MODEM MAKER) polyester resins with stranded glass HE new Viatier have opened up many new fields of building techniques in the boat-building world, to combat rot, and to provide amazing strength with very little added weight from their woodbuilt counterparts. These techniques also apply to model boatbuilding; but the reason for my selection of these materials was to reproduce a 10-rater yacht on the exact lines of my mahogany planked 10-rater yacht, Judith, number 1325; a slightly modified Halceyon design yacht, which has been highly successful, and was placed second in the 1955 10-rater champion- ships at Birkenhead. The materials I used were obtained from Messrs. Bondaglass Ltd., of Croydon, but there are many other similar materials, under trade names which come under the general category of Glass Fibre. The detachable fin, rudder, pintle and all deck fittings of the yacht Judith were first removed, and the boat placed upside down on a large plank, the deck being spaced away from the plank by 4in. wide laths lightly pinned to the plank, and 4in. from the outer edge of the deck line. This was to enable the glass fibre GLASS FIBRE for REPRODUCTION E. M. Butterworth discusses the making of a glass fibre yacht hull from an existing model. skinning to turn in at the deck line, and form a strong inwale. This turn-in and the tumblehome made it necessaiy to produce the plaster mould in two halves, but I would advocate doing this under all circumstances, as the impossibility of using mechanical ejectors makes the withdrawing of the pattern from the mould a very chancy business. A template of 1 m.m. aircraft plywood was made of the keelson line, to place between the two halves of the plaster cast and prevent them from adhering to each other. Fifty-six pounds of common pink plaster were used to make the mould, and the time taken to produce the finished article was about two hours. It should be made in the following 3. The first mix should be just viscous enough to hold itself around the hull so as to form a good inside, face free from air pockets. Before this skin sets, the keelson template should be set and pressed through the plaster into place. 4. Place a thick layer of plaster over the first, and before it sets, lay along the top strips of canvas, soaked in plaster, to reinforce the mould. 5. Finish off with a thick layer of plaster making sure that the two halves are never joined across the keelson template. In my yacht I moulded the skeg integral with the hull, but I suggest that this is not a good point, as the glass fibre tends to warp slightly, if hot sunshine is allowed to remain on one face for any period of time. A hard wood skeg is to be preferred, which passes right through the hull to the deck beams. It can, of course, be cemented into position with the resin. After two days in an atmosphere of 60°F. the keelson template can be removed, and the two halves of the mould carefully prised apart, when they can be reassembled the right way sequence:— 1. The former (the existing hull in my case) should be well polished to ensure that the mould will separate, and no undercuts or small holes can be tolerated, as these very efficiently key the mould to the former. 2. No more plaster should be mixed than can be dealt with within fifteen minutes of the mixing. 170

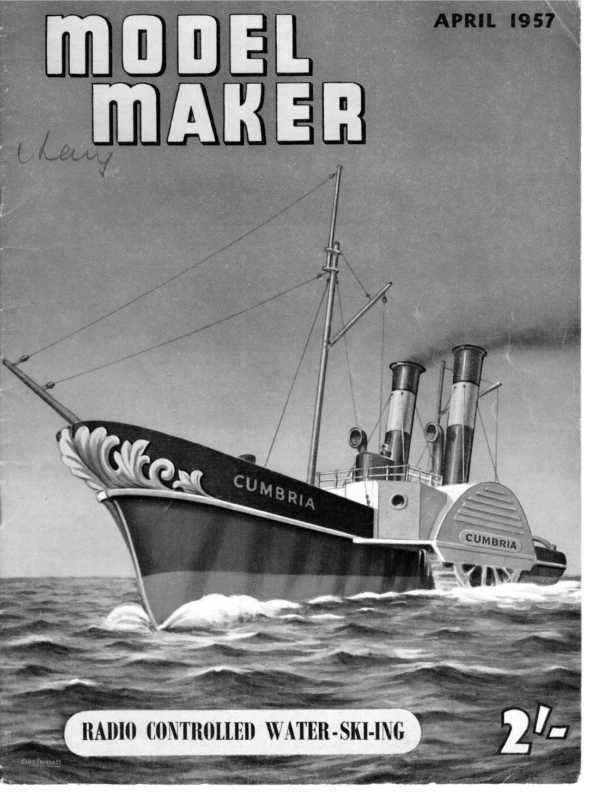

APRIL, up on a supporting frame, not forgetting the keelson template, as this will reduce the beam of the yacht by 1 m.m. if omitted. The keelson slot should be carefully plastered up to seal the openings, and all air pockets filled. The mould should now be left to dry for at least fourteen days at a temperature of 60°F. and no work should be commenced until it is certain that it is dry. Fast drying will produce surface cracks, which should be avoided. The surface can now be smoothed with fine glass paper, to remove any roughness, and the inside surface should be cellulose sprayed or very carefully hand painted. Upon this face depends the outside finish of the new model. I used the medium weave glass scrim for the reinforcement, but the glass matt is easier to mould complex curves. Before starting with the resin, the glass should be shaped into strips so as to cover the model with two complete layers. Do not overlap the layers, but lay them with the joinings in different positions for each layer. It is important to maintain a temperature of at least 65°F. during the moulding operation, as below this, the resin will take hours to set, and will run down the walls to the centre of the boat. A little running can be tolerated as the resin flows to the centre-lower part of the boat and considerably strengthens the garboards. ‘ The resin and catalyst hardener should be measured to the exact proportions stipulated by the maker, and only the amount which can be used within ten minutes should be mixed. The mould should be treated with a releasing agent, or polished liberally with a silicone polish. Paint the resin on to the inside prepared wall of the mould and allow to set. Paint another layer of resin on to the first, and press the glass cloth on to the mould, well into the resin, and allow to set. Repeat with another coating of resin, a layer of cloth, and a final coat of resin, which will give a wall thickness of approximately 1/16 in. When the resin has completely hardened, which will depend on the room temperature, the mould may be split, and the cast model withdrawn. Two brass ribs should be made, and bonded into position with a layer of glass and resin, to strengthen the hull at the points where the keel bolts come through the keelson. Inwales of 5/16 in. square obeche were held Heading picture shows Scarab wearing Fudith’s sails, the latter being in the background. Right, picture 1 shows the mould exterior, 2 the interior before removing the new hull. and 4 are of the hull as removed from the mould, 5 shows the cleaned-up result mp 6 the finished boat ready for rigging 171 1957

MODEL MAKER) in place with “G” clamps and glued with resin into position, and the same applied to a reinforcement of the stem and transom. I find that the polyester resin without its glass stiffening is very brittle, so after fitting the deck beams and tacking the 1 m.m. aircraft ply deck into position, I used a mixture of the epoxy resin “Araldite D” with 951 hardener to run into the groove formed by the curve of the gunwale and the overhang of the oversize deck. After the resin sets, it can be planed and filed, and no joint can be seen. Also, layer can be added to layer, which bond together perfectly. Both the resins can be stiffened by a 10-20%, addition of french chalk (magnesium silicate). The final result is a very strong hull, which can be easily repaired, but it takes much longer to build, and my 10-rater was 8 oz. heavier in the hull than the timber-built yacht. The photograph shows Scarab, number 1441, before she was measured, wearing her sistership’s sails. In her first year she has won the main Birkenhead 10-rater club event, for the 1956 season—The Auderny Cup. udith, the original pattern, is a slightly modified version of John Lewis’ Halceyon <——<— — SKI - BELLE (Continued from page 166) skis as illustrated, but we mounted it with plastic bands over the skis for ease of transport, and we also removed it quickly on taking the Skier out of the water to baffle the pond side knowalls (which it did). A plastic keel may also help to keep the Skier tracking out to round the buoy on the outside as in fullsize water slalom practice, but this was never tried. The method of fixing the tow rope is shown, the legs, arms and body were cut from off-pieces of balsa block, and the whole finished in an evening. A matt paint would have given a more realistic appearance to the body, but the whole thing was made in a rush, so gloss had to suffice.” i eg The idea caught our imagination, and we immediately fell upon a lump of balsa and started to hack out Ski-Belle. Trials with both models were carried out (we were unsure whether the added height of our figure in the true skiing stance would make things difficult), but with the extra spread on the legs found no trouble of this nature. The competitive possibilities opened up by this scheme are vast—how many radio men could tow one of these figures, steered to run on the boat’s quarter, accurately enough for it to jump a model water-jump as in fullsize practice? Once proficiency was obtained in getting a successful jump on nearly every run the question of distance jumped could then be introduced, or three or four jumps be spaced on a turning course, so that the boat whose skier jumped every time successfully would win. 172 This is one of those gimmicks which MODEL MaKeR thinks will catch on fast, since besides being so much fun to operate, it is a natural crowd drawer, and could do much to popu- larise public support of club regattas. Construction is pretty straightforward with a fretsaw and a sharp modelling knife; drawings are full-size, and a rake over the scrap-box will soon produce enough odd block to produce the six pieces (head, trunk, two legs, and two arms). Double-cement all joints and line up the arms on the dowel before finally cementing them to the shoulders. ; The skis are 1/16 in. ply with the tips soaked and dried to the required curve. before use. cemented on Doll’s or finishes Varnish them theatrical the head crepe hair although a bathing cap could be carved in if preferred— or, come to that, a razor-cut hair style (joke?). Apart from the celluloid plate, the secret is the four-point thread tether, which ties off on the dowel ends and two pins in the ski-toes. The planing angle can be adjusted by shortening or lengthening the lower two lines, Incidentally, our model has more spread on the skis but needs a high speed to stay on the surface without the celluloid. With the celluloid, she will rise to the planing attitude from any position once the boat is moving, which is going to be useful when we fluff jumps, which we'll be trying very shortly.

APRIL, ee REVISED EDITION of the M-Class Rating Rules is now obtainable from the Publications Secretary of the M.Y.A., Mr. G. Leeds, 151 Charlbury Crescent, Yardley, Birmingham 26, price 1s. Od. post free. Except for some clarification in wording, there is no real change in the Rules, which remain UCKER’S TOPICAL intrinsically unaltered. During the preliminary discussions on the Rating Rules by the M.Y.A. Council, Mr. F. Jennings made a valiant attempt to have the Garboard Restriction eliminated, at any rate as far as sharpies are concerned. Of course, he was perfectly correct about this, as a filled garboard angle is totally incorrect for a hard-chine yacht, and altogether incongruous. It is true that a few sharpies have been built under the rule, and at least one was highly successful, but her padded garboard was a _ needless artificiality produced by the restrictions. Another restriction prohibits Metal Fin Keels and is obviously aimed at the prevention of plate fins with lead bulbs at the bottom (usually known as “Bulb-Fins”), but there is nothing in the rule to prevent the use of this type of fin in wood, if it has a padded garboard angle! Prognathous Keels (i.e. keels having any part of the leading edge projecting forward of any part of the leading edge above it) are also prohibited, a nothing is said about excessive Seal Flipper — oe ins. I was sorry to see that Sliding Rigs are not yet prohibited, especially since all internal trimming ballast must be fixed and recorded on the certificate, and an alteration of even a couple of ounces invalidates the Certificate and entails re-measurement. It is also curious that while the M.Y.A. 36-inch Restricted Class Rule specifically prohibits Bowboards, and thereby eliminates Prams and Sailing Punts, these are permissible in the M-Class. Hence it is surprising that some enterprising and original designer has not tried these out before now. Of course, it would involve the sacrifice of some L.W.L. length, but the gain in actual sailing length might make it worth while, except possibly in the lightest winds. In consideration of the M-Class Rule, it must be remembered that it is an International Class Rule, originating in America. Therefore the M.Y.A. cannot be blamed for any shortcomings in it, nor can the M.Y.A. amend or improve it, unless the majority of member nations in the I.M.Y.R.U. agree to the alteration. * * * * * From all I have heard, model yacht builders during the past winter have found it increasingly difficult and expensive to obtain suitable materials. This has applied particularly to those building a first boat, and those who have not built a boat for some years, and are in consequence out of touch with suppliers. Far too often the laiter refuse to supply the small quantities that are required, particularly for boats of the smaller classes. In consequence, the would-be builder wastes an enormous amount of time in a fruitless search for materials, and often finishes by accepting inferior substitutes at a grossly exaggerated price, or buying far more than he needs because the vendor will not sell a less amount. Suitable timber is particularly hard to find, and even when the right quality is available, boards of the right thickness and width are often unobtainable. In addition, timber merchants are frequently unhelpful as regards planing to an exact thickness. we TALKS 1957 ‘M’ RULES: SOURCES OF SUPPLY: M.Y.A. NEWS: Fy Thin boards, such as }-inch wood for planking, are practically impossible to find. I fancy one reason for this is the almost universal use of plywood in furniture-making these days. As a designer, I have found it convenient, in the larger classes at all events, to space my W.L.s and Buttocks at 1l-inch intervals, but 1-inch wood for bread-and-butter building is decidedly difficult and usually has to be planed specially from 14-inch or even 14-inch timber. This is wasteful and naturally adds materially to the cost. On the other hand, boards ¢ inch thick are far commoner, as they are planed down from timber 1 inch thick. In consequence, I propose spacing my W.L.s and Buttocks at 4-inch intervals in future, and venture to suggest to other designers the advisability of this change. Although a few builders cast their own lead keels, most people prefer to entrust the job to a foundry. Since the war, however, it has become increasingly difficult to find a founder willing to undertake this, particularly when only a small keel, such as that for a 36-inch model, is concerned. I know of one builder who wanted a keel for a small model recently. He tried at least a dozen London foundries. Only one of these displayed any interest whatsoever, and this firm in reply to a telephone inquiry, thought they could oblige him, but asked to see the keel pattern. It was accordingly taken right across London and shown to the manager, who talked about making steel moulds and minimum quantities of 50 to 100 keels. On hearing it was one only, he said “Oh, a sand mould job, could not consider it under three months, and it will cost about £10!” Ultimately the order was given to London Metal Warehouses Ltd., 15-17 Edgware Road, London, W.2, Their foundry is at Summer Road, Thames Ditton, Surrey, and it was explained that if the pattern was delivered to the foundry it could be put through the following day. As it was left at the Edgware Road depot, it would have to go by lorry to the foundry and wait until they had one coming up te the depot, say seven days in all. Nowadays, most new yachts are equipped with Steel masts are decidedly expensive metal masts. and have the disadvantage of rusting through, usually at deck level. In consequence, particularly in the smaller classes, aluminium or duralumin masts are preferred. These are made from tube with a wood topmast plugged in. Duralumin is preferable to aluminium, as not only is the former stronger but is less subject to deterioration in sea water. On the other hand, aluminium tube is easier to procure. It is, therefore, of interest to note that dural. tube in all sizes and cut to any desired length can be obtained from Alcob Metals Ltd., 367 Edgware Road, London, W.2. These two addresses are well worth noting, but I would suggest that many readers must similarly 205

MODEL MAKER have good sources of supply for various materials that are difficult to get, not only in London, but other places in the U.K. If they care to let me have these, I will compile a list for publication early mext autumn. I am in particular referring to items which would not be worth while to advertise, but which cause the model builder endless trouble in issued quarterly in future. The subscription is 4s. Od. per annum, and single copies cost 1s. Od. All model yachtsmen interested in organised model yacht racing should make a point of subscribing to the “News.” The cost of printing and circulating even a little magazine of this nature is great. Every subscription counts, and it does not help matters along is you merely borrow a friend’s copy, or look at the number on the Club table. Not only does the “News” require subscriptions, it also needs reports from M.Y. Clubs, results of important races such as National and District Championships, Inter-Club events, etc. If members of Clubs find their Secretaries are lax about contributing reports, I venture to suggest it is worth considering the appointment of a suitable member as “M.Y.A. News” Correspondent. finding. Model yachtsmen are well served by sailmakers, several of whom advertise in the MopEL Maker, but the position is less happy as regards fittings and vane steering gears. Most of these important items are made by metal workers amongst model yachtsmen themselves, and their makers usually have as such on hand as they can reasonably cope with. Since everything is made to order, delivery takes a few weeks, especially if chrome plating is required. If one considers the number of small fiddly component parts in a vane gear, it is not astonishing that plating works charge high prices and take their own ‘time for the job. * * * * In this connection, it may be observed that it is not too easy to write interesting and informative race reports, especially when these must be reasonably short. It is also important to remember that the report is not primarily intended for local consumption, but mainly for readers at a distance, who may not know the competitors or their yachts, or even the lake where the race was sailed. I suggest that a satisfactory report should contain information about all these points. I may add that this criticism applies not only to * Model yachtsmen will be pleased that after the lapse of a year, it has now been found possible to resume publication of the “M.Y.A. News.” This js entirely due to the efforts of our Birmingham friends, Mark Fairbrother (52 Alderbrook Road, Solihull, Warwickshire) and Joe Meir (129 Ladypool Road, Birmingham 12), the former having taken on as Editor, and the latter having made _ himself responsible for looking after the circulation of the magazine, subscriptions, etc. The “News” is to be reports in the “M.Y.A. News,” but also to those published in the public Press. Nor do I write without experience, for after all, I was Editor of the pre-war “Marine Models” for 114 years. =“ BACK-GARDEN FOUNDRY (Continued from page 202) readers would no doubt prefer to expend their energies on something more useful, then see that the actual point where they join the casting is not too great. Experience will tell how large to make them ‘because obviously the casting size influences the These remarks conclude the general description of the home foundry, but I shall have more to say about the moulding of the engine parts when this design is published; at the moment there is plenty for intending constructors to carry out. Once you possess this simple equipment there is opened before you a dimensions. fascinating and instructive branch of engineering, in Having severed these pieces—and you will appreciate they are remelted when you next require that metal, so there is no waste—trim the surfaces of the casting with the aid of an old file until it matches with the casting outline. In modern foundries this operation is carried out with the aid of pneumatic fact, I suggest every model you undertake in future will receive due consideration regarding the possibilities of making them by casting instead of the lengthy processes needed when machining. One final paragraph. Never use old_ gutters, cisterns, broken pieces of lawn mowers and kindred articles because the iron is seldom of high quality. Fill the crucibles about two-thirds full with broken scrap—motor-car cylinder blocks or old machine tool parts are ideal if you require cast iron details, and use scrap pistons for aluminium castings. Start up chippers and grinders when the castings are too large to handle, but a file is good enough for the model maker’s small details. While performing this task, clean off any sand adhering to the surfaces as this is the real cause of blunted tools, cutters and drills when machining a casting. An acid pickle is sometimes recommended for this, but with only a few castings, such a practice is not really worthwhile. Remove all the bumps or thin fins of metal where it may have run between the two halves of the mould, and then the subsequent setting-up process on the lathe is much easier. A brief check of all the important dimensions is also well worthwhile as this can save you undertaking a good deal of work before suddenly finding that a certain facing will not clean up and the casting is thus scrapped. A pattern with the proper machining allowance never produces castings of this description, but practically every component of this nature is checked in the large engineering workshops just to make sure everything is in order; by following this idea you cannot make errors, and if the pattern is a “scant”, as we say, then you can rectify that particular facing before commencing machining. the fire, place this in the centre and then pack the coke to within an inch of the rim—pieces about the size of a shilling are best—and then turn on the blower unit. In twenty minutes you can melt aluminiun and half-an-hour will see a pot of iron ready for pouring. Skim the top with a piece of bent rod, but make sure the latter is hot before attempting this task otherwise the metal will spatter when the cold bar contacts it. With the moulding sand only just wet enough to ensure adhesion when you crush it in the hands, and care to see that the molten metal never contacts a cold surface, there is little risk with this process and you can turn it into a lucrative hobby by casting parts if necessary for your circle of friends because while making your own particular castings you can also include these in the same box; therefore there is no extra melting cost. 206 :