The Model Yacht is a published three times a year by the US Vintage Model Yacht Group

- The Layline.by John Stoudt. John discusses several ongoing projects:

- Eight Bells for Tom Alessi. by TMY Editorial Staff. The Chester Springs Model Yacht Club says goodbye to club member and US VMYG Board member Tom Alessi.

- 2025 North Central V36 and VM Regional Championships. by Ken Young Photos by Larry Kmiecik and Debbie Young. Ken’s report on the first ever NC Championship for V36 and Marbleheads held in Vernon Hills, IL.

- Simple Quantitative Comparisons of Model Sailboat Designs. by John Henderson. Photos by Nancy Henderson. John describes an active research project where he discusses how to understand “static stability” by addressing several interrelated parameters to arrive at the most efficient stability level of model yachts.

- Geo-positioning Buoys: FAQ. by the CSMYC Buoy Development Team. Photos by John Stoudt. In a follow-up to an article in the Spring 2025 issue, the development team answers questions readers have about Geo-positioning buoys.

- John Black. Reprinted from The Model Yachtsman Vol 4 #8 November, 1931. John Black’s success in designing and racing model boats in the early 20th century.

- Geo-positioning Buoys: A Simple, Effective Solution. by the CSMYC Buoy Development Team. Photos by John Stoudt. This is a follow-up discussion following an article in The Model Yacht, Spring 2025 concerning building GPS positioning buoys.

- Adhesives. based on a presentation by Alan Phelps Reprinted from Ropewalk, April 2024. Alan gives a full comparison of adhesives including the properties of different types of glue and the materials they are best suited for.

- A.J. Fisher. by TMY Editorial Staff. History of AJ Fisher’s model yacht parts manufacturing business and what has happened to his tooling and parts.

- Hands-Free Mast Calipers. article and photos by Joseph Valentine. Joe explains how to construct mast centering calipers that are hands-free, making final adjustments easier.

{person:John Black}

{person:Tom Alessi}

{person:A.J. Fisher}

{person:A. J. Fisher}

{person:AJ Fisher}

The Model Yacht Stability Spring 2025 Journal of the US Vintage Model Yacht Group Volume 26, Number One Journal of the U.S. Vintage Model Yacht Group Volume 21, Number Three Journal of the US Vintage Model Yacht Group Volume 26, Number Two Summer 2025

The Model Yacht Summer 2025 US VMYG Leadership President: John Y. Stoudt*, jstoudt309@gmail.com…………………………………………………………………..(610) 316-8695 President Emeritus: John Snow, jsnowj@comcast.net………………………………………………………………..(978) 594-8521 Treasurer: Chuck Lage*, chucklage@yahoo.com……………………………………………………………………..(484) 682-3091 Secretary: Richard McOrmond*, Mcormondrc@gmail.com…………………………………………..…..(610) 717-8285 Journal Art Director: Bruce Richter, richterbruce@gmail.com……………………………………………………(917) 575-2221 Journal Editor: Jeff Beck*, beck.jeff@gmail.com……………………………………………………………………..(240) 252-0236 Editorial Staff: John Henderson, jgnhenderson@gmail.com……………………………………………………….(443) 282-0277 Ken Young*, youngrun@sbcglobal.net……………………………………………………………..(630) 957-7490 Gudmund Thompson, gudmund.thompson@gmail.com………………………………………(613) 852-0648 Membership: Chuck Lage*, chucklage@yahoo.com………………………………………………………………….(484) 682-3091 Regatta Coordinator: Nick Mortgu, mortgu@comcast.net………………………………………………………….(609) 820-0509 Archivist, Chuck Lage*, chucklage@yahoo.com……………………………………………………………………….(484) 682-3091 Awards Coordinator: Rob Dutton, edwin653@aol.com.mortgu@comcast.net………………………………(703) 608-8812 Resources Coordinator: John Y. Stoudt, jstoudt309@gmail.com…………………………………………………(610) 316-8695 Plans Coordinator: Stanton Smith, stantonesmith56@gmail.com…………………………………………………(443) 629-4202 Historian: Earl Boebert, boebert@swap.com…………………………………………………………………………….(505) 823-1046 Boat Identification:………………………………………..…………………………………………..Currently Open Boat Yard Coordinator: Cliff Martin, Cliff-Martin@comcast.net………………………………………………..(508) 533-5971 Construction Advice: John Henderson, jgnhenderson@gmail.com………………………………………………(443) 282-0277 Jeff Gros, Jeffreygros48@gmail.com………………………………………………………..(630) 673-2201 Social Media: Chuck Lage, chucklage@yahoo.com…………………………………………………………………..(484) 682-3091 Class Coordinators Free Sailed: John Fisher, j sher577@gmail.com……………………………………………………………………….(719) 651-0762 Intl A Boat: Tom Kiley, kileyhills@me.com…….…………………………………………………..(207) 701-1661 Schooner: Ken Young, youngrun@sbcglobal.net……………………………………………………………………..(630) 957-7490 Skipjack: John Henderson, jgnhenderson@gmail.com……………………………………………………………….(443) 282-0277 Unrestricted: John Henderson, jgnhenderson@gmail.com………………………………………………………… (443) 282-0277 Vintage 10-Rater: Jeff Beck, v10rclass@gmail.com………………………………………………………………….(240) 252-0236 Vintage 36: Rob Dutton, edwin653@aol.com……………………………………………………………………………(703) 608-8812 Vintage Marblehead: Colin Parker, captcparker@yahoo.com……………………………………………………..(410) 404-3093 Vintage Power: Peter Kelley, pdkelley@sympatico.ca………………………………………………………………..(905) 301-9977 Regional Coordinators Australia:………………………………………………………………………………………………………………………………Currently Open Canada: Gudmund Thompson, gudmund.thompson@gmail.com………………………………………………..(613) 852-0648 European Continent:……………………………………………………………………………………………………………….Currently Open Mid Atlantic: George Schuld, gschuld@hotmail.com……………………………………………………………….(732) 966-7981 North Central: Ken Young*, youngrun@sbcglobal.net……………………………………………………………….(630) 957-7490 North East: Cliff Martin,Cliff-Martin@comcast.net ………………………………………………………………….(508) 533-5971 North West: Brian Schneider, schneider560@gmail.com……………………………………………………………(207) 715-2644 South Central:………………………………………………………………………………………………………………………Currently Open South East:……………………………………………………………………………………………Currently Open South West: Ernie Mortensen, usvmygsw@gmail.com………………………………………………………………(858) 525-5217 United Kingdom: Graham Reeves, graham@reevesmail.co.uk………………………………………………..+44 151 936 1140 *Denotes US VMYG board members fi i

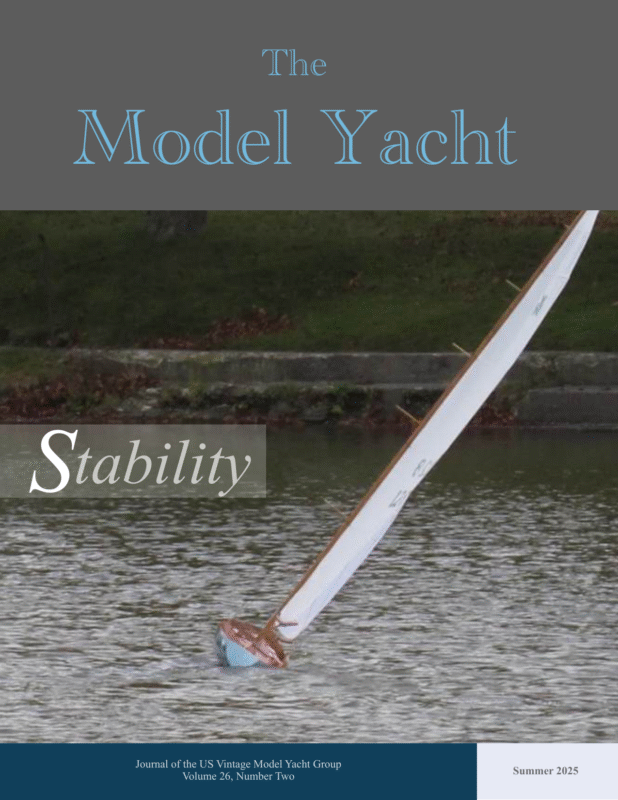

Summer 2025 The Model Yacht The Model Yacht is published three times per year by the US Vintage Model Yacht Group. Copyright 1989 to 2025 by the US VMYG. Reproduction for noncommercial purposes permitted; all other rights reserved. Other copyrights are maintained by the original holders, and such material is used here under the fair use provisions of the relevant copyright acts for nonprofit research and educational purposes. Editorial Address: John Stoudt 309 Sundance Drive Chester Springs, PA 19425 On the Cover: A Vintage Marblehead heels gracefully while maintaining stability on Redds Pond in Marblehead, MA. Photo by Candace Stoudt. Membership Renewals: Membership is now being managed on a rolling 12-month period. The annual membership fee will be due on the anniversary of your last payment. You will receive an email notification leading up to your due date. Please see the “Membership” page at https:// usvmyg.org/memberplans/ memberships/ for more information. Requesting a sail number: You can get a new sail number or transfer a registration from a previous owner here:https:// usvmyg.org/registration-2/ Select the class to open the correct form. There is a $7.00 fee for new registrations but no charge for transfers. The class coordinator will contact you to confirm your registration and sail number. The US VMYG is a 501(c)3 corporation. The Layline By John Stoudt Definition: A layline is a straight line (or bearing) extending from the next mark to indicate the course a boat should be able to sail on the one tack in order to pass to the windward side of the mark. (vsk.wikia.com/wiki/Layline) As you know, The Model Yachting Center (TMYC) has been our vision for some time. This concept was discussed numerous times over the years and started with an article called “In 2000” in a 1947 MYRAA newsletter that discusses the concept in a creative exposé (https://tinyurl.com/yc7c33w4). In the winter 1978/1979 issue of Model Yachting (https://tinyurl.com/yyu4vn8k) it was noted that a museum was started at the Probar manufacturing facility. Our proposal was the development of a location for The Model Yachting Center to preserve and perpetuate the sport of model yachting, which has its roots in the 1850s. This facility would include a museum housing various exhibits, archival and research spaces, and sailing venues for local, regional, and national regattas. Our concern is that there is no museum in the United States that has devoted any significant space or resources to the historical recognition and preservation of model yachting. The people who are involved in this sport are aging; there are few younger people becoming involved in the sport. Many of the existing models and the associated archival items have been disappearing, and the potential for many more to disappear is increasing every day. They will be lost to history forever. At this moment? Let’s bring you up to date on The Model Yachting Center. We have been trying to raise the money to do the creative ideation and research to determine if this concept is viable. The US VMYG board reached out to the AMYA board and made a presentation to them. While it was well received and AMYA voted to support the effort, no actual support was received. Most AMYA members that we contacted seemed ambivalent to the effort. We were told more than once, “If it is not in my backyard, I will not support it.” 1

Spring 2025 The Model Yacht Inside The Leadership Team……..…..i The Layline……….…….…….1 Inside……………….….……..2 Barnacles…………………9, 30 Eight Bells for Tom Alessi.…..5 After our communications efforts, we received contributions in the amount of $11,303. Note that we account for these donations within our budgetary records. Most of these donations came from members and friends. AMYA members donated a total of $75.00. Non-monetary donations Other donations of artifacts have been received: books, old model yachting magazines and journals, historical documents, plans, postcards, 3D viewer cards, manuals, marketing material, newsletters, hulls and molds, articles excerpted from other media sources, a complete set of Model Yachting, a complete set of The Model Yacht, model yachting catalogues, and photographs. Thus far we have had approximately 1,700 items donated to the US VMYG, valued at approximately $27,000. Mystic Seaport 2025 North Central V36 and VM Regional Championship…6 Simple Quantitative Comparisons of Model Sailboat Designs………………………10 Geo-positioning Buoy: FAQ…16 John Black………………..….18 Geo-positioning Buoy: A Simple, Effective Solution…..20 Adhesives……………………22 A. J. Fisher…………………..28 Hands-Free Mast Calipers…..31 2025 National Championship Regatta Announcement……..34 In 2002 the US VMYG met with folks at Mystic Seaport and formed a relationship to grow the American Model Yachting Collection. Thanks to the efforts of Rod Carr in Seattle and John Snow in Marblehead and the extreme generosity of the Houk family, the American Model Yachting Archives were initiated with the collected papers and plans of the late Dr. “Ted” Houk. What was established in 2002? The US VMYG was designated by the AMYA and Seaport Library to act on their behalf as the screening organization for potential material donations to the collection. The purpose of the US VMYG involvement is to provide a level of understanding of where in history a given donation fits, its provenance, and historical value. The library staff were generally not experts in model yacht history. US VMYG could provide that expertise. It should be noted that not all model sailing material may be deemed acceptable for donation, given the scope of the collection, whether the material is already in the collection, or whether the material is suitable given its condition. The Seaport cannot accept material with stipulations attached, such as agreeing to display it, providing special rights or access to it, or promising to return it at a later date to the donor. The Seaport owns all the material once it is officially donated and accepted, and a signed certificate of gifting is on file. The Seaport Library will informally work with donors to meet any reasonable requests relating to copies of gifted material. According to Earl Boebert there was never a formal agreement signed, just an understanding, a handshake if you will. 2

Spring 2025 The Model Yacht Mystic Seaport (today) The current US VMYG board has been in communication with Mystic to discuss the relationship. We had a good first, virtual meeting and are planning a visit to discuss this further. Mystic has a different intake process today. They are very concerned about the provenance and quality of the items accepted into their collection. There is also an application process for requesting to donate to the Seaport collection. The US VMYG needs to fully understand the process and discuss how model yachts and related items can be assimilated into the American Model Yachting Collection at Mystic Seaport Museum. Rethinking Our Model Yachting Center Concept The lack of support from the general model yachting community has forced us to look at other options. These include: • Other ways to consider the various components of the center, their value, necessity, and public interest. • Ways to preserve the collection of items donated to the US VMYG. • Rethinking potential donors. • Looking outside of the model yachting community for support. Digital Archive Project Over the past few years, several individuals have donated their collections of books, magazines, journals, pictures, newsletters, articles, videos, postcards and other historical records on model yachting to us. This collection fills 13 banker’s boxes and consists of over 1,500 unique documents. Although fun to poke through, we kept thinking, nobody else will ever see these items. So, we hatched a simple idea: let’s digitize as much as possible and post these items on our website for others to enjoy as a searchable archive. We realize we also need an easy and engaging way to display and share this information. Soon we will start looking at plug-in modules to our website to manage and make this information available. Organizations come and go, but once digitized, we will look for a way to endow our “digital legacy” to be enjoyed through the years. We are also in the process of a newspaper search project using Newspapers.com. Regional volunteers are searching newspapers for anything published on model yachting. Thousands of articles have been found to date from a worldwide collection of newspapers. These will be added to the data set when practical. Recently, a member donated a high-end, overhead scanner to assist us with the scanning project. This will enable us to scan items that were very difficult to scan by other means. Overhead scanner. 3

Spring 2025 The Model Yacht USVMYG.ORG work in progress We are having intermittent technical difficulties with our website. We expect our website usvmyg.org to do more all the time. This is causing it to act a little strange. We rely on a number of what they call “plug ins” to enable our website to manage all of the various data and functions we need to do our work and to share information with you. WordPress, our website package, is built on a basic platform with add on features. These are those plug-ins. They are developed independently, and their updates are not always timed efficiently. So, it causes issues from time to time. We are in the process of rebuilding the site and have engaged a website developer/designer to help with various tasks and to provide expertise outside of our comfort zone and ability. The site will not change its appearance much, but it will just behave as we expect and provide access to more vintage model yachting information. Conclusions Due to our lack of ability to fund TMYC research, we are looking into ways to modify some of our goals and to utilize the resources we have available. We will be updating our website, making it stable, enabling us to make more information available to you and others. Our efforts and current funding will be used to maintain the website and ensure its longevity. We will continue to seek out the funding to enable the research to do the creative ideation and feasibility study for TMYC. Your Assistance There are ways that you can continue to support our efforts: • Donate your papers, magazines, books or other paper items related to model yachting. (Please reach out with a list so we can compare it to what we already have in our archives). For more information contact Chuck Lage at usvmygt@gmail.com. • Loan items to us for scanning if you prefer not to donate. We have already done this, completing the scanning and returning the items to their owners in a timely fashion. • Donate funds to US VMYG to support our vision for this project. You may donate to the US VMYG here: https://usvmyg.org/giving/ We will provide you with a tax-deductible receipt for any type of donation made. A special thanks to those who have already made a financial donation and those who have made a physical contribution. All of the various donations have helped make a difference. We are not giving up; we are redirecting our thinking. We are continuing our initial vision with our purpose in mind; and we are ensuring the long-term protection of what we started. 4

Spring 2025 The Model Yacht Eight Bells for Tom Alessi From the days of tall ships, Eight Bells signifies the end of a sailor’s watch. Time for a sailor to rest. — Ed. Article by The Model Yacht Editorial Staff. Tom Alessi served as Treasurer and Membership Secretary of the US VMYG for a number of years. He was an avid R/C sailor and builder and a member of the Chester Springs Model Yacht Club (CSMYC). One winter day in 2012 while sailing at Marsh Creek with the water level down, the rocks showing, the marks thrown from the shore, and a cold wind blowing, a bundled-up couple appeared on the shore to watch us sail. It was Tom and his wife, Jan. They watched us struggle in our boots: wading among the rocks, falling in, breaking a mast, and generally doing an absolutely crazy thing because we could. Tom Alessi, August 19, 1943 – December 14, 2024. Photo by Jan Alessi. He loved it and proceeded to build his first boat, a Soling 1 Meter. He became an ardent, competitive, and regular member of our club. He swallowed the bait, built another boat and then another boat: a Soling 1 Meter, a Madcap Marblehead, a Chris-Craft Typhoon, an Oyster Sharpie, an EC12, boats for friends’ children, and the schooner Atlantis. He got involved in the US VMYG as a member and then as the Treasurer/Membership Secretary, bringing many improvements to the organization. He became a real R/C sailing enthusiast. Tom loved the CSMYC and the members. It was the highlight of this time in his life. The CSMYC ship’s bell was rung eight times to honor his “end of watch”. There was a “sail away” at the lake. Atlantis sailed off surrounded by club boats. They peeled away one by one, returning to the dock. Tom’s boat sailed away. You can view the sail away on YouTube. Photo by John Stoudt Tom, we are going to miss you. We will see you at that great lake in the sky. See the “Sail Away” video on YouTube: https://youtu.be/bl1RkbOKuUk 5 Atlantis making way. Photo by John Stoudt

Spring 2025 The Model Yacht 2025 North Central Regional Championships: and Article by Ken Young Regatta skippers and Race Committee. Photo by Larry Kmiecik. T he Chicago RC Model Yacht Club hosted the first ever Regional Championship Regatta June 20–22 at Century Hills Park in Vernon Hills, IL. Fourteen skippers registered 10 V36s and 13 VMs. The regatta committee. Photo by Larry Kmiecik. The regatta committee was made up of Jeff Gros, Bob Armbruster, Tom Germanson, Jean Bower, Karen Richmond, Joe Richmond, Debbie Young, and Larry Kmiecik. A special thanks to Nick Mortgu for his help with registration. The schedule of events was: Friday, June 20: V36 racing all day. Friday evening informal gathering at Portillo’s Hot Dogs. Saturday, June 21: V36 racing in the morning; Marblehead racing in the afternoon. Saturday evening informal gathering at City Works restaurant. The rescue crew hard at work on a blustery day. Photo by Debbie Young. Sunday, June 22: Marblehead racing all day. 6

Spring 2025 The Model Yacht Vintage 36/600 Friday morning was almost perfect sailing conditions: cloudy, wind 6–10 mph, temperatures in the low 80s. Electronic and mechanical gremlins kept two boats on shore, so we had a fleet of eight. After lunch, the sun came out and a serious breeze came with it. We completed nine more races for a total of 18, but the big breeze had reduced the fleet to four by the end of the day. Saturday’s forecast was for big winds and brutally high temperatures to 95. Unfortunately the weatherman was right. At 7:00 am the wind was at 15 mph and forecasted to build to 22, with gusts to 35. The V36 skippers decided their little boats had enough, so we ended the regatta with 18 races. A V36 on a run. Photo by Larry Kmiecik. Head on in a moment of relative calm. Photo by Larry Kmiecik. V36s on the course on Friday. Photo by Debbie Young. Joe Richmond receiving the V36 Craftsmanship Award. Photo by Debbie Young. 7

Spring 2025 The Model Yacht Vintage Marblehead When the V36 skippers ended their regatta Saturday morning we all sat in the shade telling stories. After a while some of the more intrepid Marblehead skippers wanted to give it a go. Winds were now about 18 mph with much higher gusts. Not many skippers took the plunge. Before the regatta, Clark Fremgen had rummaged around in his basement and found a Soling rig with wood spars so he used that as a B rig. John Fisher put his V36 rig on his Marblehead. John Richmond was sailing a Littlejohn 50, designed in the early 1970s when there was a fad going where the jib is larger than the main. So his rig was much shorter. They ended up being the fastest three on the water. The fleet battled through nine races with only three left sailing by the end of the day. Photo by Debbie Young. Sunday dawned with a much more manageable 10–15 mph breeze, but still 95 degrees and humid. But the carnage had been done the day before. We had a total of eight boats that competed in the regatta. We completed 24 races, with trophies for the top two in each division. The wind took its toll on the boats and the heat took its toll on the skippers. A close race. Photo by Debbie Young. 8

Spring 2025 The Model Yacht Special Thanks John Fisher receiving the VM Craftsmanship Award. Photo by Debbie Young. Marbleheads approaching a windward mark. To my knowledge, this is the first time a Regional Championship has been held in the Midwest. It was great to have this many skippers register for a new event. Vintage regattas are special. Much more easy going. We had spectators unfolding their chairs to sit down and watch and ask a lot of questions. “Everybody is so friendly”, was heard repeatedly. I want to thank all the skippers, workers, and spectators who made this event special. Photo by Debbie Young. Barnacle Servo Mounts—These Servo Mounts (standard) from Servo City allow you to fasten a standard size servo on top of a flat surface. The mounts include hardware to fasten the servo to the top, leaving three holes at the base to run fasteners through into the surface below. Servo Mounts (mini servo) – These products have been hand created by the ServoCity R&D team. Most mini servos will work with these mounts. 9

Spring 2025 The Model Yacht Simple Quantitative Comparisons of Model Sailboat Designs Article and drawings by John Henderson. Photos by Nancy Henderson. plans), with the possible exception of Mast Height and Ballast weight. These parameters might have to be estimated or measured. This essay discusses metrics to evaluate some basic elements of model boat performance. The goal is to enable informed model choices and to evaluate designs before committing to building, restoring, or purchasing. The model specifications and resulting calculations are presented in a spreadsheet. I have deliberately limited the input parameters to those that are usually provided in summary specifications. I have deliberately avoided requiring data that could be obtained only from lines drawings. Metrics The metrics calculated by the table are: • • • • I view this as a work in progress. As the Comparison Table will show, I have applied these metrics to a variety of models, and the calculations relate well to observed performance. I would like, however, to expand the selection of models before I am satisfied. To that end, I solicit from readers data for models of their own. This would be a list of the parameters required by the table and comments about the model’s performance, e.g., “good in light air”, “goes upwind well”, “needs lots of wind to perform”, “seems excessively tippy”. I would be particularly interested in documentation for Schooner, V10R, and Unrestricted model classes, because of their great variety of designs. The first three of these metrics are standard “big boat” formulas, except that I used overall Beam rather than waterline beam because waterline beam data is generally not available without resorting to plans. Using the overall beam is fine for the relative L/B ratios of this modeling spreadsheet, but they would make our models look “fat” if the numbers were compared with full size. Note that these ratios are “dimensionless” (i.e., the dimensions in the numerators and denominators in each ratio are the same and thus cancel). SA/D, DLR, and L/B compare directly with the same ratios for full-size boats. Parameters The model parameters that I input to the table are: • Length on Deck in inches (LOD or LOA if no bowsprit) • Waterline Length in inches (LWL) • Sail Area in square inches • Displacement in pounds • Weight of ballast in pounds • Draft in inches • Beam in inches (max beam at deck level) • Mast Height in inches Most of these specs are readily available (usually they can be found in the US VMYG’s online views of Sail Area-to-Displacement Ratio (SA/D)1 Displacement-to-Length Ratio (DLR)2 Length-to-Beam Ratio (L/B)3 An estimate of “Relative Stability”, which I will explain For general reference: • SA/D much greater than ~20 is a fairly sporty boat. • For full-size boats, DLR below ~90 is “ultralight”, 90-180 is “light”, and 180-270 is “moderate”. • Higher L/B is a narrower, more easily driven hull. Comparison Table 10 On the following page is the Comparison Table, with commentary to follow:

Table I. This is a snapshot of the Design Comparison Table. Some columns have been hidden in this image to make the entries easier to read in print (Subclass, Designer, Performance Comments, Other Comments). Entries shown in red have not yet been built. The complete table is available online at https://tinyurl.com/4yxjckdw. The table will be updated as the data for more models are submitted. The Model Yacht Spring 2025 11

Spring 2025 The Model Yacht Relative Stability deep, round hull of the same displacement. A longer hull with the same displacement and same fairbody draft would likely shift the CB less than a shorter, wider hull. This might seem to penalize length, but a longer hull with the same displacement would have a narrower beam and would shift the CB less. (A longer hull with more displacement would be a different situation.) • The Sail Area is multiplied by 0.00694, which is the force in pounds of a 10-knot wind on a square inch of sail area (usually stated as “1 pound per square foot”, per Hobbs’ book Model Sailing Boats). This conversion of sail area to force makes the units in both the numerator and denominator of the ratio to be “inch–pounds” (a unit of torque and of the righting/heeling moment), and so the ratio is dimensionless, as the other three ratios are. • I divided the Mast Height by 3 as an approximation to the height of the Center of Effort of the sail plan. • These approximations are subject to review (as is the whole concept). The “Relative Stability” column requires explanation. It is my own creation, and perhaps I will revise it if new data show that revision is warranted. It is an attempt to capture sail-carrying ability using numbers that are available without drawings. Proper stability calculations—even of static stability—require lines drawings, which are generally not readily available for this simple comparison. Also, the calculations are tedious, and I don’t know how well they relate to models, where dynamic stability is also important and is more difficult to scale. For example, the ability to handle sudden gusts is dependent, at least in part, on the Moment of Inertia, which is a measure of resistance to rotational changes. The Moment of Inertia varies as the 5th power of scale factor, so there is a huge difference between models and full size. This explains, in part, why models seem so “twitchy”. The Relative Stability numbers should be understood as relative and are intended to be useful for model comparison purposes. Bigger numbers indicate more “stability” and greater sail-carrying ability. The formula I came up with is: The general notion that a wider, flatter hull has more stability—at least up to the point of knockdown—is intuitive. But there are some details that both support the above approximations and reveal their limitations. Heeling and Righting Arm The idea is to put attributes that contribute to stability (Draft, Beam, Ballast) in the numerator and attributes that cause heeling (Sail Area and tall masts) in the denominator. Some details: • I divided beam by the L/B ratio to try to get a general approximation of how far athwartships the Center of Buoyancy (CB) shifts at a reasonable heel angle. (This shift of the CB generates “righting moment” to prevent knockdowns.) I am trying to give stability “credit” for a shallower, flatter hull, for which the CB would shift outboard more than for a Figure 1 is a sketch of the central cross-sections of two hulls that have the same Displacement but different Beams. The Center of Gravity (CG) is shown below the bottom of the hulls’ fairbodies, as I think is typical of our models with their high ballast-to-displacement ratios. The upright and heeled waterlines are shown. In each position, I have indicated an approximate location for the CB, which is the center of buoyancy of the actual volume of the hull that is immersed at the particular heel angle. (The CB would be on the 12

Spring 2025 The Model Yacht centerline in the upright drawing.) The righting arm (RA) for each hull is the horizontal distance between the CG and the CB. It is evident that this distance is greater in the wider hull. me. Entries shown in red are models under construction and so untested; entries shown in black are for models that have sailed successfully. Fig. 1. Effect of beam on heeled CB location. Note also that Fig. 1 shows the hulls heeled to an angle that brings the deck edge of the narrower boat down near the heeled waterline, while the deck edge for the wider hull is submerged. If the freeboard had been higher, the hulls would have had more volume to immerse and thus greater stability. I have ignored freeboard in the Relative Stability calculation because the data are not easily available. The three “standard” metrics (SA/D, DLR, L/B) contain no surprises. The Relative Stability numbers for successful models seem to concentrate around 1.0, although some of the smaller boats (e.g. the V36 designs) are successful with Relative Stability numbers in the 0.7 range or a little below. It is possible that I improperly penalized short LWL and its associated lighter Displacement, but longer hulls, having typically greater Displacement, would indeed be likely to be more stable. I note also that none of the V36 designs currently in the Table has an aggressive SA/D, and this conservatism may contribute to their success. In any case, the Relative Stability table should be used to compare designs of roughly similar size. Without this “Relative Stability” column (or something better), the table would seem to say that the key to better performance is reducing weight (displacement). Lower D makes both the SA/D and DLR ratios look better, but lighter weight usually means less ballast. Unless draft is not a controlled parameter (and draft is controlled for our boats, except in the non-scale (fin/bulb) Schooner class), less ballast means less stability. So the “Relative Stability” column is meant to be cautionary and to preserve sanity. Note also the somewhat low stability number for the Skimmer V10R, which has a relatively short LWL, but which actually handles stronger winds quite well. It has a flat bottom and wide beam, which allows the CB to shift well outboard. The Skipjack has a low stability number, and I think this is appropriate. Observations from the example spreadsheet My own designs are disproportionately represented, but that is because the data were easily available to 13

Spring 2025 The Model Yacht keep it safely at home if the wind is much over 7-8 knots. Its stability issues are exacerbated by the prototypically long boom, which can drag in the water when heeled and then cannot be eased to relieve pressure. Note that the full-size America’s Cup race boats of this era similarly did not sail when it blew. Of course, the model does a bit better in more wind if I remove the gaff topsail. The data for the Unrestricted Class model of NG Herreshoff’s 1899 America’s Cup cutter Columbia may be particularly instructive. I made this model as close to scale as I dared, but I probably should have shown even less courage. The sail area is about 20% less than scale, and the draft is about 10% deeper. Even so, the data show an extremely aggressive SA/D, and the Relative Stability is among the lowest in the table. As the photo shows, it sails well in light air, but I Fig. 2.1899 America’s Cup cutter Columbia. 14

Spring 2025 The Model Yacht A much better all-weather model design is my Vintage 10-Rater Sweet XVI, shown in Fig. 3. It is shown at a comfortable angle of heel in a modest breeze. As predicted by the Comparison Table, it has good stability; it sails well in breezes of 10-15 knots with gusts over 20. (It is a new design and I have not yet sailed it in windier conditions.) How you can participate To enable further study of these stability and performance matters and to make the information available to members, the US VMYG offers three online links: The Design Comparison Table The table will be maintained by the US VMYG as a public dataset. It is viewable on the US VMYG Google Drive at: https://tinyurl.com/4yxjckdw It will be updated from time to time by the curators as data on unusual, instructive, or other designs of general interest become available. A Stability Project Data Entry Form The US VMYG welcomes additional model data to expand the utility of this Design Comparison Table or, if necessary, to improve its Relative Stability equation. Members can submit information about their models via the Stability Project Data Entry Form, which is available at: https://usvmyg.org/stability-project-entry-form/ This data entry form will be visible to the curators, who will enter it into a private Worksheet or the public Comparison Table. We will attempt to provide feedback to the submitter. Fig. 3. V10R Sweet XVI. A Design Comparison Worksheet If you want to experiment on your own with design parameters before committing to a build, you can use the Design Comparison Worksheet, which is a downloadable Excel file that you can run locally. The file is available from: https://tinyurl.com/43ky4h4w Because you run this on your local machine, your results will not be public. But you can share your results using the entry form above. The Sail Area-to-Displacement ratio (SA/D) is calculated by dividing the sail area (in square feet) by the boat’s displacement (in cubic feet) raised to the 2/3 power. [2] The Displacement-to-Length Ratio (DLR) is calculated by dividing a boat’s displacement in long tons (2,240 pounds) by the cube of one one-hundredth of the waterline length (in feet). [3] The Length-to-Beam ratio (L/B) is calculated by dividing a boat’s length at the waterline (LWL) by the beam at the waterline – although in this case we are using the maximum beam. 15 [1]

Spring 2025 The Model Yacht FAQ Geo-Positioning Buoys: This is a follow-up to the article “The Geo Positioning Buoy Project” in The Model Yacht, Vol 26 No 1, Spring 2025 Article by The Chester Springs Model Yacht Club Buoy Development Team. Photos by John Stoudt. If you have built your buoy well, maintained it, and prepared it correctly for deployment, you should have very few problems. The 2025 spring was very windy at our lake. It was a good test of the durability of the entire buoy system. Geo-positioning buoy. Here are some questions that we anticipate based on our experience with the Geo-positioning buoys. Q: Why does my buoy have water in it? A: If you have a buoy that was manufactured and built as instructed, it should not leak. We have found small amounts of water in buoys on occasion. In each instance we: • Check the hull and lid for cracks in a dark room with a high intensity light. We have found one crack in our parts. It was the result of mishandling, and we repaired it. • Ensure that the thrusters screws are tight. We have found a couple that were loose after numerous uses. • Inspected the wire tubes. We have not found leaks here yet. • Evaluated the hull and lid. We have found that water has leaked in through this seal. The lids had not been secured correctly. Because the lid seals around the entire top of the buoy, you must make sure the lid seals against the rim around the hull before the thumb screws are tightened, or the seal will not be waterproof. 16 Lid gasket. Lip at the top of the hull.

Spring 2025 The Model Yacht Q: A: Do the thrusters get fouled with debris in the water? Yes. This is true of any underwater prop and is noticeable on most ROVs (remote operated vehicles). Every natural body of water has some plant and animal material that can get drawn into the thrusters. We found that you must check the thrusters after each use, and: • Clean them using tweezers, dental picks, and toothbrushes. • Once a month (~50 hours of use), we remove the hub and prop and thoroughly clean the prop and housing. • Lube the shaft on the thrusters once a month with WD-40 ®. Cleaning tools. None of these actions takes a lot of time, but they are important to ensure the proper operation of the thrusters. Q: A: • • • • • • • • What kind of maintenance is required on the buoys? The routine maintenance is pretty straightforward. You should: Have parts that were printed using the print parameters we provided and assemble them correctly. See the instruction manual (https://tinyurl.com/2unzzf4u) for more information. Check the thrusters for fouling and clean them routinely. Make sure all of the possible sources for leaks are checked routinely. Make sure the lid is sealed against the hull’s rim before deployment. If there is water in the buoy when it is opened, dab it out with a sponge. Be careful of the Bluetooth antenna wires. Do not touch the satellite antenna on top of the control board with your finger. Replace a flag when necessary (very seldom.) Q: How do you handle and store the buoys? A: We are able to store our buoys in the boathouse at the lake where we sail. We have a custom hand truck, “The Octopus”, that we use to store, work on, and move the buoys to and from the water’s edge. You will have to come up with a solution for your location. Q: What type of battery do you use? A: We are able to charge our batteries in a charging station in the boathouse where we sail. The Octopus”, which we use to store and transport the buoys. We are cautious about the type of battery we use and charge in this location. We therefore use a 7.2 volt, 6200 mAh, NIMH battery, 6-cell flat pack rechargeable battery pack and an inexpensive, simple, NiMH/NiCd universal R/C charger battery charger with six connectors. Sample battery. These take a full charge each time they are charged and are left on the charger between sails (we sail five times each month). One charge has been lasting 8+ hours in 20-knot winds or one full day of sailing. If you have any other questions, please feel free to contact us. 17 Sample charger.

JOHN B L AC K is portrait was originally published in e Model Yachtsman, Vol 4, No 8, November 1931 issue. e Bostonia IV photographs were published in e Model Yachtsman, Vol 4, No 6, September 1931. J ohn Black is a school master by profession and a model yachtsman by inclination. Although he hails from Boston, Mass., his forebears were Scottish. We do not know John Black’s age, but he is surely one of the greatest boys of his years. Although he had considerable previous model yachting success, John Black’s star rst shone on Europe in 1926 when he won the American Selection Races with the original Bostonia rst of the line of yachts bearing her name, and thus had the honor of carrying the Stars and Stripes in the World Championship Races at Gosport. He was beaten by the redoubtable De ance (Captain F.W. Lazell). From an original Drawing by W.G. Munro fi fi Th 18 fi Th Th Th Spring 2025 The Model Yacht

Spring 2025 The Model Yacht His next venture at Gosport was in the following year when with Bostonia II he came as near to winning the World Championship as is possible without actually securing the coveted honor. On this occasion he lost to the British Gertrude (R. Jurd) by a single point. Bostonia IV, however, repeated her success in this year’s American Races, and Mr. Black accordingly came to Gosport. In the World Championship Races he lost to Hermione (T.H. Willey). During this year’s trip to Britain, Mr. Black took Bostonia IV to Scotland, where he was very successful against the Scottish A Class boats. John Black is a thorough sportsman, ghting every board to the end of the race. He knows how to win modestly and lose gracefully. He is the cleanest sailor possible and has never been known to infringe a rule. His cheery sportsmanship has endeared him to British model yachtsmen, and nobody would regret it if he took that “old mug” back to Boston with the projected Bostonia V. Bostonia IV in a hard slam at the 1931 World Championships. He won the American Races again in 1929 with Bostonia III, but at Gosport he struck a tough opponent in Albion (L. Rudd), which nished ahead of her American opponent. Although his next boat, Bostonia IV won the American Selection Races of 1930, she was passed over in favor of Yankee Doodle II as the Committee considered that the latter boat would prove more suitable to Gosport conditions. fi fi John Black and Bostonia IV waiting for Cresset to come aboard the launch that conveyed the competitors to the venue of the Open Water Races. John Black with Bostonia IV. 19

Spring 2025 The Model Yacht Geo-Positioning Buoys: A SIMPLE, EFFECTIVE SOLUTION water than anchored buoys do. The GPBs return to their anchored position more quickly than the anchored buoys. This is a follow-up to the article “The Geo Positioning toy Project” in The Model Yacht, Vol 26 No 1, Spring 2025 After continued conversations with Dave Baker, the developer of the computer control board, we decided to attach a piece of ½-inch PVC pipe on the bottom of the GPB using the keel bolt hole in the hull of the buoy. The hull of our buoy design is so efficient in the water that additional “resistance” below the waterline was needed to improve the noticeable reaction of the buoys to the commands from the software. In other words, the buoys would move back to their established position more slowly thus making their movement much less noticeable. Article by The Chester Springs Model Yacht Club Buoy Development Team. Photos by John Stoudt. We designed a weighted keel for locations where more stability may be needed, such as areas prone to waves and tidal action. The weighted keel information can be found on pages 15 and 16 of the Geo-Positioning Buoy Instruction Manual (https:// tinyurl.com/2unzzf4u). This new design, outlined in this article, is similar to the weighted keel option but provides more underwater resistance without the added weight. This design with slight modification could be used with a weighted keel. The assembled keel. Geo-positioning buoy with the keel attached. You may recall the article in the Spring 2025 issue of The Model Yacht about the geo-positioning buoys (GPB). One thing mentioned in the article was how these buoys appear to behave differently in the 20

Spring 2025 The Model Yacht Materials (per buoy) Install the Keel These materials can be purchased locally or from Amazon. The underlined items below are active links to their respective page on Amazon. • • • • • • • One 12-in length of ¼-20-in all-thread (stainless) Three ¼-in ID, 1-in OD fender washers (stainless) One ¼-in ID, 1 ¼-in OD fender washer (rubber) Two ¼-20-in nut (stainless) One 9-in length of ½-in PVC pipe Two ½-in PVC end caps One container of PVC adhesive Tools • • • • Adjustable or 7/16-in open-ended wrench Cordless drill ¼-, 5/16-, and 3/8-inch drill bits Hand or bandsaw Procedures Make the Keel Body 1. Cut a 9-in piece of PVC pipe. 2. Drill 5/16-in holes in the middle of the ends of the PVC end caps. 3. Add additional resistance to the tube by drilling 3/8in holes every inch through the piece of pipe. a. Drill the first hole in the pipe 1 inch from one end of the pipe, then rotate the pipe 90 degrees and drill the next hole through the pipe. b. Continue this process until you reach the end of the pipe. 4. Clean up the burrs on the holes and the debris from the inside of the pipe. 5. Glue the end caps onto the ends of the pipe. 6. Drill a ¼-in hole sideways through one end cap into the pipe to help drain the water when the buoy is lifted out of the water. 1. Remove the keel hole bolt and washers from the bottom of the hull. Removing the keel hole bolt 2. Using the keel bolt hole in the bottom of the buoy hull, attach a 12-in piece piece of ¼-20-in stainless steel allthread. Thread the rod into the heat sink nut from the bottom until it is visible at the top of the hole on the inside of the hull. 3. Add the rubber washer, the stainless fender washer, and the stainless nut. 4. Tighten the nut until the rubber washer visibly compresses against the hull. 5. Place an additional stainless fender washer onto the all-thread. 6. Slide the ½-in PVC pipe assembly onto the threaded rod. Make sure that the ¼inch drain hole is at the bottom when it is installed. 7. Place a stainless fender washer and nut on the bottom of the all-thread and tighten the nut until it is snug. Illustration of keel assembly. NOTE: The fender washers noted with the asterisks are placed on the assembly to prevent the PVC end caps from being broken when the lower nut is tightened. The GPB team and other club members who have observed the buoys in the water have been impressed by how well this simple solution works. Illustration of the keel body. 21

Spring 2025 The Model Yacht Adhesives This article has been republished from Ropewalk, May 2024. Ropewalk is the newsletter of the Shipwrights of Ohio. It was presented at their April 2024 meeting by the author. Find out more about the organization here: https://shipwrightsofohio.com/ Report on a presentation by Alan Phelps. The objective of this presentation was to provide information to help the modeler to: “Determine the most effective adhesive for every substrate or combination of substrates.” Alan covered the subject by each class of adhesive, but first, he covered the subject of material preparation which is important for ensuring a tight bond. 22

Spring 2025 The Model Yacht Preparation As with all adhesives, proper preparation of the surfaces is key to a strong bond. Glossy or shiny surfaces should be dulled or roughed up. Non-porous hardwood joints should be sanded to provide “tooth”. Metal joints should be roughed up and free of oils, oxidation or other contaminants. Surfaces should be cleaned with a solvent for adhesives. Alan then provided the following chart. It lists the types of adhesives and if they work with the various substrates. The red pips in the chart indicate the best fit for the application. The black pips are applications that will work as a second choice. On the following pages are the adhesive characteristics of 11 different adhesives types. 23

Spring 2025 The Model Yacht Class: PVA – Type 1 Product: Elmer’s white, Titebond Original, School glue. Compatible materials: Paper, cardboard, porous materials. Cure mode: air. Working life: 15 min. Cure time: 2 hours. Price/oz: $1.80/oz. Color: white, off white, amber. Flexibility: moderate to high. Strength: low. Solvents: cleanup – water; thinning – water. Pros: safe, non-toxic, easy clean-up, fingers de-bond in water. Cons: Not waterproof. Class: PVA – Type II Product: Titebond Premium, Woodweld, Weldbond. Compatible materials: Paper, cardboard, porous wood. Cure mode: air. Working life: 1 hour. Cure time: 3 hours. Price/oz: $0.50/oz. Color: light yellow. Flexibility: less than Type III. Strength: Greater than type I. Solvents: cleanup – water; thinning – water. Pros: fast setting, clear, no air required. Cons: not for outdoor use. Class: PVA – Type III Product: Titebond Ultimate, Carpenter’s Max, Gorilla Ultimate, Weldbond Polyacetate. Compatible materials: Porous & non-porous woods, metal to wood bond. Cure mode: air. Working life: 30 min. Cure time: 24–48 hours. Price/oz: $1.93/oz. Color: off-white, tan. Flexibility: low. Strength: Extremely high – stronger than I or II. Solvents: cleanup – water; thinning – water. Pros: Fast setting, clear, no air required, waterproof, good for outdoor. Cons: longer cure time. 24

Spring 2025 The Model Yacht Class: Cyanoacrylates Product: Bob Smith Industries super glue, Weldwood instant wood adhesives, Extreme Power. Compatible materials: most everything. Cure mode: air and humidity. Working life: 5 sec Cure time: 30 min. Price/oz: $5–10/oz. Color: frosty clear. Flexibility: very low. Strength: high. Solvents: acetone. Pros: quick bonds, broad applicability. Cons: fumes, bonds skin. Class: Epoxies Product: Loctite, JB Weld, Permatex Cold Weld, Locktite E-20NS. Compatible materials: almost everything. Cure mode: 2-part mix, some 1-part. Working life: 1–15 min. Cure time: 12–48 hours. Accelerator: heat. Price/oz: $13.00/oz. Color: amber or gray. Flexibility: more flexible than CA. Strength: Very high at final cure. Solvents: acetone, alcohol, no air required. Pros: large variety available depending on materials, strength. Cold weld bonds most metals, dishwasher safe. Cons: very slow final cure. Class: Epoxy Hybrids Product: Locktite HY 4090. Compatible materials: Everything. Cure mode: 2:1 mix. Working life: very short. Cure time: 30 min. Accelerator: included. Price/oz: $14.70/oz. Color: various. Flexibility: More flexible than CA Strength: Very high. Solvents: Acetone. Pros: fast set epoxy, very strong bonds. Cons: Costly. 25

Spring 2025 The Model Yacht Class: Contact Cement Product: Stick ‘n Seal, Gorilla Clear Contact, rubber cement, Weldwood Contact Cement. Compatible materials: laminates, hard woods. Cure mode: air. Working life: Cure time: hours. Price/oz: $2.00/oz. Color: amber. Flexibility: moderate. Strength: moderate to high. Solvents: acetone, lacquer thinner. Pros: fast setting, clear. Cons: Notes: Spray on contact available at art stores; used for gluing sandpaper to blocks. Class: Anaerobic Product: Thread lockers (many brands). Compatible materials: metal, usually steel. Cure mode: ionic. Working life: 5 min. Cure time: 60 min. Price/oz: $14.00/oz. Color: color coated by strength. Flexibility: none. Strength: High. Solvents: no, acetone, lacquer thinner. Pros: can be used before, during, or after assembly. Cons: no debonder. Class: Polyurethanes (PU) Product: Permabond PT321, Gorilla Glue (foaming). Compatible materials: 3M DP605NS, most woods. Cure mode: air and water. Working life: Short. Cure time: hours. Price/oz: $6.00–$10.00/oz. Color: Flexibility: Strength: Extremely strong bonds. Solvents: thinning – none; clean up – acetone. Pros: fast setting, clear, no air required, hard cure. Cons: Toxic, foam (clamping needed). Notes: Foaming glue, clamping required, extremely strong bonds. 26

Spring 2025 The Model Yacht Class: Acrylics Product: Gorilla Clear, Super Gray Glue, Glass glue, Plastic Fusion. Compatible materials: 3M DP605NS, glass, plastics, acrylics, polycarbonate Cure mode: air & water. Working life: short. Cure time: hours. Price/oz: $6.00–$10.00/oz. Flexibility: Strength: Extremely strong bonds. Solvents: Thinning – none; clean up – acetone. Pros: fast setting, clear, no air required, hard cure. Cons: Toxic, Foams (clamping needed). Class: UV Cure Product: CRL /clear C740, Locktite 352, Donique, 3m LC-3200 Compatible materials: glass, clear plastic, metal, wood, ceramics, Cure mode: one part liquid and UV light Working life: NA. Cure time: seconds. Price/oz: $15.00/oz. Color: clear. Flexibility: Rigid. Strength: extremely strong bonds. Solvents: Thinning – none, clean up – acetone. Pros: fast setting, clear, no air required, hard cure. Cons: Toxic, Foams (clamping needed). Brands with multiple cross class products: • 3M • Weldwood • Titebond • Gorilla • Loctite • JB Weld Barnacle Shroud Attachment Options—Given how difficult it is to find good inexpensive ways to attach the shrouds to the shroud racks, we are always looking for options. Here are two available on Amazon: Metal Clevis Assembly (brass) – These come 4 per package and are available in M2 or M3. Metal Clevis Assembly (silver) – These come 10 per package and are available in M2 or M3. 27

Spring 2025 The Model Yacht A. J . F I S H E R Article by TMY editorial staff. Photos from the US VMYG archives. AJ Fisher had a model yacht business for many years outside of Detroit in Royal Oak, MI. He printed numbered catalogues every year. The picture in this article is from Number 10 (1933). The catalogues span over 75 years. If thence math is accurate, he began his business sometime in the early 1920s. The catalogues advertised parts, plans, and construction sets for static and sailing models. We will focus on the model yacht parts. AJ Fisher sold both brass and chrome-plated fittings distinguished by the “AJ FISHER” stamp on the larger pieces. These fittings were made in his shop in Royal Oak. While we know that he made the parts for model yachts in his tool and die shop, we are The AJ Fisher Tool and Die shop in Royal Oak, MI. pretty sure he acquired the static model parts from others. That may also be true of the construction sets and other things he was offering for sale. Fisher stored all of the various die components to make a particular part or piece of a part in boxes. There were many of these boxes because some parts needed only one set of “fixtures”, while others needed as many as seven sets of dies to complete it. Much of the work AJ Fisher did required the use of a multi-ton press that punched, cut, and formed the various parts. We have been told that it took as many as seven operations to make a part such as one of the goosenecks. That means there were seven of those boxes needed to store the fixtures. There were eight different size goosenecks offered in 1933. There were a lot of model yacht parts AJ Fisher made. That is a lot of those boxes. 28 Manufacturing components in boxes for each part.

Spring 2025 The Model Yacht Various dies for making a part. It was an unfortunate day for model yacht enthusiasts in 2001 when the iconic AJ Fisher Company closed after 76 years of operation. Tooling parts. Shortly after that, the inventory of scalemodel parts for static display ship models, as well as some of the die-casting equipment for making those parts, was sold at a public auction in Michigan. The parts inventory Specialized tooling and production machine. Various parts for model yachts. and press tooling for making Fisher’s line of competition model yacht fittings generated little interest. Apparently, the auctioneer incorrectly cautioned bidders that the press equipment was “illegal to operate.” Luckily, despite the safety warnings, the model yacht parts inventory and press tooling was purchased by a local model train enthusiast. Although he hoped to restart that part of the Fisher operation, health problems became an issue, and those plans never materialized. The Fisher tooling and parts inventory remained in secure storage in southern Michigan for 14 years. Through a fortunate series of events, another individual became aware of the availability of the original Fisher tooling and parts inventory. This individual acquired them and is keeping the collection together. A page from the A.J.Fisher’s catalog 29

Spring 2025 The Model Yacht The following quote was inside the cover of the 1933 catalogue. Why You Should Use Fisher Fittings in Building Your Ship Models The building of ship models has developed to a point where anything less than faithful reproduction and accuracy as to scale is not acceptable. The Fisher organization is directed by a man who has spent twenty years of his life at sea and in marine repair shops —a man who knows and loves ships—a man who has a wide, practical knowledge of ships and ships’ gear. A master model builder himself, Mr. Fisher began, several years ago, to make parts and fittings for others, until now his entire efforts are devoted to the manufacture of accurate, authentic fittings, construction sets and custom-built fittings. This work is carried on in a modern shop, equipped with the finest precision tools, automatic machinery, die casting equipment and many specially designed machines, manned by experienced craftsmen who take a conscientious pride in producing the tiny parts that are required. Only the very best materials are used, as there is only one standard of quality—the best. Fittings are not only accurate as to their dime sions, but they are correct and authentic in design. You may order with complete confidence, as every shipment is made on the basis of “Satisfaction or Your Money Back.” We will contract for a limited number of finished models and can also furnish finished hulls. Accurate scale models will never become commonplace, and such models deserve the best-the highest-grade Fittings by Fisher. Barnacle Battery Caddy—These are great if you use AA batteries. Place all of your fresh batteries in in one direction. When you remove them, put the old ones in upside down. Storacell 12AAORG by Powerpax AA Battery Caddy, Orange (available in other colors) • Store your batteries in a compact, easy to find caddy; holds 12 AA batteries • Dispense batteries with one hand for safety and convenience • Terminal protection at both ends regardless of how the battery is inserted • Unique, easy to use locking mechanism; batteries snap into place and remove easily n 30

Spring 2025 The Model Yacht Article and photographs by Joseph Valentine. HandsFree Mast Calipers Setting up your boat correctly can be the difference between a successful or disappointing day at the lake. A lot of people use mast calipers to make sure their mast is square side-to-side. It is an iterative process of check, adjust, check, adjust. This handsfree mast caliper allows you to put the caliper in place and then adjust your rig. By notching the bottoms of your calipers to fit on top of the deck and just over the edge of the hull, you can use a rubber band to pull the calipers together so that they hold themselves in position leaving both of your hands free to adjust the shrouds and plumb the mast. This makes plumbing the mast very easy. Fig.1. Calipers in place. 31

Spring 2025 The Model Yacht Materials Tools • Two pieces of ¼- ⨉ ¾-in straight, clear wood stock long enough for the caliper legs • One strong rubber band • One ¾-in #8 stainless steel machine screw • One #8 stainless steel nut • Two #8 stainless steel flat washers • • • • hand or bandsaw drill 5/32 drill bit sandpaper and/or file Procedures 1. Cut two strips of ¾-in wood stock to be ¼ in thick for the legs of the calipers. 2. Measure 3 in down from the top end of one leg and mark the center. Place both legs together and drill a 5/32-in hole for the pivot pin. 3. Install the bolt just tight enough so the legs can move but hold their position. Use a washer under the head of the bolt and under the nut. 4. At the end away from pivot pin, mark the center of both legs. Spread the legs so that the center of each leg is set to match the beam of the boat at the mast location (see Fig. 2). Fig. 2. Defining the notches based on the beam. 5. With the legs still spread to the beam width, set the calipers vertically on a flat surface and use a piece of the ¼-in stock to mark a straight line parallel to the surface to mark the top of the notch. 6. While the calipers are still upright, use a square on the flat surface and mark a vertical line from center of each leg to the line that was drawn parallel to the flat surface. This marks the notch that will be parallel to the deck and just over the side of the hull. 32

Spring 2025 The Model Yacht 7. Cut the notches out. 8. Spread the calipers to the exact beam width and mark the legs tops on both sides at the intersection so that when the legs are the width of the deck, the two leg ends will form a single point to sight against the mast (see Fig. 3). Fig. 3. Marking the legs to define the centerpoint of the mast position. 9. Remove the bolt and cut the tips. 10. Put the legs back together so that the notches on the bottom are together so they can be adjusted for length. File or trim them so that they match. Fig. 5. Calipers held in place with the rubber band. Fig. 4. Cleaning up the notches. 11. Remove the bolt and reposition the legs so that the notches oppose each other and will clasp to the hull. 12. Install a rubber band, and you are ready to plumb the mast without having to hold the calipers with your hands. With both hands free, it is easy to adjust your shrouds with your calipers free standing. 33 Fig. 6. The point of the caliper defines the centerpoint of the mast.

Spring 2025 The Model Yacht US Vintage Model Yacht Group 2025 National Championship Series Regatta October 3 – 5, 2025 Photos from 2022 and 2023 National Championship Regattas by Judy Bonanno Beachwood, NJ (on the Toms River) Hosted by Barnegat Bay Model Yacht Club For more information: US VMYG NOR or contact George Schuld (gschuld@hotmail.com) 34