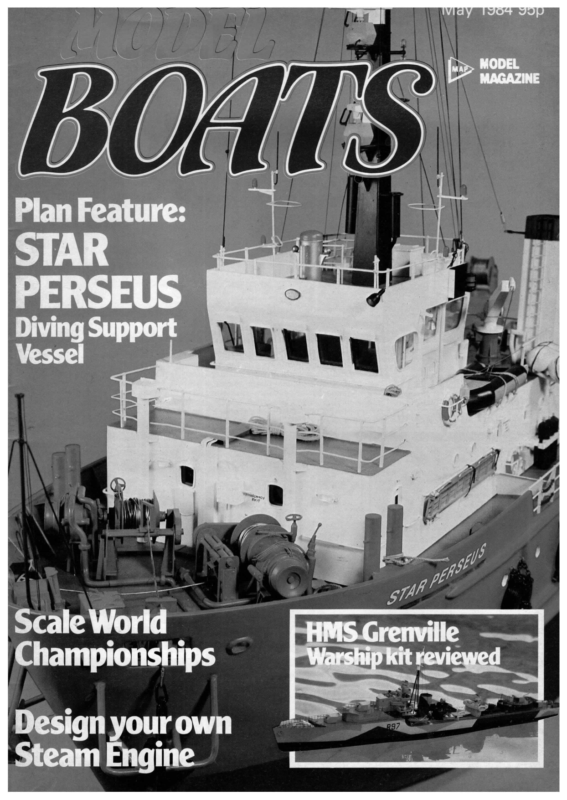

a Fentiaie STAR PERSEUS© Diving — Vessel Scale World Championships Design your own Steam Engine-

formed in order to cater for the basic kit plus £21.69 for the keel event. As well as trade stands and and £12.11 for the mast. extensive railway layouts are in- mind then take a look at the waterproof receiver box from Robbe, distributed by Cougar Craft. The box is moulded from plastic and is substantially ribbed for strength. corporated The lid uses a snap fitting action display areas, a boat pool, radio controlled car racing circuit, and in the overall plan. and is sealed by a rubber O ring. wiring harness, aerial etc. leads out through a _ softened plastic gland. Once everything has been positioned a simple but effec- Other activities will include radio controlled and The ‘round-the-pole’ flying demonstrations by scale air- craft, and an outside 5in. gauge steam railway track. tive It is also hoped that business and industry will support the event, screwed expansion device seals the openings. A neat aerial of plug and socket is supplied so that the receiver can be easily removed and used elsewhere. This inexpensive unit will no doubt be of benefit activity planned, it is anticipated to boat and buggy users, priced at with sponsorship opportunities available for both competitions and major displays. With such a large range that the exhibition will appeal not only to £6.06 inc. VAT. societies and confirmed Staying with Robbe and Cougar modellers, but also to the general Craft, it is pleasing to see that the British distributors for this German public as a family day out. Further information for the model trade societies, and model- market ling enthusiasts, is available from: Mary White, Argus Specialist Exhibitions Ltd. on 04427 73291. ScotModex 84 is jointly organised by Conex Ltd. and Argus Specialist Exhibitions Ltd. Hydroplane and steam enthusiasts will be sorry to hear of the recent death of Jim Bamford of Fleet, Hampshire. Jim commenced his model boat operations about 1950 with a daring project consisting of a flash steam hydroplane driven by a turbine. Experiments continued with varied success but always with great enthusiasm; several times lap speeds of over 45mph were reached and at the St. Albans regatta in 1954 32mph was attained over 500 yards, and it is believed never that been performance approached by has any other driven model. Flash steam fever having taken hold, Jim then produced a series of very successful piston included engined boats which piston-operated disc valve engines — robust and simple but giving a lot of power with steam economy. Perhaps his greatest achieve- ment was in the design of flash boilers in which all air passed through the blowlamp flame thus ensuring complete combustion. Severl boilers were capable of evaporating 1¥,lb of water per minute without cooling off. Jim was an_ experimental engineer at National Gas Turbines and his knowledge of combustion of fuel within turbines must have helped in a succession of boiler designs from which time to were published time in Mode/ Engineer. Seven years ago Jim took early retirement owing to ill-health but his recent passing was sudden and unexpected. On behalf of all model power boaters we offer our sincere sympathy to Peggy Bamford and family. J.H. Benson May 1984 Robbe Piro/ is a radio Marblehead in the modern idiom a selection of the radio control products. One item that will gk Ce) Py ee Pt be of interest to model boat (and and is supplied in a highly pre- buggy) enthusiasts is the Mini 300 moulding in Robbe’s Plura, a light volts, fabricated form for quick and easy HEC electronic speed controller. The unit is rated at 9.6 to 12 building. The hull is a one piece accepts Obituary — J. A. Bamford Model The but strong plastic which * * * bed range are now bringing to the UK epoxy readily adhesives, and 15 measures amps maximum, 78 45 x x and 245mm, weighing around 90gm. The con- provides access through a single troller large hatch. All other necessary control in forward and reverse and cut-outs and holes are pre-cut, shaped, or drilled. The kit rudder and components’ shaft, include keel strake, sliding hatch and clear superstruc- all provides functions are proportional adjustable by means of small presets in the side of the case. The unit can also be switched to give forward speeds only for fast electric boats, etc. This top suit of sails one unit, therefore, will suit most (other suits available), all rigging of, if not all, the required applica- ture, pre-sewn fittings, including booms, cord and tions of a scale, fast electric or thread, buggy/car modeller. Wiring con- shroud tensioner, main boom fitting with ball links, ball- race supported swivel for the jib boom, shroud and mast rails in aluminium and r/c fittings kit. The drawings are excellent and should be easy to follow, being of the normal exploded and keyed type; plus a three times enlargement of the rigging and fittings. The packaging is excellent. The hull is protected in a thick plastic envelope; all the fittings, etc, are packaged and the sails, in primrose yellow, are supplied rolled in a heavy cardboard tube. The from which keel two bolt support plastic is moulded components together around a specially shaped brass reinforcing tube which is fixed through the deck and hull bottom, culminating in a threaded socket to accept the cast metal shaped ballast keel. The aluminium channel nections amount to three leads, one to receiver and the two standard two-pin power lead plugs and sockets running to the battery pack and motor. The receiver plug is the Futaba type — but not the style recently introduced. Most users should be able to position to assist. The unit retails at £45.05 inc. VAT and there is another version called the Mini 200 which gives proportional forward and reverse at four to 14 volts, maximum adjusting facilities. latter is £31.38 inc. VAT. * * * is very and the bushings are in aluminium alloy. Their short length and interchangeable splined bushings allows for easy installation and gives a quick- change facility. The bushings are available threaded or plain andina large range of sizes which shouid suit the majority of motors/shaft combinations. The range is now being RM exclusively Trading Co. distributed and by coupling centres are now or will shortly be Prices are very competitive and as units can be purchased in individual components, expense is reduced prices to are a a minimum. single Typical coupling at £1.65 and a double at £2.82 inc. VAT. * * * The propellers are part of range from a new Germany developed over the last two years by one of that country’s leading modellers, and they are known as the original Charlier special racing propellers. They are cast in aluminium and polished, the blades are thin and tube even in size, and the bosses are strapped to a piece of 2in. by lin. boat now moulded in shatter resistant thermoplastic Price of the tapped for either timber for protection. The sive system was evolved specifically for the modeller; the joints are current 10 amps, but without the mast, a 4mm or 5mm shaft. attractive, modern and racing looking. Of course, only time will tell as to how she performs in races. We will be publishing a full kit review shortly. Pirol is distributed by Cougar Craft and retails at £89.78 for the Jest the mast is in one piece and is supplied cardboard in the model shop ought to be in a must be purchased separately. The substantial covered available in your local model shop. are not included with the kit and a originally Bench, February 1983. This exten- rewire to plugs fitting their individual systems, and if in doubt 220mm long, and the ballast keel in The HUCO Dyna-Po/ couplings were There are nine sizes in the range at present; the largest is called 8A and is suitable for the most power- If you are one of those modellers who forever suffers from wet radio gear, or you want extra piece of ful 15cc motors — dropping in size to the numbers 3 and 4 which have been found ideal for larger electric boats running Keller motors. At a 247

four-year periods and the possibility of the M.Y.A. hosting the event in 1986 should the Americans not be able to arrange it in 1985 is being looked at. Ken Shaw reported that one or two minor matters of wording remain to be agreed on the insurance policy, but nothing actually affecting the cover. He was thanked for his efforts in this connection and also for managing to get out the address/ fixture list at such an early date. (Club members get these when their clubs’ affiliation has been paid). Some discussion took place on the A.G.M. and decisions taken there. Since reprinting of the Constitution was now required, a sub-committee was set up to examine the t the January Council Meeting of the M.Y.A., held on January 28th, the Treasurer reported that only 15 clubs had paid affiliation fees at the time. This is perhapsa little disappointing in view of the fact that the insurance negotiated by the present situation. There have been several amendments since the last printing of the Constitution and some tidying up may be helpful. The new 36R rating rule was discussed, especially with regard to one particular Association comes into effect only when affiliation is paid. Subjects covered included the kind boat which has sailed for many years without a hint of complaint; because it has a g.r.p. mast and spars (made froma dumped fishing rod at no cost) itis now illegal, which most people would agree is an manufacture of a case for the Eric Nuttall Award by Mr. Bantock senior, the turning down of a grant request by the Fosters Draught Foundation, an accepted explanation for an entrant’s failure to arrive at a radio championship and the timing of the Yachting Monthly Cup event within the A Class championships, which one or two overseas competitors feel should absurdity. Regrettably, council has no power to vary the rule, which can only be changed by a simple majority at a G.M. (Constitution 7 (6), so for this reason this particular yacht will be out of rating, a victim of an attempt to limit the cost of models in this class. The new rules and certificates are now available price 15p and 10p respectively from the new Publications Secretary, C. Jackson, 5 Crofton Court, Cypress Road, S. Norwood, London SE25 be given greater prominence. Mention was made of the recognition of the A.M.Y.A. as the national authority for the U.S.A. and the possibility of a world championship being held on the West Coast in 1985. Under the terms of the world trophies they should be competed for within 4BB. A number of minor matters relating to National Championships received attention, including what appears to be an area of misunderstanding in respect of entries for particularly, the RM, where the host club was under the impression that entry was limited to a maximum of 50 yachts. Although the possibility of some limit was brought up on one occasion, there is no limitation on entries in any class. Chelmsford club, due to host the RA Championship, will probably be in the throes of moving to a new lake, and the event will now be held at Fleetwood, June 23/24; closing date for entries remains May 26. Last year’s RA threw up a considerable number of discrepancies (incorrect entry forms, incorrect certificates, no certificates, etc.) and this increasing slackness has been evident in other classes. A sub-committee has now been set up to investigate entry procedures and recommend any revisions felt necessary. New clubs affiliated were Canterbury M.B.C.(N. Ward, 256 Beaver Road, Ashford, Kent) and Crawley D.M.B.C. (P. R. Tobutt, 1 Fairview, Horsham, W. Sussex, RH12 2PY) and there was notification ofa change of secretary for Ashton T.R.Y.C. (D. Blundell, 96 Laneside, New Mills, Nr. Stockport, Cheshire, SK12 4LU). A brief report was made on discussions which are taking place on possible changes to CB regulations and an exclusive band (possibly around 40mHZ) for surface models. Nothing would be likely to be decided for at least 18 months, but naturally if there is any news it will be reported. Date Event Class Venue Date Event Class Venue 14/15 15 15 15 15 20 22 23 23 23 MYA National Team Championship. Met. & South District Championship. Met. & South District Championship Rawdon Cup. Open Event. Mayoral Cup. Charnwood Cup. Trojan Cup. ; Parks Committee Cup. ; Northern District Championship and A R10R M RA RM M R10R Birmingham New Forest Clapham Leeds & Bradford Cheltenham Fleetwood Leicester Gosport Birkenhead 12 12 13 13 13 13 13 13 20 20 Tamplin Cup. Gilbert Cup. Midland District Championship. Met. & South District Championship. Eastern District Championship. Eric Nuttall Memorial Trophy. Open Event. John Waller Trophy. Midland District Championship. Northern District Championship. R10R 6m 6m RM RM RM RM RM RM 10R Gosport Birmingham Birmingham Woodley Dovercourt Fleetwood Chippenham Lincoln Milton Keynes Newcastle 29 29 29 29 29 29 29 May Midland District Championship. Festival Cup. Nylet Trophy. Cheddar Cheese. Jesmond Bowl. Alpha Cup. Open Event 20 20 26/28 27 Barnaby Dun Trophy. Cole Cup MYA National Championship. Nyria Cup. RM R10R RM A Doncaster Birkenhead New Forest Gosport June 2 : Plant Cup. basin Trophy. A RM Birmingham Leicester RA & R10R Poole April Northern Team Championship A RA M RM RM RM M RM RM Fleetwood Bournville Etherow New Forest Woodspring Newcastle Birkenhead Milton Keynes May 20 : 5/7 6 6 6 Currey Mug. aplin Cup. RM Gosport MYA National Championship. M Fleetwood 3 Fred Parkes Trophy. M Cleethorpes Round Welford Race. Hatfield Trophy. Canada Cup. RM RM RM Leicester Chelmsford Poole 3 3 3 Windsor Trophy. Corporation Trophy Eastern District Team Championship. R10R RiOR RM Fleetwood Hove & Brighton Dovercourt CAPITAL SHIPS THE ENTIRE SAILING SHIP & POWER CRAFT SERIES OF AUTHORITATIVE DRAWINGS By Harold A. Underhill, A.M.1.E.S. By courtesy of the Executors Di ip Illustrated list of 70 Sailing ls Is * — isl y Ship Designs £1.00 Illustrated list of 35 Power Craft 7Op From Leading Dealers or Direct from: BASSETT-LOWKE LTD. 19 KINGSWELL STREET, NORTHAMPTON NN11PS May 1984 Its collection of superb colour prints have proved very popular: HMS Hood, Duke of York and Warspite are now offered with mounts to fit a standard 12x 16 frame — still only £4.95 each — or £14.00 per set, signed by the artist P. J. Boville. Also available are a fine collection of original oil paintings and watercolours depicting all aspects of maritime life. Send £1.00 SAE for details and list. ty Boville Studios, Dept. MB, 55 Blenheim Ave., Marske by Sea, Cleveland, TS11 GBB. 271

t one time it seems to have been standard practice, where ribs were not inset flush with the inwale, to plank the hull and at a later stage insert filler pieces between the top plank and the inside from rib to rib. (Fig. 1). Presumably this allowed the plank to adopt a fair curve round the ribs even if the steamed inwale flattened between shadows; there seems no other obvious explanation, but if the ribs were rebated into the inwale there would be a greater chance of kinking and yet the plank would lie more intimately against the inwale. Having tried both methods in the past, it seems better, at least with laminated this was to neaten the appearance at the deck edge by having a single joint between material rib of strips short with the covering board and sheer plank, uninoverlaps glued directly to the inwale. Apart from terrupted by the side/end grain of the deck. being easier, a better glue joint can be made (Fig. 3). Covering boards were used in the days of one or two-piece sheet wood decks to than by sliding fillers in at a later stage. inwales and thin ply ribs (which is a more modern approach) to fill between the rib The backbone ends of the ribs, if rebated, need not be actual ends, since most of the ribs can be inwale-to-inwale, possibly just cracked at the centre line. However, the ribs can simply butt to the backbone, since the area of plank covering the joint will bond Covering board protect the deck-edge; a blow against a sharp vertical corner etc., could split the deck along the entire length. This danger disappeared with the availability of waterproof thin ply (initially ‘aircraft’ grade) Sheer plank Fig. 3 around fifty years ago, but covering boards Planking lingered on long after their functional need Most larger yachts traditionally are ticular, With the angle at which the plank had become obsolete because without them planked with cedar or mahogany and there covering the joint lies, nothing short of a a yacht did not look finished. There is no are many non-club builders who derive total split along the plank would allow doubt that a modern yacht looks pretty considerable pleasure from building in this separation. For the best of all worlds, the tip stark even today when placed beside one way, often with a bright varnish finish of each rib could rest in a small rebate at the with covering boards and a neatly lined which allows the work in the planking to be deck. edge of the backbone. (Fig. 2). seen and appreciated. Not only non-club builders, of course, for there are still com-Some early planked yachts had decks inset into the top planks. This meant peting skippers who prefer a nicely planked them together, with modern glues in par- hull. Ken Jones, who will build to order, must have exceeded 200A and 10 rater allowing the top, or sheer, plank to extend above the inwale by slightly more than the deck thickness and after completing planking, pinning or clamping a strip of deck-thickness material to the inwale and trimming the sheer plank down. The idea of planked hulls, and Hugh Shields from Scotland has built a new A boat virtually every winter for something like 30 years. Nowadays sources for traditional a9 Gap’ Inwale Sheer plank Planked (with mostly parallel-sided planks) up to backbone at each end. Ragged plank ends are left in place until bow blocks and transom AI A EE veneering are ready to be tackled. Fig. 2 TIP REBATED materials are very limited (Punctilio at Hinckley, Leics., is the only one advertising) and obeche or sometimes spruce are used for planks. Hulls have been seen planked with y,,in. ply strips, but this is quite hard work and is fairly heavy, despite the thinness of the ply; the latter makes it difficult to achieve an absolute fair hull, since there is so little scope for sanding. Normally, timber a full ‘4in. thick is used, allowing sanding down to a bare %,in. at the thinnest, while for larger hulls (say 5ft. and above) ‘/,,in. is more normal, planing and sanding to around in. finished thickness. These figures need qualifying, since weight is important and a harder, heavier timber should finish up thinner (without material loss of strength) in order to achieve a reasonable weight. Model Boats 272

Planks should be glued only to the ribs and other permanent hull members, and some builders fit strips of waxed paper under the ribs to prevent glue from straying into the wrong place. Veneer pins can be tapped in to hold the planks, which should be induced to lie as flat as possible or too ‘much material may have to be planed off to achieve a smooth surface, resulting in thin spots in the planking. Bamboo trennals can be permanently inserted where the underlying structure is thick enough, but otherwise pins can be used and withdrawn when the glue is dry. Twisting a pin to break free any glue film before attempting to pull it makes withdrawal easier, incidentally. Turning to Hobnoblin In the case of Hobnoblin we are going to use in. balsa and adda toughened skin ata later stage. With care, the entire planking can be got out of only a fraction over three 3x36in. sheets. Further, most of the planks will be parallel-sided, simplifying and speeding up the work, although it is far better to fit a couple of planks each side per evening than to rush the job. Normially there is a considerable dif- ference between the girth of a hull at its largest section and the ends and the procedure is to divide off the largest section into an equal number of plank spaces and then divide a section at each end, often the waterline endings, into the same number of spaces. These points, connected by straight lines on the body plan, provide a planking plan from which the plank width at each station can be plotted, so that a complete plank can be drawn out on the planking timber. The plan also indicated which planks will terminate on the backbone, fore and aft. Now, having outlined proper planking technique, we can turn to Hobnoblin and find that it’s easier. For one thing, there is not so big a difference between the largest section and the transom B1, where we are terminating the planking, so we haven’t so much plank taper to worry about. Working in balsa obviates the need for planing, etc., Above: hull with first two planks in place. Sheer plank is parallel but second plank is wider in centre than at ends. Ribs are clearly visible, as is bevel chiselled/sanded on backbone. Right: butting the planks together on the centre line of the backbone at the stern. Dark plank each side is harder balsa and neither has fitted as snugly as it should. A shade more chamfer was obviously needed. All photos by the author. It will be apparent that with equal widths marked in the centre and equal (though narrower) widths at each end, all planks are effectively the same, apart from overall length where they begin to lodge on the backbone. It is indeed possible to make the planks in batches, but it is as well to mark the designed widths on the appropriate ribs and check during work that the shaped planks are matching the marks reasonably closely, and equally on each side. The usual plank form is straight on the top edge (which will be the bottom as you work, as the hull is upside down) and curved on the lower edge; the curve is very slight and connecting the spotted-off station points with a straight line is usually adequate. Cut to leave the pencil lines and plane or sand down to the marked points, in effect removing the pencil at the points, but leaving it showing half-way between points. This curved edge is finished square and a slight chamfer is then put on the straight side, remembering one left, one right plank. To adjust if the planks are running deep or shallow, pin a sin. square strip (a ‘spilling batten’) to the next marks on the ribs and from a prepared straight edge mark off the required widths with dividers or compasses. Cut this plank, chamfer and fit and you should be back to aligning with the marks again. Don’t wait too long before fitting a May 1984 correction plank of this type or it may come out a noticeably odd shape and show in the finished hull. Traditionally, planks at the bow end are overlapped alternatively. The first plank is fitted, then carefully trimmed to continue the surface against which it is glued. It’s opposite number is then glued over it. The next pair are reversed, and so on. When the planking is cleaned up the point formed by the planks should be planed down to a flat surface ‘4 or %,in. wide and a strip of planking material glued on. When dry this is planed and sanded to blend in. The idea is to prevent planks splitting or lifting if the hull rams a sharp object; the missing piece can be planed away and replaced if it gets very battered, though it is rarely necessary to do so. At the stern the classic procedure is to glue a piece of planking material centrally along the backbone, about one third of the backbone width. The plank ends are then cut to sit neatly in the rebates so formed, which is much easier (and tidier) then trying to bevel the opposite planks to butt together. Most modern hulls are fairly flat on the centre line aft of the fin, but if the after sections are fairly sharply v’d the central strip needs to be correspondingly narrow. and provided very hard balsa is avoided, the planks will be quite docile and can be held in place with dressmakers’ or modelling pins. What will be found helpful — indeed, almost essential — is a three-foot metal straight edge, and the easiest answer hereis to check for metal suppliers in your telephone area, then pop in and see if they have a strip of something about 2in. wide and 36in. or so long, preferably 2mm (or */;,in., or 12swg) thick or thicker, though don’t ignore quite thin stuff, 18 or 20swg, if nothing better offers. This sort of odd strip is often left over from guillotining work and can be yours for quite a small sum. It is fairly important that one edge is straight; stretch twine along it to check. A small deviation is worth filing out, but if you explain why you want it the guillotine operator might take a whisker off along the edge to give youa truer piece. Drill a holein one end to hang it up by, mark the lower edge, and you have a tool to use for years to come. The balsa to be used should be medium hard and as far as possible constant in hardness. If a sheet harder at one end than the other is used and planks are sliced off in pairs, one will be hard end forward and one reversed. Unless this was noted and the next planks reversed you could end up with a bow 273

‘MOVe GIf Ni “SHOVON]A AYOOH LOAId | LO SHROUD PLATES – 2x ‘L’ SECTION BRASS. ‘V’ HOOK. JIBSTAY HOOK: JIB HEAD HOOK. 3721/2″ FROM DECK. OF ‘V’ HOOK. TR HOLE FOR SHROUD HOOK. HEAD HOOK ENGAG EYE OF STAYHOOK. STAY HOOK IN EYE ‘BENL’ MV i8/e 40191/G WOOE air HOLES FOR JIBSTAY HOOK. BOOM. eempesennaechencr ioe Haan TESST MAIN HOLE FOR a PIN. 46″ GOOSENECK PLATE ea PAXOLIN ETC: 30.3/4″ omen 34″ ae ee “TAAIMS ONIHSI4 SWOOG NMOHS Ce “MOOH WOVYLEIC FMAST : 52″ OF 3/8! TUBE. ‘3ZIS 41VWH HOOK & JACKLINE. YO4 AOOH A: MAINSAIL HEAD y “BENL Nv w8/E 40191/S: WOO NIVW JIB RACK : ‘T’- SECTION BRASS. WIRE EYE FOR dvuels ONIMOI —1 0 Sg tte ‘Nid HOANSSOO9 os “WOOH AVLSSYOS a) NMOOH AVLSdIf YOsS SAS BACKSTAY. [ooo oo 6 o’0 0} — ‘LSSHS’D uy Y¥O3 SAS HOOK FOR 3″x 3/16″ TUBE, ~ |EYE FOR KICKING STRAP & MAINSAIL WES ut WORD PLUG. CUT – OFF SCREW. 1 -+ i Raa em — DOWNHAUL. = —~_ ee 9.1/4″ 10.1/2. i f JIB RACK. ss 15.1/2” ae cs STRAP — SHROUD PLATE. qaTYa GNV JDdIA Ni Q3AN3L1V143 ONS e000 0 FORESTAY. a Model Boats 274

Fig. 4 ———— a EZ N Ss SS ee Hinge substantially hard on one side and soft on the other and vice-versa at the stern. Hardness variation across the width is not important but if there is a harder edge on one sheet, use this for the sheet planks. These are the first to be applied, and can be stright strips about in. wide. They are cemented all along the inwales and to the part of the ribs they cover and can be clamped in place with bulldog clips or clothes pegs. Adjust so they are flush with the deck surface on the inwales and leave to dry. Britfix balsa cement was used on the prototype, incidentally. The next pair of planks should be plotted, means that one plank must be turned end to end to use the chamfer as mentioned above, or both planks must be used on the same side. There is nothing really vital or mysterious about this, but it avoids waste — apart from the end pieces (the planked area is shorter than 36in. balsa sheets) the entire Make the ends the same height, then cement them in place on the hull, butting the wide ends to each other over the most convenient ribs, so that in effect you have added a plank in two pieces, ‘/,in. or so wide in the centre and fading to nothing at the ends. At this stage we have covered roughly 2in. on the largest shadow but about 1.*%%in. at either end, with the planking running reasonably fairly, and we can repeat the procedure, using a maximum of *%in. width, to avoid having to put too much sideways bend into the planks. The target is to reach the backbone at either end with the same plank, or only one plank difference, leaving perhapsa 2in. gap at the centre. From then on parallel planks can be used, butting level-cut ends on the centre line of the backbone. waste from the prototype could have been fitted in a matchbox. These parallel planks are now cemented on, two per side, using cement on the joining edges, the rib areas and ,in. fore and aft bulkheads and pressing them into intimate contact with the planks already in place. or marked out with piano wire or hardwood strip spline. They need to be about ¥,in. wide in the centre, tapering to about ‘in. at either end, and sliced to a light chamfer on the straight edge. After cutting, slice off the curved remnants on the sheet to leave a straight edge; cut to virtually nil width at the centre, they will be about *,in. wide at each end and each in two pieces. Put the trimmings on one side. Now mark off four planks about *,in. wide and parallel and cut, angling the centre cut of each pair to produce the required chamfer. This View from above shows the degree of access afforded by the narrow building board. Also illustrates (for those unfamiliar) the extension of Above: lit deliberately to emphasise the edges which are slightly proud, this photo shows an effect which builders will be likely to encounter. Provided the ‘steps’ are not more than about \/;,in. the shadows to bring them all to a straight line at the board. As the planks reach the ends, it will be noticed that it is not always possible to pin the joining edge down absolutely with the they will sand away without weakening the hull unduly. Right: view from above. preceding plank. The only way to do this is to use a collection of bird-beak clamps. (Fig. Pins skewed through into the shadows, missing the ribs, should hold them while the cement sets. Now take the trimmings from the earlier carved planks and re-cut the curved edges into a slightly convex shape, which will probably leave a full Y,in. at the wide ends. May 1984 4) or modified clothes pegs, which is why the planking can be a slow process. In our case, however, provided the visible step is very tiny (say ¥,in. or .5mm) we need not be too concerned. Pins should hold the planks to this limit, if necessary edge-pinning through one plank into the next. The only snag then is that the pins get in the way of fitting the next plank. There is no point in rushing the job, and to fill in time we have included this month the rigging and fitting details, sothat impatient builders can work on those between planking sessions. These with a little experience can also refer to the hull plans and get the bow blocks in place, so that the hull is ready for external sanding. 275