- Maree III – Ten-Rater Sharpie Design

- A lightweight, high-performance 10-Rater yacht designed for portability

- Proven success in major championships; planes well in the right conditions.

- Symmetrical hull with constant chine angles.

- Detachable keel for convenience.

- Laminated keelson for strength.

- Reinforcing stringers prevent bottom drumming and distribute fin stress.

- Panels fitted using templates; careful beveling for accuracy.

- Deck beams and gussets added for rigidity.

- China Boy – Hard-Chine Marblehead (Part Two)

Tools Required, Materials, Jig, Keelson Assembly, Hull prepared for paneling and deck installation. - Radio Control & Vane Steering Discussion

Key Insight: Combining vane gear with radio control offers better course-keeping and maneuverability.

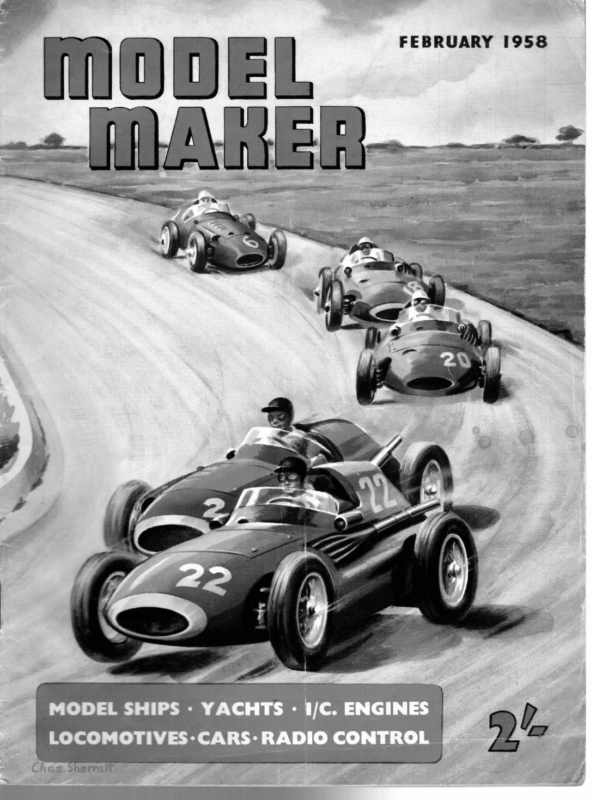

ema es FEBRUARY [958 MODEL SHIPS – YACHTS- 1/C. ENGINES LOCOMOTIVES-CARS- RADIO CONTROL

MAREE III A top-performing, simply-built tenrater, fitting companion to the China Boy Marblehead, designed by A. Wilcock ee ee Turning now to the design, it will be seen that the hull is perfectly symmetrical about the mid-section with the bow and stern cut off to give adequate overhangs but keep the hull length down to the limit required for The chine angles, it will be transport. observed, are constant and a further feature is that when heeled to the gunwale the hull cross-section presents that of a punt with a – flat bottom—brought about by making the chine angle equal to that of the “V” bottom. The L.W.L. of course presents a problem While which will always be controversial. accepting the ever-growing length of L.W.L. in the 10 Rater class with continual improving efficiency of sails, the author considers their advantage lies at open coastal waters where others have to change to a second suit or sail inefficiently with a larger first. Since this boat is likely to see most of its service on the London waters where it is unusual to have to change to second it seems sound to be able to carry a first suit which is not too restricted. The method of construction followed justifies description in some detail particularly because the hull is so light and strong and the detachable keel fits right to the “V” bottom of the canoe body. The canoe body and deck came out of one sheet of 1.2 mm. resin bonded three ply, 6ft. long by 32 in. together with ten laths of obeche 6ft. by #in. by 4in., two blocks of obeche for the bow and transom fashion pieces and a block of wood 12in. by jin. by 2in. for steadying the fin attachment. Construction is commenced in the usual way by cutting shadows of the body sections less the thickness of the skin, in this case 1.2mm. Slots are then cut to take the keelson, chines and inwales and the 12in. by 2in. by #in. reinforcing block. The latter has one of its jin. wide faces shaped to the curve of the keelson as shown in Fig. 1 and by measuring the depths at the positions of the shadows, the slots. in HERE are few sharpie designs available for 10 raters, and the correspondence seems to show that there is a demand. In some quarters there seems antagonism to sharpie design but this can hardly be on performance. Maree III, whose lines are given here and whose design and construction are described, was runner-up in the 1956 Metropolitan and Southern District M.Y.A. Championship sailed at Hove in light airs with a fleet of 20 boats—more than the National Championship now draws—and is the 1957 holder of the President’s Cup of the London Model Yacht League, where eight of London’s “crack” boats are always expected. This was sailed in a good fresh first suit breeze. Its general performance and “way in the water” has been much admired and its design sought In the right conditions it will plane after. delightfully. The author therefore feels some confidence in publishing the design. The design was undertaken with a purpose which may recommend it to other builders. This was that it should have a detachable keel and the hull (with split mast, within the length of the hull) should be accommodated on a London Transport bus without question. So far the author has found this to be the case —it will stand on its bow bumper and clear the ceiling of the lower deck by an inch—the hull without keel is so light that it is very easily manageable and seems to get in nobody’s way. The keel and sails are carried in a small aluminium-faced one’s mobility. ply case the central shadows can be cut to the correct depths. Five of the obeche laths are used for the keelson, i.e. $in. plus four glue lines. which completes 68

FEBRUARY, oo we caenane ©) TI 338vW ew eeenbey ae Aineeseoe POM Y JDIANIS SNVId Wetaive ¥ YIAVN I300NW 7 Four more of the laths are cut with a razor blade or craft tool into 5/16in. and 7/16 in. laths. Two 5/16in. laths are used for each inwale and two 7/16in. laths for each chine. The tenth lath is cut, again with a craft tool, down the centre into 2in. laths and one of these is cut into two 3ft. lengths to be used as reinforcing stringers over the central 3ft. of the bottom sheets. These stringers perform two functions, (a) to prevent drumming of the bottom in choppy water; and (b) to distribute the fin stresses to the hull. The characteristic 1958 inwales. Before proceeding further remove the chines, inwales, and keelson from the shadows and then replace them over strips of tissue paper or polythene, which will prevent the hull when finally finished being so securely glued to the shadows that they cannot be removed. ~ The bow and transom blocks may be glued now in position on the ends of the keelson, chines and inwales after they have been trimmed to their correct lengths, allowing for the rabbets into the blocks. It is recommended = 69 I) = A os isin required and a line also drawn down the centre The keelson can now be of the top face. removed from the shadows (as a laminated member it will keep its shape) and the shaping to the “V” section completed in a vice with a sharp plane or Surform tool—the latter will be found ideal because of the varying grains in the five layers—the shaping of the chines, where so much wood is not involved, can be done in place on the shadows. The bow and transom blocks are next roughly shaped. It will be found that the back face of the bow piece and the forward face of the transom are given on the body section plan—{shadows are not required for these). These blocks should be cut the full size of the body sections and then a rabbet 2in. back cut for the side and bottom sheets to be glued to. Rabbets should also be cut in them for the keelson, chines and __ mae keelson allows only for the laths. The shadows are set up on a building board in the normal way, the shaped 12in. by ¢in. block placed in position and the five 6 ft. laths glued with a waterproof synthetic resin glue to the block and each other and held to the curve of the shadows; the inwales and chines are glued similarly. When set, say after 24 hours, marks should be made on the sides of the keelson at each shadow showing the shaping eee oat shape of one of the central shadows is then as shown in Fig. 2. The shadows nearer the ends are similar except that the slots for the bottom stringers are not required and the slot for the

ti that a single countersunk brass screw in each Attractive shape portability and is used to reinforce this joint. At this point a are only two of the features of careful check should be made of the surfaces this simply built which to which the side and bottom panels are to be 10-rater, on proved has glued by running the edge of a steel over them several occasions match a than more| and looking to see that the angles are right, for conventional, see Fig. 3. A Surform tool is ideal for correctheavier designs ing any errors, a long file next best. Next bore These are desirable because the panels cannot the holes for the keel bolts, rudder tube and the be readily cramped to the frame. Wipe away slot for the skeg. The “frame” is now ready for panelling, and one bottom panel is fitted- any surplus glue squeezed out at the chines before it sets. The side panels are fitted in first. It is useful to make a stiff brown paper a similar manner but for the best final appeartemplate by laying a sheet of brown paper over ance these are left proud at the inwales so the frame and rubbing over the corners of that when the deck is fitted and the cappings, the keelson and chine and then cutting out. either of the two finishes shown in Fig. 5 can A check of the accuracy of the frame should be applied according to taste. be made at this time by turning this paper The canoe body with shadows can now be template over on to the other side of the frame. detached from the building board. Before If it does not fit, the inaccuracy should be removing any shadows insert temporarily some sought and corrected. Cut the sheet of ply fine panel pins in the outer layers of the slightly oversize and secure it with say a dozen inwales at about 6 in. spacing and zig-zag some 4in. “O” countersunk brass wood screws. wire round them over the length of the hull, The edges may now be trimmed with the this will hold the shape when the shadows are Surform tool. The other bottom sheet may removed which may now be done. now be cut and fitted from the one template Wedges are now glued between the 12 in. by turned over. It is most important to see that 2 in. keel bolt member and the chines as shown the panels lie naturally in fitting them. The in Fig. 6; three each side is adequate but good overlaps of the panels are shown in Fig. 4. fitting is essential as the strains between the These two panels are now removed for fin and the canoe body are largely distributed glueing. There is some advantage in using the by these. The final 6 ft. by 2in. by }in. lath separate glue and hardener type here, although is now cut to make laminated deck beams fore by no means essential, as the glue can be put and aft while the central ones and hatch formon the precise faces of the chine and keelson ing should be made from some }in. by tin.: and stringer and the hardener brushed over a material. The positions for the deck beams slightly larger area than the contact areas on should be chosen to “line up” with the type the panels. The two panels should be fitted and position of the deck fittings. When they in the original order and additional screws have been glued in place and preferably placed between the original fitting screws, (Continued on page 76) DECK

FEBRUARY, aati me ( | Ey 1958 In Part Two designer e D. A. Macdonald lists tools and materials and describes construction of the hull frame for Building this outstanding radio or free-sailing hard-chine Marblehead. notes apply to most other hard-chine yachts HE tool-kit required for building this hull is quite modest, and no special or expensive tools can be considered essential. It is advisable, however, to be sure of having the necessary items ready to hand before work is commenced. The following list should enable the builder to check up and make good any deficiencies. on his equipment (1) A fretsaw, preferably with a cutting table. This is an invaluable tool for all kinds of modelling in wood and metal. There are many jobs, difficult or even impossible with other tools, which the fretsaw will tackle with care. A cheap, simple 12 in. or 14 in. frame is adequate, and two kinds of blades are required: fine (No. 0 or 1, or metal cutting blades which are very fine and can also be used for metal fittings) and medium (No. 2 or 3). A cheap wooden cutting table will serve our purpose, and this could be made from a piece of }in. hard timber, with a “V* cut at one end and a hole for a G-cramp at the other. (2) A small tenon saw. (3) A bowsaw, coping or compass saw. The latter is an extremely useful tool; it resembles an enlarged keyhole saw, with a thick, rigid blade and sharp teeth with virtually no “set.” For cutting out gentle curves in thick or effective and easy to use. thin material it is very If items (1) and (2) are available it is not a necessity, but it would save a lot of hard work. (4) A small block plane. (5) A spokeshave, preferably of the curved type. (6) This is rather a luxury, but a very welcome one—a fiddle plane. These are hard to buy but easy to make. A very small wooden block plane can be shaped to a curve on the underside as in Fig. II. Better still, the blade also can be ground to a curve, and the body rounded off in both planes as in Fig. IiI. Alternatively a moulding plane with a suitably rounded blade (these can be bought cheaply from a second-hand tool dealer), can be cut down to a convenient size and the wooden body shaped in a similar way. (See Fig. IV.) (7) A wheel-brace and a selection of twist drills. (The morse sizes 55, 51, 42, 32, with 4-in., 3/16 in., and jin. will cope with both hull and fittings). (8) A carpenter’s brace (not essential, but useful for the heavier drilling operations). Twist drills sandpaper (Nos. M2 and 1 will cover all requirements). (12) A medium size G-cramp. (13) A bench or table vice, adequate to hold the entire boat on its building jig during construction. (14) A small hammer. (15) Two screwdrivers, small and medium. (16) A pair of pliers. (17) medium-sized second-cut file (flat). (18) carpenter’s square. (19) ruler and pencil. (20) in. paint brush (for applying hardener). > >>> Tools Materials The design has been based on the use of materials not difficult to obtain. In choosing between small dimensions with hard timber and large dimensions in softer wood, the latter has been adopted as requiring less skill and care. The hull is a shell of 1/16in. plywood with a deck of the same material. Waterproof plywood is essential, but it is not necessary to have the full marine quality. British plywood which conforms to BSS 1455 grade 1 WPB or 2 WPB will be satisfactory and, in general, any phenolic-resin bonded plywood of good quality can be used. The keelson is in the form of a “sandwich,” the middle layer, in common with the fin and skezg are shown in the drawings as 5/16in. ply. This must be of marine quality to BSS 1088. In this thickness, it is available from timber merchants who cater specifically for the boat-building trade. The outer layers of the keelson are 5/16 in. obechi. The chine strake and inwale are }in. square and can also be of obechi, provided it is not too soft in quality. Fig 4 5/16 in. and 4in. are required for this. (9) A scriber or burnishing awl (this is for providing starting holes for small pins and screws, and for marking out). (10) A small cabinet rasp. (11) A cork sandpaper block and supplies of | CUT DOWN “1 —«+— ! ea | TO THIS SHAPE

ml MODEL MAKER) There is, however, no need to use hard, heavy wood for these strakes. Bow and stern block are laminated from obechi. The moulds on which the boat is built can be made from jin. obechi or, in fact, any warp-free material. Plywood could: be used, but would not be found so pleasant to work with. Any 4-in. square hardboard strip is used to attach the moulds to the building board. The latter is 4in. x lin. and absolutely free from warping. It could, as an added precaution, be made up as a T-section girder from two similar pieces of wood. Deck beams can be made of obechi, the dimensions indicated for the main beams being adequate for this material. For gluing operations an Aerolite 306 glue pack is recommended, and care should be taken in mixing .this correctly; it will be well repaid. The plywood is fastened to the keelson and strakes by pins. The size is gin. xX 20 s.w.g. copper, 4 lb. should be ample, and these can be obtained from A. T. Chamberlain of Waterloo Road, London, S.E.1. The following are the main requirements for wood screws: lin. No. 8 R/H steel. 7 in. No. 6 R/H steel. q-in. No. 2 R/H brass. Two dozen of each of these will be sufficient. Miscellaneous requirements include some 0 B.A. brass studding, two 0 B.A. brass nuts, 4 in. brass tube for the rudder post, 5/16in. x 24 S.wW.g. ‘brass tube for the rudder tube and a few brass screws of various sizes to be detailed later. Some 1 in. thick obechi will be required for lead patterns and end blocks, and the scrap box will have to be raided for a few pieces of sheet and strip wood for structural details. A half-pint ‘of yacht varnish (Spinnaker or Ryland is recommended) will be required for protecting the inside of the hull and for priming the outside. For a two-colour finish with varnished deck, x7pint tins of “Valspar” in each colour and in clear will also be needed. The building jig Begin by marking out the building board. On its face side, mark a centre line from end to end. This must be dead straight; if a reliable straight edge is not available, stretch a taut thread from the centre at one end to the centre at the other end, and mark a number of points along the thread. By joining up these points an accurate centreline will be occupied by the midsection mould and, with a set square, mark all round the board at this point. From this centreline, set off the positions of the other mould stations (1-3 and 5-7 inclusive) at 61 in. intervals. Now set off in the same way the position of the inner faces of the two transoms FT and AT. The patterns for moulds 1-7 may be traced from the body plan. Tracing paper should be used to copy each half-section. The paper is then folded accurately down the centreline, and the cpposite side traced through. In tracing these patterns, follow the cutouts for the inwale, chine strake and keelson. For FULL-SIZE FULLY -DETAILED DRAWIN GS FOR CHINA BOY ARE AVAILABLE, PLAN MM/S501, PRICE 10s. 6d. POST FREE. IN ADDITION A SHEET OF FULL-SIZE RIGGING AND FITTING DETAILS SUITABLE FOR THIS AND OTHER MARBLEHEADS HAS BEEN PREPARED, MM/503 PRICE 4s. 6d., FROM MODEL MAKER PLANS SERVICE, 38 CLARENDON ROAD, WATFORD, HERTS. moulds 1-7 only, follow the dotted line between chine and inwale. This is important, since the moulds must be cut away in this fashion to allow the completed hull to be lifted easily off the jig. In tracing, mark off the deck line (top of chine strake) in every case. The transoms will remain as part of the com- pleted hull, so these should not be cut away between chine and inwale. Paste all the patterns on wood and cut out with the fretsaw. The transoms should be of solid wood, not ply, and if some mahogany is available for these it is worth using it to give added strength. The half-inch square fillets are screwed to all the moulds and transoms (it will be found most convenient to fix them to the back, as they do not obscure the centreline of the pattern). Moulds and transoms. are next assembled on the building board by screws through the fillets (see drawing of hull cross section). Note carefully the positioning of the moulds in relation to the section stations marked on the building board. The mid-section (No. 4) is placed centrally over the line. Those forward of this (FT and 1, 2, 3) have their aft faces on the section lines; As each mould is fitted to the board it must be checked carefully with the square to ensure that it is exactly at right angles to the centreline, and exactly vertical to the building board. The centrelines of the moulds and transoms must also register exactly with the centreline of the building board. The keelson As previously explained, this is a lamination, or “sandwich,” with two outer layers of obechi and an inner layer (part of which is provided by the fin and skeg) of plywood. The outer layers can be marked off by laying the profile plan on the wood and pricking through with the scriber, following the inner and outer lines given on the profile plan. The keelson outer layers extend from the forward face of transom FT to the aft face of transom AT. The position of section stations 1 to 7 should also be marked on the wood. Two identical layers are marked out in this way and cut out with the compass saw. The cut edges need not be cleaned up at this stage, as there will be a certain amount of surplus wood to be removed later in any case. If, when these pieces are cut, they are not used immediately, they should stored away from direct daylight, weights on a dead flat surface, to warps or twists occur. be held down by ensure that no Five pieces are involved in the inner layer of the keelson “sandwich.” The centre section (B-C) comprises, in one piece, the fin, keelson layer, and the two posts extending up the deck. Forward of this is a section (A-B) which is similar to the outer layers, as is the section between fin and skeg (C-D). The skeg section (D-E) includes the skeg itself, and a small section (F-G) from behind the rudder tube extends to be aft face of AT. A quarter-inch gap will be left between this last piece and the skeg section (i.e. from E to F), to be enlarged later to receive the rudder tube. All five pieces of the keelson centre layer are marked off from the drawing on to the 5/l6in. marine plyw-od, the section station positions being also marked to assist in correct registration of these parts when joined to the outer layers. It is also advisable to mark the profile line on the pieces which include the fin and the skeg. All these parts can be cut with the fretsaw.

FEBRUARY, The assanthiy am of two ways. M.M. “LameetTM skeg sections am omitted at 2 = CHAMFER = g@ectmod used in the OFF ‘Gis system, the fin and memer layer would ove im effect, slots in the keelson imte Wilt Ge Ge and skeg could be fitted after the comme Gewiy Ged been built. This method 1958 Fig, simplifies “he auwerime of the hull, since the plywood In the second method, the keelson assembly, complete with fin and skeg, is laminated up at this stage. A sound pressure joint can then be made between fin and keelson. When the complete assembly is fitted into the jig, the tops of the fin posts are locked in a central position on the building board, thus ensuring that the fin is maintained upright during building. Assuming we are to use the latter method, all the components of the keelson assembly can now be glued together. It is suggested that panel pins then be used to hold the parts temporarily in place while the glue is drying. Accurate registration of all the section markings should be ensured so that the fin and skeg are accurately positioned. The glue should be applied to the obechi and the hardener to the plywood. It is recommended that the assembly be placed between two flat boards, and held down with a number of weights while the glue is drying. It is also a good idea to put chocks made of scrap 5/16 in. wood on either side of the fin and skeg when the assembly is held between the boards, to ensure that they retain their exact position during drying. Allow a full 24 hours for the resin glue to “cure” completely. While the glue is drying, two pairs of blocks made of scrap 4in. square strip may be fitted to the face of the building board, in positions such that the two fin posts will be locked in a central position when the assembly is placed on the jig. If the Lancet method of construction is adopted, the fin and skeg pieces are omitted from the assembly operation. Dummy pieces of 5/16in. ply should be placed in the slots left in the keelson to ensure that the correct slot dimensions are maintained. Care should be taken that these do not encounter any stray glue, otherwise their removal afterwards may prove difficult. A considerable amount of surplus glue will be squeezed out when the layers are pressed together. This should be washed off with a brush dipped in hardener. The slots in the keelson should be fitted to the jig. The bottom of the slots in moulds 1-7 will need to be bevelled as necessary to suit the curvature of the keelson. An exact fit into the slots in the transoms js essential; either these are bevelled accurately to the inside curve of the keelson, or the latter is shot off at the ends, parallel to the datum line so that the keelson fits into the slots as cut. The inside edge of the keelson may be smoothed off with the spokeshave as desired before finally fitting. It should fit nicely into all the slots and the section stations marked on it should correspond correctly with the moulds and transoms. To secure the C/SK. FIXING \ x skins would met awe to be fitted up to the fin and skeg, bat oowl@ Set right over, leaving the obscured slot to be cleared out later. A disadvantage of this method i that mot much pressure can be applied to the joimt between fin and keelson when the fin is fitted. amd there is also a risk of the fin not being dead upright if any torsional stress had been placed on the keelson during covering. HOL assembly to the jig it is glued and screwed to the transoms. The screws should be counter bored so that their heads are just below the level of the top of the transom pieces. If this is not done, they will have to be removed later when the keelson is being bevelled off, but there is no harm in doing it this way if it makes the work easier, and if sufficiently long screws are available. As part of this assembly operation, chéck that the fin is dead vertical; this can be done by measuring with a length of thread fixed to the extremity of the fin at the midsection point and stretched to the deckline on each side of mould No. 4 in turn. These two distances should be identical. Again allow a full 24 hours for the glued joints to cure before proceeding with work on the hull. Chine strakes The next job is to fit the two chine strakes. These are chamfered off at both ends so that when fitted round the moulds, in the chine slots, the chamfered ends will fit snugly to the keelson, tapering off to nothing at the transoms. The shaping and fitting of The these will be a careful cut-and-try process. strakes are glued and screwed to the keelson at both ends. It is permissible to steam the inwales, or paint them with water to assist in an easy fit round the moulds, and to relieve strain on the end joints. Gussets may be glued between the ends of the chine It is and the keelson as indicated in the plan. desirable to secure the chine strakes to the moulds, temporarily, by thin screws (} in. No. 2); these screws will have to be removed before the sides are fitted. The screws at the ends of the chines should be counterbored slightly to allow for the chine strakes being bevelled later. When the glue is dry, both keelson and chine strakes are now bevelled off so that they are in line with the bottom edge of moulds and transoms. In this process, the moulds and transoms themselves will become slightly chamfered to conform with the foreand-aft curvature of the hull. The small block plane and spokeshave will remove most of the surplus wood. The finishing off should be done with sand- paper on a long flat block which will reach right across the hull. The drawing (Fig. V) will show how | the hull cross-section should look at this stage. It is important that there should be no rounding of the edges of chine strake or keelscn—a ruler laid along the bottoms of the moulds should sit exactly on the sloping edges of chines and keelson, and the edge of the bevels should be in a fair curve from end to end. This is essential for a proper fit of the covering.

i MODEL MAKER} yachty, but it certainly has a number of advantages. When a number of craft are being produced to the same design, it is cheap and admirably adapted for mass production. The hulls are toredo-proof, and do not need painting, or even anti-fouling protection. Also these hulls are strong and leak-proof. UCKER’S OPICAL Another feature of the Boat Show was the kit boats ‘for the “Do-It-Yourself”? enthusiasts, and I feel that many possible recruits to model yachting may be diverted to full-size sailing by these kit boats. In this connection, it must not be forgotten that ALKS THIS MONTH RADIO AND Ne H.B.T. ‘‘CHINA DISCUSSES model yacht racing has become so highly competitive that if an owner aims at being successful, he must have the finest gear and sails available, and a full inventory. In fact, even if the owner is a skilled builder, a high class BOY’’, AND THE INFLUENCE OF FULL-SIZE KITS model yacht is quite a costly item. eg B the January issue of the MopEL Maker, Mr. D. A. Macdonald presented the plans of China Boy, a sharpie model yacht, primarily designed for easy construction, and mainly intended for radio control. In his introductory remarks, Mr. Macdonald recommends that in addition to the R.C. gear, an ordinary vane steering gear should be fitted to act as an autopilot, and keep the yacht accurately on her course, which would be set by the skipper through the radio equipment by the trim of the sheets and vane angle. Now Mr. Macdonald is not only an expert model yachtsman, but also a professional radio engineer. Hence he is in all respects fully qualified to give an authoritative pronouncement about the possibilities of R.C, Yet readers may recall that about a couple of years ago when I suggested using a vane steering gear in combination with R.C., I was rebuked by certain R.C. enthusiasts, who told me I did not know what I was talking about! When an 8-ft. sailing dinghy (including sails) can be obtained for a little under £40 in kit form, it is not to be wondered at if the would-be boat owner decides on a full-size dinghy rather than a model sailing yacht. Moreover, these kits include the loan of a building jig, and are pre-fabricated to an extent that makes their assembly a far simpler matter than building a model yacht hull. Hence, people who would not be able to tackle a model yacht, can easily put one of these kit-boats together. Also it takes far less time, particularly if two people work together. Again these kit-boats can be obtained in all sizes up to cabin cruisers of 22-24 ft. L.O.A. Since car trailers, specially adapted for boats, are available, transport presents no more difficulty than for a model yacht. It is, of course, excellent news that the Model Yachting Association and the R.C. Model Society are working together to promulgate a code of rules for R.C. model yacht racing. Yet it must not be forgotten that the apparatus required for R.C. is quite an expensive item, and when this is added to the cost of a model yacht, the sum involved is quite considerable. Now, as far as I can see, the main attraction of R.C. model racing is that in addition to pitting the speed of one’s craft against the other man’s boat, one can also Yet in spite of these gentlemen, I have always retained the idea that R.C, yachts need a vane steering gear to take care of the ordinary straightforward sailing with the R.C, arranged to cut in and take charge for manoeuvring, altering course, etc. Hence I am now delighted try to out-manoeuvre him. Yet in controlling the yacht that Mr. Macdonald has endorsed my opinion, though from the bank, one has not the advantage of the skipper in his article, he has, possibly, stated the case decidedly who is actually aboard his craft. Hence I rather wonder better than I originally did. whether the cheapening of full-sized sail-boats through Now admittedly, I have no technical knowledge of the kit-boats, may not prevent R.C. model yacht racing R.C., but as far as I can see an R.C. outfit capable of ever becoming really popular. trimming a yacht’s sails and setting the vane angle As regards ordinary model yachting, I know one or would be a rather complicated affair, needing several two skippers, including at least one front-rank model wave channels and using quite an amount of apparatus. skipper, who have turned from models to full-sized To provide the necessary current for this gear, would boats. Hence I suggest that those interested in the presumably entail carrying fairly large accumulators, government of the sport of model yacht racing should which are weighty things. I see that the displacement give serious consideration to the possibility of limiting of China Boy is 16.75 lb. For the free-sailing version, the expense. How this is done would require careful the weight of the lead keel is given as 10 lb. of the R.C. consideration. One way would be the adoption of a ‘equipment. It would be of interest to know what the one-design class, and since races are determined by the latter should weigh and how much lead will remain skill of the skipper far more than by the merits of the after making provision for it? yacht, this would focus attention on the thing that really China Boy is described as to the M-Class. At the counts. Another way of cheapening model yachts same time, it must not be forgotten that many early would be by standardising fittings, limiting weight of boats of this class were about 16/17 lb. displacement, lead keels, etc. In connection with the latter, it must and it was quickly found that this is much too light. not be forgotten that castings for lead keels cost about Modern M-Class models are 22/23 Ib. Hence one : 4s. per lb. Hence the keel of a big A-Class can cost wonders whether for competitive work, China Boy between £10 and £11. Again the number of suits of might not be somewhat on the light side, though apart sails could be limited. These are merely preliminary from this she should be quite a useful little yacht. suggestions. * * * In conclusion, there are two respects in which the The National Boat Show this year was remarkable model yachtsman has the advantage over the yachtsman. for several things. One was the great number of glass He stays dry on the bank when the dinghy sailor is fibre hulls on show. Quite candidly, I personally am sitting his boat out (fisherman’s luck!), and he can sail not fond of this material as somehow it does not seem in winds that no yacht can stand up to. 102