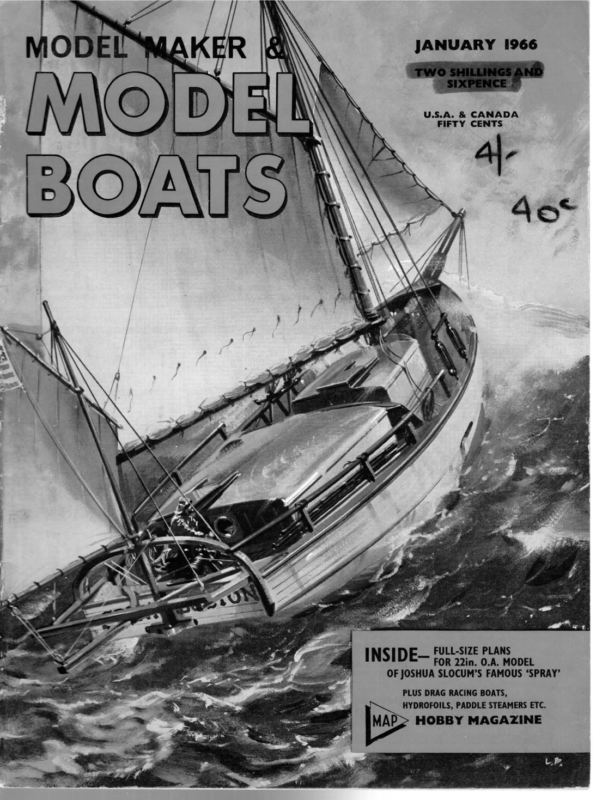

JANUARY 1966 U.S.A. & CANADA FIFTY CENTS & 40“ FULL-SIZE PLANS INSIDE— FOR 22in. 0.A. MODEL OF JOSHUA SLOCUM’S FAMOUS ‘SPRAY’ PLUS DRAG RACING BOATS, HYDROFOILS, PADDLE STEAMERS ETC. HOBBY MAGAZINE

BOATS $CARAB LTHOUGH there is no great resemblance, Scarab is a direct development of Green Dragon, though not in detail, as it was concluded that due to some of the latter’s shortcomings a new approach would be advisable. However, much was learnt from Green Dragon, both good and bad, and it is on this basis that Scarab has been designed. Over a season’s racing it was observed that the two main faults with Green Dragon were that she was too light for competitive sailing on exposed waters, against the heavier modern boats, and that the flat scow section tended to slap and pound in rough water. In Scarab these two faults have been duly rectified, the first by increasing the displacement to 27.7 lbs. which gives her a righting moment equivalent to that of a 34 lb. conventional boat, and the second by reshaping the sections so that the size of the bottom planking is reduced. The bow overhang has been drawn out nearer the waterline, as with this type of section and the increased displacement she will be able to settle in the water and use a longer sailing length. The midsection is well raked with the greatest body depth fairly well forward and the greatest beam well back. The effect of this can be seen in the V sections forward and the very flat sections aft. This hull shape has been produced within the acceptable imits of hull balance. A DOUBLE-CHINE 10-RATER DEVELOPED FROM “‘GREEN DRAGON” BY D.M.J. HOLLOM Lest I be accused of copying another and well-known designer in my arrangement of the deck and sail plan I shall immediately confess my guilt, but would also point out that not to use an idea with such obvious advantages would be akin to burying one’s head in the sand. I refer of course to the turtle deck which is cambered to gain as much free sail area as possible. I have, however, left the afterdeck to the builder’s choice. The common arrangement is of course for this to be dished, but for the life of me I cannot find an acceptable reason or purpose for this layout. In the sailing canoe and similar craft it is used, I assume, to allow the helmsman to be lower in the boat, when he happens to be in the boat, and at the same time to allow water to drain away through the centre board slot. It would appear that in a model yacht the water may well drain into the hatch. The only advantage that I can think of is that a cambered deck can be lighter without warping, but why not camber it in the normal manner ? Perhaps someone would tell me the reason, which I feel sure I have overlooked. Owing to the extra strength of these cambered decks it will be possible to use 1/32in. marine ply, available from model aeroplane shops, without adding any additional beams. I have seen this ply used on a conventional deck and it has proved to be of ad2quate SCARAB vesewen. ey DMJ. Hollom. Re Sey MODEL MAKER PLANS SERVICE Sm10GE oT. HEMEL MEMPSTEAD, wears. FULL-SIZE COPIES OF THE DRAWING ABOVE, WHICH GIVES HALF SIZE SHEER AND WATERLINES WITH FULL-SIZE PLAN AND BALLAST BULB, ARE AVAILABLE, PRICE 9/- INCLUDING POST FROM MODEL MAKER PLANS SERVICE, BRIDGE STREET, HEMEL HEMPSTEAD, HERTS. BODY 13-35

JANUARY 1966 shrouds and no forestay, and the length of rigging wire required is, in fact, less than that of a conventional rig, with beating shrouds and a forestay. On the credit side, therefore, we have less windage because less rigging wire is required and because the mast is proportionately smaller than its conventional counterpart. On the debit side there is the small extra windage created by the spreaders. I think that it will be agreed, therefore, that the system offers considerable advantages for very little extra effort. Briefly it works in the following manner. A wire backstay is required which must be kept taut by means of a bottle screw. To enable this force to be transferred to the forestay, two jumper stays are led forward at an angle of 90° to each other, over the two spreaders attached to the mast in the same position as the jibstay. These jumper stays are then carried down to the mast and are attached at a point mid-way between the boom and the spreaders. To absorb the forward pull on the mast at this point, and also to provide lateral support, two stays are led down to the gunwale just abaft the mast. A jib stay is then attached in the normal manner and two stays from the attachment point of the jib stay to the gunwale to provide lateral support at this strength. The saving of any weight such as this, is, of course, vital. Whilst on the subject of construction, a method which I have found to be very suitable, producing as it does a very light boat, is the stressed skin method. The boat is built in the normal manner, but on completion all the frames or formers are remoyed, the only constructional members remaining being the keel, chines, and inwales. 3/4in. tapering to 3/8in. x Three light floors, 3/8in. 3/8in. at the chine are then fitted in way of the fin to absorb the twisting stresses in this area, and of course the usual deck beams. The result is an extremely light and strong hull. The sail plan shown is a little higher than usual, the aspect ratio being 5:1, and more than usual area is contained in the jib to allow a really large spinnaker to be used downwind. A jib horse extending the full width of the boat with adjustable stops is recommended to provide full control of any twist in the jib. Masts today seem to be almost universally made of dural tube but I’m sure that they could be made of very much thinner material provided that they are suitably stayed. A 1/2in. dural tube was used on Green Dragon with only one set of shrouds and proved to be quite satisfactory as the mast is short. With a very tall sail plan, such as is shown in Scarab, additional staying would be required, but as the unstayed sections of mast would be shorter, an even smaller tube could be used. The atrangement shown in the diagram needs no beating point. A short study of the diagram will make this clear. I feel quite sure that Scarab will be a definite improve- ment on Green Dragon, and if carefully built and fitted out with an eye on weight saving, she will prove to be a formidable contender. Any information from those who build and sail her will of course be welcomed. Building the ‘Barbara’ I first got the boat ‘‘bug’” in the Spring. I made one or two simple models and then started looking round for a boat in the ‘‘ large power driven’’ class. In April of the following year, I discovered the ‘‘Barbara’’ design whilst browsing through my many catalogues. I sent for the plans, measured up the various kinds and thicknesses of wood required and started building it during from each edge. This gave two pieces of 4 in. x 4 in. and some spare. When the stringers had been glued and pegged to the frames, A cardboard skinning began. template was used to ensure accuracy in the size of the four pieces of ‘‘skin’’. The tensioning strings were used where there was either lack acetate sheet. The forward cabin roof to the runners previously described, The shaft angle was bent on the aluminium 4 in. x din. beech (deckbeams). Some weak parts in the web needed strengthening, namely, the part just above the slot This item was constructed from #% in. ply with fretsawed windows glazed with fretsawed out of 1/16 in. ply strengthened with 4 in. square ash and cut to admit the keel. The 4 in. square and the deckbeams were glued and pegged with dowel to ensure a really tough joint. These frames were then screwed to the baseboard which was made from a 5 ft. length of ply with runners affixed and drilled to admit tensioning strings. During the Easter holidays I steam bent the stringers and keel. An ordinary kettle was fitted with a length of 2 in. diameter copper tubing. The pieces of ash were inserted into the tube, the kettle filled with water and the gas was lit. After half an hour in the steam the ash was taken out of the tube and clamped round a former already cut out of thick ply. The stringers offered no problems, ut the keel had to be bent approximately 89 deg. The keel is composite — being made from two pieces of } in. xX 4 in. ash straps sandwiching a piece of j in. x 3/16 in. ash. Only the straps were bent because the inner keel had to be scarphed to the stem web. The method of bending a piece of + in. x 4 in. was that I bought a piece of 1 in. x } in. and bent this with the help of a willing father. This piece was then sawn } in. were hammered out of 1/16 in. copper superstructure. eleven clamps, tweny-four strings and their associated wedges, and the clamp end of a mincer! As soon as the skin was By Chrismas all the frames had been water tube boiler like all full sized marine boilers. The holes for the five water tubes were accurately drilled in the firetube. The water tubes—? in. in diameter —were brazed in and this whole assembly was brazed into the boiler ends. The ends sheet over a high carbon steel former made by a local garage. The ends were silver soldered into the copper drum, and the fittings were silver soldered to the A_ petrol blowlamp_ (Bassettdrum. Lowke) fires the boiler. The boiler and engine were bolted to a length of 4% in. of clamps or where the clamps could not On one section of skin there were reach. and that summer. pumped the bellows! It is a centre flue dry, the dowel pegs were glued in. I is then turned removable for the to easy blowlamp and boiler. access to the Meantime, the hull was being primed and undercoated. Inside, the runners were being glued to the frame webs to take the engine baseboard. The shaft angle was worked out by trigonometry (a use- ful method if one does not forget to take into account the height of the keel) and a suitable hole was drilled in the keel. I used a Ripmax 14 in. shaft and a 2 in. diameter 5 in. pitch propeller. The rudder stock and keel were then drilled and the rudder was fitted. the engine was being Meanwhile, machined by a model-making friend. The engine is a Monarch sold by A. J. and is a of Birmingham, Reeves, reversible + in. b. & s. side valve type gives which crankshaft balanced a with exceptionally high power and speed. I timed and weekend one over it assembled the valve gear. The reversing is obtained by making use of a slip eccentric. When the engine is running free it reaches a speed of approximately 1,000 r.p.m. I always maintain that my father helped me braze the boiler—he did the brazing, I 13 Mi aluminium sheet which was bolted down ensuring a perfectly aligned job. Two pieces of 1/16 in. ply were cut out and veneered for the deck. The deck was struck down and pinned to the deck planking is represented by beams. The Indian ink lines on the veneer. Four ieces of + in. x 4 in. channel wood 4 in. channel) were struck and screwed to the deck to take the superstructure. This means that the whole superstructure can be removed in less than two seconds in the event of a fire. The funnel was constructed from soft brass sheet bent round a former of wood. The deck was given three coats of varnish and the hull was given ten coats of undercoating. The baseboard was then converted into the stand with the addiThe colour scheme is powder blue under the water line, white above, varnished mahogany deck, white channel tion of supports. wood, varnished mahogany superstructure topped by white cabin roofs and funnel. Commercial fittings were bought to enhance the appearance of this 4 ft. long, 10 in. beam boat.

MODEL BOATS READERS 20)ritc SPLIT IN FINS Experimental Fins by D. M. J. Hollom. Page 388, Sept. Issue. Dear Sir, ! would appreciate if Mr. Hollom could explain to me (a novice) why he does not adopt the simpler solution to the problem of ballast and lateral resistance by varying the area®* of the skeg (before the rudder). In my ignorance, it would seem that the best of three worlds (no weedcatching!) might thus be attained. What are the snags? Dundee. W. Stratton. *Actually, ratios of areas of skeg and keel Since as much correspondence as possible is dealt with by our own staff, the Editor replied: Dear Sir, Thank you for your letter which | may be able to answer for you. Increase in the An attractive presentation wallet of miniature chrome-yanadium spanners in the hard-to-get B.A. sizes is presented to the writers of letters published in Readers Write. The Editor is not bound to be in agreement with any view expressed. not too much, | should think. There would be a limit, of course, to how far apart the two ‘‘halves” might be, but| suspec t this would be a practical rather than a theoretio limit. The modified boat might look us:- o> This goes suggestion some way regarding as F Se — Goes section towards Mr. my Hollom’s ‘‘Weedcatcher”” arrangement. Infact, if the suggestion about increasing the skeg is unacceptable,! can’t for the life of me s why thus:- he does not modify the boat would act about the centre of greater increase in area would be needed to balance the effect of the increased skeg size. The result otherwise would be for the boat to bolt i.e. as it is pushed sideways by the wind, instead of making leeway but maintaining a heading, the bows of the boat would gradually turn downwind. A further objection is that below water area is always kept to a minimum to reduce the wetted surface, which provides a very high proportion of the drag of the whole boat. To which Mr Stratton replied: Editor. Dear Mr. Smeed, !am most grateful for your letter of 15th instant concerning fins and_ lateral resistance. Unfortunately, the very arguments you put forward seem to strengthen all the more the suggestion | put forward. | do appreciate that there are so many variables involved with boats that even a fair sized computer might be hard to put to it to come up with a usable answer, however, assuming that we could have a “‘balanced” hull with a detachable keel(I know this is quite impossible) of say 1 square foot and of optimum stream- equal to optimum required ond location of CLR determined by ratio AsB Maybe I’m just dumb. Wm. M. Stratton. Since Mr, Stratton had now introduced an additional idea, i.e. splitting the fin, which is rather different from simply adjusting the skeg size, we thought Mr. Hollom’s comments would be of interest iy they are as follows. Dear Sir, ! would like to thank Mr. Stratton for his observation on my experimental fins and | hope that the following notes will explain my reasoning on the matter. A well balanced hull is one in which there is no appreciable movement of the centre of buoyancy when the vessel heels, so that at all angles of heel she remains on the same fore and aft trim. Now if a sail plan is placed on a balanced hull in such a position that the centre of effort is appreciably forward of the centre of buoyancy, then on heeling the depressing force of the wind working through the centre of effort will tend to depress the bows and the vessel will trim by the head and become unbalanced, even though the hull itself may be perfectly balanced. It is obvious, therefore, that the centre of effort of the sail plan should come approximately above the centre of buoyancy and in Green Dragon this has been achieved by moving the fin well aft which results in the lead, if it is going to be Crom section line section as sketched, then if this keel were detached and replaced by two separate keels with total area of 1 square foot (and a water resistance the same as the single keel), then provided the centre of lateral resistance of the pair of keels taken in conjunction, were located in the same position as the optimum found for the single keel, statically the boat would have similar characteristics to that with the single keel; the movement of the centre of resistance as the boat gathers speed might complicate things a little but With two large lateral The boat would also tend, | should think, to have great directional stability and would therefore lose the ability to point up and pay off to each wind shift. Resistance due to wetted surface would it is true, be increased, but form resistance, which is the resistance created by the passage of a body through the water, excluding wave and wetted surface resistance, would be increased. Instead of the water being displaced and replaced once by the appendage, it would in this case be displaced and replaced twice, with a resulting increase in resistance even though the same bulk would be passing through the water. | would conclude by once again stressing that the arrangement shown in Green Dragon is by no means perfect and was only built as an experiment to satisfy my curiosity about this particular arrangement. Experience gained has convinced me that under perfect condi- tions this configuration is ideal. Another means of overcoming the problem is shown in my Firebird design and although the fin is slightly further forward than the optimum it is still nearer this optimum than other comparable designs and shouldn’t catch any weed. D. M. J. Hollom. There the matter rests at the moment. Has any reader any comment? Dear Sir. | have recently had great success and a lot of fun with steam driven models and, for the benefit of readers who, like me, are lured by the smell of steam and oil, enclose a few details of my own approach to the problems. It all started a few months ago with the purchasing of a ‘Mamod’ ME 3 Marine front of the fin. | believed that where sailing conditions allow, this is the best Steam Engine (manufactured by Malins, Birmingham); the cost was a very reasonable £2.17s.6d. Next came the choice of model in which to install it. | decided that practice as it seemed to be in theory. steam for the reasons that no fantastic turn of speed would be required for such a model and the fact that a beamy hull would best accept a steam plant. So a tug it was to be. carried as low as possible, protruding in =ag snags. planes so far apart, and they would be far apart if they were not to interfere with each other, there would be the difficulty of tacking. The boat would be very slow to come about and would probably be in irons for longer than is desirable. not, Totel cree of kee! A+ kee! 8 to be mode aft and the moment through which the area to bring the sail plan anywhere near its optimum position. This in turn brings many fsa. ft area of the skeg would have the effect of moving the centre of lateral resistance buoyancy of the hull would be considerable. Since the fin is almost centrally placed beneath the centre of buoyancy a plan still appears to be placed on the bows of the boat with results that have just been explained. The skeg would therefore have to be even further enlarged way of solving the problem, but as mentioned in my article, conditions do notalways allowitand therefore the whole project was intended as an experiment to find out if the system was as perfect in Now there are usually more ways than one of achieving a given result and in theory Mr. Stratton’s ideas seem to be sound and are favoured by at least one designer, although not to the extent shown in his diagrams, although | gather that these are accentuated. My main criticisms of the system are that in present designs using this idea, the sail 40 a tug would make a good subject for | spent the next few weeks building the hull for a 24 x 8 in. tug model on the bread and butter principle from block balsa. The superstructure was beaten up from 18 g. aluminium; although basically to my own design, the finished model owed much to the popular Veron “Titan” Tug kit both in regard to overall dimensions and general appearances.