This manual was provided by The Center for Wooden Boats in Seattle, WA. It was the result of building seven generations of Pirate Pond Boats with Alternative School #1 in Seattle since 1999. The instructors and students have both learned a great deal about building pond boats over these years.

- Overview & Plans

- Materials

- Templates

- Lifts

- Layout

- Cutting

- Fabrication

- Hull

- Gluing Up

- Shaping

- Profile

- Outer Hull

- Inner Hull

- Bow Sheer Lift

- Sheer Cutting

- Transom

- Sanding

- Keel

- Forming Blank

- Shaping Blank

- Attaching Ballast

- Attaching To Hull

- Stand

- Rudder

- Fabrication

- Tube Installation

- Deck

- Fabrication

- Installation

- Painting

- Priming

- Finishing

- Mast

- Shaping

- Hardware Installation

- Fitting

- Sails

- Layout

- Cutting

- Sewing

- Installing On Mast

- Rigging

- Bowsers

- Spreaders

- Standing

- Running

- Radio Control

- Rudder

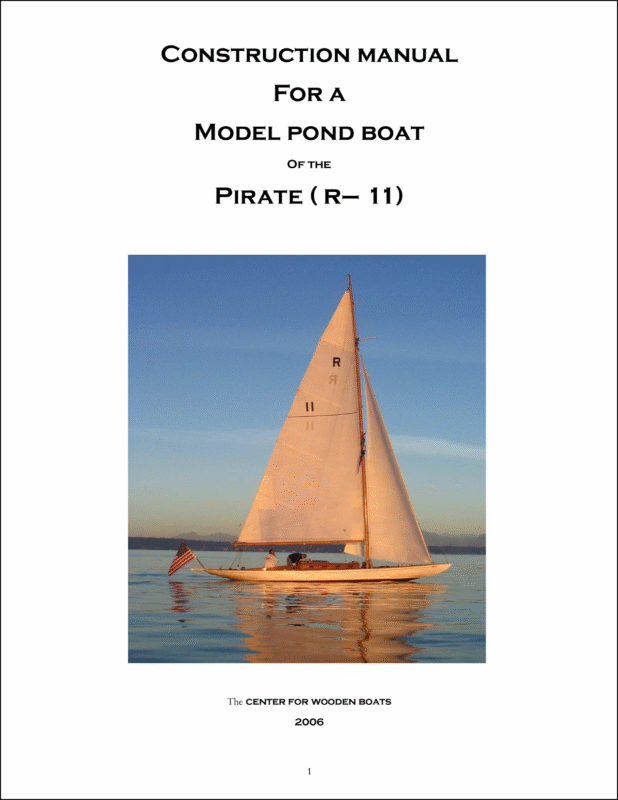

CONSTRUCTION MANUAL FORA MODEL POND BOAT OF THE PIRATE (R— 11) The CENTER FOR WOODEN BOATS 2006

POND BOATS: REGATTA & FREE SAILING

TABLE OF CONTENTS SUBJECT OVER VIEW & PLANS MATERIALS TEMPLATES LIFTS LAYOUT CUTTING FABRICATION HULL GLUING UP SHAPING PROFILE OUTER HULL INNER HULL BOW SHEER LIFT SHEER CUTTING TRANSOM SANDING KEEL FORMING BLANK SHAPING BANK ATTACHING BALLAST ATTACHING TO HULL STAND PAGES

TABLE OF CONTENTS RUDDER FABRICATION TUBE INSTALLATION DECK FABRICATION INSTALLATION PAINTING PRIMING FINISHING MAST SHAPING HARDWARE INSTALLATION FITTING SAILS LAYOUT CUTTING SEWING INSTALLING ON MAST RIGGING BOWSERS SPREADERS STANDING RUNNING RADIO CONTROL RUDDER

OVERVIEW THIS MANUAL IS THE RESULT OF BUILDING SEVEN GENERATIONS OF PIRATE POND BOATS WITH ALTERNATIVE SCHOOL #1 IN SEATTLE, SINCE 1999. THE INSTRUCTORS AND THE STUDENTS BOTH LEARNED A GREAT DEAL ABOUT BUILDING POND BOATS OVER THESE YEARS. WE HAVE A MOTTO ABOUT BUILDING A PIRATE “ THERE IS NOTH- ING YOU CAN DO TO A BOAT THAT CANNOT BE FIXED”. THIS IS A REASSURANCE FOR THE STUDENTS WHO ARE TAKING ON A MOST COMPLEX PROJECT AND FOR ADULTS THAT MAY FEEL OVER WHELMED BY THE COMPLEXITY OF THE PROJECT. A FURTHER RE- ASSURANCE FOR ADULTS, IF 6TH , 7TH AND 8TH GRADERS CAN BUILD THESE BOATS YOU CAN TOO. A WORD ABOUT CRAFTSMANSHIP: DO NOT OBSESS ABOUT IT. REMEMBER YOU ARE BUILDING A POND AN EXHIBIT FOR THE SMITHSONIAN. BOAT TO HAVE FUN WITH, NOT DO THE BEST YOU CAN AND LEARN FROM YOUR OUTCOMES. REMEMBER THERE IS, “NOTHING A LITTLE BONDO WON’T FIX”’. PLANS A SET OF SIX PLANS IS PROVIDED FOR BUILDING THE F?I- ATE. LINES PLAN: TRADITIKING ONAL LINES PLAN. PATTERN PLANS: TEMPLATES FOR THE HULL SAIL PLAN: FOR CUTTING THE SAILS MAST AND RIGGING PLAN DECK LAYOUT PLAN NEWPAPER ARTICLES: HISTORICAL BACKGOUND

TOOLS : POWER, HAND & ABRASIVES THE ONE POWER TOOL THAT IS MANDATORY FOR BUILDING THE FPIRATE |S A BANDSAW, WITH A 1/72 INCH BLADE. VERY LIGHT WEIGHT BANDSAWS WILL BE UNABLE TO CUT THE LIFTS. A SABRESAW WILL NOT SUBSTITUTE FOR A BAND SAW, THE CUTS WILL BE WAVY AND THE EDGES WILL NOT BE SQUARE, GIVING A UNSYMMETRICAL HULL . A VARIABLE SPEED PORTABLE DRILL IS NECESSARY FOR DRILLING HOLES AND DRIVING SCREWS. NOTE: THE USE OF POWER SANDERS POWER SANDERS ARE NOT USED TO SHAPE THE HULL .THE HULL SHAPE IS COMPLEX WITH RAPID CHANGES OF CURVATURE . POWER SANDERS WITH SOFT PADS ARE TOO BIG TO USE EFFEC- TIVELY ON THE HULL.. THE USER HAS NO SENSE OF WHAT SHAPE IS BEING CREATED. EXPERIENCE HAS SHOWN THAT POWER SANDER WILL CREATE FLAT USING A SPOTS OR GOUGE ALMOST IN- STANTLY. THIS IS ESPECIALLY TRUE WITH YOUTH, WHO SEEM TO LACK THE ATTENTION SPAN AND COORDINATION TO USE POWER SANDERS. EFFECTIVELY. HAND TOOLS : SEE APPENDIX 1 THE ENTIRE BOAT IS CONSTRUCTED USING HAND TOOLS. EXPERIENCE HAS SHOWN THAT THIS IS THE EASIEST, QUICKEST AND MOST PLEASANT WAY TO CONSTRUCT A P/RATE. THE TYPES AND NUMBER OF TOOLS CAN BE AS EXTENSIVE AS ONE WISHES, THE TOOL LIST HERE IS A BASIC ONE. EXPERIENCE HAS SHOWN THAT, AFTER MANY BOATS, COME IN HANDY, A FEW SPECIALIZED TOOLS BUT ARE NOT NECESSARY.

TOOLS: HAND HAND TOOLS CHISELS 1/72 INCH CHISEL 3/74 INCH CHISEL 3/74I1INCH GOUGE MALLET (OPTIONAL) RASPS 12” RASP — HALF ROUND — TAPER, ROUGH 10” RASP — HALF ROUND — TAPER, MEDIUM HORSE SHOE RASP a PLANES TRIM PLANE — STANLEY LOW ANGLE BLOCK PLANE FILES ROUND 3/716— DRILL BITS 1/72 174 3/716 LONG SHANK 1716 TAPERED 3 3 —

TOOLS ( CONTINUED ) 6” TRI-SQUARE DIVIDERS FINE TOOTH SAW HAMMER SQUEEZE CLAMPS HAND DRILL — (OPTIONAL) BASIC HAND TOOL S FOR CONSTRUCTION

MATERIALS: SEE APPENDIX 2 LUMBER: THE HULL IS MADE OF LIFTS OF 3/74 1INCH SUGAR PINE BOARDS. ONE BOAT TAKES 15 LINEAL FEET OF 3/74 INCH BY 8 INCH BOARDS. IF POSSIBLE BUY THE WIDEST BOARDS POSSIBLE. THE IDEAL IS A BOARD 16” IN WIDTH THAT CAN BE CUT DOWN THE MIDDLE AND BOOKMATCHED. BUY PATTERN GRADE THAT IS KNOTLESS. EXPERIENCE HAS PROVEN THAT NO MATTER HOW HARD ONE TRIES, A KNOT INEVITABLY ENDS UP IN THE HULL. KNOTS COMPLI CATE THE LAY OUT PROCESS AND END UP USING MORE MATERIAL THAN IF THE MORE EXPENSIVE PATTERN GRADE IS PURCHASED. MASTS AND BOOMS ARE MADE OF CLEAR, STRAIGHT GRAINED RED CEDAR. A 5 FOOT SECTION OFA 1/2 X 4 BOARD WILL PROVIDE MULTIPLE MASTS AND BOOMS. THE DECK IS MADE OF 1/78 INCH MAHOGANY DOORSKIN. TEMPLATE STOCK IS 1/4 INCH HARDBOARD. 1/8 INCH IS TOO FLIMSY FROM OUR EXPERIENCE. GLUE: TWO TYPES OF GLUE ARE USED IN CONSTRUCTION, POLYURETHANE FOR GLUING THE HULL LIFTS TOGETHER AND FOR THE DECK. G-5, A FIVE MINUTE EPOXY, BY WEST SYSTEMS IS USED FOR GLUING THE LIFT HALVES TOGETHER. SPRAY GLUE IS USED FOR ATTACHING THE PAPER PAT-

MATERIALS: ABRASIVES & FASTNERS ABRASIVES ADHESIVE BACKED SHEETS OF SANDPAPER (3M- )ARE BEST. THEY ARE USED FOR MAKING SANDING BOARDS AND HAND SANDING. GRITS OF 36 AND 80 ARE USED. 80 IS THE PREDOMINATE GRIT. HIGHER GRITS OF 150 AND 220ARE USED FOR FINISH SANDING. FASTENERS: 3D FINISH NAILS ARE USED FOR VARIOUS PURPOSES. A QUARTER POUND OF NAILS WILL BE ADEQUATE FOR ONE HULL. CARRIAGE BOLTS OF 8” AND 2-1/2 “ ARE USED TO FASTEN THE HULL TO THE BUILDING AND SHAPING JIGS. WING NUTS AND FENDER WASHERS ARE NECESSARY. KEEL BOLTS: 2EACH OF ALL ITEMS 6” X 10-24 MACHINE SCREWS 1” STAINLESS STEEL FENDER WASHERS 10-24 STAINLESS STEEL NUTS JIGS THE PLANS INCLUDE TEMPLATES FOR MAKING JIGS. THESE HAVE BEEN DEVELOPED TO SIMPLIFY AND SPEED UP THE PROCESS OF BUILDING . JIGS ARE USED FOR ALIGNMENT, SHAPING , CUTTING AND GLUING . ITIS POSSIBLE TO BUILD THE P/RATE WITH OUT THEM, AS THE FIRST BOATS WERE, IT JUST TAKES MORE TIME. APPENDIX 2: A FULL BILL. OF MATERIALS BILL OF MATERIALS IS PROVIDED DIX 2 AT THE END OF THIS MANUAL. 10 IN APPEN-

TEMPLATE CONSTRUCTION LAYO 11

CONSTRUCTION TEMPLATES: CUT OUT EACH PAPER PATTERN FROM THE SHEET OF TEMPLATES USE A STRAIGHT EDGE AND RAZOR BLADE FOR THE CENTER LINE OF PATTERN (THE LONG STRAIGHT EDGE ) LEAVE EXCESS PAPER ON THE OUTER EDGE. IT WILL BE CUT OFF WITH THE BANDSAW. SPRAY ADHESIVE ON THE TEMPLATE BLANK. LET IT CURE FOR SEVERAL MINUTES. ALIGN CENTERLINE OF PATTERN PAPER ON ONE EDGE OF THE HARDBOARD TEMPLATE. TACK ONE END OF THE PATTERN DOWN AND TENSION IT FROM THE OTHER END . PRESS CENTERLINE EDGE UP TO EDGE ON THE TEMPLATE BLANK. USE YOUR FINGERS TO PRESS THE PATTERN DOWN ON THE TEMPLATE IN A RADIAL PAT- TERN TO AVOID WRINKLES. BANDSAW TECHNIQUE: ADJUST THE GUIDE TO ABOUT 172” ABOVE THE STOCK. CUT TO THE OUTER EDGE OF THE LINE. FEED THE STOCK AS QUICKLY AS THE SAW WILL TAKE IT. A SMOOTH FLOW OF FEED MAKES FORA SMOOTH LINE. MAKE CORRECTIONS IN THE LINE AHEAD OF THE CUT, CUT YOUR WAY OUT, 12

TEMPLATE CONSTRUCTION: CUTTING CORRECTING AT THE CUT MAKES FOR A JAGGED EDGE. CUTTING TIGHT RADIUSES WILL PINCH THE BLADE, MAKE MULTIPLE CUTS. TEMPLATES : FINISHING SAND THE CUT EDGE WITH A SANDING BLOCK WITH 80O GRIT PAPER. USE LONG STROKES TO EVEN OUT THE SURFACE. BE CAREFUL NOT TO GO BEYOND THE PRINTED LINE, OVER SANDING WILL RE- SULT IN A TEMPLATE THAT IS TOO NARROW. DRILL OUT THE INDEX HOLES FOR MARKING THE INNER EDGE OF THE TEMPLATE ON TEMPLATES FOR THE FOLLOWING LIFTS ; SHEER 1A 2A USE A 1/716 INCH DRILL THE OTHER LIFTS ARE CUT OUT AND ONLY REQUIRE 3 HOLES FOR LOCATING AND HOLDING THE TEMPLATES IN PLACE. 13

LAYOUT: ,\ _ _ aN & PREPARATION & BOOKMATCHING BEFORE THE TEMPLATES CAN BE USED, THE SUGAR PINE BOARDS THAT WILL BECOME THE LIFTS MUST BE BOOKMATCHED. BOOKMATCHING IS THE PROCESS OF DOUBLING UP THE BOARDS. ATTENTION IS PAID TO HOW THE GRAIN RUNS. THE IDEAL IS TO HAVE THE GRAIN RUNNING IN THE SAME DIRECTION. THIS MAKES FOR EASIER SHAPING OF THE HULL, BECAUSE THE LIFTS DO NOT HAVE THE GRAIN RUNNING IN DIFFERENT DIRECTIONS ONCE THEY ARE LAMINATED TOGETHER. FOR BEST RESULTS, THE HULL LIFTS SHOULD COME OUT OF ONE LARGE BOARD. THE BOARD SHOWN WAS 16” IN WIDTH AND THEN SAWED IN HALF LENGTHWISE. IT WAS THEN FOLDED ON BACK ONTO ITSELF AND SECURED WITH NAILS AT EACH END AND MIDDLE. ONCE THE BOARD IS BOOKMATCHED, THE EDGES ,EXCEPT THE ENDS, ARE TRIMMED IN A TABLE SAW TO MAKE STRAIGHT, SQUARE EDGES. IF IT IS NOT POSSIBLE TO BOOKMATCH FROM A SINGLE BOARD, JUST PAY ATTENTION TO THE GRAIN AND MAKE THE BEST MATCH LAYOUT: TEMPLATE DIRECTION THE TEMPLATES FOR THE LIFTS ARE LAID OUT USING BOTH EDGES OF THE BOARD. THE ARRANGE THE TEMPLATES SO THAT THE BOWS ALL FACE THE SAME DIREC- TION, THIS MAKES SHAPING EASIER BECAUSE THE GRAIN IS RUNNING THE SAME WAY ON ALL THE LIFTS. 14

LAYOUT: TEMPLATE DIRECTION & NESTING NEST THE TEMPLATES TO MAKE MAXIMUM USE OF THE BOARD. THERE IS NO CORRECT ORDER. LEAVE 3/8” BETWEEN LIFTS FOR CUTTING. LAYOUT: MARKING TECHNIQUE RUN PENCIL ALONG EDGE OF TEMPLATE AT A RIGHT ANGLE. NOTE: THE TEMPLATES ARE NAILED TO BOARD WITH TWO OR THREE NAILS DE- PENDING ON THE SIZE OF THE TEMPLATE. NOTE: OBSERVE THE 378 “ GAP BETWEEN THE TWO TEMPLATES. LAYOUT: MARKING STATION 20 THE MARKING OF STATION 20 IS A CRITICAL PART OF THE GLUING UP OF THE LIFTS INTO A HULL. STATION 20 IS USED TO ALIGN THE HULL LIFTS INTO THE PROPER FORE AND AFT POSITION . EACH LIFT MUST BE MARKED ON ALL SURFACES. IT IS BEST TO USE A TRI-SQUARE TO AFTER CUTTING OUT THE LIFT, RUN THE STATION 20 LINE OVER THE CUT SURFACE. 15

LAYOUT: MARKING INNER EDGE USE A SHARP OBJECT, AN AWL OR A SHARP NAIL TO TRANSFER THE INNER EDGE POINTS TO THE LIFT. NOTE: NAILS ARE SHOWN FOR CLARITY PURPOSES. LAYOUT: INNER EDGE MARKING ONCE THE INNER EDGE POINTS ARE TRANSFERRED, USE A PENCIL TO FREEHAND A LINE CONNECTING THE POINTS . WHEN FREEHANDING THE LINE, ERR TO THE INSIDE , WHICH MAKES THE LIFT THICKER. MAKING THE INNER LINE TOO THIN WILL RESULT IN A HOLE IN THE HULL WHEN LAYING UP. LAYOUT: LIFTS 2-B &LWL LIFT 2B IS NESTED IN SIDE OF THE LWL LIFT. CAREFUL ARRANGEMENT OF THE TEMPLATES WILL ALLOW THE USE OF A COMMON STA- TION 20. LIFT 2B HAS TWO ADDITIONAL SETS OF MARKINGS, KB FOR THE KEEL BOLTS AND L FOR THE COMPRESSION BOLTS FOR LAMINATING THE HULL AND FOR ATTACHMENT TO THE SHAPING JIG. 16

LAYOUT: SHEER & 2A —STATION 20 LAYOUT LIFT 2A READY FOR CUTTING. A BRIDGE HAS BEEN LAID OUT USING STATION 20 AS A CENTER AXIS. THE BRIDGE IS TEMPORARY. IT IS USED TO KEEP THE LIFT FROM FLEXING. IT WILL BE USED TO SE- CURE THE HULL TO THE SHAPING JIG. DO NOT REMOVE IT UNTIL THE DECK IS TO BE GLUED ON. WIDTH OF THE BRIDGE IS BE- TWEEN 3 TO 4 INCHES. THE SHEER ALSO HAS A BRIDGE AT STATION 20. LAY IT OUT THE SAME WAY. RADIUS THE BRIDGE INTO THE IN- NER EDGE. THE RADIUS CAN BE BORED WITH A FORSTNER BIT. LAYOUT: FINISHED BOARD THE FINISHED LAYOUT OF THE LIFTS ON THE BOOKMATCHED BOARD SHOULD LOOK LIKE THE PICTURE ON THE RIGHT. NOTE: THE LIFT PIECES ALL HAVE TACK NAILS TO KEEP THE UPPER AND LOWER PIECES FROM MOVING WHILE BEING CUT. 17

LIFTS: CONSTRUCTION OF LIFTS OVERVIEW : CUTTING LIFTS THE CUTTING OUT OF THE LIFTS IS A CRITICAL PROCEDURE IN THE CONSTRUCTION OF THE HULL. HOW WELL THE LIFTS ARE CUT WILL DETERMINE THE SHAPE OF THE BOAT. THE OBJECT IS NOT TO HAVE WAVY CUT LINES , WHICH WILL CAUSE THE USE OF BONDO, BUT SMOOTH FLOWING CUT LINES. AFTER THE LIFTS ARE CUT, THE BOOKMATCHED HALVES ARE GLUED TOGETHER. WHEN ALL THE LIFTS, WHICH ARE NUMBERED, ARE FINISHED THEY ARE DRY FITTED MARKED AND THEN GLUED TOGETHER. 18

LIFTS: INSIDE CUTTING FOR SHEER, 1A &2A THE TOPSIDE LIFTS, SHEER, 1A & 2A , REQUIRE SPECIAL CUTTING FOR THE INSIDE, THE BRIDE WHICH IS CENTERED ON STATION 20, Is DIFFICULT TO CUT OUT ON A BAND- SAW BECAUSE OF THE THROAT SIZE OF MOST BANDSAWS. IN ORDER TO MAKE IT EASIER TO CUT OUT, TWO HOLES ARE DRILLED TO PROVIDE THE RADIUS CURVE THAT IT IS NOT POSSIBLE TO DO ON A BANDSAW. THE RADIUS HOLES ARE 2 TO 3 INCHES IN DIAMETER, WHICH IS NOT CRITICAL. THE RADIUS HOLES CAN BE MADE WITH A FORSTNER BIT, HOLE SAW OR CUTOUT WITH A SABRESAW. THE INSIDE EDGE IS CUT WITH THE BAND SAW AND THE LEGS AS MUCH AS POSSIBLE WITH THE BAND SAW OR WITH A SABRE SAW. THE SHAPE AND QUALITY OF CUTS FOR THE BRIDGE ARE NOT CRITI- CAL. WHAT IS IMPORTANT IS THAT THE BRIDGE BE WIDE ENOUGH FOR USE ON THE SHAPING JIG. THE BRIDGE WILL REMAIN IN PLACE UN- TIL THE DECK IS READY TO INSTALL. 19

LIFTS: ROUGH CUTTING OF THE LIFTS THE LIFTS ARE ROUGH CUT OUT OF THE BOOKMATCHED BOARD. TRY TO ROUGH CUT THE BOARD INTO TWO OR THREE LARGER PIECES , LEAVE 1/4 TO 3/78” EDGE FOR THE FINISH CUT. TAKE THESE LARGER ROUGH CUT PIECES AND ROUGH CUT AGAIN TO SEPARATE EACH LIFT. NOTE : DO NOT TRY TO FINISH CUT LIFTS FROM THE FULL BOARD. IT IS TOO AWKWARD. LIFTS: LIFTS READY FOR FINISH CUTTING TAKE EACH INDIVIDUAL LIFT AND FINISH CUT THE OUTSIDE EDGE. ONCE THE OUTSIDE EDGES HAVE BEEN CUT, THEN CUT ALL THE INSIDE EDGES. NOTE: WHEN CUTTING THE INSIDE EDGES. THE CURVES AT THE ENDS MAY BE TOO TIGHT FOR A SINGLE PASS. CUT OUT AS MUCH AS POSSIBLE IN AN EASY CURVE. MAKE A SECOND AND THIRD PASS IF NECESSARY. WHEN HOLLOWING THE HULL MOST OF THIS WILL BE REMOVED WITH A GOUGE. 20

LIFTS: LIFTS AFTER FINISH CUTTING THE FINISHED LIFTS SHOULD LOOK LIKE THIS WHEN YOU ARE DONE. THE GLUING FACES OF THE LIFTS ARE PREPARED BY RUNNING A MEDIUM RASP LIGHTLY OVER THE SURFACES OF ONE OF THE LIFT PAIR. THE TROUGH ALLOWS THE GLUE SURFACES TO FIT MORE CLOSELY THE LIFT GLUING JIG. USEA SCRAP PIECES OF FIBREBOARD WITH A FORMICA SUR- FACE. BLOCKS AND WEDGES ARE USED TO HOLD THE PIECES IN PLACE. ONE SET OF BLOCKS CAN BE SUBSTITUTED FOR WITH A PAIR OF CYLIN- DERS BOLTED TO THE BOARD. PUT THE BOW ENDS IN THESE 21

LIFTS: LIFTS IN GLUING JIG — DRY FIT DRY FITTING IS THE PROCESS OF MAKING SURE THE PIECES OF AN OBJECT THAT HAVE BEEN CREATED WILL FIT TOGETHER CORRECTLY BEFORE THEY ARE PERMANENTLY GLUED TOGETHER. REMOVE THE NAILS FROM THE LIFT AND LAY FLAT ON JIG. NAIL THE WEDGE BLOCKS IN NEAR THE STERN END OF THE LIFT. LAY THE LIFTS IN BETWEEN THE BLOCKS INSTALL THE WEDGES. DRIVE WEDGES TIGHT CHECK THE ALIGNMENT OF PIECES AT THE BOW AND STERN. ADJUST THE LIFT PIECES FORE OR AFT AS NECESSARY. THE STATION 20 LINES SHOULD MATCH ON THE BRIDGES FOR THE SHEER AND 2A LIFTS. ADJUST WEDGES AND BLOCKING IF A TIGHT, FLAT FITTING OF THE GLUING SURFACES IS ABSENT. 22

LIFTS: GLUING UP STAGE THE LIFT PIECES FOR EASE OF GLUING. LIGHTLY WAX THE JIG WITH PARAFFIN WAX. MIX ONLY ENOUGH EPOXY FOR ONE LIFT. MIX UP QUICKSET EPOXY GLUE (G-5). SPREAD EPOXY EVENLY ON BOTH PIECES. LAY PIECES IN JIG. USE WEDGES TO FORCE THE PIECES TOGETHER. CHECK ALIGNMENT OF PIECES WIPE EXCESS EPOXY OFF TOP SURFACE. EXCESS EPOXY REQUIRES SANDING. COVER GLUE JOINTS WITH WAX PAPER. WEIGHTS ON LIFT OVER JOINTS. WAIT FOR JOINT TO CURE. USUALLY 15 MINUTES IS BEST. NOTE: PRACTICE GLUING ON SOME 23

FINISHING LIFTS: AFTER THE EPOXY HAS CURED, SAND OFF THE EXCESS EPOXY ON BOTH SURFACES OF THE LIFT. THE SURFACES SHOULD BE FLAT. USE A LONG SANDING BOARD WITH 8O GRIT SAND PAPER. LIFT 2B — PREPARATION LIFTS: LIFT 2B IS A CRITICAL ELEMENT IN THE HULL.. IT IS THE GARBOARD OF THE BOAT. IT IS THE LIFT THAT THE KEEL ATTACHES TO AND THE LIFT WHICH IS USED TO COMPRESS THE HULL WHEN IT IS GLUED TOGETHER. 2B REQUIRES SOME PREPARATION BEFORE THE HULL CAN BE GLUED TOGETHER. TWo 1/4 INCH HOLES THREE INCHES ON EI- THER SIDE OF STATION 20 ARE DRILLED ON THE CENTERLINE. THESE HOLES ARE FOR THE COMPRESSION BOLTS THAT WILL SQUEEZE THE HULL TOGETHER WHEN THE HULL IS GLUED UP. STATION 20 IS MARKED ON BOTH SIDES OF 2B USING A CHISEL. THIS PROVIDES A PERMANENT POINT FOR DRILLING THE MAST STEP AND ALIGNING THE KEEL TO THE HULL. 24

LIFTS: LIFT 2B PREPARATION FOR GLUING ONCE THE TWO HOLES ARE DRILLED , THE CLAMPING BOLTS ARE TEST FITTED. THE BOLTS ARE 8 X 1/74 CARRIAGE BOLTS WITH FENDER WASHERS AND WING NUTS. NOTE: THE 2B LIFT’S SHAPE IS DECEIVING. IT APPEARS THAT THE FINER END SHOULD FACE FORWARD. IT DOES NOT. MAKE SURE THAT THE ARROWS FROM THE TEMPLATE ARE ON BOTH SIDES OF THE LIFT. 25

LIFTS: GLUING LIFTS TOGETHER OVERVIEW: GLUING OF THE LIFTS CREATES AHULL. THE CRITICAL ELEMENT IN THE PROCESS IS THE DRYFITTING . HERE THE ALIGNMENT OF ALL THE LIFTS IS CARRIED OUT. THE LIFTS ARE ALIGNED FORE AND AFT USING STATION 20 AND THE CENTERLINE JOINT OF EACH LIFT USED FOR THE SIDE TO SIDE ALIGNMENT OR AMIDSHIPS SYMMETRY. THINK OF THIS AS AN ALIGNMENT IN THREE AXIS, X,Y,& Z.. NOTE: MAKE SURE THAT STATION 20 IS CLEARLY MARKED ON ALL SIDES OF THE LIFTS BEFORE GLUING THE HULL TOGETHER. MATERIALS: LAMINATING JIG: 3/74 x 12 x 48 INCH PLYWOOD FORMICA FACED IF POSSIBLE WAX PAPER URETHANE GLUE 2—8””xX 1/4N CARRIAGE BOLTS , WASHERS & WING NUTS 26

LIFTS: GLUING — PREPARATION OF JIG CARRIAGE BOLTS ARE INSERTED FROM BACK OF THE LAMINATINGJIG. COVER THE JIG WITH WAX PAPER. LIFTS: GLUING — DRYFITTING THE LIFTS THE LIFTS ARE PLACED ON THE JIG IN REVERSE ORDER , STARTING WITH THE SHEER. THE ORDER IS SHEER, 2A, 1A, LWL, 1B AND 2B. THE LIFTS ARE THEN ALIGNED FORE AND AFT USING STATION 20. THE MIDSHIP ALIGNMENT USES THE CENTERLINE OF THE LIFTS. 27

LIFTS: DRYFIT OF LIFTS — ALIGNMENT TIGHTEN THE WING NUTS ON LIFT 2B. CHECK AND ADJUST THE ALIGNMENT OF THE LIFTS. ONCE THE HULL IS IN ALIGNMENT, A PENCIL IS RUN AROUND THE EDGE OF any EACH LIFT. THE HULL IS DISASSEMBLED AND THE LIFTS STACKED IN ORDER OF ASSEMBLY. THE HULL IN NOW READY TO BE GLUED TOGETHER. GLUING UP THE LIFTS EACH LIFT IS LIGHTLY MOISTENED WITH WATER, USE A FINGER AS AN AP- PLICATOR. WET INSIDE THE MARKED LINE FROM THE DRY FITTING. URETHANE GLUE IS SPREAD ON THE MOIS- TENED AREA USING A STICK. GLUE UP EACH LIFT AND ALIGN USING THE PENCIL MARKS AS A GUIDE. TIGHTEN THE WING NUTS AFTER THE LIFTS ARE STACKED UP. CHECK FINAL ALIGNMENT AND DRIVE WEDGES UNDER BOW AND STERN 28

HULL: SHAPING —- ROUGH OVER VIEW: THE P/RATE HULL IS THE MELDING OF SEVEN CURVED REGIONS INTO ONE COMPLEX CURVED SHAPE, SHAPING IS A PROCESS OF GOING FROM ROUGH TO SMOOTH, INA SERIES EVER FINER STEPS, STARTING WITH CHISELS, PLANES, RASPS, BLOCK SANDING BLOCK AND FINALLY HAND SANDING. THE BASIC STEPS TO SHAPING THE HULL ARE FIRST CREATING THE BOW AND STERN PROFILES THEN THE KEEL—HULL JOINT, NEXT, THE TRANSOM AND FINALLY THE SHEER. THE PROFILES ARE ROUGHED IN AND ARE REFINED AS SHAPING TAKES PLACE. TOOLS: 172” CHISEL 1” CHISEL TRIMMING PLANE – STANLEY MALLET RASPS JIGS: LAMINATING JIG SHAPING JIG BOW TEMPLATE JIG NOTES: DO NOT USE A GOUGE ON THE OUTER HULL, IT CAN DIG TOO DEEP AND CREATE THE NEED FOR THE USE OF FILLER. WORK FROM AMIDSHIPS- FORWARD OR AMIDSHIPS-AFT. THIS GENERALLY KEEPS YOU GOING WITH THE WOOD GRAIN AND KEEPS TEAROUT TO A MINIMUM. 29

SHAPING — BOW PROFILE THE SHAPE THE BOW AND THE FORWARD SECTION OF THE HULL BY ROUGH CHISELING THE PROFILE OF THE KEEL. LOOK AT THE PLANS TO SEE THE COMPLEX PROFILE CURVE . START IN THE MIDDLE AND CHISEL A 172” GROOVE TOWARDS THE BOW. STOP AT THE END OF THE LWL LIFT. A TEMPLATE IS USED TO SHAPE THE BOW BEYOND LWL. CHISEL BACK TOWARDS LIFT 2B. LEAVE ABOUT 1/8” STEP AT THE JOINT BETWEEN LIFTS. THIS IS JUST A PRELIMINARY REMOVAL OF MATERIAL. USE A CHISEL AND OR A TRIM PLANE TO REMOVE MATERIAL DOWN TO THE CHISELED PROFILE. THE BOW PROFILE IS MARKED ON THE HULL AND A RASP IS USED TO ROUGH SHAPE THE CURVE OF THE STEM 30

THE PROFILE OF THE STEM IS ROUGHLY MARKED ON THE LIFTS. USE A MEDIUM RASP TO SHAPE THE STEM CURVE. USE THE STEM TEMPLATE FREQUENTLY. THE SHAPE OF THE STEM IS NOT FINISHED, BUT LEFT TO ABOUT 1/78 INCH HIGH. AS THE HULL IS FINISHED THIS WILL DIMINISH TO THE DESIRED PROFILE. MARK THE RASPED FLAT OF THE STEM PROFILE WITH A LEAD PEN- CIL. COLOR THE WHOLE SURFACE. THIS PREVENTS THE PROFILE FROM CHANGING WHEN THE BOW IS BEING SHAPED. THIS IS CALLED A SIGNAL COATING. IT WILL DISAPPEAR DURING THE FINAL SANDING OF THE HULL. SCRAPE THE EXCESS GLUE FROM THE LIFTS BY USING A SHARP CHISEL AS A SCRAPER 31

HULL : SHAPING — STERN PROFILE THE STERN PROFILE IS DONE MUCH THE SAME AS THE BOW. THE PROFILE IS A SHARP CURVE THAT FLATTENS OUT AS IT REACHES THE TRANSOM. THE BEST TECHNIQUE IS TO CARVE A ROUGH PROFILE RAMP AND THEN REMOVE THE MATERIAL AROUND IT. WHEN CARVING THE PROFILE RAMP, STOP ONE INCH FROM THE END OF LIFT 1A. THIS IS THE APEX OF THE TRANSOM. GO NO DEEPER THAN 378 “. THE TRANSOM WILL BE SHAPED LATER. A SMALL GOUGE , RASP AND TRIM PLANE ARE USED TO SHAPE THE STERN. USE THE RASPS AND GOUGE AT THE KEEL AND THE TRIM PLANE ABOVE THE WATERLINE. HAVE THE PLANS NEAR BY AND REFER TO THE PROFILE IN THE PLANS. THERE IS NO JIG AT THIS TIME, IT IS BEST TO HAVE A COPY OF THE PLANS BEHIND THE HULL, SO THAT THE PROFILE CAN BE REFEREED TO. ONCE THE PRELIMINARY SHAPING OF THE PROFILE IS DONE THE HULL IS MOVED TO A SHAPING JIG, WHICH ALLOWS THE HULL TO BE SHAPED WHILE IN A VICE AND AT DIFFERENT POSITIONS. 32

HULL: SHAPING — MARKING 3B, BASE OF KEEL ONCE THE BOW AND STERN PROFILES ARE ESTABLISHED, THE GARBOARDS ARE SHAPED. THIS IS A MORE COMPLEX OPERATION DUE TO THE CON- CAVE SHAPES INVOLVED. THE OBJECT IS TO SHAPE LIFTS 3B AND 2B WHICH ARE THE TRANSITION PIECES BETWEEN THE HULL AND THE KEEL. THIS INVOLVES THREE DISTINCT PROCESSES IN A 6 INCH SPACE. THE LEADING EDGE OF THE KEEL IS FAIRED INTO THE HULL. THE MIDSECTION , FAIRING THE BOW AND STERN TOGETHER , FINALLY, TRAILING EDGE WHICH FAIRS THE RUDDER AND KEEL TOGETHER. THE FIRST STEP IS TO NAIL LIFT 3B To THE HULL.. IT IS ALIGNED USING STATION 20. TWO FINISH NAILS ARE ADEQUATE FOR THE JOB. IT IS THEN MARKED WITH A PENCIL ON LIFT 2B. LIFT 4B IS THEN ALIGNED AND ITS OUTLINE MARKED ON TOP OF 3B. REMOVE 4B. 3B IS THEN DRILLED FROM INSIDE THE HULL THROUGH THE GLUING BOLT HOLES. THE HULL WITH 3B IS THEN FASTENED UP SIDE DOWN ON THE SHAPING JIG. 33

SHAPING JIG THE SHAPING JIG IS DESIGNED TO HOLD THE HULL IN A HORI- ZONTAL POSITION OR A VERTICAL POSITION. THE HULL IS HELD ON TO THE JIG BY USING THE 8” CARRIAGE BOLTS THAT WERE USED IN GLU- ING UP THE HULL OR BY 2-172 “ CARRIAGE BOLTS WHEN THE HULL IS RIGHT SIDE UP FOR HOL- LOWING. TO KEEP THE HULL FROM ROCKING, A STOP THAT MATCHES THE SHEER LINE 3” ON EITHER SIDE OF STATION 20 IS FITTED. THE BRIDGE FORMED BY THE SHEER AND 1A LIFTS IS AN IMPORTANT PART TO THE USE OF THE BOARD. IT PROVIDES A BEARING SURFACE FOR THE HULL TO PRESS ON THE SHAPING JIG. AN ALTERNATIVE MEANS OF FASTENING THE HULL TO THE JIG IS TO USE DRYWALL SCREWS THROUGH THE BACK OF THE JIG AND INTO THE BRIDGE. THIS TECHNIQUE IS USED WHEN THE KEEL IS FITTED , JOINED AND FINISHED ON THE HULL. THE HULL IS HOLLOWED BY TURNING THE HULL UPRIGHT AND US- ING THE SHORT( 2-1 72 “) CARRIAGE BOLTS 34

HULL: SHAPING — GARBOARDS, FORWARD THE GARBOARD IS SHAPE IS A RADIUS, A CURVED LINE, THAT CON- NECTS THE HULL TO THE KEEL. THE RADIUS CHANGES ALONG THE ENTIRE LENGTH OF THE KEEL. BEGIN BY ROUGH SHAPING LIFT 2B ABOUT HALF WAY UP TO 3B. USE A GOUGE TO BEGIN THE RADIUS ON 3B, BY GOUGING DOWN AND FORWARD FROM MIDSHIPS. WORK SLOWLY BACK TOWARDS THE 4B LINE, BUT NOT UP TOIT. LEAVE MATERIAL FOR RASPING AND SAND- ING. THIS IS JUST THE ROUGH SHAPING. BEGIN TO RASP THE SHAPE, USING THE ROUNDED SIDE OR THE ROUGH RASP. ALWAYS WORK DOWN AND AWAY IN LONG STROKES THAT ARE SHAPING 2B AND 1B AS WELL. NOTE: SEE PAGE 3X THE SHAPING PROCESS IS ABOUT MAKING A CURVED SURFACE NOT A FLAT ONE. RASPING IN ONE SPOT JUST DIGS A GROOVE AND DOES NOT MAKE A CURVED SURFACE. AS THE SURFACE WORKS DOWN, THE JOINT LINE BETWEEN THE LIFTS WILL BEGIN TO SHRINK IN HEIGHT. SHIFT TO THE MEDIUM RASP WHEN THE JOINT LINE IS ABOUT 1/78 “ STOP RASPING WHEN ABOUT 1/716” IS 35

HULL : SHAPING — GARBOARDS, AFT THE PROCESS OF SHAPING OF THE GARBOARDS AFT OF AMIDSHIPS IS GENERALLY THE SAME AS THE FORWARD ONES, EXCEPT THE RADIUS BECOMES SMALLER. NOTE: MARK THE FLAT BEHIND 3B WITHA SIGNAL SCOAT AND THE SIDES OF 2B. SHAPE THIS LAST. THERE SHOULD BE A SMALL TRIANGULAR FLAT FOR THE RUDDER TUBE TO REST ON WHEN THE SHAPING IS FINISHED. 3B NARROWS DOWN AT THE TOP AND IS ALMOST VERTICAL BY THE RUDDER. BEGIN WITH A GOUGE AND WORK DOWNWARD AND AT AN ANGLE TOWARDS THE STERN. SHAPE 2B AND 1B AS WELL BEGIN RASPING TO SMOOTH AND SHAPE AS WAS DONE IN THE FORWARD GARBOARD. 36

HULL : SHAPING — GARBOARDS, RASPING RASPING IS DONE WITH LONG STROKES TO BEGIN WITH. THE OBJECT IS TO CREATE A ROUGH CURVED SURFACE AND NOT TO CREATE FLAT SPOTS. GENERALLY, RASP AT A 45DEGREE ANGLE TOWARDS THE BOW OR STERN. AN X PATTERN GIVES A BETTER SMOOTHING RESULT, BECAUSE THE SURFACE IS BE- ING SHAPED IN TWO DIRECTIONS. CONTINUED ONE DIRECTION RASPING LEADS TO FLAT SPOTS AND OR GROOVES. AT THE TURN OF THE GARBOARD, THE ROUNDED EDGE OF THE RASP IS USED TO CREATE A RADIUS BY ROLLING IT AND PUSHING IT ALONG THE RADIUS. NOTE: BE CAREFUL BY THE RUDDER, WHERE 3B IS ALMOST VERTICAL, IT IS COMMON TO HOLLOW TOO MUCH. IF THIS HAPPENS, THE AREA CAN BE FILLED WITH BONDO AND SANDED. RASP TO 1/78” OF A FINISHED SURFACE WITH THE ROUGH FILE , THENTO WITH THE MEDIUM RASP AND FINISH WITH SO GRIT SANDPAPER 37 1/16TH

HULL : SHAPING — GARBOARDS, SANDING SANDING OF THE GARBOARDS IS DONE WITH A SERIES OF SANDING TUBES MADE OF PLASTIC PIE SECTIONS AND DOWELING. THE TUBE ARE 4TO 6 INCHES LONG. THE DIAMETERS GO FROM 174, 1, 374 AND 1-— 172, 1- 172. USE 80 GRIT 3M— ADHESIVE BACKED PAPER ON THE TUBES. FINER GRIT CAN BE USED FOR FINISHING. ROLL AND PUSH THE TUBES IN THE SAME WAY THE RASPS WERE USED. IF ADHESIVE PAPER IS NOT AVAILABLE, USE SPRAY ADHESIVE TO GLUE THE SAND PAPER TO THE TUBES. FINISH SANDING IS DONE WITH A SOFT PIECE OF OPEN CELL FOAM AND BY US- ING THE PALM OF THE HAND. USE GITS INTO 100 — 200 RANGE 38

HULL: SHAPING — MEDIUM AND FINISH SHAPING THE HULL IS THE LONGEST AND HARDEST PART OF CONSTRUCTING A F?- RATE. PATIENCE, PERSISTENCE AND ATTENTION TO DETAIL WILL DETERMINE THE OUTCOME OF THE SHAPING. THE ROUGH SHAPING IS DONE AND THE MEDIUM AND FINAL FINISHING BEGINS. MEDIUM SHAPING IS THE PROCESS OF JOINING THE ROUGH SHAPED AREAS OF THE BOAT TOGETHER INTO A CONTINU- OUSLY CHANGING CURVED SHAPE. THERE ARE NO FLAT SURFACES. MEDIUM SHAPING REMOVES MATERIAL WITH RASPS AND SANDING BOARDS UNTIL THE EDGES OF THE LIFTS ARE ALMOST GONE , 1/16” ORLESS. AT THIS POINT ONLY SANDING BOARDS AND HAND SANDING, USING THE HEEL OF THE HAND,WITH 8O GRIT SHOULD BE USED, FINISH SANDING IS THE CONTINUATION OF THE PROCESS, USING150 GRIT, UNTIL THE LIFT RIDGES ARE GONE. THE OBJECT IS TO CREATE A CURVED SURFACE THAT IS SMOOTH, WITHOUT LUMPS, RIDGES OR HOLLOWS. THE FINAL SANDING IS 220 GRIT. THIS WILL REMOVE SCRATCHES AND LEAVE A GOOD SURFACE FOR PAINTING. 39

KEEL: OVERVIEW FINISHED KEEL READY FOR JOINING TO HULL. WOODEN PORTION IS GLUED AND SHAPED. THE LEAD KEEL IS NOT GLUED TO WOODEN PORTION AT THIS TIME. KEEL BOLTS ARE HOLDING ENTIRE ASSEMBLY TOGETHER MATERIALS REQUIRED: LIFTS 3B, 4B, 5B &6B LEAD BALLAST KEEL 10-24 x 6” FLAT HEAD MACHINE SCREWS STEEL 2 EACH 10-24 NUTS—STAINLESS STEEL 2EACH 1” 2EACH FENDER WASHERS-—STAINLESS STEEL 5S MINUET GLUE (URETHANE GLUE SAND PAPER 8O GRIT JIGS: LIFT TEMPLATES ALIGNMENT JIG BEVEL JIG LEADING EDGE PROFILE JIG SHAPING JIG TOOLS: RASPS — ALL SIZES SCREWDRIVER WRENCH SAW 40

KEEL : LIFTS 3B, 4B, 5B AND 6B LIFTS READY FOR ASSEMBLY. LIFTS HAVE BEEN CUT WITH LONG TRAILING EDGES WHICH WILL BE TRIMMED OFF LATER. STATION 20 IS CLEARLY MARKED ON EACH LIFT. KEEL: ALIGNMENT OF LIFTS THE KEEL JIG IS USED TO ALIGN THE LIFTS AS SHOWN. LIFTS ARE PUSHED TO TOUCH THE FRONT END OF THE JIG. THE STATION 20 WITNESS LINES ARE NOT USED ,IF THE JIG IS USED. THE WITNESS LINES ARE A CHECK MARK THE FRONT EDGE OF EACH LIFT AND THE SIDES. THIS WILL MAKE ALIGNMENT EASY WHEN THE LIFTS ARE GLUED TOGETHER. KEEL: ASSEMBLED BLANK THE KEEL BLANK IS NOW GLUED TOGETHER AND IS 41 READY TO BE BEVELED.

KEEL BLANK: LAYOUT OF LEADING EDGE THE LEADING EDGE KEEL TEMPLATE IS FIT OVER ONE SIDE OF THE STEPPED LEADING EDGE OF THE KEEL. MATCH THE POINT OF THE JIG WITH THE BOTTOM CORNER OF 3B. MARK THE CURVE WITH A PENCIL.. LAYOUT OF THE TRAILING EDGE THE KEEL JIG IS PLACED BACK ON THE KEEL BLANK AND THE TRAILING EDGE IS MARKED. THIS IS A STRAIGHT LINE. THE RUDDER WILL FIT NEXT TO THIS EDGE. KEEL BLANK: CUTTING THE EDGES CUT THE LEADING EDGE ON A BAND SAW AND LEAVE 1/16 “ FOR FINAL SHAPING WITH A RASP. CUT THE TRAILING EDGE THE SAME WAY. IT WILL BE TRUED UP WITH A SANDING BLOCK KEEL: BLANK IN BEVELING JIG KEEL BLANK IS PLACED IN BEVELING JIG WITH LIFT 3B TOUCHING FRONT OF JIG. SECURE THE KEEL BLANK IN TWO PLACE WITH DRYWALL SCREWS THROUGH THE BOTTOM. 42

MARKING BEVEL MARK THE BEVEL LINE ON THE KEEL BLANK FOR REFERENCE WHEN IT IS CUT KEEL: CUTTING BEVEL START THE CUT AT THE NOSE. KEEP THE BLADE FLAT ON BOTH EDGES OF THE JIG BY PUTTING A FINGER ON THE BLADE OVER EACH EDGE AND PRESSING THE BLADE DOWN ON THE JIG EDGES. KEEP THE KNUB WHICH IS CUT OFF USE A SANDING BLOCK TO SMOOTH OFF CUT SURFACE. 43

KEEL: BEVELED BLANK ON SHAPING JIG THE BEVELED KEEL BLANK IS REMOVED FROM THE JIG AND IS SCREWED ON TO THE SHAPING JIG. SCREW THE BLANK ON TO THE JIG FROM THE BOTTOM OF THE JIG. KEEL: SHAPING LEADING EDGE OF KEEL USE RASP TO REMOVE EDGES. USE CURVED BACK OF A HALF ROUND FILE TO SHAPE THE LEADING EDGE OF KEEL BLANK. TRY TO AVOID MAKING A SHARP LEADING EDGE. LEAVE A 1/78 “ FLAT AND SIGNAL COAT IT LIKE THE STEM. THE EDGE IS ROUNDED ROUGH SHAPE AND THEN SEMI- FINISH WITH A MEDIUM RASP AND SANDPAPER. LEADING EDGE IS FINISHED AFTER BALLAST IS ATTACHED. KEEL: SHAPING KEEL BLANK – AFT SECTION USE RASP TO REMOVE EDGES AND FLATTEN SURFACE. USE THE SAME PROGRESSION OF RASPS TO CREATE A FINISHED SURFACE. DO NOT TAPER END OF BLANK TO A SHARP EDGE. LEAVE 3/7 16 INCH FLAT FOR THE RUDDER TO FAIR INTO. MARK THE WIDTH ON THE END BEFORE STARTING TO SHAPE. 44

KEEL: SEMI— FINISHED KEEL BLANK THE KEEL BLANK IS SEMI-FINISHED. FINAL SANDING WILL TAKE PLACE WHEN IT IS ATTACHED TO THE HULL. THE LEADING EDGE OF THE KEEL IS LEFT AT A SEMI-FINISHED STATE AT THIS STAGE. FINAL SHAPING WILL TAKE PLACE ONCE THE LEAD BALLAST KEEL: IS ATTACHED MARKING STATION 20 ON BALLAST PLACE BALLAST ON PLANS DRAWING AND ALIGN IN THE BEST POSITION POSSI- BLE. MARK STATION 20. NOTE: THE BALLAST WILL BE SLIGHTLY SMALLER THAN SHOWN ON THE PLAN, DUE TO SHRINKAGE OF THE BALLAST CASTING. DRILLING KEELBOLT HOLES ALIGN BALLAST ON KEEL BLANK. USE STATION 20 TO ALIGN WITH THE KEEL BLANK. USE A LONG 37 16 DRILL BIT TO DRILL THROUGH THE CORED HOLES IN THE BALLAST INTO THE KEEL INSERT A KEEL BOLT IN THE DRILLED HOLE AND SCREW IT DOWN CHECK THE ALIGNMENT OF THE BALLAST. REPEAT THE PROCESS FOR THE AFTER KEELBOLT HOLE. NOTE: WHEN DRILLING, MAKE MULTIPLE DRILLS AND CLEAN THE CHIPS FROM THE FLUTES. THIS WILL RESULT IN A STRAIGHT HOLE. 45

KEEL: BALLAST BOLTED TO KEEL — DRY FIT ONCE THE KEEL IS SHAPED, IT IS DRY FITTED TO THE HULL. THE KEEL IS ALIGNED USING STATION 20 ON THE HULL AND THE KEEL. REMOVE THE KEEL FROM THE SHAPING JIG. PULL THE KEEL BOLTS BACK TO ALLOW THE KEEL TO REST ON THE HULL. PULL ONE KEEL BOLT OUT AND USE THE KEELBOLT HOLE TO GUIDE THE 3/716” DRILL. ALIGN THE KEEL AND DRILL THROUGH THE HULL. SCREW THE KEEL BOLT THROUGH THE HULL AND BOLT UP IN SIDE THE HULL. PULL THE SECOND KEEL BOLT. CHECK THE ALIGNMENT OF THE KEEL. REPEAT THE PROCESS AND BOLT UP THE SECOND KEEL BOLT. REFASTEN THE HULL ON THE SHAPING BOARD USING DRYWALL SCREWS PLACED INTO THE BRIDGE. PUT THE JIG INTO A VICE SO THAT THE HULL IS HORIZONTAL . FINISH SHAPING AND FAIRING THE KEEL IN THIS POSITION. REMOVE THE KEEL AND STORE IT UNTIL THE HULL IS FINISHED. 46

HULL : OVERVIEW: INTERIOR — GOUGING OUT THE SHAPING OF THE INTERIOR OF THE PIRATE 1S AN EASIER PROJECT THAT DOES NOT REQUIRE AS HIGH A LEVEL OF FINISH AS THE EXTERIOR OF THE HULL. THE PROCESS IS SIMILAR IN THAT THE LIFTS ARE GOUGED, RASPED AND SANDED UNTILA SMOOTH SURFACE RESULTS. HULL THICKNESS IS DETERMINED BY THE AMOUNT OF MATERIAL REMOVED FROM THE INTERIOR. THE HULL THICKNESS SHOULD BE ABOUT 3/78 INCH IN THICKNESS. A THINNER HULL USUALLY RESULTS IN CRACKING. THE INTERIOR IS NOT HOLLOWED OUT ALL AT ONCE. IT IS DONE IN THREE STEPS. THE BOW IS HOLLOWED OUT FIRST, IN PREPARATION FOR THE ADDITION OF THE SHEER PIECE . THE STERN IS HOL- LOWED OUT NEXT. THE MIDSECTION , UNDER THE BRIDGE IS LAST , JUST BEFORE THE DECK IS INSTALLED. TOOLS: GOUGE RASPS SAND PAPER MALLET HULL : FABRICATING THE MAST STEP LOCATING AND DRILLING THE MASTSTEP IS THE FIRST STEP IN HOLLOWING THE INTERIOR. ON THE LINES PLAN, LOCATE STATION 20 AND THE INTERSECTION WITH THE TOP OF STATION 2 B. IN THE HULL ,THIS IS THE CHISELED LINE AT

HULL: INTERIOR FABRICATING THE MAST STEP THE MAST STEP ISA 1/72” DIAMETER HOLE LOCATED ON THE INSIDE OF THE HULL AND ON THE CENTER- LINE . THE END OF THE MAST IS PLACED IN THE HOLE, WHICH SUPPORTS AND HOLD STHE MAST IN PLACE. TAKE A SHORT STICK AND PUT ONE END ON THE 2B —STATION 20 POINT ON THE LINES PLAN AND MARK THE OTHER END WHERE IT CROSSES THE CENTERLINE OF THE MAST ON STATION LWL. TAKE THE STICK AND PLACE IT IN THE HULL AND TRANSFER THE POINT TO THE POINT ON THE CENTERLINE OF LIFT LWL. TAKE A 1/2 INCH BRAD POINT DRILL BIT AND BORE A HOLE AP- PROXIMATELY 378 TO 1/72 INCH DEEP. THE RESULT SHOULD LOOK LIKE THE MAST STEP AT THE BOTTOM OF THE PAGE. MARK UP THE FLAT AROUND THE MAST STEP WITH A PENCIL. THIS WILL ACT AS A REMINDER NOT TO REMOVE THE WOOD AROUND THE MAST STEP. WHEN GOUGING OUT THE INTERIOR, REMOVE THE CHIPS FAIRLY OFTEN SO THE WORK AREA IS NOT HIDDEN UNDER THEM. 48

HULL: BOW INTERIOR — GOUGHING OUT MARK THE EDGE OF MATERIAL TO BE REMOVED ON THE TOP OF THE SHEER. THE TOP OF THE SHEER IS LEFT1/72 INCH THICKER THAN THE HULL FOR STRENGTH AND TO PROVIDE A BIG- GER SURFACE AREA FOR THE DECK TO BOND TO. MARK STATION 8 ON THE SHEER IF IT WAS NOT MARKED DURING THE ORIGINAL LAYOUT. USE THE LAY- OUT TEMPLATE, ALIGN IT ON STA: TION 20 AND MARK IT ON THE SHEER LIFT. STATION 8 IS THE STARTING POINT FOR THE BOW SHEER LIFT. THIS POINT WILL BE USED IN LAYING OUT THE SHEER LINE WHEN IT IS CUT. NOTE: TO GAGE THE THICKNESS OF THE HULL WHEN HOLLOWING OUT, USE YOUR FINGERS AS A CALI- PER GAGE. PLACE A FINGER ON THE OUTSIDE OF THE HULL AND ONE ON THE INSIDE. YOUR SENSE OF TOUCH WILL GIVE YOU A GOOD SENSE OF THICKNESS. OCCASIONALLY HOLD THE HULL UP TO THE LIGHT. IF A BRIGHT SPOT APPEARS, THE HULL IS TOO THIN IN THAT SPOT AND WILL REQUIRE PUTTY. 49

HULL: INTERIOR — GOUGHING OUT BOW SHAPING OF THE INTERIOR BOW , BEGINS BY STARTING A PROFILE GROOVE. THIS IS JUST SAME PROCESS AS ON THE EXTERIOR OF THE HULL. START IN THE CENTER AND GROVE DOWN TOWARD THE KEEL, LIFT LWL. REMEMBER THAT THE MAST STEP IS NOT CUT DOWN. ONCE THE GROOVE HAS BEEN ESTAB- LISHED, START GOUGING AWAY TOWARDS THE SIDE OF THE HULL. NOTE: GOUGE FROM THE BOW TOWARDS THE STERN. GO WITH THE GRAIN OR DIAGONALLY. GOING AGAINST THE GRAIN WILL CAUSE CHIPPING, WHICH MAY MAKE THE HULL TOO THIN. GOUGE LIFT BY LIFT TOWARDS THE KEEL. REMEMBER NOT TO CHIP AWAY THE MAST STEP. AVOIDING THIS CAN HELPED BUY CLEANING THE CHIPS OF FREQUENTLY. GOUGE ONLY TO THE BRIDGE. IT WILL BE REMOVED MUCH LATER. AFTER ROUGH SHAPING WITH THE GOUGE, BEGIN SMOOTHING WITH THE MEDIUM RASP OR A SPOON PLANE. SMOOTH THE RIDGES DOWN. THE FINAL STEP IS SANDING THE SURFACE. START WITH 40 GRIT AND FINISH WITH 80 GRIT. THE FINISHED SURFACE SHOULD BE SMOOTH . 50

BOW SHEER LIFT OVERVIEW: THE BOW SHEER LIFT IS A SMALL LIFT THAT IS ADDED TO THE SHEER LIFT IN ORDER TO CREATE A GRACEFUL SHEERLINE. THE LIFT RUNS FROM STATION 8 TO THE BOW. IT IS 7/16 INCHES THICK. PLACE THE SHEER PIECE ON THE BOW WITH ONE END ALIGNED ON THE STATION 8 MARKS. HOLD DOWN AND MARK A LINE ON THE BOTTOM. MARK THE TOP AS “* TOP”, TOWARDS THE BOW. EXTEND THE LINES UNTIL THEY CROSS AT THE BOW. THE INTERSECTION SHOULD BE BEYOND THE EXISTING BOW, BY 3/78 INCH OR SO. THE EXTRA LENGTH IS BECAUSE THE STEM PROFILE EXTENDS BEYOND THE EXISTING BOW. SEE THE ORIGINAL PLANS TO CLAIRIFY THE GEOMETRY. CUT THE PIECE OUT. CUT THE INTERIOR OUT, LEAVING ABOUT 3 —1/72 INCHES SOLID FROM THE BOW BACK. TAPE THE HULL BELOW THE SHEER PIECE, IN PREPARATION FOR GLUING. DRY FIT THE PIECE AND MAKE SURE THAT THE SIDE THAT IS LABELED “ TOP IS FACING UP. MIX THE G-S EPOXY AND GLUE DOWN, USING A WEIGHT TO HOLD IT IN PLACE. URETHANE GLUE CAN BE USED, BUT ALLOW FOR A LONGER CURING TIME. 51

HULL: INTERIOR — GOUGING OUT STERN GOUGING OUT THE STERN INTERIOR IS DONE THE SAME WAY AS THE BOW. LEAVE ABOUT 3 INCHES OF THE TRANSOM UNGOUGED. THIS PROVIDES A GOOD GLUING SURFACE FOR THE DECK. THE AREA FOR GLUING WILL DECREASE ONCE THE SHEER LINE IS CUT. ONCE THE SHEER IS CUT, MORE MATERIAL CAN BE REMOVED IF NECESSARY. RASP AND SAND UNTIL A SMOOTH SURFACE IS ACHIEVED. THE BRIDGE IS LEFT IN PLACE. SHAPE THE HULL ONLY DOWN TO LIFT 2B. 2B IS LEFT FLAT FOR THE KEEL BOLTS AND WASHERS TO LAND ON. 52

HULL: BOW PROFILE — FINAL SHAPING OVERVIEW: THE FINAL SHAPING OF THE BOW IS MUCH LIKE THE ROUGH SHAPING. A MEDIUM RASP AND A SANDING BOARD WITH 80O GRIT IS USED. THE OBJECT IS TO REMOVE THE LAST OF THE RIDGES CREATED BY THE LIFTS AND CREATE A SMOOTH CURVED COMPLEX SURFACE. THE P/RATE ‘Ss BOW IS A HOLLOW FLARING SHAPE, WHICH CREATES A HOLLOW SPOT JUST ABOVE THEWATERLINE . THERE ARE NO FLATSPOTS ON THE ENTIRE HULL. THE FIRST STEP IS TO COMPLETE THE STEM PROFILE. USE THE RASP AND THE SANDING BLOCK TO CREATE SMOOTH CURVE. USE THE STEM TEMPLATE TO CHECK PROGRESS. USE A PENCIL TO SIGNAL COAT TO THE RESULTING SURFACE. DO NOT FLARE THE HULL SIDES INTO THE STEM UNTIL THIS DONE. SHAPING THE HULL SIDES BEGINS BY WORKING ON THE BOW SHEER AND SHEER LIFTS. THERE IS AN EXCESS OF MATERIAL AT THE TOP WHICH HAS TO BE CAREFULLY REMOVED. DRAW A DIAGONAL LINE ON THE BOW SHEER PIECE FROM THE TIP OF THE BOW TO STATION 8 ON BOTH SIDES. SHAPE TO THIS LINE AND NOT ABOVE IT. 53

HULL — BOW PROFILE : FINAL SHAPING KEEP FAIRING AND WORKING BOTH SIDES OF THE HULL UNTIL IT IS SMOOTH. KEEP A CLOSE WATCH ON THE STEM PROFILE AND CENTERLINE . USE A PENCIL TO MARK THE EDGE OF THE STEM. THIS WILL KEEP IT FROM WANDERING. A SMALL SANDING BLOCK, LONG AND NARROW WILL HELP FOR SMALL ADJUSTMENTS IN THE STEM LINE AND PROFILE. 54

CONSTRUCTION BOAT STAND: THE BOATSTAND OR CRADLE IS CONSTRUCTED TO HOLD THE BOAT, ONCE THE KEEL HAS BEEN JOINED TO THE BOAT. THE CRADLE IS A NICE PRELIMINARY PROJECT. IT CAN BE AS SIMPLE OR FANCY AS YOU WISH. THE BASE IS 17 X 6 X 3/74 INCHES. THE ENDS ARE 1/4 INCH PLYWOOD HALF TEMPLATES FOR THE ENDS ARE PROVIDED IN THE PLANS. THE LIGHTENING HOLES ARE BORED FOR ESTHETIC REASONS. TAKE THE BASE AND PLACE IT IN A VICE. SCREW OR NAIL AN END ON, USING THREE SCREWS. PRE DRILL THE END PIECE. FASTEN THE CENTER SCREW FIRST. USE A LITTLE GLUE FOR ADDED STRENGTH. REPEAT THE PROCEDURE ON THE THE OTHER END PIECE. TO KEEP FROM DAMAGING THE HULL , PUT FOAM PIPE INSULATION ON THE TOP OF EACH ENDPIECE. PAINT OR VARNISH AS DESIRED. THE CRADLE IS NICE OBJECT FOR PRACTICING VARNISHING. USE UP ANY EXCESS VARNISH IN THE BRUSH AND PAINT CUP AFTER VARNISHING THE MAST AND DECK ON THE CRADLE. 55

HULL : FASTENING KEEL TO HULL THE KEEL IS ATTACHED TO THE HULL ONCE THE FINAL SHAPING IS COMPLETED ON THE EXTERIOR AND INTERIOR OF THE HULL. TAPE ALL THE GLUE JOINTS. FINAL DRY FIT FOR ALIGNMENT. MOISTEN ALL JOINT SURFACES FOR URETHANE GLUE APPLY URETHANE GLUE TO SURFACES. TIGHTEN THE KEEL BOLTS. WIPE OFF EXCESS GLUE. LET GLUE CURE FOR 6 TO 12 HOURS FOR EPOXY GLUE: SAME PROCEDURE , BUT DO NOT MOISTEN THE JOINT SURFACES. REMOVE TAPE FINISH SAND THE JOINTS 56

RUDDER : CONSTRUCTION OF TUBE & SHAFT 7 | THE RUDDER TUBE IS MADE OUT OF A1172 INCH LENGTH 7/32 INCH BRASS TUBE. ONE END OF THE RUDDER TUBE IS FLARED TO CATCH THE OUTER EDGE OF THE HULL. FLARING IS ACCOMPLISHED BY PUTTING A TAPERED OBJECT IN ON END OF THE TUBE AND ROTATING IT UNTIL A LIP FORMS. THE RUDDER SHAFT IS A6-1/2 INCH X 3/716” BRASS ROD. BOTH ENDS ARE CHAMPHERED TO AID IN FITTING IN THE TUBE. DO NOT ATTACH THE RUDDER BLADE UNTIL THE RUDDER TUBE IS INSTALLED IN THE HULL. A #50 HOLE IS DRILLED INTO THE SHAFT 2 INCHES FORM ONE END. THIS IS FOR DRIVING A 18GA. BRASS ESCUTION PIN INTO THE BLADE AS A MECHANICAL FASTENER. THE HEAD OF THE PIN IS GROUND OFF. THE RUDDER BLADE IS MADE FROM SCRAP 3/7 16 PLYWOOD OR FROM WOOD. A GROOVE IS RASPED INTO THE EDGE THAT WILL JOIN WITH THE SHAFT. USE A 3/7 16 RAT TAIL FILE. THE SHAFT AND BLADE ARE JOINED TOGETHER WITH SUPER GLUE AND THE PIN. THE BLADE CAN BE TAPERED BY RUNNING IT OVER A SANDING BELT. THIS IS USUALLY DONE AFTER RUDDER IS CONSTRUCTED. 57

RUDDER: INSTALLATION OF THE TUBE OVERVIEW : THE RUDDER ASSEMBLY IS THE ONLY MECHANICAL FEATURE TO BE PUT IN THE HULL. IT CONSISTS OF A TUBE AND SHAFT WITH BLADE. THE TUBE IS THE FIRST ITEM INSTALLED . THE RUDDER BLADE IS ATTACHED TO THE SHAFT AND INSTALLED AFTER THE BOAT IS FINISHED. THE CRITICAL OPERATION IS TO INSTALL THE RUDDER IN LINE WITH THE TRAILING EDGE IF OF KEEL. THE TRAILING EDGE OF THE KEEL IS EXTENDED DOWN TO LIFT 2B. A SMALL TRIANGLE SHOULD BE LEFT. IF NOT, A PIECE CAN BE GRAVED IN AND RECARVED. THE FINISHED TRAILING EDGE OF THE KEEL IS BLOCKED FLAT, HORIZONTALLY AND VERTICALLY. A PILOT HOLE IS PUNCHED WITH AN AWL FOR A LONG SHAFT 3/7 16 DRILL. HOLD THE DRILL BIT IN LINE AND AGAINST THE TRAILING EDGE OF THE KEEL. DRILL THROUGH THE HULL. TEST FIT THE RUDDER TUBE — 1 T SHOULD NOT FIT. USE A 3/16 RATTAIL FILE TO OPEN THE HOLE UNTIL THE RUDDER TUBE JUST FITS. 58

RUDDER: INSTALLATION OF THE TUBE THE RUDDER TUBE IS TEST FIT BY INSERTING THE RUDDER SHAFT AND CAREFULLY PUSHING IT INTO THE HULL. THE RUDDER SHAFT MUST TURN FREELY IN THE TUBE. PULL THE TUBE DOWN INTO POSITION BEHIND THE TRAILING EDGE OF THE KEEL. RASP THE HOLE UNTIL A CLOSE FIT IS ACHIEVED. THE RUDDER TUBE IS GLUED IN PLACE USING URETHANE GLUE, TAPE THE HULL AROUND THE RUDDER HOLE AND USE VASELINE ON THE INSIDE OF THE TUBE AND THE SHAFT. NOTE: THE URETHANE GLUE IS VERY AGGRESSIVE IN STICKING TO METAL AND WOOD SO PLACE A BARRIER ON ANY OBJECT THAT NEEDS TO BE GLUE FREE. GLUING: DAMPEN THE HOLE WITH WATER, PUT A LITTLE GLUE DOWN THE HOLE AND ON THE OUTER WALL OF THE TUBE. PUT INTO POSITION AND USE THE SHAFT TO ALIGN WITH THE KEEL AND USE TAPE TO HOLD IN IN POSI- TION. WIPE OFF ANY EXCESS URETHANE GLUE. 59

DECK BEAMS : CONSTRUCTION A PAIR OF DECK BEAMS ARE REQUIRED TO SUPPORT THE DECK AND MAST. THE FORWARD DECK BEAM IS CALLED THE PARTNER AND THE OTHER IS THE AFTER DECK BEAM. THE BEAMS ARE CAMBERED TO CAUSE THE DECK TO SHED WATER. TAKE A SCRAP FROM THE CUTTING OUT OF THE LIFTS. MARK OUT TWO DECK BEAMS. NAIL THE HALVES TOGETHER AND CUT OUT WITH A BANDSAW. MARK THE CENTERLINE ON THE PIECES, AS WAS DONE ON THE LIFTS. TAKE THE BEAMS APART AND GLUE THEM TOGETHER. BOTH DECK BEAMS ARE DRILLED OUT AT THE CROWN, ONE FOR THE MAST AND THE OTHER FOR THE RUDDER SHAFT. THE MAST PARTNER IS DRILLED FOR A 172 INCH HOLE AND THE OTHER WITH A 3/6 HOLE FOR THE RUDDER 60

DECK BEAMS : MAST PARTNER & AFT BEAM THE MAST PARTNER IS ALIGNED WITH THE MAST STEP BY USING A 18” X 1/72 INCH DOWEL. THE DOWEL IS STUCK IN THE MAST STEP AFTER IT IS PUSHED THROUGH THE MAST PARTNER. THE ASSEMBLY IS THEN ALIGNED TO BE VERTICAL IN ALL AXIS. MAST RAKE CAN BE ADDED AFTER THE BOAT IS ASSEMBLED BY RASPING THE MAST HOLE OUT. THE PARTNER IS ALIGNED TO BE EQUIDISTANT FROM THE TIP OF THE BOW. MEASURE ONE SIDE AND THEN MATCH THE DISTANCE ON THE OTHER. HOLD THE PARTNER IN PLACE AND MARK THE SHEER ON THE BOTH SIDES OF THE PARTNER. MARK THE TOP, BOTTOM AND SIDES OF THE PARTNER. THIS FORMS THE CUT LINE . CUT THE PARTNER 1/78 INCH OUT SIDE OF THE CUT LINE. THE PARTNER IS FITTED BY HAND SANDING BOTH SIDES UNTIL IT IS CENTERED AND RESTS EASILY IN PLACE. DO NOT FORCE FIT THE PIECE, IT WILL DISTORT THE HULL AND CAUSE CRACKING. EPOXY THE PARTNER IN PLACE. SAW DUST CAN BE ADDED TO THE EPOXY TO THICKEN IT. 61

DECK BEAMS : AFT BEAM — INSTALLATION THE AFTER DECK BEAM IS INSTALLED THE SAME WAY AS THE MAST PARTNER. CENTERING IT IS DONE BY USING THE RUDDER SHAFT TO CENTER THE BEAM. MARK AND CUT TO FIT. EPOXY THE BEAM IN PLACE. THE DECK BEAMS ARE NOW FAIRED TO THE SHEER . A BLOCK PLANE IS BRIDGED BETWEEN THE SHEER AND DECK BEAM. IT IS RUN AT A 45 DEGREE ANGLE OUT TO THE CENTER LINE. THIS IS DONE ON THE FORWARD AND BACK SIDES. THE DECK IS NOW READY FOR INSTALLATION. RUDDER INSTALLATION: IF THE BOAT IS GOING TO BE RADIO CON- ROLLED, IT IS BEST TO FIT THE RUDDER BEFORE THE DECK IS ATTACHED. PUT THE RUDDER THROUGH THE TUBE AND CUT THE SHAFT OFF UNTIL THE TOP OF THE RUDDER IS 1/16 “BELOW THE HULL. FIT THE BELLCRANK ARM ON THE RUDDER. IT SHOULD RIDE ON THE TOP OF THE RUDDER TUBE AND 90 DEGREES TO THE SURFACE OF THE RUDDER BLADE. MARK THE TOP OF THE BELLCRANK ON THE SHAFT WITH A FELT TIP PEN. REMOVE THE RUDDER AND GRIND A FLAT FOR THE BELL CRANK SET SCREW. DO NOT REINSTALL RUDDER 62

DECK : FABRICATION THE DECK IS FABRICATED OUT OF A SINGLE PIECE OF MAHOGANY DOOR SKIN. A PIECE 10-12 “ x 45 —48 “ IS SUFFICIENT. TURN THE HULL UPSIDE DOWN AND MARK THE OUTLINE OF THE SHEER ON THE DOOR SKIN. MAKE SURE THE GOOD FACE OF THE DECK IS FACING DOWN AND THE OUT LINE IS BEING TRACED ON THE BACKSIDE OF THE DOOR SKIN. GIVEA 1/4 TO 3/78 INCH ExCESS ON ALL THE EDGES AND A RUNOUT ON THE TRANSOM OF 2 INCHES. THE EXCESS WILL BE TRIMMED OFF LATER. SEALING THE UNDERSIDE OF THE DECK CAN BE DONE AT THIS TIME. IF REGULAR EPOXY, (WEST ) IS NOT AVAILABLE, VARNISH OR SEALER CAN BE USED. AVOID SEALING WITH VARNISH WITH IN 1” OFT EDGES AND IN THE AREA OF THE DECK BEAMS. THE URETHANE GLUE MAY NOT BOND WELL DRY FIT THE DECK . 63

DECK : INSTALLATION TAPE THE HULL DOWN FROM THE SHEER. USE TWO SECTIONS OF TAPE ON THE HULL, THREE IF THE HULL IS FINISHED BRIGHT. PUT VASELINE IN THE MAST PARTNER HOLE AND TAPE OVER THE MASTSTEP HOLE. THIS WILL PREVENT GLUE FROM STICKING . PUT VASELINE IN THE RUDDER SHAFT HOLE IN THE AFTER DECK BEAM. THE DECK IS HELD DOWN BY WRAPPING THE HULL WITH A 12 FOOT LENGTH OF 1/4” BUNGEE CORD. START WITH A LOOP AT THE RUDDER KEEL AND WRAP TOWARDS THE BOW. PAY SPECIAL ATTENTION TO THE BOW AND STERN WHERE EXTRA WRAPS ARE NECESSARY. WRAP IN AN X PATTERN, KEEPING TENSION ON THE CORD. THE FINAL WRAP IS FROM THE STERN TO THE BOW. TIE OFF THE END. MAKE SURE THE DECK STAYS CEN- TERED AND THERE IS 3/78 “ OVERHANG ON BOTH SIDES AT THE BOW AND STERN. MAKE A DRY FIT SEVERAL TIMES USE URETHANE GLUE, WHICH HAS A LONGER SETTING TIME THAN THE 5 MINUTE EPOXY. THE URETHANE GLUE IS EASIER TO TRIM THAN THE EPOXY. 64

TRIMMING THE DECK IS TRIMMED USING A TRIM PLANE AND SANDING BLOCKS. LEAVE THE TAPE ON THE SHEER UNTIL THE FINAL SANDING. THIS PROTECTS THE HULL FROM OVER TRIMMING OR SANDING. THE EDGE OF THE DECK IS A CONTINUATION OF THE HULL AND IS A CONTINUOUS CHANGING BEVEL. THE BEVEL IS STRAIGHT AT AMIDSHIPS AND BECOMES MORE EXTREME AT THE ENDS. START AT AMIDSHIPS, STATION 20, AND TRIM FORWARD TO THE BOW. TRIMINA DIAGONAL MOTION, THE X PATTERN OF FINISHING THE HULL. DO NOT TRIM TOWARDS AMIDSHIPS, AS THIS WILL CAUSE TEAR OUT OF THE PLYWOOD DECK. PLANE AND SAND IN A DIAGONAL DIRECTION, TO PREVENT FLAT SPOTS. THE AFT SECTION OF THE DECK HAS THE MOST EXTREME BEVEL. SAND WITH 80O GRIT TO START AND FINISH WITH 150 GRIT. THE TAPE WILL WARE OFF BY THE SANDING. ADD MORE TAPE IF NECESSARY. 65 FINAL

TRIMMING THE TRANSOM THE FIRST STEP IN TRIMMING THE TRANSOM IS TO TAPE OFF THE TOP SURFACE. THIS HELPS PREVENT TEAROUT OF THE DECK. CUT THE EXCESS DECKING OFF IN AN ARC THAT MATCHES THE TRANSOM, LEAVING 3/8 TO 1/72 INCH. TURN THE HULL KEEL UP AND REST IT ON SOFT PADS. USE A SANDING BLOCK TO SLOWLY WORK THE TRANSOM DECK EDGE BACK TOWARDS THE TRANSOM. MAKE THE EDGE ANGLE MATCH THAT OF THE TRANSOM. WHEN THE EDGE IS WITHIN 1716 “ SWITCH TO A FINER GRIT AND FINISH OFF. FINISH THE FEATHER EDGE OFF BY FLATTENING IT, THIS WILL HELP PREVENT CHIPPING WHEN THE BOAT IS IN USE. CAREFULLY REMOVE THE TAPE. USE A HEAT GUN IF NECESSARY. THE HULL — TRANSOM EDGE SHOULD MAKE A VEE SHAPE. BE CAREFUL NOT TO ROUND OVER THE EDGE AT THE SHEER. 66

COCKPIT LAYOUT TO LAY OUT THE LOCATION OF THE COCKPIT AND THE MAST HOLE, USE A STRAIGHT EDGE AND RUN A CENTERLINE FROM THE TIP OF THE BOW TO THE CENTER OF THE TRANSOM. LIGHTLY MARK ONLY THE CENTER SECTION, STARTING ABOUT 20” BACK FROM THE BOW. USE A PAIR OF DIVIDERS TO CHECK THE CENTER LINE, AT AMIDSHIPS OR STATION 20. IT IS IMPORTANT TO MAKE SURE THE LINE IS ON CENTER. IF THE COCKPIT IS OFF CENTER, IT WILL BE VISUALLY APPARENT. THE COCKPIT IS OPENED BY USING A 2—1/74 INCH HOLE SAW TO CUT OUT THE ENDS. MARK A CEN- TER POINT FOR THE HOLE SAW AT 20 INCHES AND 27 INCHES FROM THE BOW. DRILL SLOWLY AND GENTLY, ROTATING THE SAW IN THE CUT HOLE. CUT TROUGH AT ONE POINT AND GENTLY INCREASE THE CUT. THIS WILL ELIMINATE TEAROUT UNDER THE DECK. CONNECT THE TWO HOLES WITH TANGENTIAL LINES DRAWN BETWEEN THE HOLES. 67

COCKPIT — CUTTING OUT THE SIDES OF THE COCKPIT ARE CUT 378 “ INSIDE OF THE DRAWN LINES. USE THE TRIM PLANE TO FINISH THE EDGES. SAND THE UNDERSIDE OF THE EDGES EDGES. LAYOUT OF MAST HOLE A MAST HOLE LOCATION JIG IS CREATED BY TAKING A 8 TO 10 “ STICK WITH A FINISH NAIL IN ONE END. THE STICK IS SLIPPED UNDER THE DECK AND THE NAIL INTO THE BACK OF THE MAST HOLE MARK THE EXPOSED END OF THE STICK AT THE FORWARD END OF THE COCKPIT. 68

LAYOUT OF MAST HOLE REMOVE THE JIG AND PLACE IT ON THE CENTERLINE OF THE DECK. ALIGN THE PENCIL MARK WITH THE FORWARD EDGE OF THE COCKPIT. THE NAIL WILL APPROXIMATELY LOCATE THE BACK OF THE MAST HOLE UNDER THE DECK. MARK THE SPOT LIGHTLY . USE A 1/8 INCH DRILL BIT TO DRILL A PILOT HOLE. IT SHOULD GO THROUGH WITH NO RE- SISTANCE. CAREFULLY ENLARGE THE HOLE WITH Ai 7/4” DRILL. USE THE 3/7 16 RAT-TAIL FILE TO ENLARGE THE HOLE GRADUALLY. EXPAND THE HOLE UNTIL IT IS 1/72 INCH IN DIAMETER. IF THE MAST IS FINISHED, TEST FIT IT. FINISH SAND THE DECK AND SEAL COAT IT WITH VARNISH. THIN THE VARNISH ABOUT 50-50 WITH THINNER 69

MAST: CONSTRUCTION OVERVIEW : THE MAST IS MADE IN THE TRADITIONAL WAY REAL MASTS ARE. START WITH A SQUARE PIECE OF STOCK AND TRIM THE EDGES INTO AN OCTAGON. THE OCTAGON IS THEN SANDED INTO A TAPERED CIRCULAR MAST. MATERIALS: THE MAST IS MADE FROM A BLANK OF 1/72 X 1/72 BY 60 INCH PIECE OF WOOD. RED CEDAR, ALASKA YELLOW CEDAR OR SPRUCE CAN BE USED. HARDWOOD DOWELING IS NOT USED BECAUSE THE OF THE WEIGHT. TOOLS: TRIM PLANE SAND PAPER 80 GRIT, 100 GRIT , 180 GRIT Ss USE THE TRIM PLANE TO START A FLAT BETWEEN THE TWO FACES. THE FLAT SHOULD BE 1/8” IN WIDTH. DO ONE FLAT AT A TIME. ONCE THE OCTAGON HAS BEEN CREATED, PICK ONE END TO BE THE TOP, MASTHEAD, OF THE MAST. MEASURE DOWN XX INCHES FROM THE HEAD TO LOCATE THE SPREADER. THIS IS ONE INCH MORE THAN THE ACTUAL LOCA- TION. ONCE THE MAST IS SHAPED, THE INCH WILL BE CUT OFF FROM THE MAST HEAD. TAPER THE UPPER PORTION OF THE MAST FROM THE SPREADER TO THE MAST HEAD. THE MAST HEAD SHOULD BE ABOUT 3/78 IN DIAMETER. 70 “

CONSTRUCTION MAST: THE MAST IS FINISHED BY ROTATING THE MAST IN A PIECE OF SANDPAPER HELD IN A CUPPED HAND. THE TECHNIQUE IS A COMBINATION OF RUNNING THE MAST OVER THE SANDPAPER AND ROTATING IT. START WITH 8O GRIT AND AS THE MAST PROGRESSES GOTO FINER GRITS TO RE- MOVE SCRATCHES. THE IDEAL MAST IS ONE CONTINUOUS TAPER FROM THE DECK TO THE MAST HEAD. FOR PRACTICAL PURPOSES, THE MAST IS 1/72” DIAMETER FROM THE DECK TO THE SPREADER AND THEN TAPERS FROM THERE. LUMPS IN THE MAST CAN BE REMOVED BY RUNNING THE MAST OVER A SANDING LONG BOARD . WHILE ROTATING THE MAST. VARNISH THE MAST WITH FOUR COATS. MAST LAYOUT JIG: THE MAST LAYOUT JIG IS A 4” BOARD WHICH IS 5 FEET LONG AND HAS THE HARDWARE PATTERN LAID OUT ON IT. A NOTCHED STOP IS ATTACHED AT ONE END AND TWO LOW PADS ARE PLACED ON EITHER SIDE OF THE MAST AT THE SPREADER TO SUPPORT AND HOLD THE MAST A STRING IS ATTACHED TO THE STOP AND IS USED AS A CENTERLINE MAST. 71 ON THE

MAST: HARDWARE INSTALLATION — SPREADER OVERVIEW: THERE ARE THREE STEPS TO INSTALLING THE MAST HARDWARE. THE SPREAD- ERS ARE FIRST. THE LUFF WIRE EYES ARE SECOND AND THE GOOSENECK AND SHEET EYE ARE LAST. THE MAST BLANK IS PLACED IN THE MAST LAYOUT JIG AND THE SPREADER LOCATION IS MARKED ON THE CENTER LINE OF THE MAST. DRILL 1/716 “ A PILOT HOLE FOR THE SPREADER BOLT. CHUCK THE BOLT IN A DRILL AND SCREW IT THROUGH THE MAST UNTIL IT IS EQUIDISTANT ON EACH SIDE OF THE MAST. SCREW THE NUTS ON EACH SIDE AND TIGHTEN THEM. LUFF WIRE EYES : THERE ARE FIVE LUFF WIRE EYES. THEY ARE ALIGNED IN A STRAIGHT LINE ON THE BACK SIDE OF THE MAST AT 8” INTERVALS. THE LUFF WIRE IS RUN THROUGH THEM. THIS IS HOW THE SAIL IS ATTACHED TO THE MAST. PUT THE MAST BACK IN THE JIG AND REST THE SPREADER BOLT ON THE TWO PADS. STRETCH THE CENTERING STRING DOWN THE MAST. TENSION THE STRING BY PLACING A SHALLOW SAW CUT IN THE END OF THE MAST BUTT AND PULLING THE STING INTO IT. USE AN AWL OR PENCIL TO MARK THE LUFF EYE LOCATION IN THE MIDDLE OF THE BACK OF THE MAST. 72

MAST: HARDWARE INSTALLATION — LUFF EYES DRILL THE HOLES FOR THE LUFF EYES WITHA 1716 “ DRILL OR SMALLER. TO AVOID DRILLING THROUGH THE MAST, TAPE OFF THE DRILL BIT SO ONLY 1/74 “ IS SHOWING AT THE TIP. TO DRILL THE HOLES VERTICALLY, VISUALLY CHECK THE DRILL ANGLE ALONG THE MAST AXIS AND AT A RIGHT ANGLE TOIT. THE LUFF WIRE EYES ARE FABRICATED FROM 1716” STAINLESS STEEL COTTER PINS, FOUR ARE CUT OFF TO 3/78 “ LENGTH AND ONE IS CUT TO 3/716”. THE LONGER EYES ARE PUT IN THE LOWER FOUR HOLES AND THE SHORTER ONE IS PUT IN THE UPPER MOST HOLE. ALIGN THE EYES SUCH THAT WHEN LOOKING DOWN THE MAST, IT IS POSSIBLE TO LOOK THROUGH ALL THE EYES. THE EYES ARE HELD IN BY SPRING TENSION. SPREAD THE COTTER PINS SLIGHTLY AND THEM INSERT THEM IN THE HOLES. GENTLY DRIVE THEM INTO THE HOLES, LEAVING 1/78” OF THE SHAFT AND EYE ABOVE THE HOLE. DO NOT DRIVE THE EYE IN THE HOLE UNTIL THE LOOP AT THE END IS FLUSH WITH THE MAST, THIS WILL PREVENT THE SAIL FROM MOVING FREELY 73

CUTTING TO CORRECT HEIGHT THE MAST JIG HAS A LINE WHICH IS THE POINT AT WHICH THE MAST MUST BE AT THE DECK. THIS ENSURES THAT THE BOAT HAS A MAST AND SAIL HEIGHT THAT IS THE SAME AS ALL PIRATE’S. THE DECK HEIGHT LINE IS USUALLY SCRATCHED INTO THE MAST WITH AN AWL. FOR RIGGING PURPOSES A PIECE OF TAPE IS WRAPPED AROUND THE MAST WITH ITS BOTTOM EDGE TOUCHING THE LINE. THE MAST IS PLACED INTO THE MAST HOLE, SOME FILING MAY BE NECESSARY TO ENLARGE THE MAST HOLE, AND IS SET INTO THE MAST STEP. THE DISTANCE BETWEEN THE DECK AND THE LINE IS MEASURED. THIS DISTANCE IS THE AMOUNT THAT NEEDS TO BE CUT OFF THE MAST. DO NOT CUT ALL OF IT OFF. LEAVE THE MAST ABOUT 374 INCH LONGER AND TRIAL FIT IT AGAIN. SAND A TAPER AROUND THE BOTTOM 172” OF THE MAST. THIS MAKES ENTRY INTO THE MAST STEP EASIER. THE MAST STEP DEPTH MUST BE TAKEN INTO AC- COUNT AT EACH MEASUREMENT. THE MAST MUST FIT INTO THE MAST STEP. REPEAT THE CUT AND TAPER PROCESS, UNTIL THE MAST LINE IS LEVEL WITH THE DECK. 74

BOOMS : MAIN & JIB THE BOOMS ARE MADE OUT OF OF RED CEDAR OR EQUIVALENT WOOD. THE MAIN BOOM DIMENSIONS ARE 23 X 5/716X 1/72. THE EDGES ARE ROUNDED OVER TO SIMULATE AN OVAL SHAPE. THE BOOM IS THEN VARNISHED TO THE DESIRED FINISH. AN EYELET IS PUT IN ONE END FOR THE GOOSENECK. AN TACK EYELET IS PUT ON THE TOP OF THE BOOM ABOUT 3/78 INCH FROM THE END OF THE BOOM THE MAIN SHEET IS RUN THROUGH AN EYE ON THE BOTTOM OF THE BOOM X INCHES FROM THE END. THE JIB BOOM IS MADE OF RED CEDAR. ITS DIMENSIONS ARE XX5/16 xX 378. ALL EDGES ARE ROUNDED TO SIMULATE AN OVAL. THERE ARE FOUR EYELETS ON THE BOOM. THE JIB IS ATTACHED TO AN EYE- LET ON THE TOP 3/78 “ FROM THE FRONT . THE BOOM IS ATTACHED TO THE DECK BY AN EYE AND A SWIVEL 2” BACK FROM THE FRONT AND ON THE BOTTOM. THE JIB IS SECURED TO THE BOOM BY A EYELET 3/8” ON TOP 3/8 FROM THE END. THE JIB SHEET IS RUN THROUGH AN EYELET 3/74 “FROM THE END ON THE BOTTOM OF THE BOOM 75

LAYOUT SAILS : OVERVIEW: TO HAVE A THE SAILS ARE DESIGNED FOIL SHAPE , JUST LIKE THE SAILS ON THE REAL P/RATE. THE SAILS MAY LOOK LIKE SIMPLE TRIANGLES, BUT THE EDGES ARE ALL CURVED , WHICH GIVE THE SAIL ITS SHAPE. MATERIAL: 1 YARD OF 36” XX OUNCE DACRON SAIL CLOTH. 72” 1” DACRON TAPE 72” 1/78” DOUBLE STICK TAPE 24” 374 “* DACRON ADHESIVE TAPE NOTE: WORK ON CLEAN SURFACES. SAILS ARE DIRT MAGNETS. THEY SHOW EVERY SPECK OF DIRT. LAY THE SAIL PLAN OUT ON A FLAT SURFACE. LAY OUT AND CUT THE MAIN SAIL FIRST AND THE JIB SECOND. UNROLL THE SAIL CLOTH ON SAIL PLAN AND ALIGN THE WEAVE WITH THE LEACH OF THE SAIL. AN INSTRUCTION ARROW IS ON THE SAIL PLAN. WEIGHT, TAPE OR PIN DOWN THE SAIL CLOTH TO PREVENT MOVEMENT. TRACE THE OUTLINE OF THE SAIL ON TO THE CLOTH USING A #5 PENCIL. MAKE THE TRACE AS LIGHT AS POSSIBLE TO MINIMIZE SMUDGING THE CLOTH. MARK THE REINFORCING PATCHES FOR THE CORNERS OF THE SAIL AND THE BATTEN LOCATIONS, USE A LINE AT THE LEECH AND A POINT AT THE END. 76

CUTTING & CONSTRUCTION ROUGH CUT THE SAIL USING A PAIR OF SCISSORS . LEAVE AN INCH ON THE SAIL FOR FINAL TRIMMING. TRIMMING OF THE SAILS IS DONE WITH A HOT KNIFE, WHICH SEARS THE EDGES. IF A HOT KNIFE IS NOT AVAILABLE, A SOLDERING GUN WITH A FLAT BLADE SHOULD BE TRIED. FOR BEST RESULTS WITH A HOT KNIFE, CUT THE SAIL WITH A PIECE OF GLASS AS A BACK- ING. THE MELTED DACRON DOES NOT STICK TO IT AND THE BLADE WILL NOT BURN OR MELT IT. RE-INFORCING PATCHES ARE CUT FROM SIGNAL CLOTH, WHICH IS HEAVY DACRON WITH ADHESIVE ON ONE SIDE. APPLY THE PATCHES. IN THE CASE OF DOUBLE PATCHES ON THE CLEWS, APPLY THE SMALLEST FIRST AND THEN THE LARGER ONE OVER IT. BATTENS: EACH SAIL HAS BATTENS, THEY ARE ON THE LEECH OF THE SAIL AND KEEP THE EDGE FROM CURLING OVER. THE MAIN HAS FOUR AND THE JIB TWO. THE LENGTHS ARE SPECIFIED ON THE SAIL PLAN. CUT THE BATTENS FROM THE TAIL OF A 1/8” NYLON ZIP TIE. BATTEN POCKETS ARE MADE FROM SINGLE BACKED TAPE THAT IS CUT 3/74 “ LONGER THAN THE BATTEN, ONE END IS ROUNDED. THE BATTEN IS PLACED ON THE STICKY SIDE OF THE BATTEN POCKET, THE ENDS OF THE POCKET ARE TURNED UP AND THE BATTEN IS ALIGNED TO MARKS ON THE SAIL AND PRESSED DOWN, 77 TRIM OFF ANY EXCESS.

SAILS : SEWING THE LUFF POCKET THE LUFF , OR LEADING EDGE, OF THE SAILS HAS A POCKET SEWED ON TOIT. THE POCKET WILL HOLD A WIRE THAT IS USED TO HOLD THE MAINSAIL ON TO THE MAST. THE JIB LUFF POCKET HAS A WIRE RUN THROUGH IT, WHICH SUPPORTS THE JIB. IT IS CALLED A FORESTAY. THE POCKET IS MADE BY FOLDING A LENGTH OF 1“ DACRON TAPE IN HALF THAT IS 4 TO 6 INCHES LONGER THAN THE SAIL LUFF. THE TAPE IS PINNED DOWN AT BOTH ENDS AND TENSIONED. ONE EDGE THEN HAS 174” DOUBLE STICK TAPE APPLIED TO THE OUTER EDGE OF THE TAPE, LEAVING THE IN- NER 1/74” CLEAR OF TAPE. THE LUFF EDGE OF THE SAIL IS THEN CAREFULLY PRESSED ON TO THE DOUBLE STICK TAPE, FOLLOWING THE CURVE CUT IN THE SAIL. MAKE SURE THERE ARE NO WRINKLES IN THE SAILS, RESET THE SAIL IF NECESSARY. FOLD THE TAPE OVER ON ITSELF ON THE ExX- CESS BEYOND THE SAIL. THIS WILL GIVE A LEAD FOR THE SEWING OF THE LUFF. A SINGLE LINE OF SINGLE STITCHING IS RUN DOWN THE OUTER EDGE OF THE LUFF TAPE AS CLOSE TO THE OUTER EDGE AS POSSIBLE. TACK STITCH EACH END OF THE STITCH 78

RIGGING: MAIN SAIL — ATTACHING TO MAST ATTACHING THE MAIN SAIL TO THE MAST IS THE FIRST STEP IN RIGGING THE MAST. LAY THE MAST AND MAIN OUT TOGETHER, ON A FLAT SURFACE… ATTACH THE BOOM TO THE GOOSENECK. MOVE THE MAIN SAIL TACK TO JUST ABOVE THE GOOSENECK AND BOOM. MOVE THE LUFF AGAINST THE MAST. MARK WHERE THE LUFF EYES TOUCH THE SAIL WITH A LIGHT PENCIL MARK. INSERT A 3/716 X 36 BRASS ROD INTO THE SEWN LUFF POCKET. USE A HOT KNIFE OR SOLDERING GUN WITH A FLAT TIP, TO CREATE AN OPENING 1/74 “ LONG BY 3716 “ DEEP FOR THE LUFF EYE TO REST IN. THE MAINSAIL SHOULD FIT ON THE MAST WITH THE LUFF EYES FITTING IN THE CENTER OF THE POCKETS CUT FOR THE EYES. SCREW A SMALL EYELET INTO THE TIP OF THE MAST. BEGIN RUNNING A 60 INCH LENGTH OF #12 WIRE THROUGH THE MAST HEAD EYELET AND INTO THE SEWN LUFF POCKET. 719

RIGGING: MAIN SAIL ATTACHEMENT TO MAST FEED THE WIRE DOWN THE LUFF POCKET AND THROUGH EACH LUFF WIRE EYE. CHECK TO SEE IF THE MAIN SAIL SWINGS FREELY ON THE MAST. IT SHOULD NOT BIND OR BE WRINKLED. IF THE SAIL LUFF BINDS ON THE MAST, GENTLY PULL THE LUFF EYE OUT UNTIL THE SAIL IS FREE. THE LUFF WIRE IS PASSED THROUGH THE GOOSENECK EYELET. AT THE HEAD OF THE MAST, THE LUFF WIRE IS BENT BACK ON SELF AND AROUND THE MAST HEAD EYE. LEAVE A TAIL ON THE WIRE THAT IS LONG ENOUGH TO BE TUCKED ABOUT 1/72 “ INTO THE LUFF WIRE POCKET. CLIP THE LUFF WIRE OFF ABOUT 378” INCH BELOW THE GOOSENECK EYE. 80

SAILS: RIGGING THE JIB THE JIB IS ATTACHED TO THE MAST BY A WIRE FORESTAY. IT IS THE SAME GAGE AS THE MAINSAIL LUFF WIRE. THE WIRE IS RUN THROUGH THE LUFF POCKET. NO EYES ARE REQUIRED LIKE ON THE MAIN MAST. ONCE THE WIRE IS RUN THROUGH JIB, A SWIVEL IS ATTACHED TO THE TOP END OF WIRE BY CRIMPING THE WIRE BACK ON TO ITSELF. THE WIRE AND SWIVEL SHOULD EXTEND 1 INCH BEYOND THE HEAD OF THE SAIL THE LOWER END OF THE WIRE IS ATTACHED TO THE TIP OF THE JIB BOOM BY RUNNING IT THROUGH THE EYE AND CRIMPING THE END BACK ABOUT 3/74 INCH. 81

BOWSERS RIGGING : BEFORE THE STANDING RIGGING, SHROUDS, CAN BE ATTACHED TO THE MAST; SEVEN BOWSERS MUST BE FABRICATED. A BOWSER IS NAUTICAL TERM FOR A TOGGLE, WHICH IS A FRICTION DE- VICE THAT ALLOWS THE TENSIONING OF THE SHROUDS WITHOUT TYING A KNOT. A BOWSER IS MADE OF BY MAKING THREE HOLES IN A PIECE OF FLAT STOCK. A LINE IS THEN WOVEN THROUGH IT, WHICH CAUSES FRIC- TION . THE BOWSERS FOR THE RIG ARE MADE FROM THE TAIL OF A 5/16 “ WIDE TAIL OF A NYLON ZIP TIE. A BENT NAIL IS HEATED TO CHERRY RED WITH A PROPANE TORCH AND SERIES OF 3 HOLES ARE BURNED DOWN THE CENTER LINE OF THE TIE, ABOUT 178” APART LEAVE 1/74” OR MORE BETWEEN SETS OF HOLES. USE A CHISEL TO SCRAPE OFF THE MELTED NYLON FROM BURNING THE HOLES. CUT INDIVIDUAL PIECES FROM THE STRIP, LEAVING ABOUT 1/78” ON THE ENDS. THE BOWSERS CAN BE SHAPED TO OVALS BY SANDING THE ENDS OR 82

SPREADERS RIGGING: THE SPREADERS ARE USED TO CARRY THE LOAD ON THE UPPER PART OF THE MAST BY CREATING A TRUSS. THE SPREADERS ARE CUT FROM 1/78 “ BRASS TUBE. TWO ARE CUT 3-172 “ LONG. A TUBING CUTTER IS BEST FOR CUTTING THE TUBE. AN ALTERNATE USE IS TO USE THE WIRE CUTTER IN NEEDLWNOSE PLIERS AND CUT THE TUBE 3/78 “* LONGER AND THEN GRIND IT BACK ON A GRINDING WHEEL EYES TO HOLD THE SHROUD AT THE END OF THE SPREADER ARE MADE FROM 1716” STAINLESS COTTER PINS. INSERT A PIN IN ONE END OF THE SPREADER TUBE AND SWAGE THE END WITH NEEDLE NOSE PLIERS. SPREAD THE COTTERPIN SLIGHTLY BEFORE INSERTING IT IN THE SPREADER. THIS KEEPS IT FROM SLIPPING OUT BEFORE IT IS SWAGED. 83

RIGGING: DECK FITTINGS AND LAYOUT af THE CHAINPLATE AND SHEET EYES ARE LAID OUT AND INSTALLED BEFORE THE SHROUDS CAN BE RIGGED. USE A TEMPLATE WITH AN INDEXING HOLE THAT USES THE MAST HOLE. AFTER ALIGNING LINE. THE TEMPLATE TO THE CENTER- USE AN AWL TO MARK THE FITTING LOCATION OF THE JIB BOOM ATTACHMENT, JIB SHEET FITTING AND CHAIN- PLATES. THE MAIN SHEET FITTING IS LOCATED SEPARATELY. OPEN THE CHAINPLATE EYELETS SLIGHTLY, SO THE SHROUDS CAN BE SLIPPED ON AND OFF. DRESS THE THREADS WITH PARAFFIN WAX, FOR EASE OF INSTALLATION. ( IT REALLY DOES MAKE A DIFFERENCE) THE HULL IS NOW READY FOR RIGGING. 84

RIGGING: SHROUDS THE SHROUDS HOLD THE MAST IN PLACE AND TAKE THE LOAD PUT ON THE MAST BY THE SAILS . THE MORE THE BOAT HEELS THE GREATER THE LOAD ON THE SHROUDS THE PIRATE HAS TWO SHROUDS, AN UPPER AND A LOWER. THE UPPER IS INCHES LONG AND THE LOWER IS INCHES LONG. THE LOWERS ARE ATTACHED TO THE MAST BY TYING A SOFT EYE, WHICH GOES OVER THE SPREADER ON THE OPPOSITE SIDE OF THE MAST AND AROUND THE MAST. TIE THE EYE AS CLOSE TO THE MAST AS POSSIBLE, BUT NOT ON THE MAST, SO THE LOWER RUNS SMOOTHLY TO THE EYE IN THE DECK. RIG A BOWSER TO THE OTHER END OF THE SHROUD. SLIP THE LOOP FORMED THROUGH THE EYE IN THE DECK AND TIGHTEN UP REPEAT THE PROCEDURE FOR THE OTHER SIDE OF THE MAST. THE UPPER SHROUD IS DONE THE SAME WAY, EXCEPT THAT THE SHROUD IS THROUGH THE SPREADER EYE RUN AND AN EYE AT THE HEAD OF THE MAST. THE UPPER SHROUD USES THE SANE EYE AS THE LOWER. SEPARATE EYES ABOUT 1” APART CAN BE USED, BUT IT IS NOT NECESSARY. 85

SHEETS RIGGING: EACH SAIL HAS A SHEET, A LINE, WHICH CONNECTS THE BOOM AND SAIL TO THE BOAT. IT IS THE MEANS BY WHICH THE SAIL IS TRIMMED, CONTROLLED, EACH SHEET HAS BOWSER, WHICH ALLOWS FOR ADJUSTMENT WITHOUT TYING A KNOT EACH TIME THE SAIL IS AD- JUSTED. THE MAIN SHEET IS THE LONGEST, IT STARTS WITH AT AN EYE ON THE AFTER DECK, GOES THROUGH AN EYE ON THE BOOM, THROUGH A BOWSER AND THEN THROUGH AN EYE ON THE MAST. THE JIB SHEET FOLLOWS THE SAME PATH, EXCEPT THAT IT GOES THROUGH THE BOOM EYE AT THE SWIVEL. THE SHEETS ARE TRIMMED TO BALANCE THE BOAT. 86

PAINTING: TOPSIDES OVERVIEW: PAINTING IS THE LAST STEP BEFORE RIGGING THE BOAT. IT CAN BE AS TIME CONSUMING AS ONE CHOOSES IT TO BE. A GOOD CHOICE IS A 3 FOOT PAINT JOB, I.E— IT LOOKS GOOD FROM THAT DISTANCE. TECHNIQUE: SEVERAL THIN COATS ARE PREFERABLE TO ONE THICK ONE. THIN COATS DRY QUICKLY AND FLOW ON SMOOTHLY. THERE ARE TWO BASIC CHOICES IN PAINTING, SPRAYING OR BRUSHING. IN EITHER CASE, PREPARATION PRIOR TO PAINTING WILL DETERMINE THE QUALITY OF THE FINISH. THE PAINT SCHEDULE IS AS FOLLOWS FOR A TWO COLOR HULL: SEALER — 2COATS —CLEAR TAPE OFF WATERLINE FOR TOPSIDE & DECK PRIMER TOPSIDE — 2 COATS PUTTY – SAND — 150 & 220 GRIT PRIMER – SAND 220 COLOR COAT 1 COLOR COAT 2 SAND LIGHTLY — 220 GRIT COLOR COAT 3— LET DRY 2 DAYS TAPE WATERLINE ON TOP EDGE OF EXISTING TAPED WATERLINE REMOVE OLD TAPE 87

PAINTING: BOTTOM & DECK PAINTING THE BOTTOM IS DONE IN THE SAME MANNER AS THE TOPSIDES. PRIME — 2 COATS SAND 150 &220 PUTTY SAND PRIME SAND 220 COLOR COAT 1 COLOR COAT 2 SAND 220 — IF NECESSARY COLOR COAT 3 RUDDER BLADE — PAINT AT SAME TIME THE DECK IS VARNISHED ONCE THE HULL IS PAINTED. TO KEEP VARNISH FROM RUNNING DOWN THE HULL, MAKE A TAPE DAM BY RUNNING MASKING TAPE AROUND THE HULL AT THE SHEER AND1 /8 “ ABOVE THE SHEER. BUILD UP THE VARNISH WITH THIN COATS. SAND EVERY OTHER COAT WITH 220. SIX COATS WILL GIVE A NICE FINISH. A PAINTING STAND CAN BE FABRICATED BY CUTTING THE DECK CAMBER INTO THE END PIECES AND COVERING THE SUR- FACES WITH FOAM. 88

RADIO CONTROL: RUDDER AT THE PRESENT TIME ONLY STEERING IS USED IN THE BOATS. THE RC UNIT USED IN THE BOATS IS THE JRC “ BEAT GEAR” UNIT. IT HAS TWO CHANNELS. THE CONNECTING ROD IS MADE OF 2- 56 THREADED ROD, TWO STOP NUTS AND THE SNAP ENDS. THE ROD IS APPROXINMATELY * LONG. THE ROD IS THEN ATTACHED TO THE BELLCRANK ARM. ATTACH TO THE MIDDLE HOLE IN THE ARM. THE LONGEST SERVO -ARM SUPPLIED IN THE RC KIT IS USED. TO PREVENT INTERFERENCE, THE AFT FACING ARM IS CLIPPED OFF. A BASE AND HOLDER ARE FABRICATED FROM PLYWOOD. THE BASE IS SCREWED INTO THE HULL BETWEEN THE KEEL BOLTS. THE HOLDER WITH THE SERVO IS THEN SCREWED INTO THE BASE. THE RECEIVER , BATTERY PACK AND ON-OFF SWITCH ARE HELD IN PLACE BY USING VELCRO TABS. THE RECEIVER AND SWITCH ARE PLACED UNDER THE DECK AMIDSHIPS, NEAR THE SERVO. THE BATTERY PACK IS PLACED IN FRONT OF THE SERVO. NOTE: REGULAR AA BATTERIES WILL LAST FOR HOURS. DO NOT BY RECHARABLE ONES. 89

RADIO CONTROL : RUDDER 90

APPENDIX 1 TOOL LIST HAND TOOLS TRIM PLANE – STANLEY BLOCK PLANE – LOW ANGLE SPOON PLANE CHISEL~ 1 INCH CHISEL ~ ‘/2 INCH GOUGE – 1 INCH GOUGE – ‘/2 INCH RASP 12 INCH HALF ROUND TAPERED — ROUGH RASP 10 INCH HALF ROUND TAPERED — MEDIUM FINISHING FILE ~- HORSESHOE RASP – 8SINCH 6 INCH 3/716 FILE – RAT TAIL MALLET HAMMER TRIFSQUARE — 6 INCH DIVIDERS — 8 INCH HAND DRILL SAW ~ JAPANESE OR FINE TOOTH SCISSORS HoT KNIFE PROPANE TORCH NEEDLE NOSE PLIERS 91

POWER TOOLS BAND SAW 9” OR BIGGER VARIABLE SPEED DRILL 3/78 OR 1/2 INCH DRILL PRESS DRILL BITS 1/2 INCH ( BRAD POINT — IDEAL ) 1/4 INCH 3/16 INCH – 8 INCH SHANK 1716 INCH #50 FORSTNER BITS HOLE SAW – 2-1/4 INCHES 92

APPENDIX 2 MATERIALS HULL & DECK 3/4 X 6 SUGAR PINE 16 FEET 12 X 48 MAHOGANY DOOR SKIN — DECK JIGS & PATTERNS 4X 4X8 HARD BOARD aX 12 X 48 PLYWOOD 3/4X 12 X24PLYWOOD-~3/4 PLYWOOD (HALF SHEET) ~ LAMINATING BOARD -SHAPING JIG – MISCELLANEOUS JIGS 2 lax8B8NC CARRIAGE BOLTS 2 Va X2-172 NC CARRIAGE BOLTS 2 la X71 2 ‘t/4 WING NUTS FENDER WASHERS KEEL LEAD BALLAST – PRE-CAST 2 10/724×6” MACHINE SCREW 2 10/724S.S. NUTS 2 10/724S.S. FENDER WASHERS — 1INCH RUDDER 3/716 BRASS TUBE 4INCHES 7/32 BRASS ROD 6 INCHES #18 ESCUTION PIN 93 LIST

MAST /2 X 142 X 60” RED CEDAR – MAIN MAST 6 3 1/16 COTTER PINS – CUT TO S/8” LENGTH # EYELETS 1 2/754 THREADED ROD – 2-1/2 INCHES 2 2/54 Nuts (2 EACH) 6 1/716 S.S. COTTER PINS 2 178 X3 BRASS TUBE BOOMS 5/716 X 24” RED CEDAR – MAIN BOOM 5716×5/16X 12 RED CEDAR – JIB BOOM X # #£«-EYELETS X # #£«-EYELETS 4 #EYELET~- GOOSENECK & SPREADERS IFT INSIGNIA CLOTH ~- SQUARE FOOT 3BFT TAPE~- SINGLE SIDED 3 ELECTRICAL ZIP TIES – BATTENS GFT LUFF WIRE – #12 GALVANIZED STEEL RIGGING 20FT 2 9O0OLB DACRON KITE STRING SWIVELS ~- 40# S.S. 12IN ELECTRICAL ZIP TIE # TAIL 7 BOWSER – 3 HOLE 4. Ba EYELETS – DECK FITTINGS 94

CRADLE 1 BASE 3/4 X 2 UPRIGHTS ‘/74X 7X9 6 SCREWS 17 X 6 Woop #6 X 3/4 PLYWOOD ROUND HEAD 12IN 3/4 PIPE INSULATION – PADDING ADHESIVES POLYURETHANE GLUE ~- ULTIMATE GLUE G-5 EPoOxy KIT — SMALL ULTRA LIGHT FAIRING – POLYESTER PUTTY SPRAY ADHESIVE PLASTIC SQUEEGEE BUNGEE CORD 1/4” – 12FT ABRASIVES 40 GRIT SANDPAPER~ ADHESIVE BACKED 80 GRITSANDPAPER- 120 GRIT SANDPAPER- 220 GRIT SANDPAPER – “ “6 “ ‘6 ‘6 ‘6 PAINT MASKING TAPE 2/2” – 3M BLUE PAINT THINNER VARNISH CHIP BRUSHES — 1 INCH TACK RAG 95

SAFETY EQUIPMENT VINYL GLOVES SAFETY GLASSES & GOGGLES DUST MASKS SAILS 1TYD 6’ 1FT SAIL CLOTH -X OZ DACRON 1° LUFF TAPE — DACRON SIGNAL CLOTH 2” 3’ 1/4 DOUBLE SIDED TAPE DETAILS: LUMBER SUGAR PINE 16LINEAL FEET 7/4 X G6 OR 8 — PATTERN GRADE DOOR SKIN 12X48 RED CEDAR 2X2xX6 OR COMMON LENGTH — FASTENERS & METAL PARTS 2 4X8 2 174 X 2-172 2 MAHOGANY CARRIAGE BOLT CARRIAGE BOLT 1° FENDER WASHER WING NUTS 10/724xX6 10/724 NUTS MACHINE SCREWS STAINLESS STEEL 1° FENDER WASHERS STAINLESS STEEL 7/32” BRASS TUBE ~ RUDDER TUBE 3/716” RUDDER SHAFT BRASS ROD – 96 CLEAR

X # EYELETS ~GOOSENECK AND CHAIN PLATES X # EYELETS – MAST & SAILS 1 2/56 X 2-1/2” 2 2/56 NUTS SPREADER ROD — BRASS 1716 X 3/4 COTTER PIN – STAINLESS STEEL 10° #12 STEEL WIRE — GALVINIZED — LUFF WIRE RADIO CONTROL JRC BEAT GEAR —- 2CHANEL 97 75 MHZ

98

99

100

101

102

103

104

105

106