- Cheaper Model Yachting – Fibreglass Hulls Model yacht building costs have risen sharply; A-Class yachts can cost as much as kit-built dinghies.

- Advantages of Fibreglass: Strong, lightweight, ideal for repetition work. Smooth finish critical for reducing skin friction (75% of resistance in light airs).

- Construction Notes: Finishing: Rigging Tips:

- Design Features of “Duck” Hulls Compensate for lack of overhangs (due to rating rules) with “Duck” bow for reserve buoyancy.

- Do-It-Yourself Sailmaking (Part Two & Three)

- High aspect ratio sails are sensitive to mast bend; proper luff curve essential.

- Roach adds unmeasured drive but must be correctly shaped:

JANUARY, A* Model Yachtsmen, we have to face the fact that our sport is at present passing through a bad period, and losing ground. On the other hand, full-sized yachting, and in particular dinghy sailing, is becoming increasingly popular. The truth is that model yacht building has become disproportionately expensive, whilst low-priced “Kit” boats for amateur construction have brought full-sized sailing within TOWARDS CHEAPER MODEL YACHTING the reach of many who previously could not afford it. In this connection, we must remember that to-day well-equipped A-Class models cost almost, or quite as much as many “Kit” dinghies. are undoubtedly feeling the cost yacht can be pretty costly, especially if professionally built, or if the amateur builder has to get component parts specially made. It is, therefore, worth sidering how production can be cheapened. Now due to con- the low price of “Kit” dinghies is solely the adoption of One-Design Classes, which permits strict standardisation in building , and the employment of new materials and methods of construction. If model yachtsmen wish to. effect comparable economies, they must do likewise. Undoubtedly, a One-Design Class provides excellent sport, sinc® in it a skipper’s success is entirely due to his skill, and owes nothing to the possessi on of a long pocket. Nevertheless, it may have one possible drawback, as an owner may find himself unable to enter races outside his own club and district. On the other hand, if the One-Design falls within . Recognised National Classes, boats to it will be eligible to compete in Inter-Club events, District and National Championships. Hence it seems logical to adopt a suitable H. B. M-Class yacht as a One-Design. Until recently no suitable boats at reasonable prices have been available, but Messrs. Mitchenal l Bros., Ltd., of Amesbury, Wilts, are now turning out fibreglass M-Class hulls to my own “Jemima Duck” design that are a credit to all concerned. The firm are specialists in high-class moulded plastics, and have evolved their own methods and technique. It may be of interest to observe that they make the renowned “Avon” Fairings for motor cycles, and number among their customers celebrated racing motor-cyclists like John Surtees, ete. Fibreglass hulls are stronger than similar boats built of wood by conventional methods, and no heavier. Moreover, this material js admirably suited to mass-production, since once the moulds are made, it lends itself to accurate repetition work. I am, however, by no means convinced that fibreglass is a suitable material for amateur builders, who are unlikely to have either the facilities or experience to turn out a highly finished job. When a yacht is sailing in light airs at slow speeds, of the total resistances to her forward progress, skin friction represents no less than 75 per cent. As the wind increases, this proportion gradually drops, but even when she reaches her best pace in a fresh breeze, skin friction still accounts for 25 per cent. of the resistances. The importance of good external finish is, therefore, obvious. TUCKER DISCUSSES THE FITTING Model yachtsmen of building, par- ticularly to the larger classes, and as a result, the M-Class is gaining popularity at the expense of the 10-Raters and A-Class. Yet even an M-Class OUT OF A GLASS FIBRE YACHT HULL of the builder. Only one mould is employed in boat-building, so only one side of the skin will have a smooth surface, and the other side is likely to be rather rough—in fact just as left by the resin which covers the final layer of mat. As the outside of the hull must be the smooth side, built up inside a female mould. the shell must be To make a female mould, a male former has first to be made. After this former has been treated with special wax or anti-adhesion solutio n to prevent the fibreglass sticking to it, the female mould ‘s built up on it from fibreglass. To get a perfect surface on the hull, one needs a perfect surface on the female mould, which in turn calls for a perfect surface on the male. former. The female mould is usually made in two halves to facilitate the withdrawal of hulls, especially those with tumble- home. As the mould is inclined to be flimsy, it must be mounted in a cradle or framework to prevent distortion. treated After the inside of the mould has been with the anti-adhesion material, the is ready to start on making his actual hull. builder It will now be clear why this is very expensive and laborious ous way to build a single hull, as these elaborate preparations are only justified when mass producti on is intended.* Since one of my “Duck” designs has been selected for mass-production in fibreglass, I trust readers will pardon a few words about these boats. Both the 36 in. Restricted Class and the M-Class Rating Rules embody a strict limitation on L.O.A. (length Over All), which forces designers to produce boats with- out overhangs. Overhangs serve several useful purposes besides enhancing a yacht’s appearance. As the craft heels, she immerses her ends and lengthens her sailing lines, thereby increasing her speed potential. Overhangs also provide invaluable reserve buoyancy, and materially increase the overall stability, as (* We that take leave material for to point out a_glassfibre Marblehead described in MODEL MAKER cost 35s. including both mould and hull. Time taken was not more than that needed for a wooden hull, the builder had no Previous experience and no facilities, and the result was excellent.—Ed.) | | ‘ ; ‘ 1 @200000000000 Pin 0c0000000@000 Mast Stide © Fibreglass hulls are built up from liquid resin and thin “mats” composed of fine-gauge filaments, applied in layers. The number _of layers used naturally depends on the finished thickness required. The whole of the work has to be done by hand, so the result depends mainly on the skill and care 1960 ° ° Mast slide shown enlarged order to clarify detail. 17 aM in Deck Plote

A Besser = 1 well as preventing the boat buryin g her ends. The latter 1s most important, especially when the yacht is al} running under a press of sail in heavy weather. In order to get reserve buoyancy in a boat without overhangs, I invented the now well-k nown “Duck” bow, and although it does not entirel y replace a for- ward overhang, it is the best possibl e substitute in a boat with limited L.O.A. Consequently the “Ducks” are immensely powerful and can be driven hard. In addition they are very well balanced, which makes them most reliable and easy to handle. The first of the brood was the 36in. “Donald Duck *, which proved a phenomenal success. To all intents and purposes “Jemima Duck” is the same design, enlarged and adapted to the M-Class, and has likewise proved ts te, teks het om ing the boats, as well as alternative sail-plans for high and low rigs. Deadwood, skeg, and rudder, band-sawn to shape and ready for finishing, can be supplied as extras. Lead keel castings (including keelbolts) are also obtainable. Seg eeeeh =e, Some people do not like the “Ducks” as they consider the round nose ugly, whereas it is merely unusual, and is in fact beautifully efficient. The Mitchenall “Duck” hulls are beautifully finished and very reasonable in price. They are supplied with two heavy wood floors bonded inside the hull in the way of the keel bolts. Strong inwales, ready for shaping and fitting, are included in the price, also a full-sized plan giving details for complet- Although fibreglass hulls are very strong, the shell N = s \E very successful. is thin, so the builder should start by complet ing the internal framing to avoid any possibility of distortion. Begin with the bow and stern blocks (known Appram ttas Pratibon respectively as the “Apron” and “Fashio n Piece”), Make and fit these, but before finally bonding into position, cut across their tops chambers (or grooves) to receive the forward and after King Deck-Bea ms. The Apron and Fashion Piece are bonded to the glassfibre shell with ‘Araldite’ (or similar) epoxy resin glue. Z/t is essential to use the correct type of resin for fibreglass construction, as the wrong kind of adhesive is liable to have most deleterious effects. After the Apron and Fashion Piece have been fixed in place, the inwales can be finally shaped. Now in a planked wooden hull, inwales must be bent into position before the notches for the ends of the deckbeams are cut in them otherwise they become a series of flats instead of bending to an even curve. As in these hulls the inwales are “cut” members (i.e. sawn to shape), the notches for the deck-beams can, with advantage, be cut out before the inwales are bonded into position. As will be seen on ihe plan, the deck-beams are “halved” into the inwales. Although the “King” (or Central Deck) Beams are housed in the Apron and Fashion Piece to their full depths, they are halved into the deck-beams. Mast Partners and Hatch Carlines are likewise halved into deck-beams. It will save trouble if all these parts are prepared, with ends halved, etc., before the inwales are finally fixed in place. It may assist assembly if small brass screws are put through the ends of deck-beams. In installing deck-beams, start in the middle of the boat with the beams forward and abaft of the hatchway, and work forward and aft alternately. Since the “Duck” has a flat sheer and no deck camber, this work is very easy. Nevertheless, things should be checked frequently with a straightedge during the installation. The fin and skeg have now to be dealt with, and for several reasons, it will be better to fit the skeg first. 18

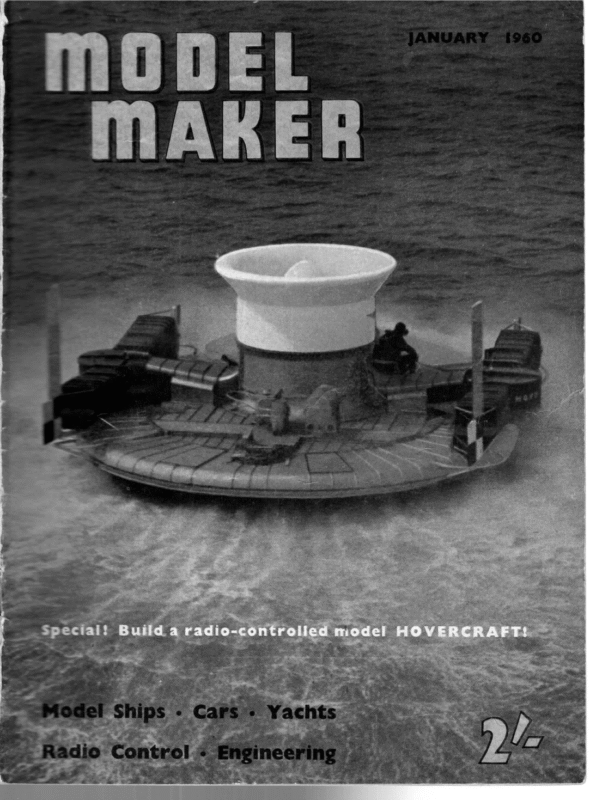

JANUARY, For one thing, the hull is easier to handle without the lead keel; also the upper part of the skeg itself. The skeg should be finished off before the slot for it is cut through the hull. The rudder-trunk (i.e. the tube through the hull) should also be made, and fitted to the after end of the skeg. From the plan it will be seen that the upper part of the skeg butts against the underside of the king beam, while the rudder-trunk passes through a hole in the beam and extends tin. above deck. When the skeg is ready, the slot for it must be cut through the hull. Fibreglass can be drilled, cut and filed readily, so the job of fitting and lining up the skeg presents no more difficulty than in a wooden hull. It is finally bonded in position, and a couple of screws put through the king beam into the top of it. The fin is bolted in place and faired. In this connection, it should be noted that the after edge of the lead keel as supplied by makers is shaped to key in to the deadwood. This is a neat arrangement which enables builders to dispense with a locating pin (or screw) to hold the after end of the lead ‘3 the deadwood. Otherwise a locating pin is required. 1960 the final coat is dry, rub down with powdere d whiting using a damp pad of cotton wool. Finally polish well with Simoniz Wax Motor Car Polish. Your surface should then resemble the lovely ‘patina’ found on a cherished piece of antique furniture. Certain small but worth-while economies can be effected in the fittings. Deck pulleys for gybe-lines can be dispensed with, as the lines will run equally freely through decent sized screweyes. Goosenecks for spinnaker booms are unnecessary, as the booms can be set equaily efficiently in the old-fashioned model-yacht manner with a hook into an eve on the gunwale, provided a topping-lift is used to take the weight of the boom off the sail. Many other fittings commonly in use are unecessarily elaborate , and comeagcadinsly expensive, if the builder has to buy them. Masts can be duralumin tube with a wood topmast plugged in. Aluminium tube should not be used, as not only does this metal deteriorate rapidly in sea air or salt water, but also it is not as Strong as duralumin. Now in “Jemima Duck”, as in many other modern yachts, the mast position is rather close to the hatch- way. The handle is held in position across the floors vy The hatchway cannot be moved aft if our carrying handle is to be over the yacht’s the keel-bolts, and the mast-step is mounted on top Centre of Gravity, and otherwise the yacht will balance of it, thus obviating the necessity of fitting a wood badly and will be awkward to carry Hence a slight Kelson (inner keel) and stiffening the hull immensely. variaat of the usual mast-slide is desirable. This is Actually the hull is subjected to considerable stresses shown on the Construction Plan full-size, but as the at this point. The shrouds exercise an upward pull, latter has to be greatly reduced to fit the pages of while the mast exerts a strong downthrust, which this magazine, it is also shown separately on a larger is re-inforced by the downthrust of the sails. Simulscale. taneously, the lead keel exercises a wringing strain on the garboards, which also have to support its The slot through the deck-plate allows the mast a weight. movement of 3 in. either way from the central posiAll internal woodwork must be well varnished (to » tion. The forward end of the slide is full length. out protect it from water) before the deck is put on. the after end cut short only extending 4 in. beyond There is no need to varnish the inside skin itself, so a the slot. The mast can thus be moved aft until the few ounces of weight can thereby be saved. The slide is stopped by the hatch coaming. On the other underside of the 14 mm. plywood deck must also hand if the mast is being moved forward, the slide be varnished. ; must be turned end-for-end to keep the mast-slot Hitherto it has been customary to “line-out” a covered. model’s deck in imitation of a laid plank deck. In tuning-up a yacht, mast rake is almost more When well done, this looks very nice, but takes time critical than mast position. To provide a very fine and is not easy to make a good job of. Moreover, adjustment of rake, the slide has rows of holes these days very few (if any) new full-sized yachts have spaced in + in. on e’ther side, these are exactly planked decks, so it is not really true to modern opposite each other. There are only two p’n-holes through the deck-plate, one either side, and one hole yacht practice. Hence I suggest painting the deck is 1/16 in. ahead of the other. either a cream or light stone colour, and eliminating By putting the pin through the appropriate hole, the rake can be the lining-out. : : When the deck has been painted, hatch coamings, adjusted by 1/16 in. The mast-heel moves by 4 in. also deck-rail (or covering board) together with nosepiece and taffrail, have to be installed. The hull proper has also to be painted. Actually, the fibreglass hull itself could be left unpainted, but sooner or later in racing, the yacht will scrape along a concrete wall to the detriment of her pristine surface. She might as well be painted from the start, especially as the fin, skeg, etc. must be painted. I have a strong personal prejudice against a boat being painted all over the same colour; a contrasting boottov, or stripe, along the waterline makes all the difference. 3 Before painting, the fibreglass can be given a final burnishing with “Brasso” or similar metal polish. This has a very slight abrasive effect. These boats can be painted with any of the usual paints, or they will take a fine spray finish. Cellulose (Scotch) tape is about the best thing to use for masking at the waterline. Whatever type ofr paint is used, the best can be obtained as follows. After racing surface in the mast step. In conclusion, I suggest that these hulls made Sy Messrs. Mitchenall Bros., could well prove the “shot in the arm” our sport at present needs. since they provide the opportuntiy of obtaining a really compe- titive M-Class yacht for about half what it normally costs, Moreover, it is possible that clubs adopting these boats for a One-Design Class might obtain some concession on orders for several boats at a time. Further, these hulls should prove a boon to novices as one need not be a skilled craftsman to make a good job of their completion In addition. they are very suitable for fitting with Rad‘o Control. as “Jemima Duck” is one of the heavier M-Class models with 22} Ib. displacement. Hence she can afford to sacrifice 4 Ib. or so of lead to compensate for the weight of the radio gear. far better than lighter boats of the class weighing only 18 or 19 Ib. A new boat of this type is a better bargain than the old “toreouts” so often used by R.C. enthusiasts.

Ee UI “itil Do-it-yourself sO measure SAILMAKING for model racing and cruising craft PART TILL with us? Fine! Now following on what we worke d out about “spilling? last month it would seem obvious that as the mast head is held Pretty well rigid by the fore and back stays and the central section is enabled to move slightly fore and aft under the thrust of weather drive, we have an inbuilt spillin g tendency at the leach; it is also obvious that the higher the aspect ratio the greater the tendency, the sail being naturally more sensitive to exact set. So we have to cope. does a “Jumper” or “Jenny” (a small Good “Runner Backstays” help, so does a fairly stiff mast, so also wire stay set on a forward facing spreader) from jib hoist to masthead—a bit of help here and a bit there, but a vital bit is the cut of the sail, and if the sail was cut badly, or has been used badly, so that the masthead has to be pulled forward to give the mast a slight forward bend to keep the leach in (and you will tind this with ever so many today), you will never get full drive without either gelling an excessive “bad hollow” at some part of the luff, or a sail that holds up to a certain wind strength and then partially spills in a gust, and sags you off to lee. So take your boat (or if you are building , borrow someone else’s of equivalent class and with the same sort of rigging and mast you intend to use), set up with all tight ready for racing, except for no sails on, and set up two cords from jib hoist to jibrack, one just taut and tied or bowsered to tension strained, Clotson), and follow cn with measure, a (just, not Muggins further line to the same points, but with a long, very light, rubber band in it. to maintain tension. Now put her in the lake and walk alongside at a smart pace (walk, not trot). holding her by and pushing forward from a little below the Ist suit Jib Hoist (if the lake is drained or frozen you can get the same result from a wheeled stand. slightly uphill on a smooth path), and observe the approximate reading of your muggins scale, the gap between the two lines as the taut one slackens and the elasticized one holds. Now return to shelter, enlist a willing helper, chock boat in stand, fasten a strong cord and bowser from gooseneck top to headboard position and, while thrusting mast forward to reproduce the “gap”, get W.H. to tighten the cord, tensioning until the mast stays put at the “gap”. You now have about the position your mast will take up under “Full First Suit”, oO Luff Now, if the convex luff of the mainsail is cut to the curve indicated, or just a trifle less, when the takes drive, this curve as the under load luff will not the sail be pulled will keep forward. Granted, in light airs the sail will have rather more flow than often seen, but this does not harm, and if at any time you feel a little less flow is needed, tighten the backstay, thereby bowing mast a shade and deflowing sail a wee bit. (The late W J. Daniels was always very fussy about his backst ays and forestays, and he has had few peers for sailing.) If on the other hand you need more flow still, easing the clew along the boom will give it, provided the lub is matched to the mast. And if you are using cloth we will still need the “Plot” , Now a word on roaches, before we start cutting . The roach is unmeasured drive, but if wrong, is worse than useless; for terylene, with an aspect ratio of over about 3:1, the max. breadth needs to be about ; of the way up, a bit less if this seems to be “forcing the spline”, but certainly over half 4 is too high. For lower ratios and all cloth this breadth should be about midway, but you use the spring in the spline to give a slight parabolic effect just the same. ALWAYS allow the last foot or so towards the clew to come out nearly straight, and the “head” 4 to 6 inches also (this for a 10-Rater first suit—ot her suits and sizes about pro-rata). Roach: limits are for an A 4in. I think, 10-Rater none, but don’t try over 3/3, 6M and M 2? in. 4 per sail, equal spacing, A and 10-Rate r, bottom Sin., centre all 4 inches. Jib battens 3, for other two 3 in. will do no harm; for M, 7in. Battens top and 6M 5 and 6 inches, and M A, 10-Rater, and 6M top 24 and be about max. and $in. less will none over 2 in. A word on Jib Roaches. About 1in. is all you need, for it you use more, it will catch on the mast as the boat tacks. and you will have to “hook out or up” to clear, thereby losing more measure d area than you will gain unmeasured. The less the roach, within limits, the less the batten stiffness, for battens in a jib are really to prevent the leach curling in and causing a draught to backwind the mainsail, causing a reverse curve in the flow (a sort of visible bag) and spoiling the drive. And, again within limits, the less the batten stiffness the better the jib will pull. Max. width a trifle over half-way up, even curve. ; Now I know you often see manned up craft with a huge jib causing a huge backwind. This is not nonsensical regarding the above. for the extra drive of the huge loose-footed jib is more than outweighing the loss from the mainsail. and the mainsail will be quite a low ratio, probably less than 24:1. and there- fore less sensitive to the backwind in the widest part. A hoist actual, B cutting point to allow for “end.” Cc… C datum, Shaded portion is later cut off or You can’t use a loose foot for the model jib and your mainsail is high and narrow and very sensitive to backwind. It is true, the old saw. ahout an inch in the luff being worth a foot in the leach. but the luff half won’t work without the leach hilf. so we keep our sails as narrow as we can. and the roaches as high, for the mainsails, as possible to keep the effective width as well as can be. covered by head- leas 6in. intervals (about right first. mast BY J. S. DRURY at, say, even a trifle more for an “A”, If it is a lot more you must look to your standi ng rigging and get this its TWO the offsets where the sail hooks come, it’s not exactly critical to fractions), and note down. Usual reading is from 3/16th in. for an “M” to 4 plus for a 10-Rater and board. A… XX allows for stretch in’ luff during season 34

JANUARY, I feel that we have enough “gen.” now to see why and wherefore (I know that there are other theories @s well as this, but the “Rule of Thumb” theory given works out and will not let you down in sailing). If I get around to consideration of actual sail plans, and the reducing of sizes for small suits, and calculation of C. of E., etc., we shall get to cutting about next autumn, whereas you may want the sails for spring sleet and squalls. So I must assume you have your sail plan, more or less. Now Clotson said, “All you need to do is lay out your material on the floor, mark out with a straight edge and a bit of string, and awl as a “Big Dividers”, rough out with there you are. the scissors before benching and O.K. for the expert, but we rescued C, in time for there to be enough usable terylene from his Ist Suit Main to make No. 2 jib. We also had nearly enough strips to stuff the dog’s cushion! We will take terylene first, as most will use this. Take a bit of twine or old rigging cord, a trifle shorter than the bench after making small loop at each end. Chalk the line with the school variety, not tailors, secure loops each end, about 2 inches in from edge of bench with the awls, and carefully snap cord down to leave straight chalking (it will if lifted gently and not pulled sideways). Likewise 1 in. further in. _ Lay the line down 4in. apart a normal ensure the masking tape between, and using a chalk this as a guide, inscribe two parallel lines with Indian or other good ink. If using ruler, etc., sight down the chalk first to line is really true. Mark a heavy cross line at foot position, and lay off, from the inner to the one nearest bench edge, the offsets you got earlier with the mast. Mark headboard position with heavy ne cross line, join the offsets with spline, and nk in. You will observe that the foot is at rather less than a right angle to luff, you can either take this angle off the plan with a piece of paper as a dummy, or plot as follows, if you are working to a set of figures, or the plan is not true scale (check first, unlike Clotson); tape a pencil to cord, loop t’other end, plant one at foot position (inner line, don’t forget) measure distance at about right angle, hold pencil on point, secure loop with other awl, and draw the awl out this arc. Lengthen line and repeat for the leach. Extend intersection point both ways in pencil and right away stick strip of tape centre line between “Foot Point and – Clew Point”, and clearly mark in pencil. Ink in centre line, and allow for stretching; with terylene you : i mee plot ated and aoe Foot plot muc exagger- shortened). A tack B head M’s Ist, C M’s 2nd, D M’s 3rd tape much foreshortened, A tack, B clew, Croach curve, D luff flow o — B : =| S| c curve and approx. 3/16 each side of foot centre. about 4 in. off luff and leach for stretch. be ignored. Now leave it for today, have a nice cuppa and a the draft is really like the top suit. Correct? Fine, so mark out the smaller suits mainsails with coloured ink or Biro, just the triangles, with the parallel roach allowance limit. You can draft cut the roaches with spline all complete, and tape on, but do not mark the luff curves, for two reasons. One you’ll get con- fused, second we’ll come to anon. Likewise the jibs, if the luffjfoot angles are the same for all suits, if not wait. | Take a quantity of newspaper, and using the staight edge against the outer line of the luff tape, cut out approximately to shape from the draft. You will find that with scissors, and lifting as you go, this is quite easy. Leave a good inch allowance all round and clearly mark on the blank the leach and which sail it is. If the jibs are differing angles cut three or four firsts and reduce by working with the line and pencil and leaving ample allowance. Now unroll your terylene on a carpet or lawn. Take off your shoes, and being sure to keep leach parallel to selvedge of material always and no: tilting to save the odd inch, make the most economical use of the material by juggling the blanks around a bit. Then fastzn down by scraps of tape, cut round with scissors, remove patterns, and stick a tape slip with the sail J.1. or M.2. or what it is inked on. Each slip on as the pattern comes off, unlike Clotson. Then you can’t mix up. Now, with some odd shaped scrap you have left practise cutting out with the razor blade and spline, till you get the knack, which will vary a bit with blade, spline being used, bench surface and you. ADDITIONS SUPPLIERS LIST TO Liverpool 22. Rigging fittings. evelets, etc: — point of clew corrected for stretch to double cross line point in wasting it) of tape down leach line, offset on luff datum line, fiill in headboard shape below and there ’tis. Dot down a few short fragments (no roach and spline in pencil, check curve is fair by eye, put a dozen short fragments of tape over pencil and ink in the spots. Exactly likewise for the jib, allow- ing + hollow about or just below half-way up luff, Allow Foot can read or something akin. Tomorrow, not today, recheck the lot and ensure all is in order and that stretching of luff and leach a simple way is to draw this on, taking a triangle with the top point at the headlimit so to speak (except for the “A” where I would minus an extra + allowance), as sketch. You can, therefore, draft the leach by chalk cord from A S| Sussex. To allow for /| Se D. need a bit of flow given in foot, so }in. for an M, 3/16 for 10r/6M, and } for A is ample. Reduce foot measurement by this and ink in. Mark 4 out each side of centre line about 45 per cent of distance from foot to clew. Spot and spline into foot and clew points both sides, using nice even curve. Ink in. Now a headboard is used for all classes (width A .98 10r 1in., 6M .8in. and M .7S5in.). 1960 Sails, materials, rigging, and fittings, e.g. bowsers, etc:— A Mullett, 16 Meeting House Lane, Brighton, : Also from this source 34 ounce. union silk 42 in. wide 9s. per yard and terylene 28 in. wide 10s. 6d. per yard. Sails, rigging, fittings. eyelets, etc :— Mersey Marine Models, 10 South Road, Waterloo, Web Model Fitting Company, 204 High Road, Wood Green, London, N.22. Bench taped for layout, jibs at xxx or yyy according to size of sails and room available Cf Za EXZZZZZZZ LLL La BA. Xe a wa Le -X i ae 2 inca ly. ey Scant ‘bees ee SARE, i . \ oe Fatiis ere se a <<} ee re. yU--—------>Y eee