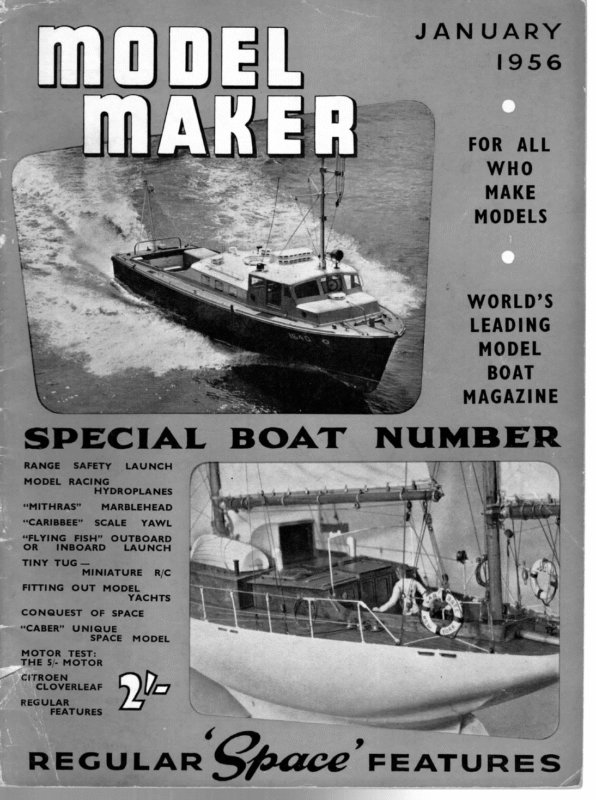

JANUARY 1956 FOR ALL WHO MAKE MODELS WORLD’S LEADING MODEL BOAT MAGAZINE RANGE MODEL SAFETY LAUNCH RACING HYDROPLANES “MITHRAS” “CARIBBEE” MARBLEHEAD SCALE YAWL “FLYING FISH” OUTBOARD OR INBOARD LAUNCH TINY TUG — MINIATURE FITTING OUT CONQUEST “CABER” R/C MODEL YACHTS OF SPACE UNIQUE SPACE MODEL MOTOR TEST: THE 5/- MOTOR — CYTROEN CLOVERLEAF 7 REGULAR FEATURES , Gp ace FEA TUR ES

MODEL MAHER) A NEW ‘MITHRAS’ HEAVYWEIGHT MARBLEHEAD by D. A. MacDonald fore been made conventional in form, but weli above the current average for beam, draught, and displacement. ‘ne sailplan has been devised to combine etticiency with ease of handling, the proportion of sail area in the jib being about as great as can be achieved without spinnaker difficulties which arise when the jib boom length begins to approach the 15-in. maximum allowed for the spinnaker 1 boom. Several problems arise when a large displacement has to be accommodated on a limited length. First, care has to be taken to ensure that the hull is easily driven at low speeds. This can be done by keeping the ends fine, but in the process the lines will turn sharply round the midsection, causing increased form resistance at high speeds. The boat will then sf HE choice of a name for this design was a __‘dissipate driving power in digging a large hole topical one in view of certain excavations —_0F itself, and will not be capable of developing going on in London at the time it began to emerge from the drawing board. a high speed, however hard it is driven. The Roman |, god Mithras stood for everything straight- forward, honest and conventional, and it is wet ; 2/20 ppvocient these qualities which I have tried to incorporate into this design. It is a feature of the M class ta Sa oA \ Mocuberries mere ses Kc 2 Le i or oh = = —— that most yachts built in recent years have been made to a relatively small number of well- i tried designs, all of very similar character and proportions. Very few serious attempts have been made to break away from a stereotyped form and proportions. The notable exception . has now been built in small numbers and is At aa is, of course, Mr. Tucker’s Jemima Duck, which 50-25″ 46-25) 1+ 2s “eas beginning: to show a handsome pay-off in racing. The fashionable proportions for this class are, at present, displacement about 20-21 Ib., beam 94-10 in., draught 10-104 in., and L.W.L. 48-50 in. A further design to these proportions would be superfluous unless it held promise of a significant improvement over anything already existing, and in the present state of the art, this would appear to be unlikely. My own experience over a period of several 23-7585. = ZA years’ sailing with both a conventional yacht Sie of 24-Ib. displacement, and two “ Ducks” of 22-23 Ib. have led me to the conclusion that for sailing under good conditions, especially with some rough water thrown in, the big boat is really worth while. Mithras has there30 F ee

JANUARY, Two boats have already been built to this design. . Both perform to windward in an impressive manner, especially in a good breeze. the same time the section shape must be carefully planned to allow an easy heel to a small angle, with a certain amount of inherent stability to keep the boat as upright as possible They will carry their top The design was intended for conventional rib-and-plank construction in mahogany, and the table of weights shows an adequate allowance for a substantial hull to be built in this manner. No difficulties should be experienced in laminated veneer or fibreglass construction, or of course in the popular “ bread-and-butter ” methods. While the fore-and-aft position of the C.G. is critical, as on all yachts, the overall weight can, in a hull of this type, vary appreciably without any detectable effect on performance. An error of up to 1 lb. either way in overall weight could be tolerated. The builders of the first two “ Mithras ” yachts have commented on the ease with which the hull can be planked, and report that no difficulties at all were encountered in the design. ) J Wi Pa WEIGHTS. ar te ore o ” Z Cy rw Ss A reasonable forward overhang has been The _ adopted, with a slight oyerhang aft. former has assisted in securing a good hull balance and will contribute to good behaviour in a seaway. The overhangs as drawn will be fully utilised when they are required, and no loss of effective sailing length should result. Upright and heeled curves of area have not been shown on the drawing as published; for the information of readers interested in design, the C.B. moves aft by 1/10 in. at 25 deg. heel. A metacentric analysis shows very slightly the reverse effect, indicating that the yacht would, other factors not considered, bear off to a minute extent when heeled to the same angle. This, in the author’s opinion, is a good feature, since it would contribute to fast sailing when heeled, and little or no tendency to fall off in light airs. The vane gear should thus have very little work to do to hold the yacht on its course in any weight of wind, provided she is correctly trimmed. ) —\ / | \ iW KEEL eet \ ia taal iit 1m suits in a much stronger wind than most boats in the class, and have proved both fast and docile down wind. It is interesting to note than in very light winds on a sheltered inland lake, they compete eflectively with yachts of up to 6 lb. less displacement. when driven hard. LEAD 1956 eS ay ALTERNATIVE TRANSOM |

i MODEL MAKER STARTING ON THE RIGHT TACK AN INTRODUCTION TO MODEL YACHT RACING PART THREE: FITTING OUT (2) THE STANDING RIGGING spiral flow when the wind increases, and pulled down tight when the wind decreases. The reverse would in fact be preferable, but not easily obtainab.e. What is, in fact, required is a control of the amount of lift imparted to the sail, such that the trim once set in. (continued) BY D. A. MACDONALD constant despite variations in wind strength. The jibstay should therefore terminate on the deck and be used solely as a stay, the control of the j.b-boom being carried out quite independently by a kickingstrap, in the same manner as the main boom. The conventional system is a survival from the technique of sailing early types of yacht with very low aspect ratio sails. A rubber or spring kicking strap on the main-boom allowed the mainsail to lift and spill off excess wind in a slam. The conventional jib-boom [F this method of rigging a jib is to be adopted, the points to watch are:— 1. The position of the hook D (Fig. XII) determines how the sail will set. If the hook is positioned well back on the boom, the downward pull on the clew of the sail is considerable, the boom will rise only in a very strong wind, and the top of the jib can backwind the mainsail unless the latter is also held down by a very hard kicking strap. If the hook D is well forward, the jib-boom will lift with every puff of wind, and could spill off excessively at the top, especially on reaching courses. Due to the above effects, the trim of the yacht will in effect vary with wind pressure, to an extent determined by the position of the hook at the tension on the jibstay. An adjustable position for the hook D is provided by the rack arrangement shown in Fig. XIV. This allows for some control] on the balance between wind pressure lifting the boom and a fixed stay tension system allowed the jib to do the same and the spill- ing of wind helped to prevent the yacht from gripping into ‘the wind on every puff. The two sails could be made to act more or less in step, and this requirement still exists. Nowadays, however, the mainboom has a rigid kicking strap, and it is therefore only logical that the jib should have the same. A more effective method of setting a jib is shown in Fig. 15. A post (A) made of brass + in. dia. is secured at the bottom of a heelplate fastened to the keel of the yacht. It passes holding it down, and enables the best results to be obtained under varying sailing conditions. However, in the opinion of the writer, the conventional method of Fig. 15 through the deck and is positioned by a plate (B), rather similar to the sliding position of the mast slide previously described. The post is raked to the angle of the luff of the jib and positioned so that the jib- rigging a jib as described above, is unsound in principle, since it causes the trim of the yacht to vary with wind pressure, and to wrong way, in the in that the jib is given a greater vary Fig. 16 stay can be hooked to an eyebolt (C), The top of the post is plugged and provided with a tapped hole into which the eyebolt is screwed. The forestay and the tack of the jib are both hooked to this eyebolt, so that the post now forms virtually a continuation of the jibstay, terminating it in effect on the keel of the yacht. The deck is thus relieved of the strain of a taut stay. A tube (D) is free to rotate on the post and is kept captive between the deckplate (B) and the disc (E). The latter is simply a strong brass washer held in place by the eyebolt (C). The jib-boom (F) is attached to the rotating tube by a simple swivel joint The kicking strap consists of the long wire strainer (G) attached at one end to a lug on the rotating tube, and at the other end to an eye or plate on the jib-boom. It will be seen that this arrangement provides the jib with the same facilities as those normally provided for a mainsail. The main disadvantage of the system shown in Fig. 15 is that it is not easy to make provision for moving the post fore and aft to allow for variations in 32 mast position or to accommodate

JANUARY, arrangement similar to a complete mast slide. The deck would need to _ adequately O= reinforced, preferably by additional deckbeams with a stringer or carbines between them. The device shown in Fig. 16 has been used by the author on an M-class yacht and has proved quite effective. The post (A) is developed into a tripod by the support arms (B), post and arms being brazed into a stout plate (C), which can be moved in the slide (D). Its position is fixed by a screw at E, in the same way as a mast slide. Fig. 17 shows details of the principal moving parts required for use in The rotating either of the assemblies described. tube with the lugs for the boom swivel and the kicking strap is shown at A. The boom end ferrule (B) can be either turned from the solid brass or fabricated from tube and rod. The ferrule neck is drilled and tapped to receive a bolt which secures it to the top lug of the tube (17a), The slot in the neck of the tube is free enough, and so is the clearance. hole in the lug, to allow the boom to swivel up and down quite freely. Fig. 17c shows the stanpractice.. Dealing with’ the three cor- ners of the sail in turn, Fig. 19’ shows the peak and its halliard. The combina-: tion mast fitting position can be determined by unstretchable. 53 MCE ‘ trial. The cord used Terylene or fibreglass are preferred. protruding ends of these strips carry the core (A) the 3/32 in. hole in which provides a clearance for an 8 B.A. bolt or 3/32 in. diameter brass rivet, which forms the bearing of the core. C shows the spider band which forms the mast portion of the universal joint. This spider band can be made up from brass sheet, the same material providing the two lugs which carry the rod (E) about which the corepiece (A) is free to rotate. A piece of brass tube (inner diameter ¢ in.) is brazed to each side of the spider band. These tubes accommodate the spin- naker boom joint, which will be described later. A further spider band (D) is provided with one solid brass lug drilled to take the lower end of the rod E. A large eye is brazed into each side of the spider band. These eyes will be found useful for stowing the main shroud turnbuckle hooks when the mast is removed for transport. The rod (E) is of fin. dia. of spiral that he can appreciate the precise control maximum pervarious aii * Sif nour © To deal with the tack of the sail, Fig. 20 shows a complete assembly of mast, sail, boom and kicking strap. The boom is attached to the mast by a simple universal joint, the component parts of which are shown. The core (A) of the joint is made of square section brass (5/16 in.x jin. for the smaller classes). Two strips of brass (4 in.x 18 s.w.g.) are bolted to the sides of the mainboom as shown at B, and the to break over-arched for windward work, or refuses re advised to avoid tack. The beginner is thereforigging the jib in the the radial jib, and to start by conventional method, graduating to the kicking strap system of Fig. 15 or Fig. 16 when he feels confident under | ||:| for the halliard should have a high breaking strain, 25-30 lb. for an M-class, up to 60 Ib. for an A-class yacht, and should be shrink-proof and the period of years and has eventually come to used be conclusion that, if used at all, they must -strap in conjunction with one or other of the kicking arrangements just described. In any case the amount to advantage of “radial” effect which can be used is very small indeed, otherwise the jib either becomes needed for UJ described. The halliard is fed through the mast at B. The ideal arrangement here is, of course, to build a pulley into the mast. This is not so easy as it sounds, and would also weaken the mast considerably. I have found that a sufficiently long eyelet, pushed in from the front, and turned over in the usual way on the other side of the mast, forms an effective feed-through for the halliard. It is worth while having more than one point in the headboard to which the halliard hook can be attached. The set of the sail will be affected quite appreciably by the point of attachment of this hook. If two or three holes are provided in the headboard the best provided by this arrangement to provide for a radial jib. The “radial” system is based on the jib boom or club being shorter than the foot of the sail, and pivoted at a deck point aft of the forestay (see Fig. 18). The object is to provide increased flow to the jib as it is freed off. When close hauled, the jib is fairly flat, but when set for a beam or following wind, the job is well arched. The author has tried radial jibs in a variety of forms over a formance has. been previously the eyebolt (C of Fig. 15). Fig. 17d shows how the bottom of the post (A of Fig. 15) is secured to a Tsection mounting plate screwed into the keel of the yacht. It is an easy matter to extend the facilities flow (A) “@HOLE wind conditions. It is a much_ easier matter to set the mainsail cor- rectly than it is the jib, and there is brass. The top end is pierced to take the mainsail tack hook. The lower end is provided with a large eyeplate brazed into a slot. This eyeplate provides A wire ring a termination for the kicking strap. soldered round the rod just above the eyeplate serves to keep the kicking strap clear of the lug as the boom rotates. After the rod has been assembled into the lower spider band, a second wire ring is added to make the rod captive. It is then not likely to be lost when the yacht is dismantled for transport. The kicking strap (F) can be either a specially made turnbuckle with long ends, or a normal turnbuckle extended by brass rod or stainless steel wire. 33 a TT eee corporated into a sliding from dard SE a ! Pah ? in much ee eee | I> re) and the plate (B) in- point varying => | I . {|, little ae | Pe smaller jibs. To do this, the post (A) would have to terminate on deck, Se) ‘i Fig. 17 aaa 1956

% ‘ was / b) anys, os ® Ree Rha otcK COMPLETELY EXCEPT FOR FOREHATCH & COCKPIT “ cos a — RAI Te) Paria » Bre mw oecn as bi if j . FIT THIS EOGE To INTERNAL HULL CARVING. x. % onass vor-® “Ye THICK LEAD CENTRE BOARD e, & LOOP ON THE BOTTOM AS WELL MULTIPLICATION OF MAIN & MIZZEN SHEETS. RIGGING [mia aes |} THE COMPLETE FULLY-DETAILED DRAWINGS FOR THIS MAGNIFICENT SCALE WORKING MODEL ARE AVAILABLE ON THREE LARGE SHEETS, THE THIRD OF WHICH IS REPRODUCED ABOVE AT APPROXIMATELY 1/5 SCALE. PRICE PER SET IS 15/- POST FREE, FROM MODEL MAKER PLANS SERVICE, 38 CLARENDON ROAD, WATFORD, HERTS.

PART I1. CONTINUED £ Bae next stage is the fitting of the centre board box or case. First cut and glue in place V/1 and V/2 which form the ends. ‘Cut the two sides, CBB/S and P. It is understood, of course, that the base must be fitted to your inside carving which may well be different from the plan. The stand should now be made and used hereafter. Now cut the beams, you will note that the ends of all beams must be fitted to your carving. B/3, B/4, and B/7 are first halved into the gunnel and glued. When correctly placed, a straight edge laid from the bow to the middle of the stern should exactly touch their centre points, i.e., the centre line of the deck is a straight line. After this, L/1 and L/2 can be glued in place, and then the rest of the beams, from B/1 to B/12 inclusive should be glued as well. The cockpit and beams B/13 and B/16 should be fitted as a unit, and the whole of their under suffaces should be primed with paint, after RP/1 and RP/2 have been fitted. Finally, beams B/17, B/15 and B/14 together with L/3/P and /S and FH/P and /S are also glued into place. After the centre board case covering, CBC/C has been fitted the whole of the deck beams, gunnel, etc., are sanded using a large wooden block and glass paper, to the correct curvature. Decking is done in two halves, port and starboard forming along the centre line. 1mm. plywood should be cut a little oversize and temporarily pinned in place along the centre to make sure that it really does fit. The whole of the inside, including the top surface of the deck beams and top edge of the gunnel, and the whole undersurface of the deck itself, is primed with paint and allowed to dry. The deck is fixed on with brass panel pins and the waterproofing is done by generous use of a mixture of putty and paint, which should, of course, be painted on before the deck is finally tacked down. (Be careful not to drive any tacks through the middle of CBC/C, but drive them through CBB/P and /S). Finally, any overhang should be sanded flush to the topsides and the deck smoothed. Planking is marked out with a black Biro, each plank being 4 in. wide, and then varnished. The bulwarks consist of mahogany sawn to shape, NOT steamed, and stuck down around the edges. Deckhouses The only thing to say about the deckhouses is that they are constructed of 2?in. spruce, and 3/16 in. mahogany, all sides being covered with Imm. ply and french polished, except for those that have doors marked on them. In this case, the doors are drawn on and then painted in water colour, finally varnishing over the top. (Wireless panel ditto). The roof is also 1mm. ply, and small blocks of wood are glued underneath it where screweyes will be fixed (not shown on the plan). All curved wood is steamed, and the portholes glazed with boiled photographic plate and puttied in. The interior of the deckhouses are painted black. The for’ard deckhouse is held in place by small battens stuck and screwed to the deck. and is removable, whilst the aft-deckhouse is secured in the same manner, but not removable, because the 1mm. ply side facings are a continuation of the cockpit coamings. Painting The next stage is painting the hull, but it is wiser though not essential, to make and fit the centre-board weight or weights first. A mould is built up of three layers of ordinary wood. Holes are drilled in the proper place, through which are slotted large nails. It is best to assemble the mould with small screws, so that it is easily dismantled. Place the mould in a vice so that the open edge is dead level. Melt 520z. of scrap lead in a ladle (L used an old aluminium pan), and pour carefully into the mould. If the nails are joggled while setting they will come away easily. The first casting may be no good, being badly pitted. This is caused by steam from the fresh wood. I actually remelted the lead three times before I got a perfect casting. The boat should be given between 20 and 25 thin coats of white lead paint—NOT glossy. Each coat should Le put on last thing at night and left for a day. It should then be sanded down ready for the next coat. When perfectly smooth, a final ONE THIN coat of high gloss enamel is applied.

ee el eS ne ee. ae JANUARY, ~ IN the November issue of this magazine, | dealt with the fore-and-aft trimming effect of Vane Steering Geers, and showed that to counter-balance the effect of placing this weight so far aft, the C.G. of the Lead Keel has to be very appreciably ahead Tucker’s Topical Talks of the yacht’s C.B. I gave a worked example of this for an average A-Class model ,showing that the C.G. Lead has to be 0.27in. ahead of the C.B. In workng this out, I took a boat of 57lb. displacement with a lead keel of 434lb. and a vane gear weighing 60z. However, some vane gears for these big boats weigh as much as 8oz., and in such cases, the distance the C.G. Lead would have to be ahead of the C.B. would be a third more, making this 0.36 in. I also referred to 10-Raters, which are about the same length on the L.W.L. and L.O.A. as the A-Class, but far lighter, with less than half the weight of lead. In these boats I suggested that it might be a good idea to counterbalance half the weight of the vane by putting a 30z. weight the same distance ahead of the C.B. as the vane gear is abaft it, when the C.G. Lead need only be 0.27in. ahead of the boat’s C.B. In working out this example, I took a 301b. displacement yacht with 18lb. Lead Ballast and a Vane Gear weighting 60z. I may add to this, by saying that if the full weight of the vane is taken into account (i.e. if no counter-balance is used), the distance ahead of the C.B. for the C.G. Lead Keel will be 0.625in. I should add that this does not present the same difficulty in a 10-R. as it does in an A-Class boat, since there is not the same volume of lead to deal with. Builders can with advantage bear these points in mind in case difficulty crops up during building operations. On the other hand, it is undesirable to put too much weight in the ends of a boat, particularly forward, as it detracts from the buoyancy. At the same time, it must be remembered that weight can be too concentrated in the middle of the boat, since this tends to produce a rocking-horse movement, when the yacht see-saws up and down in the same spot. shaking the wind from her sails and not progressing as she should. I mention this as readers might be inclined to think it a good idea to counterbalance the whole weight of the vane gear. The amount of weight that can be put into the ends without spoiling the boat depends on her size and type entirely. Up to a certain point it may improve her, but above that it may spoil her performance. Having dealt with the A’s and 10-R’s. here are the figures for the other classes :— 6-Metres. With a Vane Gear of 60z., and Lead Keel of 21lb.. the C.G. Lead Keel would have to be 0.46in. ahead of C.B. 1956 PRACTICAL TRIMMING PROBLEMS WITH VANE GEAR STEERING NE the Lead Keel will affect their accuracy within fairly narrow limits, and so will differences in A small amount of internal trimming building. ballast should, however, suffice for final adjustment when the boat goes afloat. In my November article, I explained why the designer cannot be absolutely specific on these points, but must leave final adjustment to the actual builder. Let us assume the hull is finished with deck beams in place. The deck is cut out but not yet fixed. Our Lead casting is back from the foundry but not finally fixed in position. The first step is to compare the weights, as far as we have gone with the designer’s Table of Weights,. In this connection, it can be assumed that such items as painting, rig, fittings and steering gear will come out very nearly to the designer’s figures, in any case there can, at most, be a variation of an ounce or two to be adjusted on our Inside Trimming Ballast. From this we see how much lead we can have, and whether our casting must be reduced so that the total weight is not exceeded. It is obviously better to be slightly under than over weight ,since a little extra inside ballast can always be added to bring the yacht to her designed bearings. Our next step is to test the yacht for fore-and-aft balance. Drive a screw into the keelson at the foreand-aft position of the C.B., but leave it standing proud. Twist a piece of stout wire round this screw and suspend the boat from it. The lead keel (even if over-weight) should be temporarily in position, and so should the deck. The wire, of course, passes through the hatch-way. Now place a weight equal to the weight of the rig where the mast-step will come, and another equivalent to the Vane Gear on its position. Test the fore-and-aft balance. Now since your lead keel has probably cast somewhat over-weight, this surplus can be used to correct any error in balance. Lead keels nowadays are usually designed quadrilateral in profile with a horizontal top face and raked after face. If the boat is stern-heavy, you plane lead away from the after face. testing both weight and balance at frequent intervals. If she is nose- heavy, you plane from the top face. If you are still M. Class. over-weight when you arrive at the correct balance, With a Vane Gear of 60z., 1nd Lead Keel of 1441b., the C.G. Lead Keel would have to be 0.68 in. ahead of C.B. If 20z. of the weight of the vane is counter-balanced, this distance is reduced to 0.45 in. you plane from both faces until you get both weight 36 in. Restricted Ciass. With a Vane Gear of 40z. and about 7lb Lead It should be mentioned that lead with an ordinary iron jack-plane, work and plane sole are liberally turpentine. Small adjustments can be holes in the lead downward from the If you arrive at the correct and balance right. weight but are still out of balance, you test with a counterbalance weight, and see what further adjustment is needed. Keel. the C.G. Lead Keel would have to be 0.69 in. ahead of C.B. If 20z. of the weight of the vane s counter-balanced, this distance is reduced to 0.34 in. is easily planed provided both lubricated with made by drilling top face. These are afterwards filled with stopping wax to prevent These figures can be used as a rough approximation for the various classes. Minor variations in weight and position of Vane Gear and in the weight of water lodgement. Wood is inserted where any deadwood is missing owing to lead being reduced. 43 TT

se | es ae MODEL MAKER) Readers write… The elegant little plastic walletcontain- ing chrome vanadium double – ended B.A. spanners in the hard-toget model sizes will which be pre- sented to our **Readers Write” cor- respondents, Marbleheads at Hove: 0.0.D Sneaks Dear Sir, : The report in the November number of MOopDEL MAKER on the “M” Class Championship held at Hove says that the large entry “undoubtedly caught the M.Y.A. by surprise, for an additional day of sailing allotted would have made everybody’s task much easier, though not to say more enjoyable.” As Hon. General Secretary of the organising Club, and as officer of the Day, and therefore respon- sible for most of the organisation of the event, I ‘would like to refute the implied criticism of the M.Y.A. for not allowing more time for sailing, The time available for model yachting at the Hove Lagoon is restricted by an ‘agreement between the Hove Corporation and the pleasure boat company, and is limited to every Sunday and two Saturdays during the summer season. Application has to be made very early in the year for the water to be reserved for the Club’s use on Saturday, and it is not possible, under present arrangements, to arrange for more than two consecutive days’ sailing. The Hove and Brighton M.Y.C. is well aware that this sailing reservation is inadequate, but it has not been found possible to get it increased. These facts are well known to the M.Y.A. Council and are taken into account when the Council is considering the venues for the M.Y.A. Championships at its meeting in September each year. The venues and dates for all Championships are published at the beginning of the season, and even if another day had been made available, it is doubtful whether all the competitors could, at short notice, have made arrangements to spend an extra day at Hove. The popularity of the “M” class undoubtedly sets problems for future Championships. but it is by no means certain that all skippers who could attend for a week-end of sailing could be present for a full week. What is certain is that entries as numerous as they were at Hove are a powerful argument in the hands of model yacht clubs when negotiating with local Town Councils! Yours faithfully, Haywards Heath. F. JENNINGS Car Comments—Rail, Cable and Scale Dear Sir, : : Though there are many obvious weakneses in Mr. Weaver’s somewhat retaliatory letter, I shall not prolong this correspondence further, but suggest that interested readers re-read the three letters concerned, and deduce. their own conclusions. However, I do, most sincerely, regret that Mr. Weaver has chosen to interpret a reply to criticism by an individual as making the issue a personal one against the individual. If I in turn misinterpreted Mr. Weaver’s original letter, then I can say I was not alone in this respect. This, like a rocking horse, is getting us nowhere fast, but the recent news that the Patentee has supplied rail fittings to a Club affiliated to the M.C.A. in accordance with the terms of the Agreement is more hopeful for the future of all concerned. Now, Mr. Editor, I wonder if I may deplore the almost complete absence of reports of R.T.P. Car meetings in the MopEL MAKER this year? The position has steadily worsened, and whereas in the past MODEL MAKER has provided a record of progress, this is no longer the case. Reports not only benefit readers in this country, but overseas readers also, and an extract from a letter recently received from one of my Swiss friends emphasises this :— “Which are the news of England? The MopEL MAKER is very bad in speed model car racing in the last time, so we have no news from the isle”. Is it too much to hope that in future you will cast a more favourable eye on reports of this nature? In closing, I would like to compliment Manuel Olive on his excellent article on the P3 Alfa Romeo. and express the hope that we shall be seeing more of his contributions in the future. Sunderland. Yours faithfully, K. PROCTER (Ken is only too right! There has been very little on cable racing recently. Reasons are twofold: (1) Lack of new cars that make news. (2) Lack of club reports embellished with photos that make news—the number of readers who want bare results are small, certainly not enough to justify such reports.—ED.) Experimental Mast in Fibreglass Dear Sir, In Mr. D. A. Macdonald’s excellent article on Masts in your October issue, he made mention en passant of fibreglass masts. Readers may be interested to hear of my experience with an experimental mast which I recently made of this material for my 1948 vintage “Tucker Duck” Marblehead. The only kind of fibreglass tube at present marketed conimercially is fishing rod which tapers in four 3ft. lengths from a minimum diameter of about }in. to a maximum of about iin. The wall of the tube is one-thirty-second thick. I wanted a diameter at truck of about three-sixteenths (which I consider the reasonable minimum for the attachment of the mastband for main halyard, backstay, etc.) and found difficulty in obtaining a gradual enough taper to produce a diameter at deck level of not more than +in. In the end the makers were good enough to produce for me a special straight section of 2 in. diameter. My mast therefore consisted of a bottom Straight 3 ft. length } in. diameter, with a top section tapering from }in. to three-sixteenths at the truck. At the joint a hardwood dowel was inserted to a close push fit and glued with Durofix (a most effective adhesive for fibreglass). Fibreglass is light and strong, but extremely

JANUARY, “whippy”. It is essential therefore to ensure that the mast is effectively braced. In this case, I used stranded stainless wire main shrouds and standing forestay, and fine gauge stainless hard drawn wire backstay. The main and maststays, jumpers spreaders were located so that the mastband covered the joint between mast sections—but this is not essential. Drilling of the mast was avoided like the plague, and all mast fittings were secured by mast- bands on the Currie non-slip principle. A_ light cordage jackline was used with round-turns immediately above luff-hooks. On the whole, | am well pleased with my fibre- glass mast. The mast without fittings weighed j oz. as compared with the l4o0z. of the +in. diameter dural mast which it superseded. The only extra fittings required (compared with the dural mast) were the jumper struts—of negligible weight. In effect, therefore, you have a mast which is considerably lighter than steel, wood or dural and stronger than these last two. The Marblehead mast I have made has a maximum diameter of }in. as against the . tin. of its metal predecessor, and I feel that the somewhat questionable increase in windage resulting from the need for mast and jumper-stays is more than offset by the reduction in the bulk of the mast itself. Incidentally, if one prefers a° thin mast to a “broom handle”, I feel that there is a lot to be said for jumper-stays in place of a topmast forestay which tends to be a nuisance when setting a balloon, and is vulnerable in collisions. The main drawback in the use of fibreglass for masts is, however, its present cost! Yours faithfully, London W.8. R. F. TATCHELL Radio Control and the M.Y.A. Dear Sir, In view of the recent criticism of the Association for its apparent lack of interest in radio controlled model yachting, the Council has directed that the following facts be made public. In February this year, the Secretary was contacted by a Colonel Taplin, who subsequently called a meeting at the Three Horse Shoes in Tottenham Court Road, on 11th March, This meeting was attended by the Secretary of the M.P.B.A., the Secretary and Vice-Chairman of the M.Y.A., and representatives of other societies; MopeL MAKER and Ships and Ship Models were also represented. At this meeting it was made clear that the M.Y.A. representatives could not make binding decisions there and then, but they would report back to the Council. The matter was discussed at the May Council Meeting, and the following invitation sent to Colonel Taplin :— ‘“At the Council Meeting held on May 7th, your request that the Association should draw up rules covering radio controlled model yachts was discussed. The Council was quite sympathetic to the idea, but wishing to know a little more about it would like to meet one or two exponents of radio control, either at the next Council meeting, or at a meeting specially arranged so that representatives could meet in a less formal manner; further, a draft set of rules, or at least some recommendations from you would help the Council in their deliberations. @ The position is that there is adequate machinery to formulate such rules as may be required, provided the request, in the form of a definite proposal comes from within the Association. Yours truly, L. MOLE. Hon. Secretary, M.Y.A. E.7 Junior Class Model Racing Yacht. Dear Sir, One reads about the failure of the 36 in. restricted class National Championship this year to attract sufficient entries plus remarks on the 24 in. and 30 in. classes ‘regarded by the public as childish”. Certain facts were put forward but I am afraid not the whole story. I shall be glad if you will let me have a little space for the afore part of tne story, witnout fear or favour. The M.Y.A. in its attitude I’m afraid must share the major portion of tne blame in not educating the public of the fact that a 36 in. model craft requires more skilled handling in some cases than its bigger class. Affiliated M.Y.A. clubs in the main themselves have barely any time for model craft under the 50 in. Marblehead craft. My Association, the Doncaster Model Yacht Association, just after its inauguration being comprised of ““NOVICES” in the main, humble working men, could not afford the 50 in. or bigger class of Model Racing Craft. Also our biggest difficulty was transportation did make an appeal to the M.Y.A. to commence action to popularise the then smallest accepted 36 in. restricted class. Such an appeal fell on deaf ears. We Doncastrians did have a good number of 36 in. craft in the Mopret Maker Trophy Competition from various towns, even as far as Brighton, as can be borne out by the MopEL MAKER Editor. I agree in part of the answer being found in the venue. Either the venue should be central or each year changed say North one year, Midlands the next and South afterwards. Even then, its up to a body such as the M.Y.A. to popularise, if possible, the smaller type of craft which would have the effect of keeping juniors off the roads and reducing road accidents. If this could be proved to local authorities they might then become interested in providing ponds. Doncaster M.Y.A. has since its inauguration five years ago, been clamouring without success for the provision of a water within the town’s boundary. As Chairman and Hon. Secretary, I wrote to certiin members of the M.Y.A. imploring for action to be taken to popularise the 36 in. (R) model and up to date without any success. In desperation one or two members of our Association plus myself purchased Marblehead craft feeling we more or less stood outside the pale because we only sailed the 36 in. boat, granted one does get a grown up type of feeling when sailing the bigger class, but it still comes back to a question of TRANSPORTATION and we just cannot afford a Club House to leave the boats at the pond side. Before leaving, although my Association five years ago consisted of ‘‘NOVICES” and in the main our 36 in. restricted model craft could be smiled upon by professionals, our record bears looking into, as craft have won National and Open awards both in the much despised 36 in, (R) and other classes. N.B.: One of our members, two vears in succession, won the Daily Despatch Trophy for Marblehead class of craft. I am all for the popularising of the 24 in. and 30 in. and 36 in., and was more than glad when MopEL Maker introduced Our Chairman, Mr. C. R. Seabrooke, is prepared to meet yourself or Colonel Bowden in order to discuss this matter. 1956 the M.M. Class 25 in. Yours etc.” The letter was dated 12th May, 1955, and no reply Bessacarr, Doncaster has been received. 45 mM Yours faithfully, JoHN S. REEVES.