk added at the rate of up to 60 per cent by weight has been found very satisfactory and it gives a surface which can be easily rubbed down. This is important in one’s first efforts because it is quite possible to produce a few bubbles which have to be filled and rubbed down later. The filler also makes the surface more resistant to abrasion. Finally, a range of colours is obtainable which, even if they are not exactly as desired, could be mixed to the desired colour or at any rate they will give a useful undercoat to the final decorations. Other apparatus required is one or two paint brushes of the cheapest kind made of fibre and one of bristle, also some acetone for rinsing brushes before finally washing them in “Surf” and water. You may also feel it safer to buy some polyvinyl alcohol (P.V.A.) as a parting agent to use in addition to the wax polish. This is diluted with three parts of water and painted on to the moulds and allowed to dry. Two coats are safer. Making the Female Mould As already stated, it was decided to make a split mould with resin and glass fibre. This is rather an expensive way of doing it, but it has two merits. (1) The new mould has a high finish, and exactly repeats the contours of the male mould. In this respect it is much superior to plaster which would have to be rubbed down, varnished and polished. (2) It gives one some practice in the arts of the so- called wet lay-up process before doing it on the final job. In my case in particular it gave some idea of the strength of the materials to be used in the final job. Owing to the experiences with removing the plaster mould described above, it was decided to make the mould in two halves. To do this, a wall of putty was put along the centre line of the male mould and also along the line of the top sides on one side. Here I feel a mistake was made, and it would have been better if the batten running along the topsides of the male could have been removed and replaced by one say +in. x 3. This would then have given an accurate step {in. wide to define the sheer in the later moulds. This would, of course, need to be built up higher by putty to about 4in. This putty wall needs to be quite thick as one has to brush the resin against it. The wall on the centre line should be as straight as possible, but it does not need to be exactly so. It should cover half the thickness of the dowel pins for keel and skeg and the keel bolts. These dowels should be given a coat of wax before they are inserted. One now proceeds to the first stage in the construc- tion of the mould. This will cover half the boat and have flanges all round. Give the male mould a final rub and coat with P.V.A. if desired. Now mix up the first coat, the so-called gel coat. Anyone who has not tried it before may prefer to make a moulding of some object such as the bottom of a plate as a preliminary exercise, but as the female moulds do not have to be perfect I went straight ahead with the job. For half the boat (a Marblehead) the following quantities were used. 6 oz. total of resin (containing 25 per cent. thixotropic resin) with 4 oz. of French chalk. These are mixed together so that one has an even mixture. The catalyst is then added at a rate of four parts to one hundred of resin. The mixture is then allowed to stand for half-an-hour for the bubbles to come up. All tools are made readyTMto hand during this time and when everything is checked, the accelerator is added at the rate of one to four parts in one hundred. Once mixed, there is only limited time to work, and one must work quickly. To be continued) The middle stage of mould-making is the finished male mould shown here. Note that the shadows are visible flush with the plaster surface and that the wood garboard piece is in place. 632

DECEMBER, [956 Tucker’s Topical Talk On the right: Hopalong, J. Meir’s successful “M’ lass yacht to H. B. TakacssEmma Duck design. Note the typical “Duck” action to windward, using maximum possible sailing length on 50 in. ; overall length On the left: Danny Boy, Belgian National 1-metre Class, Fe ge by H. B. Tucker, and built by A. Levison. There was a nice breeze when this picture was taken, and the brea travelling fast. 3Note how little water dis- turbance she makes, and how she uses almost her entire l.o.a., with bow and stern wave crests well out on to the overhangs ARLY in 1956, I received a commission from Brussels to design a yacht to the Belgian National 1-Metre Class. The formula is as follows :— L.W.L. + VS.A. until mid-October. Before sailing trials, she was checked in the measuring tank, and found to come out exactly on her designed L.W.L. and correct fore-and-aft trim. Her first short trial under sail was in a smart breeze giving a beat and run, when she went well to windward and planed readily down wind. Her second trial was in a light to moderate wind, when she showed herself decidedly faster than a good M-Class which was used as a trial horse. She was found to follow the wind well, to have very good acceleration, and to use almost her entire L.O.A., except for an inch or two at each end. In fact, as far as could be judged by eye, she has a = metre (or 100 units) where L.W.L. is measured in cm. in fresh water. S.A. is measured in sq. cm. by I.Y.R.U. Rules, 85 per cent. of fore triangle being taken for rating. There are also a few restrictions, of which the most important are:— sailing length of 56 or 57 inches to windward. Draught without penalty must not exceed 16 per cent. of L.W.L. plus 8 cm. Any excess is multiplied by five and added to rating. It is interesting to compare photographs of Danny Boy and Hopalong, Mr. J. Meir’s successful M-Class built to the Emma Duck design. Obviously, the Belgian boat is infinitely better looking due to her overhangs, Battens. Four are allowedin mainsail, equally spaced. Outer battens are limited in length to 15 cm., inner battens to 20cm. Mainsail as well as being faster than any M-Class can possibly headboard be, but that is entirely due to the Belgian National Rule being far superior to the M-Class Rule. Unfortunately, the lure that the simple rule has for many model yachtsmen led to the adoption of this American rule in this country and on the Continent. Admittedly, the M-Class is our most popular model today, but aesthetically. a boat with overhangs is more pleasing. Moreover, as a designer, I know the value of overhangs, both for reserve buoyancy in the ends, and for extra must not exceed 2.5 cm. across its base. Prohibited sharpies, bulb keels, centre-boards, and lee-boards. After considerable thought, I came to the conclusion that this called for a boat of approximately the same dimensions as a modern M-Class, but with overhangs added, and rather more sail, especially as my instructions were that light winds are frequently encountered on sailing length when the yacht heels. her home water. Danny Boy was accordingly given the following dimensions:— L.O.A. 1.62m,. (63.77in.), L.W.L. 1.25m. (49.21in.), max. beam 27.2cm. (11.42 in.), L.W.L. beam 26.4cm. (10.39in.), draught allowed 28 cm. (11.02 in.), draught actual 27.5 cm. (10.83 in.), S.A. allowed 0.5625 sq. m. (874 sq. ins.), S.A. actual 5614 sq.m. (872 sq.in.), YS.A. 74.94, displacement 10.88 kilos (24.0 Ib.). By way of comparison, the dimensions of Emma Duck, one of the most powerful M-Class yachts, are: ‘L.O.A. 50.25 in., L.W.L. 47.5 in., max. beam 10.5 in., ae 11.25in., S.A. 796 sq. in., displacement The building of Danny Boy was entrusted to Mr. Arthur Levison, who made a most excellent job of her, The Model Yachting Association will shortly be issuing its Fixture List for 1957, giving dates, venues and conditions of entry for the National Championships of the various recognised Classes. Staging a National Championship entails some expense, and much extra work for the members, especially the officers, of Clubs on whose waters events are held, so the M.Y.A. invites applications from Clubs wishing to stage these races. The sole exception is the A-Class Regatta. Unfortunately, at present there are only two lakes in the country (Gosport and Fleetwood) suitable for this major event, and in consequence, the Regatta is held on these two waters alternately. It is the turn of Fleetwood in 1957. but for various reasons her trials could not be held 633 (Continued on page 638)

MODEL The’ _ elegant little plastic wallet containing chrome vanadium double – ended B.A. spanners in the hard-toget model will be sizes which pre- sented to our **Readers Write” correspondents, INBOARD ga PLASTICS AND RADIO CONTROL Dear Sir, In your September issue you show some small plastic boats now on the market, and pose the problem as to how small a model can be fitted out for radio control. In this respect perhaps, an American idea I read about some time ago may interest readers. This was a simple radio control for “microfilm” aircraft models, which for the uninitiated, are models weighing only fractions of an ounce, and which can only be flown indoors, usually in a large hall or hangar. The method described was to fit on the model a very fine wire to the rudder, which when receiving a strong, nearby signal, heated sufficiently to stretch, and moved the spring-loaded rudder through the neutral position over to the opposite hand. To reverse the process, the signal was simply released off the transmitter. This is simplicity itself, and may be worth an experiment or two on very small boats on a confined area of water. The wire used was of a special kind, and perhaps a more radiominded reader can give an indication of a suitable sort for the purpose. Yours faithfully, P. O’ KEEFE. Maidstone. (Ep1tor: Wire used for this purpose is . bi-metal and warps at a maximum range of 50 ft. if Tx output is 50 watts—which is in excess of permitted output under British G.P.O. regulations.) WINDSOCKS REQUIRED Dear Sir, May I make a plea through your pages to those who organise the various National Model Yacht Championships, to please see that they have a wind sock or some such device at each end of their sailing water. Gosport this year was a glaring example. The wind was constantly. altering in direction from board to board and yet there was not the slightest method of indicating to worried skippers how much the wind had changed. This did not worry the locals such as Jurd, West and Gardner too much, they know these things by old experience and by the wind ripples on the lake, which in any case is not the same as the wind direction at Gosport. But to the stranger who visits Gosport for one week every other year, life becomes a nightmare of inspired or uninspired guessing for every SSS eee trim. Please let us have two socks on every Championship lake next season. B. H. PRIEsT. Prenton, Birkenhead. VIEW ‘B’ SKEG AND RUDDER Dear Sir, In reply to Mr. Blogg’s letter in the September issue regarding the sentence, “it is a definite fact that if the skeg and rudder on a normal fin keel yacht are moved forward, the sail plan has to be moved aft to compensate”’, I would like to state that the word aft was printed in italics so that readers would not think there might have been a misprint. While this sounds unusual, I am fully convinced that such is the case, although perhaps I should have made it clear that this only occurs within certain limits. For instance, I am not suggesting that if the skeg is brought right up to the fin the mast position would be further aft than with the skeg mounted at the extreme aft L.W.L. This applied only to moving the rudder post from the extreme L.W.L. position a distance of three or four inches forward. Although the reasons for this phenomenon are complex and unlike some of our older writers, I don’t pretend to know all the answers, I would venture the explanation may be due to the forces set up in the wave system when sailing heeled, as shown in the rough diagram. The model in the sketch is shown moving an S/L ratio of one, which is the best for explanatory purposes. The effect increases with the speed up to an S/L ratio of rather more than unity and thereafter remains approximately constant for greater wavelengths. For instance, in the case shown (2) the skeg and rudder already have a positive angle of attack due to wave motion, though for simplification the model is Shown without a leeway angle. If the rudder post were at the extreme L.W.L. end at the wave crest then the skeg and rudder would be without load. If the model is sailing at below S/L 1 with a shorter wavelength (1) then the skeg and rudder are without load, but if the rudder post were at the L.W.L. end then the skeg and rudder would be working at a negative incidence. At speeds in excess of S/L 1 the wave angle in relation to the skeg remains approximately the same. (Negative incidence does not occur in practice due to’the effect of the leeway angle, but the differences in loading are the same, which is the point I am trying to make.) Altogether I consider it advisable to keep the skeg away from the reverse turn of the stern wave crest. I suggest another argument in favour of the inboard skeg and rudder, in that it helps to prevent the formation of a pressure escape wave from the fin root which is so often seen. I believe that the cumulative pressure which builds up from the bow to the after edge of the fin root, cannot be balanced by a skeg and rudder mounted at the extreme L.W.L., which has no accumulated pressure and that unless a long based skeg is used, the only way of equalising the loadings on the fin and skeg is by mounting the skeg near enough to the fin 634 to make use of a certain amount of the accumulated pressure flow from the forebody and fin but far enough away to clear turbulence caused by the fin. In the definition of aspect-ratio, Mr. Blogg is technically correct as applied to an aircraft wing, but in yacht design aspect-ratio of the mainsail is always given as an ordinary ratio of luff to foot for example 3 to 1 or still more simply as 3. This simplified system is used universally by amateur and professional yacht designers and is understood by one and all so why worry ? Hull. S. WITTY. A GOOD TYPE Dear Sir, In defence of MopEL MaAkgr, I wonder if you would care to print a reply to “Brickbat”’ who wrote in your last issue ? I am one who has just joined the **Millionaires Club”. I have had to make the supreme sacrifice to buy a second-hand lathe, namely, I have sold my motor cycle combination and bought a lightweight. I would also point out that he will not need either to build his own railway or a glass case. I am sure that in his district there will be a model engineering, or small locomotive society, who will be only too pleased to let him join their ranks, and use their model railway. I have been, during my youth, a keen aeromodeller, who dabbled in ‘“‘Ruinous Radio” and of late, a boat builder with the above radio installed. I can assure Mr. Paxton that excluding the lathe, the engine will be cheaper in the long run, and will run a lifetime and give pleasure to the builder and his passengers. Yours faithfully, Brighouse, Yorks. D,. WAINWRIGHT. ARTICLES WANTED Dear Sir, I hope you will not think it presumptuous on my part, being a very new but appre- ciative recruit to the ranks of your readers, but I should like to give my support to the letter from Mr. R. Booth in your September publication. Namely, a hope for a series of articles dealing with the construction of model petrol or diesel engines by E. J. Westbury, or some other authority on the subject. As Mr. Booth states, there are plenty of commercial engines to choose from these days, but I am sure that every true model maker gets much more pleasure and satisfaction from making the whole of his model himself. Also, as petrol or diesel engines can be used for the motive power of model cars, boats, etc., and any stationary model that requires power, I am sure that these articles would appeal to a large number of your readers. Yours sincerely, Edgeley. C. W. HEPPLE.

In deciding among the various clubs applying for the an -aaaaiastoeiclauiicdaatetiec oily. 7. N-Motors Lta.: Championship of any given class, the first considera- EE EEE EEL EL ELE SE Ee tion is the suitability of the water, not only for a championship race, but for the Class in question, as regards size. Another point is whether the Club has sufficient boathouse accommodation for the number of entrants that can be expected. Further points are accessibility, local accommodation for visiting model yachtsmen and their families. It is-also essential that sole use of the lake on the required days is obtainable from the local authorities. Locality plays an important part in the success or otherwise of an event. As an example, the Scottish contingent is always larger in the A-Class event at Fleetwood, than it is at Gosport, and a championship for one of the smaller classes placed on a water that is not central, and where the class in question has little was the case with the 36-inch Championship in 1954. A further reason for placing a Championship on a certain water may be purely a matter of politics. Some clubs, such as Hove and Brighton, have only a precarious hold on their sailing water, which local Councils would gladly turn over to more remunerative uses, such as letting children’s paddle-boats, etc. Again local Councils may have spent ratepayers’ money in providing a model yacht lake. In either case, it may be of advantage to place one of the National Championships on the water in question. In deciding the number of days to be allocated to any Class Championship, the probable number of entries has to be taken into account and the number of boats per club that can be catered for. In this connection, the fact must be borne in mind that many model yachtsmen cannot afford to give up more than a certain number of days to participate in a model yacht race. Hence, three days-is- usually the- limit for all Class Championships except the A-Class event. This, of course, may entail Divisional Sailing with a Final. Now, most model yachtsmen dislike Divisional Sailing and prefer a full Tournament. There are two reasons for this. The Tournament gives every com- SESE local following, may fail to attract sufficient entries, as past, present and Pikes A merry Christmas & the best of luck for coming 1957 season ZN Motors supply everything for (Model Car Racing and have two outstanding mivcldli for 2.5 and 5 C.C. for 1957 season 904 HARROW LONDON Radio – ROAD, N.W IO Repair Service Service and repairs promptly carried out on all E.C.C. radio equipment. All work Guaranteed. G. G. Davie. 7 Davidson Road, Thorpe, Norwich, Norfolk feel that it is more conclusive. On the other hand, if Norwich 33528. there is insufficient time to sail a full tournament, Exciting ( © nth usiasts —E.C.C. petitor the maximum amount of sailing. Also many Divisional Sailing is the only way to obtain a decisive result. In this connection, it may be observed that in the early days of the A-Class Regattas at Gosport, a full Tournament was sailed and styled ish ikea eaeue tenes ee TUCKER’S TOPICAL TALK (Continued from p. 633) Scale Models — to Build Yourself ! SHIPS ‘Golden Hind’ _ the Eliminating Race. This took four aoa or five days, and after it the first eight ‘Victory’ (or sometimes 12) boats sailed a oneday Final. The scores from the Elimi- ‘Cutty Sark’ AIRCRAFT nating Contest were carried forward Spitfire between individual boats were re- S.55 Helicopter to the Final, and starting positions as Glos. Gladiator versed from those in the Elimina- tions, Thus if A had met B in the Elimination Race, and had choice of Sane Eotts-Royce positions, B would have choice when she met A in the Final. Darracq Bentley I feel it is a great pity this system daar had to be dropped, because the Finals showed model yachting at its best, EACH MODEL. 2/- RETAIL were the best boats and skippers in Gontlenialty since the fleet of eight or 12 boats the country. Also with the comparatively small number of boats engaged their respective positions and scores could be followed board by board. Se Fer deetisomeat mastic aa C : Obtainable from all leading Model Shops and Stores One added Also ask for Airfix Building Sets.. HALDANE PLACE,. AIRFIX WHOLESALERS LIMITED ¢38xt ex: