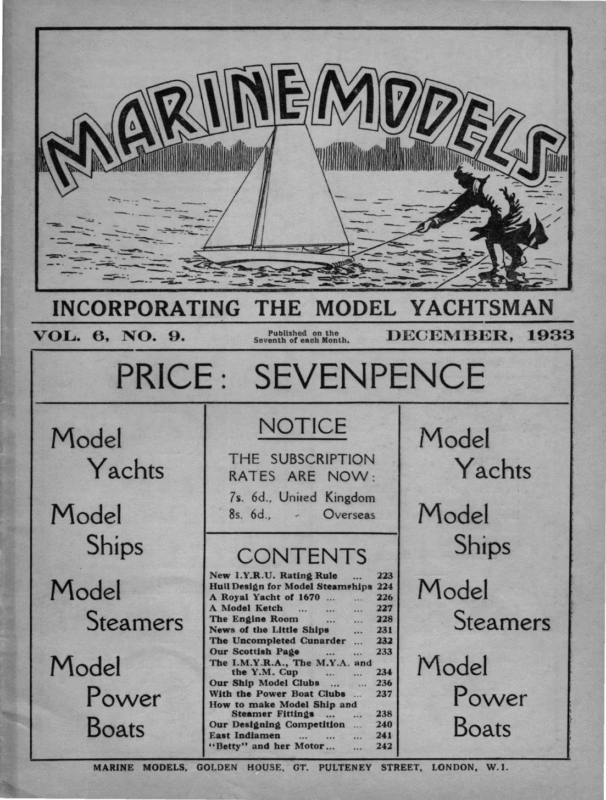

Qin el —— VOL. 6, NO. 9. sear of cutie PRICE: Yachts THE Model SUBSCRIPTION RATES ARE NOW: Yachts 7s. 6d., United Kingdom Model 8s. 6d. Ships – Overseas CONTENTS Model Model New I.Y.R.U. Rating Rule… 223 A Model Ketch… _. 0) Oe … 232 ._…._.. 233 A Royal Yacht of 1670 … .. 226 Hull Design for Model Steamehips 224 Steamers Model Power Boats MODELS, 1933 SEVENPENCE NOTICE Model MARINE DECEMBER, Seventh of each Month. News of the Little Ships The Engine Room Our Scottish Page the Y.M. Cup eu.) sae the Power Boat Clubs .. 237 | With ae aS. Our Designing Competition .. 240 East Indiamen nae a .. 241 The I.M.Y.R.A., The M.Y.A. and Our Ship Model Clubs… ___…. 236 Steamer Fittings… «bite ee ‘*Betty’’ and her Motor… … 242 GOLDEN HOUSE, GT. M tao 228 SE _……_… The Uncompleted Cunarder Ships PULTENEY O € d S | teamers Model P ower B oats STREET, LONDON, W.1.

‘Model Sailing A-class Championships | World and British Empire, Fleetwood, 1933. Craft Winner ‘‘GLENGARRY’”’ By W. J. DANIELS and H. B. TUCKER TEST WATERPROOF GLUE Built by Mr. W. J. DANIELS and constructed with THE ONLY GLUE FOR BOAT BUILDERS Crown 4to., 260 pages, Tins containing 20z. 6d., post 2d. 230 illustrations 25/- net, Postage 9d, Test Dept. M. &@ Designing Building made by reading easier & Hall, ENQUIRIES Ltd., 4 ‘ Model Yachting Association OTICE be is given Fixture List for made out at the Council Hon. Meeting on Secretaries of that the 1934 will inst. W. J. DANIELS, Affiliated 331, St. John Street, Clerkenwell, waters, dates, Phone: Clerkenwell 4708. etc., before the Meeting. The Annual will be held General on Meeting Nominations for election of Officers and Council should be in the Secretary, hands of the London, E.C.1. / MODEL YACHT SAILS” Saturday, Jan. 27th. be to Order If you want the best yacht, sails, spars or fittings, you must go to Daniels. Send a stamp for list. Statutory 21st built to any size or Class. Sails, Fittings and Spars Clubs are invited to send in any suggestions as to 4 yi Model Yachts 4 INVITED. Championships (A-class) were held in 1923. In eleven years Daniels’ boats have been successful seven times, including this year. No other builder can approach this record. Obtainable from the Offices of MARINE MODELS, all Bookshops and Libraries, or direct Publishers, Chapman TRADE The first British and International book. 11, Henrietta Street, London, W.C.2. Co., 30, Red Lion Street. Holborn, W.C.1 of Success ! this ‘*MODEL”’ Text- from the Waterproof Glue or Record Sailings are 41lb. 1 9, post 4d. a speciality. Hon. Carefully designed and adjusted. Of the BEST UNION SILK. M.Y.A., by Jan. 3rd. Reasonable in Price. Correct Fit. C. N. FORGE, W. (HON. SECRETARY), f 151, Lichfield Grove, CAINS, Sailmaker, London, N.3. y, . 7; KING’S ROAD, GOSPORT, HANTS, | In replying to Advertisers, please mention MARINE MODELS.

was sess \ANAANN seneetnatengrnabsecereerrasassesecs NAUUvt ss ayaa te as =} TECHNISAL| ms — = INCORPORATING THE MARINE Vol. 6, No. 9. MODEL MODEL YACHTSMAN AND MAGAZINE Published on the Seventh of each Month. DECEMBER, 1933 MODEL YACHTING ASSOCIATION. ALTERATION T OF LY.R.U. FORMULA. the International Yacht Racing Union Conference held in October last, it was unanimously decided to alter the Rating Rule for yachts of 14} metres and under, as it had been found that certain undesirable tendencies had manifested themselves under the old rule as recent yachts had become too long and narrow with pinched bow sections. In order to conserve vested interests it was decided that yachts built under the old rule of 1920 should be allowed to race with new craft until January 1, 1937, but that the new rule should come into operation immediately and be in force until October 1, 1939. The differences between the old rule and the new consist of the deletion of the factor “ G,” a new method of taking “* L,” including a different method of calculating the “ bow tax,’ and an adjustment in the constant used as a divisor under the formula. THE NEW 1.Y.R.U. L +26 + 48-55 FORMULA. = Rating. 2°37 The length “‘L’’ for the formula is to be the length measured at a height of 1.5 per cent. of the Class Rating above the L.W.L. plus one and one-half times the difference between the Girth at the bow section measured to points 5 per cent. of the Rating above “L”’ and twice the vertical height from ‘‘ L ”’ to those points, plus one-third of the difference between the girth, covering board to covering board, at the stern ending of this length, and twice the vertical height at the side of the yacht at this station. The minimum difference of girth at bow station, as above defined, to be 30 per cent. of twice the said vertical height. On the subjects of Limits for Balloon Jibs, Jib Hoist, Sheeting of Genoa Jibs, and the method of measuring Spinnakers, the existing Rule (1933) was left unchanged. In every other respect the method of measurement remains absolutely unaltered. In explanation of the changes in the method of taking the Bow Girth Difference, it should be noted that this is now taken to points 5 per cent of the Class Rating above the L.W.L. instead of right up to the covering board as formerly. On the other hand, the Stern Girth Difference is taken from covering board to covering board as formerly. Tue L.Y.R.U. Formuta As Appiiep TO MODELS. In view of the popularity of the 6-metres (1% in. = 1 ft. O in.) and 12-metres (lin. = 1 ft. 0 in.), particularly in Scotland, the Council of the M.Y.A. recognising the importance of these changes, and in response to numerous enquiries from Affiliated Clubs, considered it imperative to make a prompt announcement thereon. Subject to ratification by the A.G.M. the Council recommend as follows :— 1—That the above New Formula and Rule be adopted for all New models of the 6-m. (1f in. = 1 ft. 0 in.) and 12-m. (1 ft. = 1 ft. Oin.) classes—as from this date and until Jan. Ist., 1937. 2—That Old Formula and Rule (1920-33) continue in force for all existing wnaltered models until Jan. ist, 1937, when it expires, during which period the alteration of Old Rule yachts shall be at the option of owners. 3—That yachts rated under either Rule shall have the right to race together on equal terms—and both Rules to run concurrently until Jan. Ist., 1937. 4—That Rating Certificates must show whether measured under New or Old Rule. Note—In the New Rule—‘ 5 per cent. of Rating above ‘L’’’ should be interpreted as 1.62in. for 6-m.. and 1.9in. for 12-m. models. For the benefit of Measurers it may be mentioned that 1.62in. can conveniently be taken as equivalent to 1% in.

224 Presuming that the above recommendations are adopted, as there is little doubt that they will be, it will be seen that the owners of existing models are fully protected, as they are at liberty to race them without alteration if they wish. On the other hand, an owner may apply the rule at once to his boat, and possibly have the advantage of additional canvas if desired. His choice will no doubt depend on his boat, but in any event, all [IW RU. MetHop models to the 6-metre and 12-metre Classes will fall under the new rule in January, 1937. [We have to apologise that in Major Holden’s article on the new formula which appeared in the November issue of MARINE MODELS, there was a mistake in the formula quoted, as the “2d” was printed as ““d.” This perpetuated a mistake made in one of our leading daily papers.—Ed., M. M.} Formuta-— Octoper,1933. of Measuring Bow & STERN GirtH DIFFERENCES. LM = I-S per cent of Class Rating. PM = Freeboards at Bow & Stern as used Say F measurement. Ol = 5 per cent of Class Rating. OLO-20V = Bow Girth Difference. PLP-2 PX = Stern Girth Difference. HULL DESIGNING FOR BUILDERS OF WORKING MODEL STEAMSHIPS. (Continued from page 198). By ATLANTIC. N a full-sized vessel] the most elaborate calculations are necessary to ensure the vessel having the correct fore-and-aft trim, but in a model these can be greatly simplified—in fact, reduced to child’s play. Nevertheless, it is necessary to understand the principles on which these are worked. In the days of our childhood most of us played see-saw with a plank of wood and a convenient log or stump. This childish game contains the whole secret of balance. 4 a _ eee SF iw Be rc When you played see-saw the other little boys were not always the same weight as you. You rectified matters by the distance out you sat. Put more scientifically, you adjusted the length of the lever arm until an exact counter-balance was obtained. I cannot draw two boys, so I have put two weights of 50 lbs. and 70 lbs. respectively in Figure 17. The plank is 16 ft. long. Now, the 50 lbs. weight is shown 7 ft. from the balancing point (or fulerum). It, therefore, exercises a force of 50 x 7 {=350) foot pounds. The 70lbs. weight is 5ft. from the fulcrum, and consequently exercises a force of 70 x 5 (= 350) foot pounds. In other words, an exact balance is obtained. It does not matter what the units used are (they can be inches and ounces, metres and kilos), the principle is the thing. In order to ascertain the power exercised by any force applied by means of a lever, the force is multiplied by the length of the lever. Let us take another instance to show the application of this principle to model marine architecture. A steamer model, 6 ft. long, has the C.G. of her plant 8ins. aft of the C.B., and the plant weighs 20 lbs. How much ballast must be placed 2 ft. 1 in. forward of the C.V. to counteract her tendency to squat by the stern ? The engine’s 20 lbs. have their C.G. 8 in. aft of the C.B., and, therefore, exercise a power of 20 x 8 (= 160) inch pounds. The ballast is to be put 25 in. forward of the C.B., and must, therefore, have a weight of 160+25 (= 6%) lbs.

225 This process of calculation is known as * taking moments,’ and is very important in all naval architecture. It is used to ascertain the C.G. of a whole vessel. The application is somewhat more elaborate, however. What is done is that each part of the vessel is listed, the weight and C.G. calculated. Using some suitable part of the vessel as fulerum, moments are taken out and averaged. This gives the position of the C.G. It is not necessary to list and calculate every part of a model in this elaborate way, but what we can do is to calculate trimming ballast, etc. Let us assume a 50-in. model with a calculated displacement of 43 lbs. to have its C.B. (and, therefore, C.G. also) full 28 in. from the bow. The C.G. of the hull is found, by balancing on a knife blade, to be 30 in. from bow, and by weighing it we find it is 8lbs. Similarly, we get the weight of the other parts. They are then tabulated and we use the distances from the bow as the lengths of the lever arms. Moments are taken and we can thus ascertain the position of the C.G. of the whole mass. If we take it out without the ballast we can easily calculate the position for this. The calculation is tabulated below. Distance Weight Holl sen >. Deck and Super- structure… we Engine … wet Boiler … ie Lamp … in lbs. 38 3:5 «=« BH 2 Moment. x from bow. 30 = 240 x > x x 26 35 29 20 =) = = = 19] 227-5 348 30 31-5 936-5 It will be seen that the Weights are multiplied by the Arms to obtain the Moments. The weights are totalled and also the Moments. The Sum of the Moments is divided by the Total Weight, which gives the average length of Arm (or position of C.G. of the mass), We have accordingly to divide 936-5 by 31-5936°5 + 315 = 29°73 The C.G. mass is, therefore, 29-73 from bow. We have 43 — 31-5 (= 11-5) Ibs. of ballast now to place, so that the C.G. of the vessel will come at 28 in. from bow. The model, minus ballast, weighs 31-5 lbs., and its C.G. is 29-73in. from bow. This is 1-73 in. abaft the C.B., and she will be by the stern unless the ballast is put ahead of the C.B. Taking the C.B. as the fulcrum of our see-saw, we take the moment for the model. 1-73in. = 53-895inch lbs. The 31-5 Ibs. ballast weighs 11-5 lbs. and must be placed 53-895 + 11-5 (= 4-69 approx.) inches forward of the C.B. Sometimes a model lacks stiffness. either the weights are too high or parts have come out heavier than anticipated. Another contingency is that one decides to add something to the model or change a light part for a heavier one. Under such cir- cumstances it is an advantage to be able to calculate what additional weight will be required to put the model down any given distance below her original L.W.L. By the same calculation one can find out how much to take out of a model to lift her a certain distance. The first step is to ascertain the area of the L.W.L. plane. This can be done by counting the squares on the half-model on the W.L. plan. It is doubled for the whole L.W.L. plane and adjusted for scale. Let us take a boat with L.W.L. plane of 300 square inches. If we put her down 1 in., the displacement would be increased by 300 cubic inches. If we put her down 1/10 in., the increase would be 30 cu. ins. As a cubic inch of fresh water weighs 0°5786 oz., the increase of displacement for 1/10 in. would be 30 x 1 lb., 1°4 oz. °5786 0z. That is 17°358 ozs., say One thing that often misleads model designers is that they do not allow enough for the weight added by paint. On a 6ft. model the paint will weigh nearly 14 Ibs. (T’o be continued.)

H Rowl Back S8x, C2 Salisbury, of J670. (Continued from page 215). HE bulkheads are now fixed, and their ends shaped to act as top timbers. Where necessary, windows and doors were pierced in them. Also, in the well, two vertical saw cuts are made in either side of the fore and aft bulkheads, so that the pieces of wood which form the sides of the well and represent the doors of the lockers under the gangways, may be slid down them and held securely. Extra top timbers are fitted where the running backstays are secured: to the sides. Next the inner bulwark planking is fitted. It is sprung into place out of a wide piece of 4in. sycamore, its fore end fitted into the rabbet in the bow piece, and the after end into a shallow rabbet in the edge of the deckhouse bulkhead. Pieces of wood are glued between the top timbers where the shrouds are secured, to fill in the space between inner and outer planking and give a solid fastening for the plates of the deadeyes. The stern is next considered. The solid stern transom already extends as high as the wing transom ; above this is the arching counter. This is made of a single piece of boxwood fitting into the angle between the top of the stern transom and the aftermost frame. In the centre bore a hole large enough to take the stern post and rudder post. The upright stern timbers are tenoned into the top of the counter piece by boring a shallow ;-in. hole for the mortice, and making the tenon on the foot of the timber round to fit it. This method of tenoning is very quick and strong. The tops of all five stern timbers are fastened to a broad transom, which extends from the top of the cabin windows to under the poop deck, which is fastened to it. The two side timbers reach to the top rail, and to them the side planking is fastened. The three inner timbers only reach a little above the windows, and above them and between the side timbers the stern piece or tafferel is glued. This is a piece of #;-in. sycamore, the carving on it being either of boxwood or Barbola paste. The roofs of the deckhouses are now made of +; in. sycamore. The ends project a little over the bulkheads, and are formed into a moulding, the sides extend for enough for the side planking to lie flush against them. The deck of the well is also fitted with the stairs to the deckhouse door, and the sides of the well slid down the saw cuts in the bulkheads. The gangways are also fastened in. The keel is now made, and also the stem. These were fastened at the fore-foot with a vertical scarf and fastened to the hull. The upper end of the stem, above the wales, is made separately and has a shoulder on the aft side to fit on top of the bow piece. On the after edges of this upper stem are formed rabbets to hold the ends of the side planking. It is then firmly pegged and glued in position. The sternpost is also fitted, and reaches from the top of the keel to the poop, The wales are now fixed and may be steamed on or made of several sawn pieces. The strake of planking between them is omitted and the frames are visible. The outer planking is put on in two strakes aside, the join being where the sheer rail will cover it. It is made of 4 in. wood and is best put on in a long length from stem to stern. It will be found that the rounding of the tumble-home will be emphasised if the lower edge of the plank is fastened to the solid part of the hull amidships. The fore end should be carefully fitted in the rabbet of the stem and also pegged, since thin wood may shrink enough to spring out. The top-sides are now levelled up and a thin covering plank glued over the gunwale in bows and waist. Aft only the thin outer planking projects above the horizontal cabins and gangways, and pieces of ; in. wood must be glued to the inner face of the planking to make the gunwale as wide as that in the waist. The upper edges should now be shaped to the sheer of the hull. The inboard details are now made of boxwood and fitted. I may here mention that the windlass and its bearings must be assembled before any part of it is fastened to the bulwarks. The hawse pipes, one aside, are bored about } in. from the stem. The details outside the hull are straightforward, the only points being that the plates of the deadeyes are curved outwards and not straight, and that the timbers in the head are straight and have carved figures on their outer face, and are not concave as in later ships. The rest of the carvings can be made of boxwood or one of the pastes sold for that purpose. The hull can lastly be finished by varnishing and gilding. In a future number of MARINE MODELS J hope to detail the rigging of this interesting and characteristic vessel, also to publish a photograph of the completed model.

bo lo N A MODEL KETCH. By J. A. Stewart. si HE photograph shows a working model to the scale of lin. = 1ft., from a design by Mr. Alfred Mylne for an auxiliary ketch, 30 ft. L.W.L., and 36 ft. over-all. This ketch was specially designed by Mr. Mylne to comply with Eng. Rear Admiral Turner’s metacentric shelf system of balance. The model was McKinnon, built Glasgow. the times by Mr. J. It is, perhaps, a sign of the that distinguished yacht designers are ready to experiment with systems and theories initiated by model yachtsmen. The little model was tested on the Lake of Menteith, and proved to be extremely docile and well balanced. When first put into the water, trimmed for a beat, it went off full and by without a falter, and its manner of breasting the steep little waves of a large open lake was a treat to watch. Although designed as a cruiser pure and simple, the easy lines and efficient sail plan give the model quite a fair turn of speed. The lateral plane is less than in many cruisers, and the effective part of it is concentrated in the stream-lined keel and skeg; but it appears to be ample under all conditions from full sail down to jib and mizen. The wake was noticeably clean, and the quarter wave, even in the hard going, was negligible. On the whole, the experiments with this model appear to indicate that a very successful cruising yacht could be built to lines inspired by model yachting experience. The mizen of a yawl is usually too small to be effective on the wind: but in the ketch, with a triangular mizen equal to the fore triangle in area, there was no doubt that the mizen was pulling its full weight. triangle Not only is the three rig one of the simplest to handle, but it appears to be extremely efficient. SEA BREEZES. We are asked to inform our readers that SHA BREEZES is on sale at the principal bookstalls throughout the United Kingdom.

228 MAKING THE VINES’ FLASH-STEAM ENGINE. (Continued from yag2 218). HE crankshaft has next to be made. If the engine is for a racing medel, probably rustless steel, will be the best, but if the boat is a runabout, silver steel can be used as it is amply strong enough and is an easier job. The crankshaft, as shown in the drawing, is made of rustless steel (No. 5), but the only difference is in the forward end. This is turned down to a taper with a shoulder as shown, and the crank web complete secured on the end with a thin nut. If this method is employed, the nut should be silver steel and must be a good fit on the threads, as the strain is very great. In fact, the whole of this part of the crankshaft must be very carefully made and fitted. The alternative is to make the crankshaft of silver steel. Mild steel is not strong enough, as it bends. If this material is used, the taper can be dispensed with and the crankshaft, web and pin (Nos. 5, 6 and 7) all brazed up together. It will probably be found easier to make up the crankweb first, and use it whilst making the crankshaft. Although the whole process of making the crankweb is described next, it will be best merely to rough it out and leave the finishing processes until the crankshaft has been made. It will be noticed that the crank web is made as wide as possible to clear the connecting rod. The after side of the crank web will be accommodated by cutting away part of the cross member of the bedplate. The amount to cut out of the bedplate will be ascertained by actual experiment when assembling. To make the crank web, turn up a disc of mild steel, centre and drill and bore out for the crankshaft, making the hole slightly smaller than the actual diameter of the shaft. Whilst the hole for the crankshaft was bemg centred, the hole for the pin should also have been positioned. As the stroke of the engine is ? in., this is } in. from the centre of the disc. It is important to get this measurement exact. If a light line is scribed round the disc on this centre dot for the crank pin with the point of the tool, it will indicate if there is any error. Obviously, if there is any error it will double itself in the circle. The hole for the crank pin can now be drilled, putting a small drill through first. It will be noticed that the balance weight in the full engine drawing is shown in one with the crank web, but it is really better to make this separately and rivet it on. Iam here referring to the thicker part on the face to the left of the Figure 6 in the drawing. No definite weight can be stated for the balance, as the actual weight of the moving parts have to be compensated, and these are sure to vary with different makers. The elementary principle is that the balance weight must be equivalent to the weight of the big end and crank pin, plus half the weight of the piston, complete with rings, gudgeon pin and small end, plus a part of the weight of the connecting rod. There is no definite rule as to what proportion of the weight of the connecting rod should be used, and there is plenty of room for experiment and tuning up by variation of the balance weight. As the web is not a full circular disc, but is cut away on either side to the shape shown in the drawing, the superfluous metal is now cut roughly away, finishing with a half-round file. It should be noted that this figure is a sketch to show the approximate shape, but can be varied in the lower part to suit the balance weight. The point to which it is requisite to carry the manufacture of the crankweb, is the drilling of the holes for the crankshaft and crankpin. As will be explained we want a little metal jig for the other end of the crankshaft. This is a temporary affair used during turning up and brazing to ensure alignment. To make this take a spare piece of the 4in. by } in. material left over from the frame, and fix it to the underside of the crankweb. This can be done by sweating it lightly on with soft solder. It will be best to support the job on a drilling pad on the back centre of the lathe, but it is a matter of little importance how this is done provided the holes are drilled dead square. Drill

* 229 through the jig two holes corresponding to those for the crankshaft and crankweb. Both of these holes in the jig will have to be opened out to take the full size of the rods forming the crankshaft and crankpin. They should be a tight fit, however. A small drill should be first run through from the web, and the job reversed and the larger drill put through from the other side. The jig is now unsweated. Cut off a length of steel for the crankshaft, taking measurements from the drawing. Cut off another length of the same material for the crankpin, but in this case the length cut must be longer than the crankshaft by the length of the crankpin. Tf the chuck is running reasonably true this can be used for one end of the crankshaft, but if not, it must be mounted between centres. The end away from the chuck must be supported with a fixed steady. The end is faced off and reduced to a tight fit in the appropriate hole in the web. Whilst still in the lathe the crankshaft should be centred with a Slocombe drill. with a hack-saw and half-round file. The balancing must be left until the piston assembly has been made. The main bearings should be made next. Two ball-races should be bought, ? in. outside, and } in. bore. The next thing is to make the housings for these. The material required is a few inches of lin. by } in. flat mild steel. These are cut to shape as Nos. 8 and 10 in tho engine drawing, the races being shown at Nos. 9 and 11 respectively. After the hole has been made. these are split from the top down to the hole with a hack-saw. The clamping screw to hold the ball- race in position has now to be fitted. The hole for the screw is bored as a clearing hole one side, and a tapping hole the other. suitable for this job. One A 4-in. screw will be little point to take note of is that the hole to take the ball-race should be a good push fit, as otherwise there will be distortion. The forward bearing is held in position by two screws from the under side of the bedplate, Take out of the chuck and insert the other piece of rod. This is turned down as much as required to fit the hole through the web, after being faced up. Before being removed from the lathe, this also must be centred. The final operation is to drill out the crankpin leaving sufficient metal for strength. This also is now taken out of the lathe. The two rods, the web and the jig, are now assembled. The latter holds the extreme ends of the rods and thus ensures their perfect alignment. It should be placed about } in. from the end. As the jib is a tight fit there is no need to fix it in any way, as it is only a temporary affair. The last thing before brazing on the web is to check the alignment carefully. Braze or silver solder the web, shaft and pin together. Let it rest on the coke and cool off gradually. When this is cool enough to handle clean off with an old file. Put the end of the crankpin rod in the chuck just enough to hold it, but no more. Support the pin itself by means of the tailstock centre. ‘lake a cleaning up cut on the pin, and then a facing cut across the web itself. Cut the superfluous part of the rod away and remove the jig. Put the end of the crankshaft into the chuck and support the web with the tailstock centre. If the correct size of the rod has been used it will only be necessary to clean the crankshaft up lightly with emery cloth. Take a facing cut across the back of the crankweb and round the edge. Take out cf the lathe and reverse. The disc that is going to become the web is now in the chuck, the other end being supported in the fixed steady. The latter must be about lin. in from the extreme end of the shaft. Mount a suitable die in the tailstock die holder, and thread the end of the shaft. The writer used } in. by 40 in. threads, but any fine thread will answer the purpose. The web has now to be shaped up as shown in the little diagram. Remove the superfluous meta, CRANK WEB BALANCE SHOWING WEIGHT- the after one by two horizontal screws through the bedplate, as shown. This is shown clearly on centreline C in the drawing. It is not advisable to drill the holes for these screws until after the cylinder has been mounted, as some fore and aft adjustment is required when assembling. If the engine is being used for flash steam, forced lubrication is essential, and it is a considerable advantage also if wet steam is being used. To make the gear drive for this, as shown at Figure 13, a piece of pinion wire can be used. This is obtainable from clockmaker’s material suppliers, such as Smith & Sons, of Clerkenwell. It must be cut to length, bored out to take the shaft and turned down to form the sleeve on which the flywheel fits. This is clearly shown in the drawing. It will be noticed that the sleeve does not quite go through the full width of the flywheel, but is a fraction short on the forward end. This arrangement ensures the whole assembly being tight, as the pressure on the after end of the gearwheel and the fore end of the flywheel pushes the two firmly together all the time. The pinion wire is cast steel and should be hardened and tempered when ready.

2350 The writer made his own gearwheel and sleeve from a piece of steel shafting, and proper involute teeth were cut. This is a good method and can be recommended to those facilities for the job. who have the necessary As it is easier to fit the sleeve to the flywheel than vice versa, it will be as well to rough the flywheel out before making the sleeve. The flywheel is made of a suitable piece of mild steel shafting, which is roughly turned to shape. The hole for the sleeve is carefully bored out. The flywheel is a press fit on the sleeve. After the hole has been bored the sleeve can be made to fit, and in order to ensure it being a really tight fit a very slight taper is given to the sleeve. This is only a fraction of a thou’, and can be made with a fine file. If the pinion is being tempered, this should be done before the sleeve is finally pressed home into the flywheel. The method of hardening used by the writer will not be found difficult. The work is brought to a red heat, but must not be so hot that it burns. It It will be noticed that there is a thin distance piece between the pinion and the after main bearing. If the builder happens to have an end of steel tube of }in. bore, he can simply part off in the lathe, otherwise it will have to be made. The lock nut (No. 12) on the after end of the shaft can now be made. This is mild steel and is turned up to din. diameter. It is then turned to shape with the two grooves as shown. The two flats for the spanner are filed up to a convenient size. It is then centred. and drilled out for the square part with a drill not larger than in. The remainder of the lock nut is bored out with a }-in. tapping drill. As a matter of fact, the hole must be deep enough to allow the tap to get right through the length of the lock nut. It is important to get the hole true. It is now threaded through. Icave the job in the lathe temporarily. it will be too brittle. Wipe the oil off and polish with emery cloth for a sufficient space to watch the colours in the metal as they change. Again heat the metal. The colours range from a light straw through a darker colour until they turn blue. The blue represents the condition when the steel has been completaly “let down,” and the light straw is the The next thing is to make a square drift, which is used to form the square hole in the lock nut. Take a piece of }-in. square silver steel, and file the end up dead square. The idea is to get good sharp edges to make it cut properly. This has to be hardened and tempered at the business end. When the drift is made, the hole in the end of the lock nut will have vo be opened up sufficiently to permit the drift to just enter. This registers it so that the square hole is in perfect alignment. Probably the best way is to cone it with a boring tool. An alternative method would be to use an 44in. drill and bore out a shallow recess before hard ‘st part. starting to drill out. In the present instance we want to harden the pinion whilst leaving the sleeve soft. Hence, the hardening process should be carried out on the pinion end only. In tempering the heat should be applied at the end of the sleeve next the pinion. The colours will flow along the metal until the sleeve is blue and the pinion is left a dark straw. The work is now quenched. If the oil has got hot the quenching will be too slow, so sufficient should be used to avoid the temperature rising too fast. The part of the sleeve that is inside the flywheel may have contracted owing to the pressure of the flywheel and, if so, must be opened out sufficiently The lock nut is placed on a stout piece of hard wood, or better still, on a block of lead, and the drift hammered in. It must, of course, go in dead straight, and any tendency to tilt or cant over must immediately be corrected. Clean up inside. The square end can, with advantage, be case-hardened, as it will make for long wear. The outside can be cleaned up with is then quenched in oil. Any ordinary lubricating oil can be used, but not paraffin. The next step is to temper the work, as otherwise with a reamer, from the forward end. Care should be taken in pressing the sleeve into the flywheel not to get it out of true, or distortion will occur. The easiest method is to do this in the vice. Take a fresh piece of }-in. rod and cut off a piece a little longer than the sleeve. This is used to form an arbour, on which the sleeve is mounted whilst the flywheel is finally turned up. This is threaded at each end, and a small piece of tube put on to act as distance piece. If nuts are screwed on, the whole will be firmly held together during the turning. The job is now mounted between centres and a finishing cut taken. It should be mentioned that the sleeve is a sliding fit on the crankshaft, but without any shake whatever. emery cloth. The eccentric for the piston valve (No. 14), is the last part of the shaft assembly to be made. This is combined with a distance piece. The total over-all width of the eccentric and distance piece is 23in. The drawings should be carefully studied at this point and the construction will be clear. Starting from the after end there is a flange {, in. wide. Next is the eccentric sheave, or bearing, which has a spring ring in a groove to hold it in place on the forward side. Forward of this is a grub screw that locks the eccentric solid on the shaft. The extreme forward end is turned right down until only a narrow ring is left, which rests against the main bearing. In January I will describe how to make this eccentric as it is by no means difficult if done in the proper way. I shall then proceed to describe the making of the components of the piston assembly. (T’o be continued).

— —~ SCs Ee 4 TE Z-4 Cpe rd 2 y ‘sn onto “ OF – AG of ~ ’ aoe | “ 7 SO ORS RORR— aanas Ze a “ Pe =~ A = FLEETWOOD M.Y. AND P.B.C. The 10-rater Open Race in connection with the above club was sailed on the Flectwood M.Y. Lake on September 30. The wind was east-south-east, and sixteen competitors took part. There was a good sailing breeze, and some very exciting encounters took place. The race was sailed in two squadrons of eight boats each, and the three best boats of each afterwards sailed a final which resulted :—lst, “‘ Bonito ” (T. Edwards, Birkenhead), 21 points; 2nd, ‘‘ Auderny” (T. R. Andrews, Birmingham), 18; 3rd, ‘‘ Grenadier ” (J. Kelly, Bury), 10; 4th, “ Eagle” (A. H. Law- rence), 9. The O.0.D. was Mr. Wm. M. Carpenter, of Birkenhead, con- gratulated the competitors and then introduced Mrs. Cunningham, who very gracefully presented the various prizes. This ended a very enjoyable day’s racing. The race for the Livesey Cup and Prizes by the 36-in. Restricted Class was completed on October 28. Only nine of the original thirteen starters turned out for the final heats, and the issue was grimly fought out in a very strong north-easterly breeze. When making the weather boards the yachts were subjected to a very severe buffeting, and all the time were completely awash from stem to stern. Despite this rough usage, however, so good was their gear, that to use Captain Shewan’s words (in respect of his famous clipper, ‘‘ Norman Court ”’), ** they emerged from their rough ordeal all atauto ! The winner, “ Firefly,” is a new boat only very recently completed, and this was her first real Mr. Alexander is to be complimented on trial. his fine handling of her, and especially in the strong winds which prevailed throughout the two Saturday afternoons on which the races were sailed. The second prize-winner, “ Nerenuf,” was designed, built and sailed by her owner, Mr. A. Wright, of Fleetwood. Some weeks ago she was entered, sailed and won at Birkenhead, the 36-in. Restricted Class Championship, after keen racing in a light and variable wind. This win was very. acceptable “3 ATF ee = . = — = OR, BY THE QUARTERMASTER. the subject, and a general discussion of the progress NORTH OF ENGLAND. and future policy of the Society. MANCHESTER MODEL SHIP SOCIETY. (Lancashire & Cheshire.) At our meeting on October 26th, Dr. Naunton, our Vice-Chairman, gave a paper on hulls and rigging from the point of view of the beginner, and illustrated it with two models of his own. Dr. Naunton made a great feature of the point that common sense should be used to a much greater extent than was evident in many models that were seen, in that any part of a ship’s rigging that was not made in such a way as to work to the best advantage when in use on the prototype, was obviously incorrect. He pointed out that when a seaman rigged any portion of a ship he fastened his ropes in such a way that they would do the necessary work with the minimum of labour, and that some modellers evidently lost sight of this fact. The meeting that followed on November was divided between a with the Manchester Ship Canal the 9th of lantern Jecture and Docks as Arrangements are well in hand for our exhibit at the Exhibition to be held at the City Hall, Manchester in January next, for which purpose a sub-committee has been appointed, with Mr. J. N. Authers in charge, to whom all enquiries on this matter should be addressed. Mr. Auther’s address is: 4, Rydal Avenue, off Grosvener Road, Sale, Cheshire. It is proposed to offer prizes for what are considered the best models exhibited on our stand, in addition to these that are to be offered by the Exhibition organisers. For our meeting on December 7th, Mr. W. F. Hemingway has scoured the country in a search for any sub-standard cine films that might prove of interest to lovers of ships and the sea, and a very fine programme is assured. The last meeting of the year, on December 21st will take the form of a “club models” evening, when the various parts of the trawler and topsail schooner under construction will he brought along for inspection and approval by the subcommittee. Hon. Secretary :—H. Park Avenue, Sale. Griffiths, Moorlands, 27,

LIVERPOOL. THE SHIP MODEL SOCIETY. The Exhibition over, we are now getting down to the regular meetings of the winter session, and a very interesting syllabus is being prepared. Last year every meeting was a “Lecture Night,” but it was found that this arrangement was too rigid, and did notallow for the impromptu discuss- ions which are always so interesting. Accordingly, papers will only be read on alternate Fridays, leaving the intermediate meetings open for informal gatherings. Among the papers already arranged are :—THE CLIPPER SHIP “LIGHTNING,” by Captain Norman Forbes; MARITIME PRINTS, by Mr. H. Dawson; EARLY STEAMERS ON THE CLYDE, by Capt. Kennedy, whose book on early steamers has just been published, and a paper on THE FLETTNER RUDDER, by the Secretary ; other papers are still to be arranged, and it is expected that some of these will take the form of practical demonstrations of an informative nature. In addition to the above, which are all by MEMBERS of the Society, it is hoped to induce some of the Society’s PATRONS to come and give lectures. The other day, one of the members was heard to express his opinion that all the models of present day vessels should be cleared out of the Liverpool Shipping Gallery; his view, he said, was that a museum should have a “musty, historical atmosphere” and contain records of the past, instead of being full of silver-plated modern stuff. The member in question is now being persuaded to take the lead at a debate to be held at one of the Society’s meetings, and propose the motion that “In the opinion of this Society, models of contemporary vessels are out of place in the Shipping Gallery.” One of the redhot “steamship fans” will be induced to lead the opposition, and there is every prospect of a really first-class battle. An interesting feature of this year’s winter programme is that as many as possible of the papers delivered will be printed in the Society’s magazine “SEA LORE & CRAFT” and will thus be made available to members outside Liverpool and overseas. NOTE. Owing to the closure of the Minsterly Cafe, the meetings will be held in Reece’s Bank Cafe, 14 Castle Street, Liverpool until further notice. Hon. Sec: A. R. B. Lyman, 8, Wyndham Road, Wallasey, Cheshire. GLASGOW SOCIETY OF MODEL ENGINEERS (POWER BOAT SECTION). E have had a mixed season on the whole, not so good as last year as regards attendance, but some outstanding performances have been put up. The best of these were those of Mr. Rankine with his hydroplane “‘Oigh Alba.” This boat has a w.c. two-stroke engine of 25 c.c. capacity. The ignition system is the only one of its type, as far as I know, being of the flywheel mag. order. The hull is very like a tadpole in profile, and is of the “flying tea tray” type, having straight sides, flat planes and a very deep step. She acheived a speed of approximately 31 m.p.h. at the International Regatta, on which occasion she was handicapped by a new piston which was not quite run-in. On her home waters she has achieved speeds of upwards of 33 m.p.h., never, however, being officially timed, but in any case easily beating the speed of 29:2 m.p.h. claimed as a record for 30 c.c. two-strokes in the October issue of this magazine. At the time of writing Mr. Rankine has had the misfortune to lose his boat as she pulled the pole over and hit the bank during an attempt on the record. On this occasion the boat was travelling much faster than usual, probably at over 35 m.p.h., so we must deeply regret the accident and offer our commiserations to Mr. Rankine. The flash steam contingent had its leader in Mr. Denwick’s “Mustard Minor,” which always ran consistently though sometimes at no great speed. Her best performances were 19 laps at 8°9 secs. per lap, and 3 laps at just under 7 secs. per lap. Considering that the engine has lasted three seasons running, using three hulls, two flash boilers and three blowlamps, without serious overhaul, its performances are amazing. Unfortunately on the last day of the season, it objected to some specially white hot steam, and the slide valve came loose on its spindle. Mr. Lindsay’s “Babs” put in some good laps but was unreliable, while Messrs. Jeffries and Peacock had no success with their patent boiler designed to do away with a feed-pump. The free (not straight) running boats gave some splendid showings, Mr. Todd being perhaps our

MARINE MOVELS most regular attendant, but always having trouble with the boiler and lamp of his cruiser, but being very reliable with his destroyer. By far the most spectacular boat on the pond was Mr. Murdoch’s sharpie, which made many fine runs at over 10 m.p.h., but which had not much luck. Some runs round the pole were attempted, but unsuccessfully owing to the weight of the string. In this connection the writer was so disgusted by having his sharpie smash on the bank on three occasions that a run round the pole was tried using fishing gut with a 20 Ibs. breaking strain fora line. This effort was rewarded by some awe-inspiring tailsitting runs! Mr. Duff’s tramp steamer was at all times to be seen plugging about the pond, itsspeed being so good that it was placed in our straight-running competition, while the successor to the ‘‘Arrow,” whose name I do not know, did some remarkable rudderless steering. A very pretty but slightly under-powered steam-yacht glided about, while on one oceasion we saw a scale model of the “Jeannie Deans” but this was not too successful. Another member with a single attendance was Mr. McDairmid, who brought a _ petrol engined hydroplane with a Thornycroft hull. This gave some good straight runs, but on being tried round the pole its crankcase opened with the inevitable result that the whole came to a dead stop with some damage to the engine. This was hard luck as she was a fine looking craft. Our notable absentees were Mr. Moore with his fast and smooth running oscillating engined liners, who if memory serves, was only present at our Edinborough visit, and Mr. Chassels of the “‘waittill-it-reaches-melting-point” flash boiler fame, who on more than one occasion was present with an ultra respectable destroyer. Our visits were all fairly successful, the best being in my estimation those to Clydebank and Edinborough. The Edinborough Society have now a very energetic power-boat section on which we may congratulate ourselves as it is largely due to our visits that it has sprung up. The season is now closed of course, but in the next few issues I mean to deal with the mechanical side of some of our boats. W.McV. HOW TO MAKE MODEL SHIP AND STEAMER FITTINGS. (Continued from page 173). By A. P. Isarp, A.M.L.Mech.E, Ts capstan is an apparatus for lifting great weights and is employed in one form or another in all ships of any size for the purpose of raising ground tackle, hauling and warping, etc. It usually consists of a specially shaped cylinder or drum revolving on a vertical shaft and driven by means of bars put into slots in the periphery of the top of the drum, these bars being pushed round by the crew, the anchor cable, hawser, rope or whatnot being given a couple of turns round the drum and the slack led away down the chain locker leads to the chain locker, In large vessels the central shaft is carried down below decks and operated by power; hydraulic, steam or electricity as the case may be. Here again the enthusiastic model maker should try and get a glimpse of the real thing aboard the prototype or anyway get hold of some pictures or photographs, because various types are typical of the ships they are used on; for example, the modern battleship, with her huge anchors, the capstan is of big diameter but squat, while the usual Merchant Service type is much taller and smaller in diameter. Again let it be emphasized that it is of the utmost importance for your fittings to represent the correct type, see that your details are correct to prototype; time spent in getting these details is well spent; your fittings will cost you no more time in the making with the added satisfaction that at least they are correct. Fig. No. 10 illustrates a very common type of capstan mostly in the use of the Merchant Service. = ao » @ 4&4. / t ! i \ \ Se! —~—-\

239 It is well to observe that a model capstan can be made for real use aboard your model and here are a few suggestions :— 1. If your model is elec trically driven it can be made into an excellent main switch with which to control your motor or motors, simply by means of concealed contacts in its base. 2. If driven by steam it can be camouflaged as an extra ventilator for your stoke-hold by making the bar holes connect to the body which must be hollow. 3. If made up of light metal by soldering or from some light material such as cedar wood, and a light fishing line fixed to its base led down through a hole in the fore deck, neatly coiled up and fixed to bottom of craft, then should your model founder and sink it will float carrying the line with it thus buoying the position of the wreck for salvage To fix to deck, cut a disc from sheet brass, drill a hole through its centre, pass a small metal threaded screw through this hole, say about 4in. long under head, touch its head with the soldering iron, thus fixing it to the disc, now solder the disc to the base of capstan and trim off the edges all round, pass screw through hole in fore-deck and run on a washer and nut. Your capstan is now finished and will be very light and strong. Finish by blackening all over or by painting grey. Winches or windlasses are used for cargo hoist- ing, warping, and for any purpose where a hauling strain may be required; they electric, hydraulic or handpower. may be steam, Steam winches are very common and are usually double cylinder, high pressure, slide valve, non- condensing type fitted with ordinary Stephenson’s operations. N.B. Never forget that this buoy must wear a green flag which denotes a wreck, otherwise your model mariners may think it is a channel buoy and come to grief accordingly, and heavy damages will It is most important to remember that with working models, and after all these are the real models, all top hamper is so much dead weight in the wrong place, therefore it must always be remembered that all deck fittings should be manufactured as lightly as may be consistent with strength. A clever sheet-metal worker would doubtless be able to make from very thin sheet brass, soldering the various little pieces together or even an aluminium casting from a plaster of paris mould could be made, but the writer would suggest that turning a capstan up in the lathe would be easier and quicker, bearing in mind that probably your model will only require one of these fittings. Take a suitable size diameter piece of brass rod, chuck this in your lathe, mark off the capstan head into eight equal parts, (this will be at the end of your brass rod nearest your chuck) with a small brace, drill suitable sized holes at these points at right-angles to the axis of your material, these holes are your bar holes which presently must be filed square with a small watchmakers’ square file. Now turn up all over to shape; thus forming the complete drum of your capstan, witha suitable sized drill held in your tail stock drill chuck, drill up centre, remove drill and with a small boring tool carefully turn out the inside. O Q be your lot ? | a | | | PH NM) I 5 | Lf Take up your watchmakers’ square file and file out the eight round holes in the head, being careful to make all your square holes exactly the same, finish off all over and polish, with your parting tool carefully part off close to chuck. The vertical ribs on the drum can be made from short pieces of brass wire filed half round and neatly soldered into position. | FIG.U. |

MARINE MOVELS 240 oS nk link reversing gear, driving geared winding drums arranged with dogs so that they can be put in and ont of gear at will. The controls simply consist of a main steam valve, reversing lever, various gear levers and a powerful foot band brake, etc. . It will require .some skill to produce a scale working model since these auxiliary engines are comparatively small, indeed the scale of your ship would have to be quite large to even attempt such work, but there is no reason why a very good dummy should not be made provided a little care and patience be exercised. The various parts can be cut out and made up from the scrap box and finally either blackened or flainted grey. Quite a number are used on the decks of large ocean going liners, and even comparatively small cargo boats have a couple or so. In making a number of fittings which are all exactly alike, it is both quicker, easier and more accurate to make and complete each single part in its required numbers, afterwards assembling them. Suppose six steam winches are required, you will want six sole plates (as the base plates are called), twelve cheek plates (as the side plates are called), twelve cylinders, twelve piston rods, twelve pairs of guide bars, twelve disc cranks, six crank shafts with four eccentrics on each, twenty-four eccentric straps and rods, six winding drums, shafts, gears, and so on. : It all sounds very formidable, but the enthusiastic model maker must not be discouraged and he will be surprised how quickly he will be able to turn out his various parts and after a time speed will increase as little tricks will be learnt or discovered until the model dockyard will resemble a veritable mass production shop indeed. The writer does not intend at this juncture to describe in detail the making of all these parts as the reader will remember that the intention is to deal only with the commonest fittings which every model ought to possess. At the same time even a sailing fishing smack often is equipped with a special little donkey boiler and small steam winch with which to handle her trawling gear, nets and so forth, while the elegant yacht is seldom without at least her hand-power winch. Fig. No. 11 illustrates in outline a common form of steam winch used aboard liners, cargo boats and the like. (To be continued) OUR DESIGNING COMPETITION. i view of the change in the 1.Y.R.U. Rating Rule, we have decided to hold another Designing Competition for a model under this formula. The yacht must be to the M.Y.A. 6-metres (13 in. = 1 ft. Oin.), class and fulfil all requirements as to crew weight, etc. Entrants must observe the following conditions :— 1. All designs submitted become the property of MARINE MODELS, and may be published, or Blue-prints sold at the Editor’s discretion. 2. All designs submitted must be on tracing paper or tracing cloth, and shall consist of halfsize drawings embodying sheer, waterline, body and sail plans. The sail plan shall, however, be quarter size, and a full-sized body plan, as well as the half-size one, must be submitted. 3. In the designs submitted the bow of the vessel must be to the left. The profile (or sheer) plan is to be at the top, and the waterline plan at the bottom, showing the diagonals on the opposite side of the centreline, also the Curve of Areas. The body plan is to be shown on the same sheet to the right. and not over the sheer plan. Waterlines and buttocks are to be spaced 1 in. apart. The L.W.L. is to be divided into ten equal parts for the stations of the transverse sections, the bow waterline ending being numbered ‘0,’ and the stern ending “ 10.” 4. All designs must show C.B., C.L.R., and C.E., also give displacement and show leadline with weight of lead. Full rating particulars must accompany each set of drawings. 5. All drawings must bear a nom-de-plume on each sheet, and a slip with the nom-de-plume and correct name and address of competitor must be pinned to the corner of each separate sheet. 6. The Editor’s decision is final. There will be only one prize for this competition, and the designer whose*model design is*adjudged the best will receive a cheque for five guineas. The right to withhold this prize is reserved should none of the entries be of sufficient merit to warrant publication. Models may be either full-keel or fin-and-skeg. All designs must be in our hands by February 1, 1934, and the result of the Competition will be announced in our March number. All competitors must send their entries packed in a stout cardboard roll’ to avoid damage, and should enclose sufficient stamps for return in the event of our not desiring to retain same. An independent expert will be appointed by the Editor to judge the designs. Designs will be submitted to the judge under the nom-de-plume given, and designer’s name will not be revealed until after judging is completed. The name of the judge will be announced in due course. The winning design will be published as soon as possible after entry closes.

=), aca By GNV Munro. ageES — En — |* collecting data for the present series of notes on the splendid old merchant ships which sailed regularly to the Indian Ocean with passengers and merchandise, | want to give the modellers some idea of how they were built and rigged. Mr. Basil Lubbock has given us the biography of the Indiamen in his * Blackwall Frigates,’ which bids fair to becoming the classic of this type of ship. Here in these notes I am attempting a sort of anatomy. Several books were published towards the end of the 18th century and later, on the building and rigging of ships, but to-day these are very scarce and difficult to obtain. So I shall offer no apology for quoting from some of the contemporary sources. On the accompanying plate you will find the lines of a very typical example of an East Indiaman. In a great many respects these vessels are similar to ships of the Royal Navy of that time, a fact which may prove helpful to some who have an old Navy model in view for this winter’s work. I do not know whether the design ever materialised, nor do I know if a name was even proposed, but we cannot go very far astray if we use this design as a foundation on which to build up a very handsome model of a noble merchantman of about 1800. The Merchant Marine had very few ships as large as this one at that time, as the 1,000 ton vessels were only just coming into vogue with The East India Company. The length, between perpendiculars, is 159 ft., the beam 37 ft., and depth 21 ft. The tonnage, by the old 94 or Builders Measurement, works out 955? tons. I have said the date of the design is 1800, but this is purely conjectured. Personally, I am of the opinion that it is rather stupid to nail an exact date to any type of vessel, even within 10 years. The originals of the design were engraved in 1816. We may, therefore, presume the vessel, if built, was afloat a few years before this. Engravings have a knack of being out of scale, but I have corrected this fault and also faired it up where necessary. If any reader has any information of an old ship which corresponds to the above measurements, it would be interesting to try and trace the name and possible existence of the present design in connection with it. Names were not. usually supplied with the design, but, like the new Cunarder, would be known until the launch by a yard number. I have never met two model makers with the same methods, so I do not propose to go into this matter except where I have found one method more effective must adapt than the any other. following The modeller prototype methods according to the scale and skill with which he is able to carry out the job. I shall now presume we are building a large ship to the present design, the blocks having been placed the length of the slipway in readiness for the keel. To protect and strengthen the keel proper, a false keel is first laid along the blocks. This is made up of lengths of elm, 15 in. by 6 in. in section, being laid butt ended along the centreline of the blocks. The lengths of these pieces of timber will vary with the timber available, but in no case will any of them be over 40 ft. long. The keel is then laid on the false keel and is also made of elm or some hard wood. In the present case the keel is made up of an upper and a lower piece, the two being joggled into each other as shown. The false keel is bolted on from underneath. The section of the keel measures 15 in. by 15in., and the lengths of timber are scarphed perpendicularly, care being taken that the butt ends of the false keel do not come near these scarphs in the keel. The full length of the false keel should be 147-5 ft., and that of the lower half of the keel about 9in. shorter. The upper portion is the same length, except for the short portion at the after end, where the lower half projects beyond the sternpost as a protection for the heel of the rudder. The sternpost is set up on the keel at a slight angle raking aft. In this case it is not more than two degrees. The erection is housed by a mortice and tenon joint with the keel. For security it is shored up until the shape of the hull takes sufficient form to bind itself together. The height of the sternpost is terminated in a support for the main deck. On the fore side of the sternpost is the inner post, which is joggled to the stern as in the case of the upper and lower portions of the keel. From about level with the L.W.L. the after face of

242 the sternpost is cut forwards to permit the centre of the rudder post to be above or in line with the pintles. This also permits the rudder to be shipped or unshipped more readily than if it were straight all the way up. The after deadwood is next placed on top of the keel, the after ends of these pieces butting on the fore side of the inner post. The shape of these pieces will readily be followed by the present and future diagrams. On top of the after deadwood the sternson is placed, and securely bolted both to the deadwood and the inner post. This is a large piece of oak in the form of a knee and, like the rest of the curved or angular members in the structure, is cut from a natural bend in the living tree selected on this account. Several square sectioned pieces of timber are let into the fore side of the upper portion of the inner post. These are horizontally across the the transoms and are sternpost, and placed for their length follow the curve of the waterlines. The lowest transom has its extremities supported by the after fashion-piece. Those above are each supported by similar pieces of timber known as the middle and forward fashion-pieces. These supports of the transoms are really small frames grooved and bolted to the deadwood at their lower ends, and projecting upwards and outwards radially, according to the shape of the hull at this part. We shall now take a walk along to the other end and set up the stem, which in actual practice would be done by another squad of men working concurrently with those at the stern. It is obvious to everyone that here again such a large solid structure must be made up of several pieces placed together very like a modern jig-saw. The modeller will, most likely, take a piece of wood the right thickness and cut out the complete stern in one piece, as he most likely did the sternpost, sternson and deadwood, all of these being the same thickness as the keel. The shape of the stem is most easily followed from the plate rather than a written description, but the procedure is as follows. The timber which forms the stem is propped up at the fore end of the keel and curves forward and upward. The lower end is bolted to the top surface of the keel, which is deeper just at this part, as can be seen in the drawing of the sheer. The fore side of the stem is the fine line just aft of the outwater beak head gripe, etc. In model work this will all be cut out of one piece of wood unless the model is being built to definitely show each member used in the construction of the prototype. In the next plate I shall give the profile drawing, which will make all of the foregoing clear and pictorially show the method used. The sections drawn, numbered and lettered on the accompanying plate represent the frames, excepting at the ends, where the cant frames, shown as dotted lines on the waterline plan, continue the form of the hull forward and aft. There is one discrepancy in the sheer drawing that I should mention. Owing to the stretching of the paper, due to damp weather, the gun ports from the main mast aft, are a little out in the fore and aft direction. The subsequent drawings will show their correct position in relation to the sections. (T’o be continued.) “BETTY” AND HER MOTOR. By 8. L. & J. B. Innocent. Ts following is an account of the building and tuning of the present World Record holding metre hydroplane, and whilst it is realised that much can be improved upon, it is felt that this article may assist some of our friends to equal or better our own performance. Firstly, we will discuss the hull, for although it was started at a much later date than the engine, it was running with a temporary motor some time before our own was completed. As most boat people know we were tuning “Qld Bean IV,” and at the same time comparing its running with that of other hulls. The conclusions we arrived at were that the low angle high area hull, whilst capable of high speed with comparatively low power, was a very delicate proposition to get stable, and also that to put a bow on a flat bottomed hydroplane was more than a waste of time, for if the stern came up the shoulders dug in and a somersault followed. The outcome of these observations is a shovel front hull, only 35 ins. long by 114 ins. beam, with a front angle of 1 in 64, and a rear angle of 1 in 53, both being swept up after the effective plane is passed. As we anticipated this hull wants driving ; it is not really up until 34 m.p.h. is reached on smooth water, but it is stable. This boat appears to give less lift than similar hulls, and we believe this to be due to the comparatively thick bottom employed, for if the bottom is forced in by the water pressure the effective angle is increased.

243 Constructional details are quite normal, the only points worthy of note being that everything was cut and filed or bent to exact shape before assembly and the final method of tuning up. When the hull was all put together, except for the deck, it was checked on a flat table and the planes were We now have to deal with the engine, which is, to all intents and purposes, a free lance model motorcycle engine; in fact, it was designed as such, and the boat idea only came later. Probably found to be a trifle out. Next the deck was fixed down one side,a piece of paper packing put under the low corner, and both planes pressed down at the corners. Then two fins were put in the other side. discussion being left until afterwards. The crankcase and timing chest.—Motor-cycle type fitted with ball mains for }-in. shaft and ribbed cylinder—cast-iron—with deep fins and_ bolting SSSSSSSSST 1 1 1 i] the best way of describing this engine is in catalogue form, and this I will do, any necessary SSSSSESS ay Y= Primary Choke Feyrol lassage Section THROUGH CARBURETTOR. The hull was again checked, the amount of correction as compared with the thickness of the packing noted, and the correct amount of packing for the next and final attempt found. The hull is finished with yacht varnish in which is mixed white and prussian blue colour. The timber used is 35 mm. bottom, 14 mm. sides, deck and transom, all in birch three-ply, hazel }in. quartering and hazel runners cut from 2} in. by } in. Before we leave the hull the cavitation plate calls for notice. The skeg being fitted on the transom with the screw aft, it follows that there was nothing over the screw. Well, there was a hole right down to the spinner as soon as any real speed was attained. This was obviously not good enough, and the plate was fitted and does its job well. Leading down flange. The walls are unusually thick and the fins graded off into them. Head.—This is made from an aluminium casting. The ports and combustion space were dug out part by machine and part by hand. Drawn phosphor bronze seats are shrunk and riveted in, and the 90° valves work in iron guides. The exhaust guide extends to the valve head, but the inlet is cut away to conform to the port contours. Exhaust valve.—Mushroom head ? in. diameter, din. lift. Inlet valve.—Tulip head 3 in. diameter, } in. lift. The exhaust port is straight forward, but the inlet is skewed to meet the head almost at a tangent along its outer wall, and the valve is offset in the opposite direction. This is, of course, done to promote turbulence. It should be noted that the Eclge, A { I | I | > § 1 u Propetter GLanes PROJECTED B FLAT.

MARINE MOVELS 244 — re ef n inlet port is so arranged that the forward motion of the boat creates a vacuum, and not pressure, at the air inlet. The rockers are case-hardened mild steel fitted on silver steel spindles of}; in. diameter, by tapers and keys; a true rolling action is obtained on the valves. Push-rods are steel tubes with casehardened end caps pushed on. There is no adjust- The gudgeon is also in nickel-chrome, and, of course, hollow. Aluminium end pads are fitted. The piston is made from a standard electron casting, and by the use of templates the inside has been dug out to give the desired section. Only one ring, 3 in. wide, is fitted. New tappets are made The timing chest is now all that is left. A pair of case-hardened steel gears, in. wide, drive the camshaft, the full-time pinion is fitted on a The only remaining external part is the contact parallel with key and nut, and the half-time wheel ment for tappet clearance. if required. breaker, and this is a Ford arm on a Bond back- plate. Now for the inside and the bits that matter. The mainshaft is entirely built up, and it consists of separate mainshafts, flywheels and big-end pin. The mainshafts are fitted to the flywheels by parallels and keys, and the big end by tapers. The flywheels, which are 2}in. diameter by Jin. wide, were machined from the solid, together with the balance weights, and are of mild steel. Now for the rod, the toughest job of all. It was machined out of a piece of hardened nickel-chrome, which weighed 18 ozs., and it now weighs under 2ozs. The form is I section and the sides are tangential to both ends; the big-end is } in. by 2 in., and the small end 2in. by Zin. A bronze bush is is recessed and riveted to a collar on the camshaft. The camshaft is } in. diameter and runs in bronze bushes. The cams are 2in. base circle and have 3y in. lift, the odd 4, in. is lost owing to the follower pins being wrongly placed. These cams are pressed into the shaft, sf in. keys being fitted. The cam lift contours are arranged to give quick lift and eased drop in conformity with motor-cycle practice. Light slipper type followers are employed, made from the solid end, and they work on ball-headed tappets running in bronze guides. The timing is: inlet opens 30° before T.D.C. and closes 40° after B.D.C., the exhaust opens 65° before B.D.C. and closes 35° after T.D.C. This timing is not quite as it should be, as the inlet shuts too early, and it will be altered as soon as the racing season is over. used in the former, and dural in the latter. (T’o be concluded). THE SECOND EXHIBITION OF THE SHIP MODEL SOCIETY. By Our Own HIS Exhibition was held in the Old Bluecoat School, Liverpool, from October 18 to 28. It was the SECOND public exhibition of a society only just entering on its third year of existence, and yet the impression one received on entering the CORRESPONDENT. over-gunned, having something like fifty guns on two decks. Furthermore, she had no poop or forecastle, another strange feature. The exhibition catalogue gave no explanation of these, to us, unusual features, and on reference to the Main Hall was that of a professional show, organised officials of the Society, we learned that they were by people with years of experience in getting up exhibitions. The models were set on long tables, equally puzzled; the model had been loaned to the Society by Sir James Caird, and sent up specially some with a second tier behind, covered in grey cloth, the sides being draped in green. The arrangement was simple and easy to understand. from the National Maritime Museum, Greenwich, and no member had seen it until it arrived. Perhaps the authorities of the museum referred to All sailing ships were arranged in the centre, and could throw some grouped according to their dates. indication of the history of this remarkable model. All the machine- driven craft were similarly grouped together and had a long table to themselves. Other space was light on this, and give some To return to the members’ models, it is difficult to single out any single one of them for comment, devoted to model yachts lent by members of the so high was the standard displayed. Birkenhead entries in the Three Shilling Model Competition, Ship Section the most striking model was a huge waterline model, with sails set, of the ship ** Armida”’ and one or two builders’ models. of the *90’s, made by a member who had served The Model “piece de Yacht and resistance’ Power of the Club, the Exhibition was the large bone model (6 ft. 9 in. long) of the East Indiaman * Halsewell.” This fine model was much admired by visitors, and deservedly so. in her. But like many “sailor-made* models, this would not bear close examination as regards the finish and general craftsmanship. The best model in this respect was the Brocklebank four- But we were rather puzzled by one or two points. poster, For an by Mr. H. East Indiaman the model seemed rather In the Sailing “ Holkar,” Owen. a 4in.—Ilft. model made This fine model is one of the

most complete sailing ship models we have seen. In spite of the relatively small scale, almost every individual rope is there, and Mr. Owen informed us that he used 14 different sizes of line in rigging her. We gather that the process of rigging is what the maker enjoys most, and we must congratulate Mr. Owen on a fine piece of work. Other fine models in this section include the ‘**‘ James Baines” +, in.—1 ft., under construction, by Mr. Green, the Vice-Chairman of the Society; a model of the “‘ Santa Maria,” by Mr. E. V. Michael ; another model by Mr. Green, the Stuart “ Sovereign of the Seas,’ in construction, especially noticeable for the exquisite carving; the brig ‘* Daring,” by Mr. W. J. Mason ; and a wonderfully immaculate model of H.M.S. “ Victory,’ }in.—1 ft., by Mr. W. Mather, still in construction. A fine sailing ship in the Loan Section was a waterline model of the American wooden ship, “ Henry B. Hyde,” bowling along under “all plain sail.” This model was made by a Mr. Carlson, of Liverpool, who, we understand, sailed in this ship, and has never served in iron or steel sailing ships. Mr. Carlson is a shipwright by trade, and in conversation with him we learned that the model was only commenced last December, and was finished before the Exhibition, in spite of the fact that seven weeks illness held up progress in the spring. For a man of seventy-two this is “some going.” The model is almost professional in its neatness of finish and adherence to scale proportions, and its setting is remarkably realistic. The sails were made from thin aluminium, and their “set” is perfect. Throughout the period of the Exhibition this model was always surrounded by admiring visitors, many of them old shell-backs to whom this model brought back memories of days that will never return. The model, we understand, has been purchased for the Shipping Gallery of Liverpool Museum, and its maker has joined The Ship Model Society. To turn now to the steam and motor ships, grouped by the organisers under the appropriate title of “‘ Power-Driven Craft,” it is harder still to decide between the merits of the models exhibited, and it will, perhaps, be best if we confine our remarks to the models selected by the judges for the award of trophies, with just a word in passing for the runners-up. The premier award in this section is the Propeller Trophy—a silver-plated speed-boat propeller, suitably mounted. This was awarded to the Secretary, Mr. A. R. B. Lyman, for his model of the famous Wallasey ferry steamer, “Royal Iris,” built from official blue-prints to a scale of 4in.—1 ft. This produces a model just under 20 in. long, and within such small limits a wealth of detail, absolutely to scale, is incorporated. The model is representative of the prototype as she appeared in her last years with the Wallasey Corporation, running pleasure cruises in the Mersey estuary, before being sold in 1931. She is painted grey above the waterline, and fitted with an awning ; the seats from the upper deck, abaft the bridge, are removed to leave room for dancing, for which an orchestra was carried. An unusual feature of this model, which we do not remember seeing in a model before, is the representation of the shellplating, very successfully carried out with paper, overlaid on the hull before painting. The ship’s boat, only 16ft. long. 2in. in the model, is CLINKER BUILT with strips of paper, complete with ribs and knees, and the life-line round the gunwale outside. Mr. Lyman informed us that there were some 120 separate pieces of material in this dinghy, and we can well believe it. This model is a worthy successor to the “~ Royal Daffodil,” illustrated in the August issue of MARINE MODELS, and well deserves its award. A striking contrast was afforded by the inclusion in the exhibition of the builders’ model of the successor to the “Royal Iris” on the ferry service, the * Royal Iris I,” built by Harland & Wolff in 1932, with three passenger decks. But the contrast between the-ship of 1906 and her successor of 1932, is not nearly so striking as the contrast afforded by the model of the “Sir John Moore,” a Wallasey ferry steamer of 1835. This early paddle steamer was modelled for the Wallasey Corporation by Captain Nigel W. Kennedy, the Hon. Librarian of the Society, and an authority on the early history of steam propulsion of ships. The model, which is a very neat piece of work, was the runner-up for the propeller trophy. Another interesting exhibit was a working model, 40in. long, of the British and India Company’s “* Nagina.” For an actual working model this is a remarkably complete example, having a wealth of true to scale detail about her decks. Our chief criticism is that the port-holes in the hull are too large, and we are not sure that we have seen a real ship with port-holes in way of the cargo holds. The model was exhibited by Mr. John Lister, of Blackburn. Models of warships, mainly waterline, were present in force. The Leask Cup for Miniature Models was awarded to Mr. L. F. Holly for his model of H.M.S. ‘‘ Nelson,” waterline 1/64 in.—1 ft., a very neat piece of work. In this section, mention must be made of a number of exhibits made by Mr. H. N. Leask, the donor of this trophy. include three These models of German _ battle-cruisers, 1912; and 1911; ‘ Seydlitz.” the ‘Goeben,”’ ‘“‘ Hindenburg,” 1914, giving a very interesting illustration of the development in design of this class of ship in the German Navy up to the Great War. Other models by the same maker, all noteworthy for their faithful adherence to scale and neat finish, include models of the ‘‘ Mauretania” at speed, the ‘* Aquitania,”’ and two interesting models of the ‘“*‘ Normandie,” and the Cunard ‘** No. 534.”