- A Thirty-Six Inch Racing Sloop. By T. B. Davies.

- Design of a 36-inch racing sloop using the lift method, emphasizing careful gluing techniques with casein glue, frequent use of cardboard molds during shaping, and thorough varnishing of the deck underside and hull interior for durability. The design includes specific instructions for hull construction, deck installation with plywood or white wood, and the addition of a lead keel.

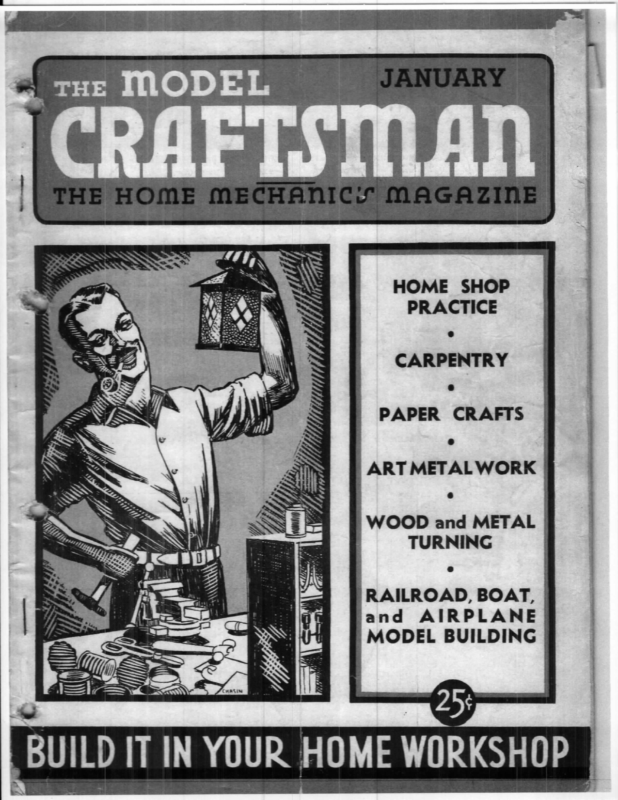

tHE MOD EL | CRA FTSM AN CARP ENTR PAPER Y CRAFTS ART METALWORK i WOOD and METAL T U R N I N G and AI RPLANE MODEL BUILDI NG

A UHIRTY-SIX INCH ACING SLOOP By THOMAS B. DAVIES This Design Has Been in Use for Sever al oO y re Seasons With Great Success. : fe 4 all and 2 LOofpetner gap. wWitnout There is ho interested and in sailing preters than an in easier shop met f and a any appreciabdie tendency to pla: sa } this the may tool than it to 1s = ‘ > (hick _ YTain . iré 7. – : at tt siSi of all very : one Set- them. u here is is a . are pin Hneics ioe ~ distanc e +7 _— marKed,. S * ancles TIP tit (c = 2 right =~ 1} strip to the to ac as center the apart – center < of ~~ any 1 ic. *-~ Sta- a CI line IO! ho-os icre alaecd ..: NaCed p : . ij am lon n | E L r curve ve at every sta> i alt 1d Stal . th ai widths the are drawn. dividers on the swing it to both point : snouild 2-5-1 1-1-1 0-2-0 ‘ IQ ‘ ao Gy i 3-43 3-3-0 0-1- 0-0-: 0-1 9-0-3 9-1-2 ~ ro) ms © Yv >) 1-5-3 — 200 » 13. bo 3-43 F © 10. E r 042 iis D & Ime l if Hreaai Dp Nm WN ry fail A Ad Station PF —~ ene ee et — vel, rew the ut the of n dividers. v t limes | ihe > pair 4 fte -il on one lift tt have been marked off, drive ordi- the | “enter _ a as opening TS = set the side of the center is marked off tie safety. se +} a by shavings, — to to make e€no OF arr _——_th remedied thinner ith \ regard 1s possible 7 eTS ff be cut S it At each station the width on g eac j with cy ‘| ae od uae them. the end of the board thinner towards Work, s twce 9.2.0

cross lines. com- — y Sav ‘ > aii me _ and then nlace ton on h ench with the S * ‘ LINE | – | | ij /) | e . _rT oe | m ~~ ne = ¥ T < ri £ ~ « = a S ss _ a ~ ome oe | | | | ) : a i _-_ 1e r no } : + r TX i her wn - a ' | r r ] ie! Te “a Be im oe | ‘ é || ‘ ol S {I s§s E i : | i onal s y > it fe | ~ ~ are LL. I ii aa = acl j y | 2 | | ! | 5 / | | | yf ~ eae of f means built 9 are 7 be sections the thickness of BASE WATER UNE mav by tAnc OSS out Hf “i wood -ocec Liic drawn, lay Fs the 2iCti LA hen ¥ 4 ; 69 V

and familiarize themselves with their jobs, everything will run like clockwork. THE WHOLE STORY It is rather difficult to go into each little detail in an article of this type, OF and if any further information is desired, correspondence is invited. Don’t forget to enclose a stamped envelope for reply. RAILROADING Address : H. W. Saler, Pres. & Gen. Mgr. BrookLtyn Rarrroap CLus, Dunwoop WEsTERN LINES, 338 74th Street, Brooklyn, N. Y. 36-Inch Racing Sloop (Continued from page 40) mixed exactly according to the directions (which usually come with any glue) as casein glue depends upon the method of mixing, and the incleding many rare ones from Railway Age. Has more il- Eesteotians then-any ocker beek of the hindi. Written by T. W. Van Metre, Professor ef Transportation, Celumbia University. Semt to you postpaid for only $3. Chapters cover: ee a Our Steam Railroads; ee ee easy Gasoline and Oil Meters; Freight Cars; Passenger Train Funiege Dasione Tesmtedies Freight’ Terminals; and’ TheandOperstion of Send today for your copy. It is 2 natMedel Railroad Gentlemen Send me a copy of and TRAVEL. I am TRAINS, TRA $3.00. If the book is not satisfactory I will return it within five days and you can refund my money. DP Tt Sets ted rps bs cesuccesiiiwseccs ‘ tt cITr oe. n n= cake Kt% ot pbibabs «© o the top, outer for surface. about 34” from the edge, the side is left a little thicker than lower down, as it is into this part that the deck beams and holding screws are fastened. If you have a good sense of touch on slant of th the chisel, the sides may be cut down to about 4” thick, depending upon how your nerve and luck hold up! Unless there is a special reason for ef ” bloc} of ea the # When the glue has set for 24 hours, take a sharp chisel or gouge A Every Model Railroader will want this. Every reader will find it imteresting, in- in The deck beams are cut from any light straight-grained lumber, and @ are set in notches cut into, but notgy ening. roading—in non-technical Tells how railroads are built, maintained and operated. the and evenly over both the surfaces to series of spaces, caused by imprisoned air, where the contact will be poor. The parts should be slid back and forth a little, to spread the glue, and cause the two films of adhesive to unite. After clamping, check up carefully to see if any lifts have moved, as this often happens, and the parts are inseparable after hard- This book discusses every phase of rail- place solde against a glued one does not always resultin a uniformly adhering joint, as there is almost certain to be a Should Own This Book low Around doing so, don’t try to make them thinner than this. be glued, as placing a dry board MODEL RAILROADER and sandpaper, and not leave a hol- proportions of glue and water, for its strength. Spread the glue thinly Every hull, work from the ends to the cen-— ter, and mever continue cutting after a shaving appears to be splitting into — a chip, as this work is all more or ~ less cross grained, and it is ex- — tremely easy to pull a piece entirely © out of the side of the boat. If this | should happen, glue it back in place,TM allowing it to stick out a little, so that it may be smoothed down with a rasp two: through, the sides. They are screwe and glued in place, having a slight rise in the center. The deck should be made of a piece of birch waterproof plywood or a piece of white wood 3/16” thick. It is screwed and glued to each beam and at intervals of 2” along the sides, using No. 1 brass screws 3/16” longer than the thickness of the wood. the p The under- mit t %” of the gluing line around the wirei side of the deck should be given at least one coat of varnish to within to be A st outer edge. This should be left unand rough off the “steps” on the out- touched, as the glue will not stick If side of the block, until it is compara- properly to varnished surfaces. tively smooth, after which a rasp is the deck is not varnished on the unsubstituted for the chisel and the surface brought down to approximately the finished dimensions. Make a series of cardboard moulds, using tracing paper and the cross sectional drawing, so that the shape of the curves on both sides may be checked as the work is done. Check- ing after it is finished is not much use—it’s either right or wrong! But the use of a mould every few minutes will do a lot to keep errors from | creeping in, and any slips may be corrected before the damage is serious. These moulds should be numbered on BOTH sides, as they have a bad habit of becoming mixed, and the use of the wrong mould is fatal. Now lay the hull bottom up on the bench, and measure the height of the deck line (known as the “Sheer”) from the top edge of the plank. Mark these and lay off a smooth curve as in the other cases, and trim down carefully. Now hollow out the inside, using a gouge, and watching the bottoms | of the steps, as these are indications | of the thickness of the side of the 58 holes Ber drill them derside, it will probably warp and buckle, lifting the screws clear out of the hull, or splitting badly. It will be necessary to mark out the hatchg os so that it will not come in the way of the deck beams. It should be over the lowest place in the boat, to per- 7 mit drying out with a sponge. The | inside of the boat should have at © least three coats of spar varnish, as © it will either be very damp or very dry according to circumstances, and § this will soon rack the hull to pieces.) if it is not very well protected inside) Make a lead keel by cutting out a replica or pattern of wood ang© having it cast, though I would recs ommend that one be purchased this much metal can do quite a le of damage if something goes wroz with the home foundry. The kedl is fastened to the hull with bolts long screws. 3 The deck and outside should nam be sanded and varnished after | coat of white lead and turps fi been put on as a filler, being m rather thin. The final finish is 4 . done with pumice and water. Hew eee

CRAFT SMAN SPECIAL MODEL SH OW NUMBE R @ ! RAILROAD, BOAT, PLANE and AIR MODEL BUILDING rf & HOME CARPE NTRY = ARTMETAL W @ ~* ; te: rf . \ Sat SS as Ly . P ai ll WOOD TURNING e ch – ay Fe oa s— i ORK ; a \ = ) PAW w n s Z = 4 \ ; , ~ — —

| ng. se, shi r A Thirty-Stx Inch Racing Sloop he tide bz 1 lower *€ a cou! Me Description of the Rig- o fulgging in this Article completes sy) F is this Series. vr) last month, only the rigging of the N sloop remains to be explained. The rigging of a racing model is kept as simple as possible. Every- ‘thing has a definite use and there are . the mast jm| . splitting. This screw is used in a series of holes in the deck plate, to permit the mast being moved slightly are not available. = ‘qualities of a boat and therefore may interest readers to learn that the il extremely fast six-meter Swedish boats carry the running rigging. up the center of the hollow mast in order to reduce windage. The benefits accrued from doing this have been quite noticeable in the improved performance of these yachts. Spars and Mast The best material for these im- | portant parts is clear airplane spruce. |} If the boat is intended to be used for racing, this wood should be used. It may be obtained by mail from j “ju manufacturers of model airplane | parts, if it cannot be had locally. If you are situated near an airport, it is quite likely that you may be able to procure a sound piece of spruce _ from a “cracked-up” plane, as the _ material is often quite good in places, even after a smash up. The mast and spars are round. They are first sawed out square, after which the corners are planed off. | The eight resulting angles of each oe The right set of the sails is thus obtained as each the shrinkage varies with certain Also each boat has model. individual! qualities, which have to be into account, as have the full taken “¢ If it were not for this should be eliminated as much as is practicable. Though it can hardly be done in a boat of this size, it age is reduced to the limit of safety. t fitted ‘very detrimental effect on the sailing The cord- : A preponderance of rigging has a i¢ is S!2€ ONES. feature, half the fun of one-design racing would be missed. The ends of the main boom and the jib boom are also ferruled to pre- no non-essential parts. a. are then shaved down, and the stick sanded to a round shape. After the mast, or spar, is rounded to the same for its full length, it is ta- pered to the dimensions shown in the wing, Unless you have had sufficient ex- perience to be able to disregard these instructions entirely, do not attempt to taper the stick until it is first wwe, of forwards or backwards. @ With the completion of the hull | end with a No. 6 screw with the head removed and a ferrule to prevent perfectly rounded and its sides are ; ‘ Parallel, as this entails performing the two operations at the same time and calls for considerable skill. The splitting. The builder may wind them tightly with fine brass Vent wire, if ferrules of the correct size The screw eyes are stock articles at any hardware ‘tre. Rigging Before any of the actual cordage work is done, it will be necessary to make the spreader for the shrouds and the slides in which the bowsprit slides. The spreader is made by soldering a bent piece of 4° brass wire to a curved plate which is screwed to the forward side of the mast by two %° or 3%” No. 1 brass screws. The slides for the bowsprit are used to permit this part of the sail area to move with the mast, if necessary. They are made by bending a strip of 1%” wide thin brass into a horseshoe shape, to fit the bowsprit, after which the feet or lugs are bent out at the sides. The holes for the A 1/16 screws are drilled last. hole for a wire pin is drilled through the top center, being extended through the bowsprit and into the deck, after the parts are in position, A series of these holes, about 347 apart, should be drilled in the bowsprit for adjustment. The cordage is best made from fishing line. About 14 feet of 23 pound breaking strain, hard line and the same amount of 40-50 pound line will be needed. The heavy line is for standing rigging and the lighter for the running rigging. The latter line is used for handling the sails, while the former holds the mast and bowsprit in place. The shrouds and the jibstay are adjusted by means of 31 small hardwood toggles, instead of deadeyes, as they are very much more practical on a racing job and cost nothing to make. The mast is first fitted with the boom and the shrouds and forestay are attached. The spreader is screwed in place and the mast stepped in the center hole in the deck plate. The forestay is temporarily attached to the end of the bowsprit and the after pair of shrouds loosely knotted into the screweyes in the deck. These lines are passed through the ends of the spreader on their way from the top of the mast, as they are used to take the “whip” out of the stick. After the mast has been brought approximately to its correct position, the second set of shrouds may be brought down and fastened to the forward screw eyes. Now set the boat in a stand, so that the waterline is level and drop a plumb line to the deck to check up on the setting of the mast. The weight should be about 3” aft of the mast, for a trial setting, and exactly in the center of the deck. Now, fasten the hooks permanently on the lower ends of the shrouds and forestay and check up again with your plumb line. These hooks are to enable the mast and sails to be removed easily, when transporting the model to and from the water. The jibstay is now fitted and should be tight, but not tight enough to slacken the forestay. Rudder and Steering Gear The rudder port, or hole, is bored 3″ and fitted with a brass tube, with a thin flange for screwing to the deck. The hole in the flange for the tube will have to be filed oval, as it is at an angle. When in place, it should be soldered to the tube; but not before, as it is almost impossible to obtain the correct angle by measur- ing. With the job cooled, the deck, a thin piece of wood is slipped over the tube and the flange pressed down firmly upon it during solder- ing. With the job cooled, the wood may be split off and the tube driven down and screwed to the deck. The tiller is made by drilling a 14” hole at an angle through a short length of brass rod. The 1%” shank is then soldered into it and the ends (See Plan on Following Page) (Continued on page 56)

32 THE MODEL Sam= wall iJ Oo 8 aa CRAFTSMAN

trains operated on the through track. TAIL NEW SUPER-DE BUILD THIS BEA UTIFUL ITALIAN LINER REX MODEL… TH > a . ein Mad = Then too, he wanted coach yards long enough to permit him to store least at six or seven passenger coaches. To accomplish this it was necessary to take the lead track to his coach yard and the lead track to his locomotive terminal off his main yard track on a curve. This pre- sented construction difficulties even on the other end. The sheet, which is a line regulating the set of the sail, runs from the boom, through the end of the tiller and back to the other eye of the boom. From there it runs to acleat. The pull of the sail draws the tiller over, preventing the wind from throwing the boat off its course. The set of the sail, together with the strength of the rubber band, if it did solve his layout problem, but eventually the switches were built Send check or money order today. g latest successfully and worked perfectly. Note that the main lead track for not be decided until the boat is in the water. all yards serves as a make-up and model 3c for illustrated folder showin is a matter of experiment and can- receiving track for the freight yards and also as the side track for the planes. & SUPPLY CO., INC. IDEAL AEROPLANE 18th St. New York 19-21 West The rudder itself is made from a piece of thin wood, with the grain running parallel to the back. The shank is a piece of tubing, 4” diameter, fastened to the wood with long, passenger station. This track should “me screws or headless brass nails be long enough to receive the longest FOR SPECIAL LIST of soldered in place. passenger or freight train which could be operated on the system. It should be arranged so as to permit PLANS switching operations on either end.The plan shows that there is plenty _of room available for storage at all | three terminals. Though this layout write to us today, enclosing 5 cents in stamps or coims to cover postage and handling. plans and nts List includes blue-pri cars. for model railroad locomotives, The Sails These are made from regular model sailcloth, as supplied by any | is small it enables the operator to | perform practically every operation of full sized railroading. This particular layout is rapidly reaching completion, and we know the builder will have’a system which will rival the best of them in arrangement and firm dealing in these materials. The after edge should be selvage, or in other words, the finished edge of the material as it is manufactured. The corners should be doubled and stitched strongly, to hold the eyelets which fasten the sail to the spar. The mainsail may be fastened to the mast either by. eyelets and cord, or by rings slipped around the mast and sewed to the sail. Apiece of light rigging line should be run through the turned over edges to take theit ‘s writer the s prove strain off the material. Otherwise n This layout and ble will be stretched out of shape. Whe possi is it that , contention made, all dimensions practicable to build a layout in a very the sail is first 34” short for each t abou be d shoul all confined space which will give The slack is ent. urem meas foot of operation, if not in size. the thrills that a larger layout can provided for by using a take-up on the top of the mast or jib stay. could have been used. It would also _ have been possible to avoid the use of Sailing give. Of course, if more space had | been available a two track main line switches on curves and to have had & co o, Ill. Chicagn St.dee 99 S.Aber guaran- teed. THE FIXEN LINE CK MATERIALS TRA for all gauges—00, 0. %%”’. 7/16″. systems have started railroed take the place of experience, but a two or more lead tracks to the loco- few hints may be useful to the beAt a later date it | motive terminal. | would have been possible to add more scenic effects, but after all, _ what single phase of railroading is should fit into a hole and not rely behind the C.L.R. more than a vent small amount, nothing will pre shaped as shown in the drawing. After all the work has been done on the shank, the hole for the rudder stem is drilled and the rudder slipped up into position and held at the bot- THE FIXEN LINE E. Fickeissen or H. Gorst as a black imme on the side elevation drawing in the January issue. The tiller is then fastened to the rudder shank by the set screw. This screw ‘THE HAPPY MAN IS A HOBBY MAN So WSHE LATHE reaped OD « amie& 5 SD tere © beh 15 oteesSeectic Bee os =~ va by Bs Termes — . merely on friction. A 134” screw is placed in the deck forward \of the a~ ES moe PR ee Se SS Meee rely ona Fe Coles how gemnd power toes amd ac wee awe _§ The Giftmeker ~<. ; 4. Y. | Pool Se. Rochester, ing model. tom by the small brass strap, shown missing from this small layout: Richmond Hill. WN. Y. | javue ttt St. Dest. MC2. peyebl e to Make chects ginner who has rot yet sailed a rac- e of To begin with, the principleffor t, of er cent the een balance betw and or center of the wind pressure oF the center of lateral resistance, the point where the side pressure of runde water is situated, must be writ ten stood. These are commonly is CE. the If .R”. “C.L “CE.” and sure of ahead of the C.L.R., the pres the wind will tend to force the bow of the boat off to one side, and if it (Continued from page 31) i There is no set of rules which can end of the tiller and is connected to it by means of a rubber band which governs the action of the sail S6 CLE... is sufficiently far ahead of thed up sailwin ly tual even will boat the is C.E. the If . wind ing before the very directly into the boat from headintog use a simple , the wind. In fact ht is very comparison, a sailing yace, so far as much like 2 weather van balance is concerned.