JUNE 1973 15p U.S.A. & Canada Seventy-five cents HOBBY MAGAZINE ae

UGNTWENGHT: 36 “RESTRETED CLASS YACHT GOSLING designed Vic Smeed ‘ : x ‘ Mies . . ny . PL i (AS 8 FROM (75 f m – Y ey = — ———- Hemel me ne 7 a ch ‘ 98 NO MAW Booms FroM 3 ALUMROUM TUBE The Model Maker Plans Service 13°35 Bridge Street. roan fiw Ts re EYE a7 SAME OST FROM PCT i Sie, ree . 4 Gap soe ace wired ear by Hempstead, Herts. TOP LIGHT WEATHER) SUTT 6020° SLACK FIT Ma (USE LOCTITE/ePOXY To SECURE) w FLATTEN Boom cd <= HOLE FOR 8 TACK 3 12 x 0 BRASS sche 10K ss bay sal “ill | iCieue Fon Kexine “7 68a Boi" THRONE / (JD PACE FRAGA BRASS CORDN RAL AT ee, wate RXR Pa DEEP 1 BOOM HEEL MAST HEEL WITH DOWEL. SAW SLOT YO FIT OVER WAST RACK ‘SIDE AND BOTTOM HULL PANELS (SKINS) AND TECK aut V32 PLY R | \ = ' wie oe wr va a00 Moa aaLsn STRINGER SAND, ADO 1732 PLY SIDE SKIN 2 TURN PLAN OVER, USE SAME PIN HOLES, A TT Full-size copies of the plan above are available, reference MM 1164, price 65p including postage and V.A.T., from Model Maker Plans Service, P.O. Box 35, Bridge Street, Hemel Hempstead, Herts HP1 1EE. [uw ties)

JUNE 1973 E left our boat last month with the hull built. fin and skeg fitted, rudder tube installed, and deck cut, with a couple of coats of clear polyurethane on the hull interior and underside of the deck; while these coats are drying attention can be turned to the lead. Some people find lead casting easier than others, and for these a circular section torpedo lead is shown. This entails turning a wood pattern on a lathe, splitting it, and making a mould from plaster or sand. No problems arise for those prepared to go about it,in this way, but for a raw beginner it may well seem a bit formidable. The prototype model uses the simpler lead shown on the drawing, and this really is an easy way of getting a lead bulb. Doubts about efficiency can be dispelled, as the prototype sails very ably with this set-up. First visit a timber yard or D.I.Y. shop which supplies timber products cut to size, and buy a piece of + in. thick blockboard somewhere around 12 x 8 in. — the sort of left-over piece that’s too small for most purposes. Trace on to this the bulb profile, twice, leaving an inch or so minimum between them. Cut out these two shapes; a band-saw is useful, but it doesn’t take long with a coping saw or even a fretsaw. Try to keep the cut vertical, which saves work later on. Cléan up the cut-outs to smoothness. then nail a piece of ply to form a bottom and if necessary a strip along the edge from which the sawcuts were started if a bandsaw was used. Ensure that the wood April issue) and the top surface. or even charred i.e. there will be you may like to is all dry, then melt the lead (see pour to fill both moulds flush with The wood will be slightly scorched when the cold leads are removed, a smell when the lead is poured, so Top, the hull and deck ready for permanent assembly; note blocks on underside of deck, Above, the deck in place on the hull being held with Sellotape and pins while setting. GOSLING Part Two of our lightweight do it outdoors. An alternative is to bend two j in. wide strips of metal to the bulb shape and nail round the outside, as in the photograph, which is even less work and should produce very neat castings. The top surface of the lead in either type of mould may not be quite flat, due to shrinkage on initial cooling, or even because impurities in the lead tend to bubble to the top. This is taken care of later; initially each casting should weigh a shade over 3lb. Clean up the keel faces if. necessary, with a file or glasspaper block; you can in fact plane lead without difficulty, using a spot of turpentine as a lubricant. Mark and drill two holes (say } in., to clear 14 in. x 10 brass screws) in one lead and one between these two in the other. Clamp the leads to the fin and spot through the fin to mark the opposite lead; drill smaller holes (say + in.) +:in. deep to take the screwed ends of the screws. Countersink the screwholes on the outer faces, then lightly screw the leads in place and check that the hull balances close to the arrow shown on the plan, approximately 20 in. from the bow. The leads can be moved fore and aft by enlarging the fin holes. When satisfied, epoxy fin faces, clamp the leads in place, and screw the three securing screws home. Fill the spaces between the leads fore and aft of the fin with scrap 4} in. wood glued in with epoxy, trim to shape when dry and force epoxy into any remaining chink. Clean up the outside faces of the leads, cut two + in. balsa shapes to the lead outline or a shade inside it, and epoxy these to the leads, cramping into contact if the lead faces are slightly concave. When dry, file and sand these panels to a smooth streamlined shape, which will also slightly round 233 36 in. Restricted class model for vane or radio sailing BY VIC SMEED Two types of lead mould are illustrated below. The upper picture shows the shapes cut from blockboard and set up ready for pouring the lead, while the lower picture shows one of the two moulds required, this time made with a strip of aluminium with nails to retain its shape.

MODEL BOATS The leads screwed into position on the bottom of the fin; the fore and aft gaps are filled with scrap i in. timber. and smooth off the corners of the lead. Now to return to the deck, check that all necessary blocks to receive fittings are in place, either glued to the underside of the deck or in place in the hull in positions where the deck will glue to them. Most fittings are arranged on the centre line, and the shroud plates screw through the hull sides, where the strain will be taken at roughly right angles to the screws. However, the backstay must be split to clear the vane feather (unnecessary if radio is to be fitted) and needs an eye each side of the hull, and it is convenient to have an eye each side for the spinnaker sheet. The only other requirements are the two blocks beneath the deck for eyes for the synchronous sheeting line. Once satisfied that all is well, the deck can be permanently fitted, using epoxy on all contacting members and tape and pins to hold the deck in firm contact all over. Pins are necessary along the hull centre line to ensure that the deck is in contact with the upper frame member. Allow to dry, trim and sand the deck edge, then sand all over ready to prime. We experimented here with Bondaprimer, which is really a _resin-based primer intended as a rust-arresting agent for car bodies and the like; however, it forms a thin, light, non-porous skin, and two coats certainly seemed to fill the grain on the ply. After dry rubbing down, a couple of coats of oil undercoat were applied, rubbed down wet to produce a first-class painting surface, followed by two coats of Humbrol enamel which. when thoroughly dry, was rubbed down with fine valve-grinding paste and then wax polished. Frankly we would have liked a little more time on the finish coats so that a reasonably good finish could have been an excellent one, but it does take time and publication dates come up very quickly! Don’t forget to include the rudder in all stages, by the way. In between coats — and any coat needs to be left at least overnight — the fittings can be tackled. These have been kept to a minimum commensurate with a practical racing model, and they can all be made with a small clamp-on vice, two or three drills, a junior hacksaw, a file, and a pair of pliers. Materials should not be too difficult; aluminium tube is stocked by some D.I.Y. shops or you can still find TV aerial material, small bits of brass sheet and curtain rail are not hard to find, angling shops sell braided terylene line and possibly stainless steel wire, and there isn’t much else. If necessary, the wire can be obtained by post from Nylet Ltd., 118-122 Station Road, Fordingbridge, Hants., W. Jones, 57 Forest Road, Birkenhead, Cheshire, or J. Roberts, 180 Crown Lane, Horwich, Bolton, Lancs., and the first two of these can also supply sails. Sails. Well, obviously, since the mast and booms etc. are to spread the sails the first step is sail size. For a working suit — that is, the sails used under average conditions — we have used exactly the same sails as the Star-C design. This simplifies the job of the suppliers but also means that an owner can have two boats both using the same ‘power plant’ if he wishes. A standard sail also helps to hold prices down. For competition sailing further suits of sails are desirable, and by using a mast extension a taller rig of greater area can be used for light conditions, say under 6 m.p.h. winds. A small suit is essential for stronger blows, but in each case the same mast and booms are used. It is appreciated that buying three suits of sails at once can seem a lot, but the average builder will only buy a working suit and sail in a reasonable wind; when he knows the boat and wants to sail in races he will be ready to buy the other suits. The areas, incidentally, are top suit 602 sq. in. (cut a shade tight to fit the U.S. 36/600 rule), working 493 sq. in., and third or storm suit 368 sq. in. Intermediate suits could be fitted, or you could use say the working jib and storm main to have 406 sq. in. and a ‘mast-head’ jib, etc. For those who wish to make their own, sailmaking articles appeared in April and September 1971 issues and the latter will be available shortly when the book version of Roy Griffin’s articles, Model Racing Yacht Construction, is published. It should once again be pointed out that there are no running costs and the performance of the boat is limited by the skipper’s trimming and the efficiency of the sails; it is therefore not unreasonable to buy a well-made suit of sails. Mast. The mast is made from ? in. aluminium tube, though if you habitually sail in rough conditions you may like to make this 4 in. diameter, or possibly, if you can get it, 7 in. Apart from cutting (Continued on page 257) The mast fittings are very simple. Centre picture shows the mast top and jumper strut which is seen in its component parts on the left. Right hand picture shows the bottom end of the mast with the hardwood plug ready to be pushed in and the Tufnol gooseneck fitting epoxied in position. The swivel for the boom end will come into next month’s article, 234

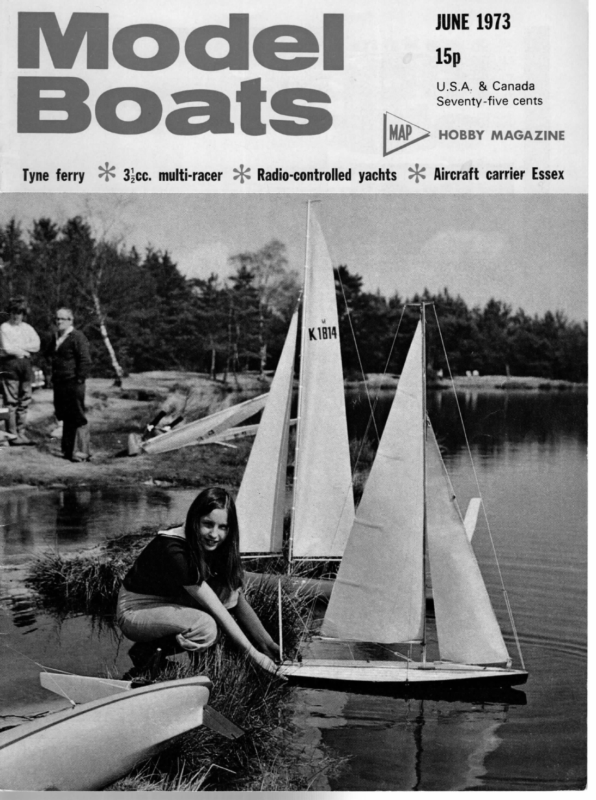

MODEL BOATS Radio Control Yachting Part Two By C. R. Jeffries Bob Jeffries, who is slightly taller than average, gives a very good indication of the size of a Marblehead for those who have never seen one of these convenient size boats. of the wind, and do it from the tiny power available from our second servo. Several schemes to achieve this are available. The simplest is to use the actuator arm of the servo to operate two microswitches, and for these to control the power of a much larger motor on the sail winch. This system is widely used, and is suitable, except one must bear in mind it only gives a positional control, and some means of limiting the movement of the winch is essential, otherwise when the boat is the other side of the pond it would ‘“Q far much has been said about the design and detail of a radio boat, but nothing about the radio. I am fortunate in having knowledge that enables me to build and design my own equipment, having spent a lifetime in the electronics industry. Others may not be so fortunate, and must rely on the purchase of one of the many excellent commercial finished sets of equipment. A radio controlled yacht needs two basic controls only; I know my later boat has three, but it still has to be proved if my third channel, which gives vernier trim on the jib, is worth while. What is needed is a control (preferably proportional) of the rudder, and a similar control over the setting of the sails. Assuming a commercial equipment has been pur- chased with two servos, one servo will operate the rudder, and here the spade rudder referred to earlier shows a big advantage over the more conventional rudder and skeg. Assuming the pivotal point of the rudder to be situated so that around 40 per cent of the area is ahead of the rudder shaft and 60 per cent behind, this design of rudder needs only small power to drive it, and any conventional servo as used for aircraft or small power boats will prove entirely suitable. The second servo must work the setting of the sails. In this we in this country are unfortunate in so much as no commercial firm has yet put on the market a suitable sail winch, so we must make our own. I have in the past published designs for such winches, but these were intended for the ‘Q’ boats, and were too big, heavy and powerful for the ‘“M’ class. We therefore must design a suitable winch with be possible to overwind and try to pull the whole rig down into the boat, or to let the setting out too far with a result the cords, or ‘sheets’ to give them their correct name, will all get tangled up. A much more satisfactory system was sent to me by a correspondent in Mexico, and started to be called the ‘Mexico system’ in the local club. Reference has been made to this scheme in an American journal, and I find it is being similarly referred to there. Briefly, the system is a means of obtaining a true proportional setting of the sails without strain on the servo. The scheme uses a sail winch of suitable power for which I will give details later, which has a contact plate with two contacts mounted suitably and geared down from the drum spindle a suitable amount. The servo has a disc with two ‘D”’ shaped areas (Fig. 2) fitted to its output, which align with the contact plate. The two contacts normally lie in a position between the two areas on the contact plate. Move the servo, and these contacts make with the contact plate. Power is applied to the motor which turns the drum. The contact plate moves until the two contacts again align with the gap in the contact plate, and the motor stops in the new position. I enclose a photograph of a sail winch using this principle, which may give enough information to enable the builder to make one, using his own gears and components. Also enclosed are sketches of the basic principle (Fig. 3). This scheme has been well tried out and is almost universally used in the local club. A further design, which I offer for the more experienced builder with sufficient electronic knowledge, is the method that I use personally. This is where the amplifier, usually sufficient power to set our sails whatever the strength 248

JUNE 1973 A sail winch made to the design shown below. included inside the case of the tiny servo, is used to operate the winch motor either direct, or through relays. I use the latter, and feel it to be the ultimate in control. It follows best commercial design, and is a proper professional approach to the problem. It is my hope this article may catch the eye of a suitable firm, who may market such a unit for the modeller. The successful design of a suitable sail winch depends on the use of a suitable motor, and in this we are fortunate that such a motor is available from Harringay Electrical Supplies of 435 Green Lanes, London, N.4. at £1.25 each plus 10p postage and packing. This motor is intended to run on 6 volts, but I find it better to increase this voltage somewhat, and now use 9 volts. A dry battery of the PP9 type used on domestic transistor radios is ample and gives many weeks service. A better supply would be the rechargeable batteries of the DEAC type, and this would be preferable. I use those of the 500 milliamp capacity, and one charge gives several hours sailing. Gears are available from Bonds Ltd., Model Engineers, of 357 Euston Road, London NWI; the actual types used are shown on the drawings but other gears available could be used, provided the overall reductions are similar to those quoted. One of my pet hobbyhorses is the phobia I have over water or even the trace of damp getting near my precious radio equipment. I go to every extreme to ensure I do not again suffer from this trouble. Examination of the photographs of my later boat Electra 1X shows the box containing all the electronics equipment, batteries and servos and sail winch, to be fitted flush with the deck. This makes a most satisfactory assembly, and again sketches of the scheme make everything clear (Fig. 4). Any water that might get into the outer grooves is led away by a self draining scheme, as the sketches show. It is usual to use the plastic picnic boxes available from any hardware shop. Invariably these are not of exactly the size required. I prefer to make my own from 7s in. thick perspex, making the joints with chloroform. (Do this in a well ventilated room, or preferably out of doors). Provided the perspex is cut accurately to size, it is surprising how easy it is to make one’s own boxes. Readers examining the photos of my latest boat will notice the unusual method of operating the sails. The conventional drum has been replaced by a double ended arm operating through 180 degrees only. This is an experiment on my part, and so far appears to achieve what I set out to do. Briefly the advantages are the fact that normally any movement of the transmitter control produces a like movement on the sail winch. With this scheme, a given movement of the transmitter control only moves the sail setting a small amount in the close hauled position (where fine setting is essential) and gives a progressively coarser control as the sails are let out. It is just a matter of elementary geometry. This type of sail winch, although basically simple et ug 28/32” REMOVE COPPER r FIG. 2 FIG. 3 13" DIA, L 1" HOLE TOP OF BOX TO DECK CONTOUR. AND FITTING FLUSH CONTACT PLATE FROM PRINTED EPOXIED TO CIRCUIT BOARD a 127 48DP 48T 64DP. % ' TRVO | | DECK ~~ \ | 6V MOTOR , PERSPEX BOX Y eee CONTACT PLATE FIXED TO SERVO CAM TO BATTERY 4" BRASS TUBE GEAR RATIO MOTOR TO DRUM APPROX. 128:1 FIG. 4 ~G.R,P. HULL DRUM TO CONTACT ARM APPROX, 25:1 EXISTING SERVO WATERPROOF BOX WITH SELF-DRAINING FEATURE 249

OS7 ‘QO1JOU BYAv} P[NOM SIsUsISOp I9y}O JqnOp OU Usy} ‘ssv[o SIY] UL SaseJUPApe SARY S[IdY SANVUIA}e 1eY} peaoid sUOSUOS J] “YISUS] SUT[IOJVM DUS 94} UO sBII jUdIOyIp ssn pue Jomod peo[/[[Ny ulejor 0} 10939q V2J SI -USAVS 0} 4 98If vole “Sulres ouea JSBOT JB IOJ US9q [ies SAY JO ul AjurTeyIOD ‘yng SsvjO SITY} SIOUSISOP yI8ue, ][e1oAO UI s[xdy ‘spIOM ‘sIesA Udd} ANVUIO]]e IYO UT Buroaye sasueys osn “S}TUWI] woly A[UO sasiIe ‘d}B8OYIVI9D 9Yy}] UO payejs se ‘UOTEI[IOURD ‘JUSIING ev Japuel [[QS SI SUIPIOM ‘4TASLI AO SIy}] pue ‘JOU .PI[BAUT soop 9}edIII00 ‘jseI[eVq [euIa}UI jo o3ueyo ve Aq uUeY} J94}0 ‘JUSWSDR[dSIP UI UOT} eI9}/[2 uy, Shes (Q)ITAX 9[N1 ‘saps 94} JO UOISIADI 9¢6] 94) UL JOB] UL pUe ‘jJseI[eq SPISUI JO Jey} SI sJBVOYNIID 9y} UO PpaepIOSeI JYsIOM A[UO oY], “NogGe jYsIOM SUIAOW Aq WIL} Ss} 3ULID}[e yNOYWM sosinod [TeV Uo jeOgG B [les 0} Ajdus si vapl oy} fo10y UWIa} Jo dejioAo JYSIS B SI 919Y} OS ‘yoeq pee] UY oY} SUIAOW pjnod os A[SNOIAGG “Weye [eloyouseq eB sAvY P[NOD UNI e IOJ UI9}S 94} O} JYSIOM B YONS SUIAO| “ouTpIO}eM I9do1d S}I 0} yeOg 94} BUIIQ 0} ‘039 MOQ 94} UI soouno InoJ *3°d ‘|s¥l[eq SUTWIWII} [VUIOUT 0} SULLIDJOI st opn1 aU ‘WSIOM [90y¥ 9Y) se Ase][eq, Jo Suryury, Aq s19y J[esuTY SUISNJUOS SI Gog 1eY) YUIY] OMA :ajJoU S.4O]IPY ‘Q[NI d[QIxay SIOU 9Y} JO. sde]URAPE dye} 0} JSsOq MOY JOpIsuod O} BUT] pey BAY SIOUSISOP USYM J9}|2B [JIM s][ny JO USIsop dy} MOY 99S 0} BUT}SAIOJUT 9q [IM WM pue ‘seq oy} O} [[B Aq [[IM SIYT ‘9/1 JW, SY} Jo UOTBOYLIL]D IO JUSWpPUSWe SIYy} JO suUOd pue sold 9y} SUISSNISIP sdUSpUOdSaIIOS 3q [IM 9194} 1QNOp ON “ed JSo][BWIS 94} UI MO}S 0} SUIG} o[duIs AIOA B ST JYSIOM [99% NoyWM [NY Y “woHnejtodsuel Jo ssva sy] 3q [TIM Avy [IM s[soy S[QRAOWOI osejURApe IOy]OUYy ‘posn oq 0} sonnei yoodse J9ysIy pue surjd [les SULIOyIp sjqeuse pue ‘jeoy oy} JO JUBWOW suNnYsU 24} UO WOWOAOIdWI s][qeiopIsuodD eB sAey plnomM ‘VY4snvIp Ul ssvdIOUI [[eWIS ev ‘djay Jo 9q pynom uy jo YISUs] JUSIOYIP 9y) “WYsIom [ooy JO oBueyo eB ynNoYyM udsAq ‘suIxy Ieprums 10 uid e Aq pyey suleq ‘ul 3njd jsnf p[nom uy oy} pUe jO]S JooIdIa}emM eB YUM pony °q plnom UonoNysuod 3uLINp [[NYy sy ‘ssoulsng ajduis Be SI Jayjoue Joy yYsIEM ay} ‘sjeey qing jo Ajylieyndod sUO JO UOTNNsqns Bulsvaiour 3} YUMA ‘gouRULIOJIOd [[eI9AO Jopim YOnu eB Jo a[qedeo [[NY & UBSISOp Oj sajnI dy} UTYyIM adods Japim Yyonw B SIOUSISOP yYORA [APOW SAIS [[IM }I yNqQ ‘aj}aTOsqo SUSISOpP Joljive [je Jepuer AjajyeIpoewmuut jou [IM 1] ‘days dAissoigoid & SI So[NI dy} 0} JUSIUpUOWe sIyy ‘[994 SeIpsutiajur oy} WY ysnf ‘aq 0} JNO UN} TIM 7 }BYM Ins JOU d1e NOA pu ‘JUdIOYIPUr sI IayyeoM 9y} pusysem JoyJOUY 308 savy NOA [a0dy }SdIAROY 9y} iy ysng ‘ayes ve SUIMO]G SI pue [eWIOU 0} pouiInjel Sey Iay}VOM dy] YOM IXON ‘9[QR[IeAe [dey 189743] 24} IY pynom sUO “puIM Jo Y}eoIg ev A[pIey ynoyWM Aep Jouuins joy SuIze[q eB UO JUdAd Ue IOJ SULIO}US QUISBLUT “SUOTIPUODS JoyJeOM JO jos SBullsyip ATepim B UL sdURUIOJIOd WnuwNdo s}I SAIS 0} BOG B UBISAp 0} ud9q sey Wie 34] sABM[Y ‘SIOUSISOp JyORA Japow 0} djsy e[qeispisuod Jo 93q |[IM pue ‘[eyUOWepUNy Ayoid SI sajni ssejo JA, 94] 0} JUSWpUsWe sIyy *"so0vI JO SOLI9S IO 9de1 B 3ULINP posueyo jou ole s[ady 3eY} peplAoid ‘suonIpuods Surpies suLayip J99W O} S}YSIOM 9}VUID][e JO s[ady OplAoId 0} poMmoyye ‘SI JI Jey) seoise oy pure “WA'W Oy) JO Alvjo1sag [eIsusyH “UOF{ 94} “IOUSpPIeH *H “YIP WO 197)9] Injdjay AIoA ev AQ poylieys 10}7eu SIy} SARY MOU | ‘yeeay Aue ul seysejo Aduanbesy Ploae yoiym shed sayiojd Pepod-inojoo ay} pPue juNnOd [eNSIA se |jamM Se sigipne ue sAIH 0} e146 seyeeds oy) ®10N GNID 3se104 May 94} Aq Pasn ad!IAep UMOP-jUNOD sy] ‘posueyo sary suol -IPUOD JOyVOM 94} USYM JUSAD Joye] eB IOJ syysIOM suIsueYyS dUO dojS 0} SUIYJOU sI 91904} ‘Ysnous IIey *‘scovi JO Solos B SULINp posuRYd sq JOU JsNU JYSIOM 24} YsnoyIe se ‘UONSIpejUOD UI o1e s}]UdTII}e]S OM} aseuL “.GALIGIHOUd S! ise[jeq SuNzIys 10 s[qeaow ‘9}BOGHAIO 9Y} UO PdpIOSSI SI JYSIOM polepsop sy}, * * $9}8]S JL SONY JO Jos sues 9y} Jo ZT] esed uO ynq , Sd0vl JO sales IO 90BI B SULINP pasueYys 9q LON TIVHS 3SeI[eq pray JO IYSIOA\, ‘o}0Nb J ‘jeYy} sozeys Ajivopo UW ‘sajna Ssejo JA, [eloyjo sy2 Jo | 33ed uC "S]YSIOM IaAo0 Ayinsiquie 9y} BuTuIsDU0D soalmbus AW sMO] -[OJ osueyo JUROyIUSIS sIOW YONUI Y “Ieasd [OIUOD pue juowdinbe oper oy} Jo UOISN[OUI 94} pue Jes UA OY} JO [RPAOWOI o[dwIs 94} Aq }vOq OIpel B se J[qIsl[o 2q [IM “JA, P2[ONUOD suURA BUTTIes sa1j 94) SULIOAOD Sa[NI oY} s}yooU 3eY} Jyeog Aue ey} poinsse useq savy | ‘SSB[D Opel sy} BULIBAOD soln [euYy jo souesqe oy} WI As “WA'W 94} YM souep -uodsdl10d SUNSOIN}UI sWIOS pey sAPY [ ‘Sse[D OIpeI B SB SSEIO JA, 94} JO UOIUZOD9I 94} SUIMOT[OF j JUSWSAOW JO sddIZap OXI 24} INoYysnoIY} suNjes Jo sdoajs Ajj ise] 3B UTe}QO UPd | ‘sAv[oI SUIALIP JoyI[dwe apeu owoy Be BSuUIsn 0} Iv[IWIs d1e UBISOp pue ‘IolIva pauomuew yey} sIy} BUIALIP somMoIjOa[a sy], ‘doys ouryporw ajeroqeyja Ajirey B O} ssd00R JNOYWM JOPNIsUOD SWOY sseIIZAB 94} JO} Jo}eW s]dWIs B ION {POs oy] Woy pouryovul useq sey j}ey} SuUIsnoy WmniurmMye ue uO pa}unow st Ajquiosse Ieos sjoyM sy} ‘jUSWUsITe AIOOVT -SHeS UIe}GO OJ, ‘ssulIveqg [[eq UO po}UNOW aq 0} sey SIy} ‘jJeYys WIOM 94} UO }sNIY] PUS d]QeJapIsuOd 34} JO MOIA UL pu ‘SUOISUSWIP ysngor sjIMb Jo jasyM pure WIOM B YSNOIY) SI Wie [O1JUOD 9Y} 0} SALIP [eUy sy] ‘smo]qoid SuLmmjoejnuew Jo joy & sey ‘UsISOp Ss} Ul

JUNE 1973 ROUND THE REGATTAS Some of the Clapham 36R entries — right, Captain Pugwash, centre, Mach I, far right, Shooting Star and Blue Shark. Note tri- angular Shooting planform Star, also of una rig. Doris Cup, Clapham One of the first races of the season at Clapham on March 11 saw ten 36 in. R boats from three clubs sailing for the Doris Cup. The morning was sunny with a light breeze and boats carried top suits. However, the wind dropped away completely in the first board but came up to almost gale force for the second. The unusual Shooting Star was unsure whether to sail under or over the water in this wind, in both directions, but nevertheless showed a fair turn of speed, and after the third board was lying equal second with Sparky to the veteran Danson Minx. Some skippers tried spinnakers which caused a re-shuffle of positions, and by lunchtime Mach I had taken the lead, Danson Minx second and Shooting Star third. The strong wind persisted after lunch and spinnakers were soon abandoned. Captain Pugwash now came up challenging for second place, and the final result was: Ist ©. Dicks Clapham Mach | 2nd I. Taylor Southgate Captain Pugwash 3rd_C. Daniels Southgate Shooting Star 4th C. Jackson Clapham Playaway 5th G. Goddard Danson Danson Minx 6th W. Dicks Clapham Misfit 7th H.Steadman Danson Blue Shark 8th J. Gilmour Clapham Sparky 9th 10th J. Pinner J. Vice Danson Clapham Piscus IT Robert Arvee Krakatoa, a new Lewis Cracker from a hull produced by Keith Armour being sailed by Bryan Jones and Gary Danks. Poppet, with a taller rig and keel modifications, performed well, although suffering with vane troubles, sailed by father and son team of Harold and Martin Dovey. Also sailing well were Keith and Sally Armour with their Cracker designs Sabre and Scimitar, Scimitar with a keel ‘a la’ Mustang, Sabre with keel as designed. After a short break for lunch the O.O.D. started the race again. The reason for the hurry was that the Parks Department was waiting to drain the lake for its annual cleaning. Towards the end the leading boats started to sail each other. Moppet took the run from Krakatoa but lost the beat. Moppet lost the run to Kintaro but took the beat. Final positions were: Ist Moppet 35pts., 2nd Krakatoa 30 pts., 31d Poppet 29 pts., 4th Scimitar 28 pts. After the prize giving the O.0.D. wished all visitors a safe journey home and said he hoped to see them at Bournville again, especially as this is the Club’s 50th year, when all visitors will be especially welcome. Boat Moppet Krakatoa Poppet Kintaro Sabre Midland District 10R Championship, April 1st This year’s 1OR Midland District was originally to be held at Witton but due to a last-minute change by the power boat club who share the lake with the Birmingham M.Y.C. the water was not available. By some hasty telephone calls visitors were told of the change of venue and 10 boats arrived at Bournville on the Sunday for the race. They were met with a 20-25 m.p.h. south westerly wind giving beat and run conditions, as opposed to the windless calm most coastal sailors think we sail in! O.0.D. Mr. W. Sykes started the event at 10.30 a.m. sharp and drove the competitors hard. There were a few breakages, notably John Don from Bradford who lost a rudder, but after a short while was back in the race. John Beatty sailed Moppet well from the start and after five heats was leading boat with 22 pts. His mate was his girlfriend, Miss Angela Colver, who was starting the boat on the run in order to allow John time to get to the other end to ‘field’ it. Several ‘fielders’ found it necessary to be in the lake to deal with their boats rather than risk them hitting the side. Runs were fast and furious but there were no serious collisions. Other boats going well in the conditions were 255 Scimitar John-Don Red Alert Tia Maria Pegasus Design Dovey L.W.L. 64 in. Club Pts. B'ham = 35 Position 1st Lewis 65 in. B'ville 30 2nd Dovey 65 in. B’ville 29 3rd 18 Poppet Cracker Poppet 60 in. B'ville Lewis 65 in. Bradford 13 Lewis 65 in. Bradford 28 60 in. Bradford 21 Lewis Kintaro Cracker Cracker Witty Dicks Shallah Littlejohn Tucker 67 in. 56 in. 55 in. B'ville Zi, B'ville 15 B'ville 4th 11 Northern Area Multi-racing Champs. The Birkenhead Model Yacht and Power Boat Club held the Northern Area Multi-racing Championship on Sunday, 15th April. The morning was overcast with a strong breeze which whipped up the Gautby Road Lake into quite an awkward chop. The water conditions did not however deter the competitors, and with over 70 entries running in 18 races the event got under way a little later than anticipated. As was expected, the small flatties encountered some difficulty in the rough conditions and the retrievers were fully occupied in returning waterlogged models to their owners. As the day progressed the weather brightened but the wind remained a problem. The first round ended

MODEL BOATS at four o’clock and the organisers decided to cut the second round to five minute races with only three minutes in between. J. Podlaski from Manchester had clocked up 19:3 laps with his ‘C’ Class entry while M. Huddleston and B. A. Stott had recorded 20 laps and 13-3 laps in Class ‘B’ and ‘A’ respectively. Leslie Senior won the electric race which was run in the first round. Despite the gruelling first round there were few retirements for the second round of multi racing. Several more boats came to grief in the second round, however, including one model which seemed intent on destroying the P.A. van and its occupants. Rob Johnson of the Birkenhead Club lost contact with his very fast Veco 61-powered model and the resulting argument with the wall wrote the boat off completely. The event drew to a close at 6.40 which, although late, was fairly reasonable considering the large entry. , Standard fuel was provided by Stan Catchpole of Model World, Liverpool, and also a quantity was brought by a visitor for use on the day. Eighteen gallons was consumed in seven and one half hours racing. Hot pies, sandwiches, tea, coffee and soup were provided all day and a vote of thanks must be given to the ladies working in the canteen. The prizes were presented by Mr. Frank Bradbury of the Manchester Club and the results are as follows :— _ Class A: Ist L. Senior, Huddersfield, 20 laps; 2nd B. Wooley, Birkenhead, 17.3 laps; 3rd P. Nelson, Manchester, 17.2 laps. Class B: lst M. Huddleston, Manchester, 30.3 laps; 2nd Mr Hulley, Manchester, 25.4 laps; 3rd S. White, Osset, 24.2 Class C: Ist J. Podlaski, Manchester, 30.1 laps; 2nd B. A. Stott, Leeds, 29.2 laps; 3rd B. Belas, Fleetwood, 26.3 laps. heats to Clapham ville on Everyone be concluded by soon after 6 o'clock. led at this stage with 89, then came Bourn764, Guildford 73, and Birmingham 71. dashed off for a quick change and a social evening at a local hotel. Sunday came in wet, cold, and windy, the wind being strong from the N.E., giving a spinnaker run out and tack and tack beat back. At the leeward end Spray was reaching the car park some yards from the lake, which coupled with light rain made setting the boats off to windward somewhat damp. Few skippers had mates, which involved rapid dashing from one side to the other on the beat: two spectators were issued with poles and turned any boat which approached them unattended, while anyone stopped any boat, several leaping into the water at the leeward end. Wind strength was 25 m.p.h. at mid-day, and had backed slightly to blow from directly behind the clubhouse, giving tricky conditions which caught some skippers out. By lunchbreak only three heats remained and these were completed by 3.30. As with the 1972 event, one day of light and one day of strong winds had given everyone a chance. Noticeable differences in performance in the varying conditions were headed by the ultra-light (11 lb.) 9 in. draught Dooloo, which scored 20 out of the possible 65 on Saturday but with possibly the smallest sails ever seen on an M and a miniature spinnaker to match, took 32 of the possible 40 on Sunday. Similarly, Bilbo Baggins had 23 on Saturday and 31 on Sunday, being perhaps the fastest downwind boat present. The race was won by a comfortable margin by the ace pair from Clapham, who were top and second individual scorers. Scores were :— National M Team Race Dovercourt water was host over Easter to eleven two-man club teams in the third annual Marblehead Team Race Championship, the best entry yet for this event. Six southern clubs sent teams, there were two Eastern District, and three Midland: lack of entries from more northern. and northwestern clubs was regretted. Although most of the country suffered appalling weather over the Easter, conditions were much better at the lakeside. Friday practice sessions in a fresh NATIONAL M. TEAM RACE Ist Clapham 2nd Hove & B’ton 3rd Bournville 4th Birmingham 5th Guildford 6th Southgate 7th Cleethorpes’ hopeful, but came the start of the race and a light and variable westerly appeared. Trimming was tricky and, as on any water under varying reaching conditions, some luck was involved. By lunchtime the wind was lighter and it dropped altogether in heat nine, to veer northwards, still light, but enabling 13 8th Norwich 9th Danson 10th Y.M.6m0O.A._ llth Dovercourt THE POWER SCENE (continued from page 237) balsa model with no trouble at all. The strapping between cells must be carried out in such a way that no strain can be imparted to any of the strip terminals and these must be well insulated from one another, or they could short out. Such an occurrence nearly wrote off David Sims’ 24 kilo boat (see last month) and Ray Kroker in the States has also mentioned the dangers of sending charged cells in the post. A slight jolt bending two terminals together could easily set fire to the parcel. The moral is to tape to make a robust and waterproof pack. Local club member Gordon Bullock came up with a very neat idea for housing his 1:2 a/h cells. One size of 35 m.m. colour transparency containers will just accept four such cells and can be taped up to make them waterproof. The only slight problem here is that you cannot so easily detect the warmth of the cells to determine the end of a rapid charge, but north-easter (straight down the lake) had everyone carry out the wiring with great care and fully dis- charged cells. Some method of preventing the from moving with respect to one another is recommended — I use plywood strips to stiffen bank of four cells which are tightly bound with cells also each PVC 256 this would be C. R. D. C. Dicks Seager Daly Colsell H. Dovey M. Harris G. Webb J, Beattie R. Cole A. Austin |. Taylor C. Daniels G. Griffin H. Briggs W. Grint M. Haines A. Larraman G. Sheward E. Carter G. Clark R. Christmas D. Pratt no problem Pterodactyl Aeolus Hamster 83 7\ 65 154 Shazzan 514 1154 50 107 Foxtrot Uncle 57 Road Runner Jester Capella Il 64 49 63 Sweet Sixteen Kazak Dooloo G.O. Bilbo Baggins Nola Eastern Promise Xerxes Noddy Hiawatha Force 13 PF.0. Micnulwan 57 42 52 38 54 39 514 Andromeda with normal 50 38 46 38 16 25 122 112 94 92 904 88 84 4l charging procedures. Rapid Charging of Nicads Later in the series, I plan to detail some improved methods of rapid charging to get over the problem of finding high power; low value potentiometers which apparently is causing some difficulty. However, if you happen to want to rapid-charge eight or

JUNE a multiple of eight cells at a time, there is a very current to make sure that it is in the range 2-10 amps and keep an eye or rather a finger on the cells to check for the first signs of getting warm when they should be disconnected. If the charging current is too high, use longer or thinner charging leads or viceversa. For Sea Wasp owners this method could be very useful as the Sea Wasp 6 requires a maximum of eight cells and the 12 uses a maximum of 16 which could be rapid-charged in two blocks. A wise precaution with this method would be to fit a fuse in one of the leads, and suitable fuse holders and fuses can be obtained from good motor accessory shops. Take especial care to connect the car battery and Nicad positives to each other and likewise the Nicad negative and car battery negatives should be connected together. Connection the wrong way round is likely to provide some expensive sparks! simple method from a car battery as I found out recently from another Coventry member, Jeff Bird. Eight cells require a charging voltage of just over 11 volts and this is 1973 the voltage which you can obtain with a pair of charging leads connected straight to the car battery with no extra resistance at all. The actual charging current depends on many factors such as the condition of the car battery, the size and condition and state of charge of the Nicads, the length and thickness of the charging leads, the connections to the car battery and Nicads etc. In fact, with eight 1:2 a/h cells connected through a four foot length of twin flex to my car battery, the current even varied from five down to three amps depending on how many lights were switched on, so don’t expect the current to stay anywhere near constant. Meter the GOSLING (continued from page 234) Mast Extension. This is simply a length of the same tube as the mast, fitted with a dowel plug epoxied into it and engaging in the top of the mast. You may like to fit a short jackstay to ensure that the head of the taller sail is held close to it. It is only rigged when using the light weather sails. to length and drilling a few holes, practically the only work is epoxying the gooseneck plate in position and making provision to engage the mast step. On the prototype the mast heel was plugged with 5/16 in. dowel (slightly sanded to a tight fit and epoxied in) and a fore-and-aft sawcut made to fit over the mast step T. A hole cross-drilled through takes an 8 BA bolt to provide fore-and-aft location. An Jumper Strut. If you can find a scrap of aluminium curtain rail and cut off a T section, or a piece of aluminium T, this is ideal. Taper as shown and epoxy into a slit sawn in the end of a short piece of mast tube. The other end of the tube has a dowel epoxied in to plug into either the mast or the mast extension. Drill three holes for hooks in the T. If a tubular strut is used, you may prefer to fit wire eyes to receive the three hooks. The idea of the strut is firstly to carry the stays (especially the backstay) clear of the sails, but it also provides leverage so that tightening one or other stay can put a slight curve in the mast, interacting with the shrouds and jibstay, which can sometimes be helpful in getting a sail to set well. alternative would be a peg screwed into the dowel plug (the usual is to screw in a brass cuphook and then saw off the hook) locating in one of a line of nas drilled along a strip of } in. ply glued to the eck. The gooseneck plate should preferably be cut from a scrap of } in. Tufnol but Perspex or other hard plastic would do. At a pinch, 4 in. birch ply could be used and should give a couple of seasons’ use before requiring replacement. It is drilled and filed a tightish fit on the mast, its site roughened slightly, then, after drilling the other four holes, it is epoxied firmly in place, accurately aligned. The only other permanent mast fittings are the Mast Step. As discussed, this is a T section on the prototype, cut from brass curtain rail and drilled as shown. Drawn brass T section would be better, though not so easily available. A drilled ply slip is an alternative, as previously mentioned. wire eye for the kicking strap and the jackstay. The former is bent from about 20g s/s wire with roundnose pliers, passed through the mast, and has a second eye turned as close to the mast as possible. Braided terylene or about 28g s/s wire can be used for the jackstay, which should be as taut as possible, made off through a hole top and bottom, Part of the idea behind this design was that it could be used with single-channel radio and asymmetric sheeting, which would mean the necessity for sail horses. If this idea appeals to you, leave the deck off your model for the time being and we will discuss the extra fittings needed, in the next issue. and strapped to the mast between sail hooks with a couple of turns of metallised Sellotape or plastic insulation tape. Its function is to hold the luff of the sail snugly to the mast. (To be continued) THE MOTOR FOR YOUR ELECTRIC BOAT * RACING U.S. * SCALE J Class Record * SPORT Best in the British 100 Watt Class Gold Medal - European Championships 500 Watt Class SELECTED Efficiency to dynamically MATERIALS 80% . balanced Weight METICULOUS only armature . 13 oz Silver . Optional graphite CRAFTSMANSHIP Water cartridge Cooling brushes ball bearings . 12 or 24 silver/copper commutator bars. . . 12 Slot Precision Overseas by post-paid insured airmail - Distributed in W. Germany by K. D. HORN WRITE FOR COMPLETE SPECIFICATIONS 6 SEA WASP 12 Kroker Engineering & Development Co., P.O. Box 14056, 257 Albuquerque, New Mexico 87111, U.S.A.